Abstract

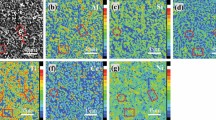

We investigated the microstructures and mechanical properties of multiphase-reinforced in situ aluminum matrix composites (AMCs) prepared with various combinations and contents of Li, Mg, Si, Cu, Zn, Sn, and Ni. The area fractions of the secondary phases in the as-cast AMCs ranged from 26% to 58%, and the types of secondary phases depended on the alloy chemical compositions. The type and amount of secondary phases were more important than matrix strengthening in determining the alloy mechanical properties. Composite hardness and compressive stress increased while fracture strain decreased with increasing total area fraction of the secondary phases up to 40%. The formation of coarse primary and soft/heavy Sn-containing phases significantly deteriorated the alloy mechanical properties. Annealing also influenced the mechanical properties of the AMCs by changing the microstructures of the secondary phases and Al matrices.

Similar content being viewed by others

References

S.L. Pramod, S.R. Bakshi, B.S. Murty, Aluminum-based cast in situ composites: a review. J. Mater. Eng. Perfom. 24, 2185–2207 (2015)

Q. Gao, S. Wu, S. Lü, X. Xiong, R. Du, P. An, Improvement of particles distribution of in situ 5 vol% TiB2 particulates reinforced Al–4.5Cu alloy matrix composites with ultrasonic vibration treatment. J. Alloys Compd. 692, 1–9 (2017)

P. Li, E.G. Kandalova, V.I. Nikitin, In situ synthesis of Al–TiC in aluminum melt. Mater. Lett. 59, 2545–2548 (2005)

B.S.S. Daniel, V.S.R. Murthy, Directed melt oxidation and nitridation of aluminium alloys: a comparison. Mater. Des. 16, 155–161 (1995)

G.I. Eskin, D.G. Eskin, Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt. Ultrason. Sonochem. 10, 297–301 (2003)

C. Li, Y.Y. Wu, H. Li, X.F. Liu, Morphological evolution and growth mechanism of primary Mg2Si phase in Al–Mg2Si alloys. Acta Mater. 59, 1058–1067 (2011)

Q.D. Ding, Y.G. Zhao, C. Liu, P.J. Cong, W. Zhou, Strontium modification and formation of cubic primary Mg2Si crystals in Mg2Si/Al composite. J. Alloys Compd. 454, 142–146 (2008)

M. Emamy, N. Nemati, A. Heidarzadeh, The influence of Cu rich intermetallics phases on the microstructure, hardness and tensile properties of Al–15%Mg2Si composite. Mater. Sci. Eng. A 527, 2998–3004 (2010)

S. Ji, F. Yan, Z. Fan, Development of a high strength Al–Mg2Si–Mg–Zn based alloy for high pressure die casting. Mater. Sci. Eng. A 626, 165–174 (2015)

N. Soltani, A. Bahrami, M.I. Pech-Canul, The effect of Ti on mechanical properties of extruded in situ Al–15 pct Mg2Si composite. Metall. Mater. Trans. A 44A, 4366–4373 (2013)

A. Bahrami, A. Razaghian, M. Emamy, R. Khorshidi, The effect of Zr on the microstructure and tensile properties of hot-extruded Al–Mg2Si composite. Mater. Des. 36, 323–330 (2012)

X. Yang, S.Y. Chen, J.D. Cotton, Y. Zhang, Phase stability of low-density, multiprincipal component alloys containing aluminum, magnesium, and lithium. JOM 66, 2009–2020 (2014)

E.-J. Baek, T.-Y. Ahn, J.-G. Jung, J.-M. Lee, Y.-R. Cho, K. Euh, Effects of ultrasonic melt treatment and solution treatment on the microstructure and mechanical properties of low-density multicomponent Al70Mg10Si10Cu5Zn5 alloy. J. Alloys Compd. 696, 450–459 (2017)

T.-Y. Ahn, J.-G. Jung, E.-J. Baek, S.S. Hwang, K. Euh, Temporal evolution of precipitates in multicomponent Al–6Mg–9Si–10Cu–10Zn–3Ni alloy studied by complementary experimental methods. J. Alloys Compd. 701, 660–668 (2017)

T.-Y. Ahn, J.-G. Jung, E.-J. Baek, S.S. Hwang, K. Euh, Temperature dependence of precipitation behavior of Al–6Mg–9Si–10Cu–10Zn–3Ni natural composite and its impact on mechanical properties. Mater. Sci. Eng. A 695, 45–54 (2017)

N. Saunders, A.P. Miodownik, CALPHAD (Calculation of Phase Diagrams): A Comprehensive Guide, vol. 1, 1st edn. (Eslevier, Oxford, 1998)

X. Yang, Y. Zhang, Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132, 233–238 (2012)

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017)

L.R. Garcia, W.R. Osório, A. Garcia, The effect of cooling rate on the dendritic spacing and morphology of Ag3Sn intermetallic particles of a SnAg solder alloy. Mater. Des. 32, 3008–3012 (2011)

H. Lee, J.H. Choi, M.C. Jo, I. Jo, S.-K. Lee, S. Lee, Effects of strain rate on compressive properties in bimodal 7075Al–SiCp composite. Metals Mater. Int. 24, 894–903 (2018)

R. Khorshidi, A.H. Raouf, M. Emamy, J. Campbell, The study of Li effect on the microstructure and tensile properties of cast Al–Mg2Si metal matrix composite. J. Alloys Compd. 509, 9026–9033 (2011)

Acknowledgements

This work was supported by the Main Research Program (PNK5270) funded by the Korea Institute of Materials Science (KIMS, Republic of Korea), and by the Industrial Strategic Technology Development Program (10062304) funded by the Ministry of Trade, Industry & Energy (MOTIE, Republic of Korea).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, JH., Jung, JG., Baek, EJ. et al. Microstructures and Mechanical Properties of Multiphase-Reinforced In Situ Aluminum Matrix Composites. Met. Mater. Int. 25, 353–363 (2019). https://doi.org/10.1007/s12540-018-0195-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0195-3