Abstract

The flammable thermoplastics are widely used in our daily life and manned space travels in microgravity, posing a potential fire risk. This work studies the flame spread along with the thin polyethylene (PE) film (15–100 µm) in the microgravity drop tower and normal gravity. Microgravity flame spread faster than vertically downward flame spread in normal gravity due to the weak buoyancy flow and greater flame preheating length. For the ultra-thin film, the influence of melting on the opposed flame spread is negligible. The upward flame spread rate reaches a maximum constant (45 ± 10 mm/s for 20 μm film) when the inclination angle is larger than 30°, due to the dripping removal of molten fuel. The upward flame spread rate changes under the competition between the enhanced flame heating by buoyancy and the dripping removal of the molten fuel. The vertically upward spreading flame cannot be maintained due to the dripping removal of the molten fuel, and a critical extinction condition was determined and analyzed. This work provides valuable data on flame dynamics in plastic films and can help develop more sophisticated material flammability tests for fire safety in space travel.

Similar content being viewed by others

Abbreviations

- Bi :

-

Biot number (-)

- c :

-

Specific heat (kJ/kg/K)

- D :

-

Diameter (m)

- g :

-

Gravitational acceleration (m/s2)

- h :

-

Convection heat transfer coefficient (W/m2/K)

- l :

-

Length (m)

- L :

-

Characteristic length (m)

- L v :

-

Latent heat of vaporization (J/kg)

- M :

-

Mass (g)

- \(\dot{m}\) :

-

Mass loss rate (g/s)

- Nu :

-

Nusselt number (-)

- Pr :

-

Prandtl number (-)

- \({\dot{q}}^{^{\prime\prime}}\) :

-

Heat flux (kW/m2)

- R :

-

Radius (m)

- Ra :

-

Rayleigh number

- t :

-

Time (s)

- T :

-

Temperature (K)

- V :

-

Spread rate (m/s

- α :

-

Thermal diffusivity (m2/s)

- β :

-

Thermal expansion coefficient (K−1)

- δ :

-

Length (m)

- θ :

-

Angle (°)

- λ :

-

Heat conductivity (W/m/K)

- μ :

-

Viscosity (kg/m/s)

- ν :

-

Kinematic viscosity (m2/s)

- ρ :

-

Density (kg/m3)

- σ :

-

Surface tension (N/m)

- τ :

-

Thickness (m)

- ∞:

-

Ambient

- b :

-

Burning

- cr :

-

Critical

- dr :

-

Drip

- f :

-

Flame

- g :

-

Gas

- ig :

-

Ignition

- m :

-

Melt

- s :

-

Solid

- tot :

-

Total

References

Altenkirch, R.A., Tang, L., Sacksteder, K., Bhattacharjee, S., Delichatsios, M.A.: Inherently unsteady flame spread to extinction over thick fuels in microgravity. Symp. Int. Combust. 27(2), 2515–2524 (1998)

Bhattacharjee, S., Ayala, R., Wakai, K., Takahashi, S.: Opposed-flow flame spread in microgravity-theoretical prediction of spread rate and flammability map. Proc. Combust. Inst. 30, 2279–2286 (2005). https://doi.org/10.1016/j.proci.2004.08.020

Bhattacharjee, S., Wakai, K., Takahashi, S.: Predictions of a critical fuel thickness for flame extinction in a quiescent microgravity environment. Combust. Flame. 132, 523–532 (2003). https://doi.org/10.1016/S0010-2180(02)00501-1

Comas, B., Pujol, T.: Flame front speed and onset of instability in the burning of inclined thin solid fuel samples. Phys. Rev. E Stat. Nonlinear. Soft. Matter. Phys. 88, 12–17 (2013). https://doi.org/10.1103/PhysRevE.88.063019

Drysdale, D.D., Macmillan, A.J.R.: Flame spread on inclined surfaces. Fire. Saf. J. 18, 245–254 (1992). https://doi.org/10.1016/0379-7112(92)90018-8

Fernandez-Pello, A.C., Ray, S.R., Glassman, I.: Flame spread in an opposed forced flow: the effect of ambient oxygen concentration. Symp. Int. Combust. 18, 579–589 (1981). https://doi.org/10.1016/S0082-0784(81)80063-X

Fujita, O.: Solid combustion research in microgravity as a basis of fire safety in space. Proc. Combust. Inst. 35, 2487–2502 (2015). https://doi.org/10.1016/j.proci.2014.08.010

Fujita, O., Nishizawa, K., Ito, K.: Effect of low external flow on flame spread over polyethylene-insulated wire in microgravity. Proc. Combust. Inst. 29, 2545–2552 (2002). https://doi.org/10.1016/s1540-7489(02)80310-8

Gollner, M.J., Huang, X., Cobian, J., Rangwala, A.S., Williams, F.A.: Experimental study of upward flame spread of an inclined fuel surface. Proc. Combust. Inst. 34, 2531–2538 (2013). https://doi.org/10.1016/j.proci.2012.06.063

Hirano, T., Noreikis, S.E., Waterman, T.E.: Postulations of flame spread mechanisms. Combust. Flame. 22, 353–363 (1974). https://doi.org/10.1016/0010-2180(74)90050-9

Hu, L., Zhang, Y., Yoshioka, K., Izumo, H., Fujita, O.: Flame spread over electric wire with high thermal conductivity metal core at different inclinations. Proc. Combust. Inst. 35, 2607–2614 (2015). https://doi.org/10.1016/j.proci.2014.05.059

Hu, W.R., Zhao, J.F., Long, M., Zhang, X.W., Liu, Q.S., Hou, M.Y., Kang, Q., Wang, Y.R., Xu, S.H., Kong, W.J., Zhang, H., Wang, S.F., Sun, Y.Q., Hang, H.Y., Huang, Y.P., Cai, W.M., Zhao, Y., Dai, J.W., Zheng, H.Q., Duan, E.K., Wang, J.F.: Space program {SJ}-10 of microgravity research. Microgravity. Sci. Technol. 26, 159–169 (2014)

Ikeda, M.: Effects of gravity on ignition and combustion characteristics of externally heated polyethylene film. Microgravity. Sci. Technol. 30, 331–338 (2018). https://doi.org/10.1007/s12217-018-9606-9

Incropera, F., Lavine, A., Bergman, T., DeWitt, D.: Principles of heat and mass transfer. Wiley (2013)

Ito, A., Kashiwagi, T.: Characterization of flame spread over PMMA using holographic interferometry sample orientation effects. Combust. Flame. 71, 189–204 (1988). https://doi.org/10.1016/0010-2180(88)90007-7

Kobayashi, Y., Huang, X., Nakaya, S., Tsue, M., Fernandez-Pello, C.: Flame spread over horizontal and vertical wires: The role of dripping and core. Fire. Saf. J. 91, 112–122 (2017). https://doi.org/10.1016/j.firesaf.2017.03.047

Kobayashi, Y., Konno, Y., Huang, X., Nakaya, S., Tsue, M., Hashimoto, N., Fujita, O., Fernandez-Pello, C.: Effect of insulation melting and dripping on opposed flame spread over laboratory simulated electrical wires. Fire. Saf. J. 95, 1–10 (2018). https://doi.org/10.1016/j.firesaf.2017.10.006

Kobayashi, Y., Terashima, K., bin Borhan, M.A.F., Takahashi, S.: Opposed flame spread over polyethylene under variable flow velocity and oxygen concentration in microgravity. Fire. Technol. 56, 113–130 (2020). https://doi.org/10.1007/s10694-019-00862-4

Kumar, A., Shih, H.Y., T’ien, J.S.: A comparison of extinction limits and spreading rates in opposed and concurrent spreading flames over thin solids. Combust. Flame. 132, 667–677 (2003). https://doi.org/10.1016/S0010-2180(02)00516-3

Link, S., Huang, X., Fernandez-Pello, C., Olson, S., Ferkul, P.: The Effect of Gravity on Flame Spread over PMMA Cylinders. Sci. Rep. 8, 120 (2018). https://doi.org/10.1038/s41598-017-18398-4

Loh, H.T., Fernandez-Pello, A.C.: A study of the controlling mechanisms of flow assisted flame spread. Symp. Int. Combust. 20, 1575–1582 (1985). https://doi.org/10.1016/S0082-0784(85)80652-4

Lu, Y., Huang, X., Hu, L., Fernandez-Pello, C.: Concurrent flame spread and blow-off over horizontal thin electrical wires. Fire. Technol. 55, 193–209 (2019a). https://doi.org/10.1007/s10694-018-0785-0

Lu, Y., Huang, X., Hu, L., Fernandez-Pello, C.: The interaction between fuel inclination and horizontal wind: Experimental study using thin wire. Proc. Combust. Inst. 37, 3809–3816 (2019b). https://doi.org/10.1016/j.proci.2018.05.131

Migita, T., Yamahata, T., Strempfl, P., Matsuoka, T., Nakamura, Y.: Methodology to Achieve Pseudo 1-D Combustion System of Polymeric Materials Using Low-Pressured Technique. Fire. Technol. 56, 229–245 (2020). https://doi.org/10.1007/s10694-019-00877-x

Miyamoto, K., Huang, X., Hashimoto, N., Fujita, O., Fernandez-Pello, C.: Limiting oxygen concentration (LOC) of burning polyethylene insulated wires under external radiation. Fire. Saf. J. 86, 32–40 (2016). https://doi.org/10.1016/j.firesaf.2016.09.004

Nagachi, M., Mitsui, F., Citerne, J.M., Dutilleul, H., Guibaud, A., Jomaas, G., Legros, G., Hashimoto, N., Fujita, O.: Can a spreading flame over electric wire insulation in concurrent flow achieve steady propagation in microgravity? Proc. Combust. Inst. 37, 4155–4162 (2019). https://doi.org/10.1016/j.proci.2018.05.007

NASA-STD-6001B: Flammability, offgassing, and compatibility requirements and test procedures. Test 1, Upward Flame Propagation. (2011)

Olson, S.L.: Mechanisms of Microgravity Flame Spread Over a Thin Solid Fuel: Oxygen and Opposed Flow Effects. Combust. Sci. Technol. 76, 233–249 (1991). https://doi.org/10.1080/00102209108951711

Olson, S.L., Baum, H.R., Kashiwagi, T.: Finger-like smoldering over thin cellulosic sheets in microgravity. Symp. Int. Combust. 27, 2525–2533 (1998)

Olson, S.L., Ferkul, P. V., T’ien, J.S.: Near-limit flame spread over a thin solid fuel in microgravity. Symp. Int. Combust. 22, 1213–1222 (1989). https://doi.org/10.1016/S0082-0784(89)80132-8

Olson, S.L., Hegde, U., Bhattacharjee, S., Deering, J.L., Tang, L., Altenkirch, R.A.: Sounding rocket microgravity experiments elucidating diffusive and radiative transport effects on flame spread over thermally thick solids. Combust. Sci. Technol. 176, 557–584 (2004)

Orloff, L., De Ris, J., Markstein, G.H.: Upward turbulent fire spread and burning of fuel surface. Symp. Int. Combust. 15, 183–192 (1975). https://doi.org/10.1016/S0082-0784(75)80296-7

Quintiere, J.G.: The effects of angular orientation on flame spread over thin materials. Fire. Saf. J. 36, 291–312 (2001). https://doi.org/10.1016/S0379-7112(00)00051-5

Quintiere, J.G.: Fundamentals of fire phenomena. John Wiley (2006)

Ramachandra, P.A., Altenkirch, R.A., Bhattacharjee, S., Tang, L., Sacksteder, K., Katherine Wolverton, M.: The behavior of flames spreading over thin solids in microgravity. Combust. Flame. 100, 71–84 (1995). https://doi.org/10.1016/0010-2180(94)00046-U

Rojas-Alva, U., Jomaas, G.: A historical overview of experimental solid combustion research in microgravity. Acta. Astronaut. (2022). https://doi.org/10.1016/j.actaastro.2022.01.037

Rojas-Alva, U., Møller-Poulsen, F., Man, S.L., Creamer, C., Hanna, D., Jomaas, G.: Flame spread behaviour of Polydimethylsiloxane (PDMS) membranes in 1 g and µg environments. Combust. Flame. 240 (2022). https://doi.org/10.1016/j.combustflame.2022.112009

Ross, H.D.: Microgravity combustion: Fire in Free Fall. Academic Press (2001)

Sun, P., Wu, C., Zhu, F., Wang, S., Huang, X.: Microgravity combustion of polyethylene droplet in drop tower. Combust. Flame 222, 18–26 (2020). https://doi.org/10.1016/j.combustflame.2020.08.032

Takahashi, S., Borhan, M.A.F. Bin, Terashima, K., Hosogai, A., Kobayashi, Y.: Flammability limit of thin flame retardant materials in microgravity environments. Proc. Combust. Inst. 37, 4257–4265 (2019). https://doi.org/10.1016/j.proci.2018.06.102

Takahashi, S., Takeuchi, H., Ito, H., Nakamura, Y., Fujita, O.: Study on unsteady molten insulation volume change during flame spreading over wire insulation in microgravity. Proc. Combust. Inst. 34, 2657–2664 (2013). https://doi.org/10.1016/j.proci.2012.06.158

Takahashi, S., Terashima, K., bin Borhan, M.A.F., Kobayashi, Y.: Relationship between blow-Off behavior and limiting oxygen concentration in microgravity environments of flame retardant materials. Fire. Technol. 56, 169–183 (2020). https://doi.org/10.1007/s10694-019-00880-2

Tewarson, A.: Flammability of Polymers. John Wiley & Sons, Inc (2003)

Urban, D.L., Ferkul, P., Olson, S., Ruff, G.A., Easton, J., T’ien, J.S., Liao, Y.T., Li, C., Fernandez-Pello, C., Torero, J.L., Legros, G., Eigenbrod, C., Smirnov, N., Fujita, O., Rouvreau, S., Toth, B., Jomaas, G.: Flame spread: Effects of microgravity and scale. Combust. Flame. 199, 168–182 (2019). https://doi.org/10.1016/j.combustflame.2018.10.012

Vetturini, A., Cui, W., Liao, Y.T., Olson, S., Ferkul, P.: Flame Spread Over Ultra-thin Solids: Effect of Area Density and Concurrent-Opposed Spread Reversal Phenomenon. Fire. Technol. 56, 91–111 (2020). https://doi.org/10.1007/s10694-019-00878-w

Wang, S., Hu, J., Xiao, Y., Ren, T., Zhu, F.: Opposed-flow Flame Spread Over Solid Fuels in Microgravity: the Effect of Confined Spaces. Microgravity. Sci. Technol. 27, 329–336 (2015). https://doi.org/10.1007/s12217-015-9419-z

Wang, S., Zhu, F.: Flame Spread in Low-Speed Forced Flows: Ground- and Space-Based Experiments. In: Wenrui, H., Qi, K. (eds.) Physical Science Under Microgravity: Experiments on Board the SJ-10 Recoverable Satellite, pp. 237–262. Research for Development. Springer, Singapore (2019)

West, J., Tang, L., Altenkirch, R.A., Bhattacharjee, S., Sacksteder, K., Delichatsions, M.A.: Quiescent flame spread over thick fuels in microgravity. Symp. Int. Combust. 26, 1335–1343 (1996). https://doi.org/10.1016/S0082-0784(96)80352-3

Wu, C., Huang, X., Wang, S., Zhu, F., Yin, Y.: Opposed Flame Spread over Cylindrical PMMA Under Oxygen-Enriched Microgravity Environment. Fire. Technol. 56, 71–89 (2020a). https://doi.org/10.1007/s10694-019-00896-8

Wu, C., Sun, P., Wang, X., Huang, X., Wang, S.: Flame Extinction of Spherical PMMA in Microgravity: Effect of Fuel Diameter and Conduction. Microgravity. Sci. Technol. 32, 1065–1075 (2020b). https://doi.org/10.1007/s12217-020-09829-5

Zhang, Y., Ronney, P.D., Roegner, E.V., Greenberg, J.B.: Lewis number effects on flame spreading over thin solid fuels. Combust. Flame. 90, 71–83 (1992). https://doi.org/10.1016/0010-2180(92)90136-D

Zhao, X., Liao, Y.T.T., Johnston, M.C., T’ien, J.S., Ferkul, P. V., Olson, S.L.: Concurrent flame growth, spread, and quenching over composite fabric samples in low speed purely forced flow in microgravity. Proc. Combust. Inst. 36, 2971–2978 (2017). https://doi.org/10.1016/j.proci.2016.06.028

Zhou, Y., Bu, R., Yi, L., Sun, J.: Heat transfer mechanism of concurrent flame spread over rigid polyurethane foam: Effect of ambient pressure and inclined angle. Int. J. Therm. Sci. 155, 106403 (2020). https://doi.org/10.1016/j.ijthermalsci.2020.106403

Zhu, F., Lu, Z., Wang, S., Yin, Y.: Microgravity diffusion flame spread over a thick solid in step-changed low-velocity opposed flows. Combust. Flame. 205, 55–67 (2019). https://doi.org/10.1016/j.combustflame.2019.03.040

Zik, O., Moses, E.: Fingering instability in solid fuel combustion: The characteristic scales of the developed state. Symp. Int. Combust. 27, 2815–2820 (1998). https://doi.org/10.1016/S0082-0784(98)80139-2

Funding

This work is supported by the National Key R&D Program of China (Grant No. 2021YFA0716203), the Opening Fund of State Key Laboratory of Fire Science (SKLFS) under Grant No. HZ2021-KF12, and the National Natural Science Foundation of China under Grant No. U1738117.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 302 KB)

Supplementary file2 (MP4 322 KB)

Supplementary file3 (MP4 515 KB)

Supplementary file4 (MP4 131 KB)

Supplementary file5 (MP4 1431 KB)

Appendix

Appendix

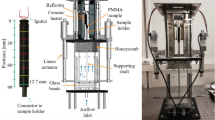

The thermogravimetric analysis (TGA) analysis of PE sample was conducted with a PerkinElmer STA 6000 Simultaneous Thermal Analyser. The initial mass of PE sample was 3–5 mg, and samples were heated at the constant rate of 10 K/min and under both nitrogen and air environments. Experiments were repeated twice for each case, and good repeatability is shown. Figure 11 shows the mass-loss rate curves of the PE insulation sample. In general, the pyrolysis temperature of PE is about 410 °C, and the ignition temperature is slightly higher.

The position of flame leading edge as a function of time under microgravity experiments and normal gravity environment for the vertically downward spreading flame. The coefficients of determination (R2) for each fitting curve are listed in the Fig. 12.

The Bi number is defined as \(Bi=h\tau /{\lambda }_{s}\), where h is the heat-transfer coefficient, τ is the thickness of the film, which is used as the characteristic length, λs is the thermal conductivity of the film. We first determine the flow condition and the heat transfer coefficient.

Thus, the flow is laminar, and we can estimate the convection coefficient as

Then, the Bi number can be calculated for PE film of \(\tau =40\) μm as

where properties of gas are evaluated at the film temperature \({T}_{f}=\left({T}_{ig}+{T}_{f}\right)/2=950 K\), where Tig is the ignition temperature of the PE, and Tf is the flame temperature. The properties of air are shown in Table 1. The length of the sample is used as the characteristic length, that is L = 0.15 m.

Rights and permissions

About this article

Cite this article

Zhu, F., Huang, X. & Wang, S. Flame Spread over Polyethylene Film: Effects of Gravity and Fuel Inclination. Microgravity Sci. Technol. 34, 26 (2022). https://doi.org/10.1007/s12217-022-09945-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12217-022-09945-4