Abstract

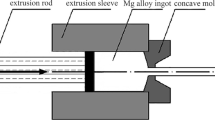

This paper presents the deformation behavior of commercial Mg-Al-Zn-Mn type alloys during hydrostatic extrusion process at elevated temperatures. In the current study commercial Mg-Al-Zn-Mn type alloys with different Al contents were subjected to hydrostatic extrusion process at a range of temperatures and at ram speeds of 4.5, 10 and 17 mm/sec. Under the hydrostatic condition at 518K, the alloy with Al contents of 2.9 wt% was successfully extruded at all applied speeds. The alloys with Al content of 5.89 and 7.86 wt% were successful up to 10mm/sec, and finally extrusion of alloy with Al content 8.46wt% was successful only at 4.5 mm/sec. These results show that the deformation limit in the Mg alloys in terms of extrusion speed greatly extended to higher value in the proximity of lower Al content. It is presumed that deformation becomes harder as Al content increases because of strengthening mechanism by solute drag to increase of supersaturated Mg17 Al12 precipitates. Also, microstructures of cast and extruded Mg alloys were compared. Defect-wide microstructure of cast alloy completely evolved into dense and homogeneous microstructure with equiaxed grains.

Similar content being viewed by others

References

E. Aghion, B. Bronfin and D. Eliezer, The role of the magnesium industry in protecting the environment. J. Mater. Process Techol. 117 (2001) 381–385.

L. L. Chang, E. F. Shang, Y. N. Wang, X. Zhao and M. Qi, Texture and microstructure evolution in cold rolled AZ31 magnesium alloy, Mater. Characterization 60 (2009) 487–491.

S. K. Guan, L. H. Wu and P. Wang, Hot forgeability and die forging forming of semi-continuously cast AZ70 magnesium alloy, Mater. Sci. & Eng. A499 (2009) 187–191.

R. C. Zeng, Y. B. Xu, W. Ke and E. H. Han, Fatigue crack propagation behavior of an as-extruded magnesium alloy AZ80, Mater. Sci. Eng. A509 (2009) 1–7.

M. Shahzad and L. Wagner, Influence of extrusion parameters on microstructure and texture developments, and their effects on mechanical properties of the magnesium alloy AZ80, Mater. Sci. Eng. A506 (2009) 141–147.

M. Pisarek, P. Kedzierzawski, T. Plocinski, M. J. Czachor and K. J. Kurzydlowski, Characterization of the effects of hydrostatic extrusion on grain size, surface composition and the corrosion resistance of austenitic stainless steels, Mater. Character. 59 (2008) 1292–1300.

W. Pachla, M. Kulczyk, M. Sus-Ryszkowska A. Mazur and K. J. Kurzydlowski, Nanocrystalline titanium produced by hydrostatic extrusion, J. Mat. Process. Tech. 205 (2008) 173–182.

I. J Polmear, Light alloys metallurgy of the light metals, Third Ed. Arnold Publishing Company, London, UK, (1995).

F. Zarandi, G. Seale, R. Verma, E. Essadiqi and S. Yue, Effect of Al and Mn additions on rolling and deformation behavior of AZ series magnesium alloys, Mater. Sci. Eng.A 496 (2008) 159–168.

Author information

Authors and Affiliations

Corresponding author

Additional information

Duc-Jae Yoon received his B.S. in Department of Product Design and Manufacturing Engineering from Seoul National University of Technology, Korea, in 1991. He then received his M.S. in Department of Mechanical Engineering from Dankook University, Korea, in 1995. and Ph.D. Department of Mechanical Engineering from Inha University, respectively. Dr. Yoon is currently a principal researcher at Korea Institute of Industrial Technology (KITECH) in Incheon, Korea. His research interests include Metal forming, plastic working and metalworking processes

Sangmok Lee received his B.S. in Inorganic Materials Engineering from Hanyang University, Korea, in 1988. He then received his M.S. and Ph.D. degrees in Materials Science from USC in 2000 and 2002, respectively. Dr. Lee is currently a principal researcher at the Korea Institute of Industrial Technology (KITECH) in Incheon, Korea. His research interests include metallic deformation, superplasticity and fabrication of nanostructured materials.

Rights and permissions

About this article

Cite this article

Yoon, DJ., Lee, S., Lim, SJ. et al. Deformation behavior of commercial Mg-Al-Zn-Mn type alloys under a hydrostatic extrusion process at elevated temperatures. J Mech Sci Technol 24, 131–135 (2010). https://doi.org/10.1007/s12206-009-1203-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-009-1203-9