Abstract

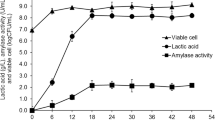

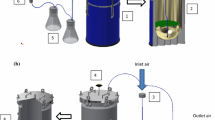

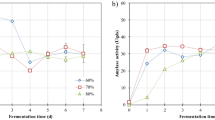

Enzyme-based unhairing in replacement of conventional lime sulfide system has been attempted as an alternative for tackling pollution. The exorbitant cost of enzyme and the need for stringent process control need to be addressed yet. This study developed a mechanism for regulated release of protease from cheaper agro-wastes, which overcomes the necessity for stringent process control along with total cost reduction. The maximum protease activity of 1193.77 U/g was obtained after 96 h of incubation with 15% inoculum of the actinomycete strain Brevibacterium luteolum (MTCC 5982) under solid-state fermentation (SSF). The medium after SSF was used for unhairing without the downstream processing to avoid the cost involved in enzyme extraction. This also helped in the regulated release of enzyme from bran to the process liquor for controlled unhairing and avoided the problem of grain-pitting. Unhairing process parameters were standardized as 20% enzyme offer, 40% Hide-Float ratio at 5 ± 1 rpm, and process pH of 9.0. The cost of production of 1000 kU of the protease was calculated as 0.44 USD. The techno-economic feasibility studies for setting up an SSF enzyme production plant showed a high return on investment of 15.58% with a payback period of 6.4 years.

Similar content being viewed by others

References

Nancy, G., Prakram, S. C., Vivek, K., Neena, P., & Naveen, G. (2014). Approach to ecofriendly leather: characterization and application of an alkaline protease for chemical free dehairing of skins and hides at pilot scale. Journal of Cleaner Production, 79, 249–257.

Rohm, O. (1910). Dehairing and cleaning of skins. German Patent, 268, 837.

Thanikaivelan, P., Rao, J. R., & Nair, B. U. (2000). Development of a leather processing method in narrow pH profile: part 1. Standardisation of dehairing process. Journal of the Society of Leather Technologists and Chemists, 84, 276–284.

Dettmer, A., Cavalheiro, J. C., Cavalli, E., Rossi, D. M., Gusatti, C. D. S., Zachia Ayub, M. A., & Gutterres, M. (2012). Optimization of the biotechnological process for hide unhairing in substitution of toxic sulfides. Chemical Engineering and Technology, 35, 803–810.

Saravanan, P., Shiny Renitha, T., Gowthaman, M. K., & Kamini, N. R. (2014). Understanding the chemical free enzyme based cleaner unhairing process in leather manufacturing. Journal of Cleaner Production, 79, 258–264.

Chellapandi, P. (2010). Production and preliminary characterization of alkaline protease from Aspergillus flavus and Aspergillus terreus. E-Journal of Chemistry, 7, 479–482.

Harish, B. K., Sneha, V. M., Kalal, K. M., & Seeta Laxman, R. (2015). Eco-friendly enzymatic dehairing of skins and hides by C. brefeldianus protease. Clean Technologies and Enviromental Policy, 17, 393–405.

Gillespie, J. M. (1953). The depilation of sheepskins with enzymes. Journal of the Society of Leather Technologists and Chemists, 37, 344–353.

Cross, T. (1968). Thermophilic actinomycetes. Applied Bacteriology, 31, 36–53.

Chandrasekaran, S., & Dhar, S. C. (1983). A low cost method for the production of extracellular alkaline proteinase using tapioca starch. Journal of Fermentation Technology, 61, 511–514.

Arunachalam, C., & Saritha, K. (2009). Protease enzyme an eco-friendly alternative for leather industry. Indian Journal of Science and Technology, 2, 29–32.

Gehring, A. (2002). Unhairing with proteolytic enzymes derived from Streptomyces griseus. Journal of the American Leather Chemists Association., 91, 406–411.

Mitra, P., & Chakrabartty, P. K. (2005). An extracellular protease with depilation activity from Streptomyces nogalator. Journal of Scientific and Industrial Research, 64, 978–983.

Muthulakshmi, C., Gomathi, D., Kumar, D. G., Ravikumar, G., Kalaiselvi, M., & Uma, C. (2011). Production, purification and characterization of protease by Aspergillus flavus under solid state fermentation. Jordan Journal of Biological Sciences, 4, 137–148.

Jarun, C., Sinsupha, C., Yusuf, C., & Penjit, S. (2008). Protease production by Aspergillus oryzae in solid state fermentation using agro industrial waste. Journal of Chemical Technology and Biotechnology, 83, 1012–1018.

Cupp-Enyard, C. (2008). Sigma’s non-specific protease activity assay—casein as a substrate. Journal of Visualized Experiments. doi:10.3791/899.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., & Randall, R. J. (1951). Protein measurement with the Folin phenol reagent. Journal of Biological Chemistry, 193, 265–275.

Shivasharana, C. T., & Naik, G. R. (2012). Ecofriendly applications of thermostable alkaline protease produced from a Bacillus sp. JB-99 under solid state fermentation. International Journal of Environmental Sciences, 3, 956–964.

Rajkumar, R., Jayappriyan, K. R., & Rengasamy, R. (2011). Production and characterization of a novel protease from Bacillus sp. RRM1 under solid state fermentation. Journal of Microbiology and Biotechnology, 21, 627–636.

Divakar, G., Sunitha, M., Vasu, P., Udaya Shanker, P., & Ellaiah, P. (2006). Optimization of process parameters for alkaline protease production under solid-state fermentation by Thermoactinomyces thalophilus PEE 14. Indian Journal of Biotechnology, 5, 80–83.

Vijayaraghavan, P., Vijayan, A., Arun, A., Jenisha, J. K., & Vincent, S. G. P. (2012). Cow dung: a potential biomass substrate for the production of detergent-stable dehairing protease by alkaliphilic Bacillus subtilis strain VV. SpringerPlus, 1, 76.

Kaur, G., Sharma, S., Nagi, H. P. S., & Dhar, B. N. (2012). Functional properties of pasta enriched with variable cereal brans. Journal of Food Science and Technology, 49, 467–474.

Prabhavathy, G., Rajasekara Pandian, M., & Senthilkumar, B. (2012). Optimization and production of extracellular alkaline protease by solid state fermentation using Bacillus subtilis. Journal of Academic and Industrial Research, 17, 427–430.

Sivasubramanian, S., Murali Manohar, B., & Puvanakrishnan, R. (2008). Mechanism of enzymatic dehairing of skins using a bacterial alkaline protease. Chemosphere, 70, 1025–1034.

Peters, M., Timmerhaus, K., & West, R. (2003). Plant design and economics for chemical engineers. Boston: McGraw-Hill.

Han, W., Fang, J., Liu, Z. X., & Tang, J. H. (2016). Techno-economic evaluation of a combined bioprocess for fermentative hydrogen production from food waste. Bioresource Technology, 202, 107–112.

Vlysidis, A., Binns, M., Webb, C., & Theodoropoulos, C. (2011). A techno-economic analysis of biodiesel biorefineries: assessment of integrated designs for the co-production of fuels and chemicals. Energy, 36, 4671–4683.

Han, W., Wang, X. N., & Ye, L. (2015a). Fermentative hydrogen production using wheat flour hydrolysate by mixed culture. International Journal of Hydrogen Energy, 40, 4474–4480.

Han, W., Ye, M., & Zhu, A. J. (2015b). Batch dark fermentation from enzymatic hydrolyzed food waste for hydrogen production. Bioresource Technology, 191, 24–29.

Acknowledgements

This work was carried out by the first author for the partial fulfillment of M.S. (By research) degree under the work titled “Development of Efficacious Unhairing Enzyme.” The author also acknowledges ZERIS (CSC 0103) for providing funds for carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 557 kb)

Rights and permissions

About this article

Cite this article

Renganath Rao, R., Vimudha, M., Kamini, N.R. et al. Alkaline Protease Production from Brevibacterium luteolum (MTCC 5982) Under Solid-State Fermentation and Its Application for Sulfide-Free Unhairing of Cowhides. Appl Biochem Biotechnol 182, 511–528 (2017). https://doi.org/10.1007/s12010-016-2341-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2341-z