Abstract

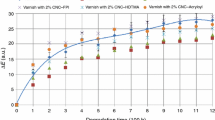

Demand for durable clear wood coatings is on the rise. Cellulose nanocrystals (CNC) constitute an organic nanomaterial widely studied in polymer composites for its reinforcing effect. In this study, CNC was used to enhance the performance of a UV curable high-solid content coating system intended for indoor environments. The CNC surface was modified by a cationic surfactant since the coating system was hydrophobic resin-based requiring hydrophobic nanomaterial reinforcement. Modified CNC was mixed with the coating system using a high-speed mixer and the ultrasonication technique. Mechanical, thermal and morphological properties and curing behavior of the newly developed UV-curing coatings were assessed. Inclusion of CNC in the coating increased the mechanical properties (hardness and reduced modulus) of the coating system to a large extent. Thermal stability of the coating system was also improved by CNC addition. The CNC did not affect the curing behavior of the coating, in contrast to most inorganic nanomaterials. The CNC dispersed well in the matrix at 1% loading. Results of this study show that CNC can be used successfully with high-solid content coating systems.

Similar content being viewed by others

References

Decker, C, “The Use of UV Irradiation in Polymerization.” Polym. Int., 45 133–141 (1998)

Decker, C, “Kinetic Study and New Applications of UV Radiation Curing.” Macromol. Rapid Commun., 23 1067–1093 (2002)

Chen, ZG, Webster, D, “Study of the Effect of Hyperbranched Polyols on Cationic UV Curable Coating Properties.” Polym. Int., 56 754–763 (2007)

Cheng, XE, Huang, ZG, Liu, JH, Shi, WF, “Synthesis and Properties of Semi-Crystalline Hyperbranched Poly(ester-amide) Grafted with Long Alkyl Chains Used for UV-Curable Powder Coatings.” Prog. Org. Coat., 59 284–290 (2007)

Cheng, X, Liu, S, Shi, W, “Synthesis and Properties of Silsesquioxane-Based Hybrid Urethane Acrylate Applied to UV-Curable Flame-Retardant Coatings.” Prog. Org. Coat., 65 1–9 (2009)

Nguegang Nkeuwa, W, Riedl, B, Landry, V, “UV-Cured Clay/Based Nanocomposite Topcoats for Wood Furniture: Part I: Morphological Study, Water Vapor Transmission Rate and Optical Clarity.” Prog. Org. Coat., 77 1–11 (2014)

Nguegang Nkeuwa, W, Riedl, B, Landry, V, “UV-Cured Clay/Based Nanocomposite Topcoats for Wood Furniture. Part II: Dynamic Viscoelastic Behavior and Effect of Relative Humidity on the Mechanical Properties.” Prog. Org. Coat., 77 12–23 (2014)

Landry, V, Riedl, B, Blanchet, P, “Nanoclay Dispersion Effects on UV Coatings Curing.” Prog. Org. Coat., 62 400–408 (2008)

Sow, C, Riedl, B, Blanchet, P, “Kinetic Studies of UV-Waterborne Nanocomposite Formulations with Nanoalumina and Nanosilica.” Prog. Org. Coat., 67 188–199 (2010)

Vlad, M, Riedl, B, Blanchet, P, “Effect of Addition of Nanosized UV Absorbers on the Physico-Mechanical and Thermal Properties of an Exterior Waterborne Stain for Wood.” Prog. Org. Coat., 72 755–762 (2011)

Auclair, N, Riedl, B, Blanchard, V, Blanchet, P, “Improvement of Photoprotection of Wood Coatings by Using Inorganic Nanoparticles as Ultraviolet Absorbers.” Forest Prod. J., 61 20–27 (2011)

Xia, T, Hamilton, RF, Bonner, JC, Crandall, ED, Elder, A, Fazlollahi, F, Girtsman, TA, Kim, K, Mitra, S, Ntim, SA, Orr, G, Tagmount, M, Taylor, AJ, Telesca, D, Tolic, A, Vulpe, CD, Walker, AJ, Wang, X, Witzmann, FA, Wu, N, Xie, Y, Zink, JI, Nel, A, Holian, A, “Interlaboratory Evaluation of In Vitro Cytotoxicity and Inflammatory Responses to Engineered Nanomaterials: The NIEHS NanoGo Consortium.” Environ. Health Perspect., 121 683–690 (2013)

Tang, I, Huang, B, Wang, S, Ou, W, Lin, W, Chen, X, “Ultrasonication-Assisted Manufacture of Cellulose Nanocrystals Esterified with Acetic Acid.” Bioresour. Technol., 127 100–105 (2013)

Wang, S, Cheng, Q, “A Novel Process to Isolate Fibrils from Cellulose Fibers by High-Intensity Ultrasonication. Part I. Process Optimization.” J. Appl. Polym. Sci., 113 1270–1275 (2009)

Sipahi-Sağlam, E, Gelbrich, M, Gruber, E, “Topochemically Modified Cellulose.” Cellulose, 10 237–250 (2003)

Peng, SX, Chang, H, Kumar, S, Moon, RJ, Youngblood, JP, “A Comparative Guide to Controlled Hydrophobization of Cellulose Nanocrystals via Surface Esterification.” Cellulose, 23 1825–1846 (2016)

Grüneberger, F, Künniger, T, Zimmermann, T, Arnold, M, “Nanofibrillated Cellulose in Wood Coatings: Mechanical Properties of Free Composite Films.” J. Mater. Sci., 49 6437–6648 (2014)

Vlad, M, Landry, V, Blanchet, P, Ouellet-Plamondon, C, “Nanocrystalline Cellulose as Effect Pigment in Clear Coatings for Wood, ISRN Nanomaterials.” Article ID 930236, 12 pages (2013).

Poaty, B, Vardanyan, V, Wilczak, L, Chauve, G, Riedl, B, “Modification of Cellulose Nanocrystals as Reinforcement Derivatives for Wood Coatings.” Prog. Org. Coat., 77 813–820 (2014)

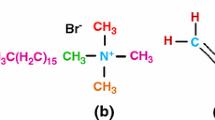

Kaboorani, A, Riedl, B, “Surface Modification of Cellulose Nanocrystal (CNC) by a Cationic Surfactant.” Ind. Crop. Prod., 65 45–55 (2015)

Scott, TF, Cook, WD, Fortsythe, JC, “Photo-DSC Cure Kinetics of Vinyl Ester Resins. I. Influence of Temperature.” Polymer, 43 5839–5845 (2002)

Scott, TF, Cook, WD, Fortsythe, JC, “Photo-DSC Cure Kinetics of Vinyl Ester Resins II: Influence of Diluent Concentration.” Polymer, 44 671–680 (2003)

Wu, Q, Meng, Y, Concha, K, Wang, S, Li, Y, Ma, L, Fu, S, “Influence of Temperature and Humidity on Nano-mechanical Properties of Cellulose Nanocrystal Films Made from Switchgrass and Cotton.” Ind. Crop. Prod., 48 28–35 (2013)

Meng, Y, Wang, S, Cai, Z, Young, TM, Du, G, Li, Y, “A Novel Sample Preparation Method to Avoid Embedding Medium Influence During Nanoindentation.” Appl. Phys. A, 110 361–369 (2013)

Oliver, WC, Pharr, GM, “An Improved Technique for Determining Hardness and Elasticmodulus Using Load and Displacement Sensing Indentation Experiments.” J. Mater. Res., 7 1564–1583 (1992)

Kaboorani, P, Riedl, B, Blanchet, P, Fellin, M, Hosseinaei, O, Wang, S, “Nanocrystalline Cellulose (NCC): A Renewable Nano-material for Wood Adhesives.” Eur. Polym. J., 48 1829–1837 (2012)

Kaboorani, P, Riedl, B, Blanchet, P, “Ultrasonication Technique: A Method for Dispersing Nanoclay in Wood Adhesives.” J. Nanomater. Article ID 341897, 9 pages (2013).

Cao, H, Li, B, Zhang, J, Lian, F, Kong, X, Qu, M, “Synthesis and Superior Anode Performance of TiO2 Reduced Graphene Oxide Nanocomposites for Lithium Ion Batteries.” J. Mater. Chem., 22 9759–9766 (2012)

Behabtu, N, Lomeda, JR, Green, MJ, Higginbotham, AL, Sinitskii, A, Kosynkin, DV, Tsentalovich, D, ParraVasquez, ANG, Schmidt, J, Kesselman, E, Cohen, Y, Talmon, Y, Tour, JM, Pasquali, M, “Spontaneous High-concentration Dispersions and Liquid Crystals of Graphene.” Nat. Nanotechnol., 5 406–411 (2010)

Acknowledgments

The authors would like to express their thanks to Forest Products Laboratory – USDA Forest Service for so kindly providing cellulose nanocrystal (CNC) for this research. Thanks are also extended to Research Center for Advanced Materials of Laval University for providing the equipment for the characterizations. This study was funded by Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaboorani, A., Auclair, N., Riedl, B. et al. Cellulose nanocrystal (CNC)-based nanocomposites for UV curable high-solid coating systems. J Coat Technol Res 14, 1137–1145 (2017). https://doi.org/10.1007/s11998-017-9929-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-017-9929-2