Abstract

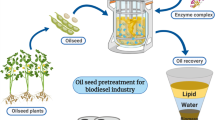

Aqueous oil extraction is an approach that could replace organic solvent extraction with water. Compared to typical solvent extraction and mechanical pressing processes, aqueous extraction has higher oil recovery (over 80%) than the mechanical pressing process, and resolve issues resulted from chemical loading and remaining in the hexane extraction. Proteases are used to assist free oil release from oil bodies by hydrolyzing cotyledon cell walls in aqueous extraction process. The resulting enzyme-assisted aqueous extraction process (EAEP) includes dehulling, flaking, extruding, enzymatic extraction, and enzymatic demulsification processes. SuperPro Designer was used to conduct a techno-economic analysis (TEA) of the extraction process. The total capital investment, operation cost, and profits were evaluated. During EAEP, insolubility of water and oil allows the simultaneous extraction of protein and oil. This decreases operation costs, especially the oil purification process, and therefore increases profits made from the main product (soybean oil). This simultaneous extraction also increases the profit towards the coproduct, i.e., protein in skim. Additionally, the absence of chemical and enzyme recycling contribute to the better economic value of EAEP. Despite the increase in facility costs due to extraction and demulsification units, the value-added coproduct extraction and high free oil yield contribute to the economic feasibility of EAEP in industrial- and commercial-scale productions when skim and insoluble fiber are used as water and carbohydrate supplies for integrated soy/corn ethanol biorefinery processing.

Similar content being viewed by others

References

Alibaba.com. (2016). Soya fiber: http://www.alibaba.com/showroom/soya-fiber.html. Acessed 15 Jul 2016.

Bureau of Labor Statistics. (2016). Occupational Employment Statistics: http://www.bls.gov/oes/tables.htm. Accessed 15 Jul 2016.

Chabrand, R., & Glatz, C. (2009). Destabilization of the emulsion formed during the enzyme-assisted aqueous extraction of oil from soybean flour. Enzyme and Microbial Technology, 45(1), 28–35.

City of Ames. (2016). Rates and structure: http://www.cityofames.org/government/departments-divisions-i-z/water-pollution-control/rates-and-structure. Accessed 15 Jul 2016.

de Moura, J., Maurer, D., Jung, S., & Johnson, L. (2011). Pilot-plant proof-of-concept for integrated, countercurrent, two-stage, enzyme-assisted aqueous extraction of soybeans. Journal of the American Oil Chemists' Society, 88(10), 1649–1658.

Domíguez, H., Núñez, M., & Lema, J. (1994). Enzymatic pretreatment to enhance oil extraction from fruits and oilseeds: a review. Food Chemistry, 49(3), 271–286.

Feedstuffs Magazine. (1980–2015). Ingredient Market. Minnetonka, MN: Miller Publishing Company, Inc.

Haas, M., McAloon, A., Yee, W., & Foglia, T. (2006). A process model to estimate biodiesel production costs. Bioresource Technology, 97(4), 671–678.

Heinzle, E., Biwer, A., & Cooney, C. (2006). Chapter 4: sustainability assessment. In E. Heinzle, A. Biwer, & C. Cooney (Eds.), Development of sustainable bioprocesses: modeling and assessment (pp. 81–117). West Sussex, England: John Wiley & Sons Ltd.

Johnson, L., & Lucas, E. (1983). Comparison of alternative solvents for oils extraction. Journal of the American Oil Chemists' Society, 60(2Part1), 229–242.

Jung, S., & Mahfuz, A. (2009). Low temperature dry extrusion and high-pressure processing prior to enzyme-assisted aqueous extraction of full fat soybean flakes. Food Chemistry, 114(3), 947–954.

Jung, S., Maurer, D., & Johnson, L. (2009). Factors affecting emulsion stability and quality of oil recovered from enzyme-assisted aqueous extraction of soybeans. Bioresource Technology, 100(21), 5340–5347.

Lamsal, B., Murphy, P., & Johnson, L. (2006). Flaking and extrusion as mechanical treatments for enzyme-assisted aqueous extraction of oil from soybeans. Journal of the American Oil Chemists' Society, 83(11), 973–979.

Li, Y., Griffing, E., Higgins, M., & Overcash, M. (2006). Life cycle assessment of soybean oil production. Journal of Food Process Engineering, 29(4), 429–445.

Lucas, E., Lawhon, J., & Rhee, K. (1982). Producing edible oil and protein from oilseeds by aqueous processing. Oil Mill Gazetteer, 86, 28–33.

Ngo, H., Yee, W., McAloon, A., & Haas, M. (2014). Techno-economic analysis of an improved process for producing saturated branched-chain fatty acids. The Journal of Agricultural Science, 6, 158–168.

Pare, A., Nema, A., & Singh, V. (2014). Combined effect of ohmic heating and enzyme assisted aqueous extraction process on soy oil recovery. Journal of Food Science and Technology, 51, 1601–1611.

Peters, M., Timmerhaus, K., & West, R. (2011). Chapter 6: analysis of cost estimation. In M. Peters, K. Timmerhaus, & R. West (Eds.), Plant design and economics for chemical engineers (pp. 226–278). New York: McGraw Hill.

Rosenthal, A., Pyle, L., & Niranjan, K. (1996). Aqueous and enzymatic processes for edible oil extraction. Enzyme and Microbial Technology, 19(6), 402–420.

Sekhon, J., Jung, S., Wang, T., Rosentrater, K., & Johnson, L. (2015). Effect of co-products of enzyme-assisted aqueous extraction of soybeans on ethanol production in dry-grind corn fermentation. Bioresor Technol, 192, 451–460.

Shah, S., Sharma, A., & Gupta, M. (2005). Extraction of oil from Jatropha curcas L. seed kernels by combination of ultrasonication and aqueous enzymatic oil extraction. Bioresource Technology, 96(1), 121–123.

Sigma-Aldrich. (2016). Sodium hydroxide. http://www.sigmaaldrich.com/catalog/substance/sodiumhydroxide4000131073211?lang=en®ion=US. Accessed 15 Jul 2016.

SuperPro Designer Data Base. (2015). SuperPro Designer heat exchange resource data base. SuperPro Designer heat exchange resource data base. Scotch Plains, NJ, USA: Intelligen Inc. Accessed 15 Jul 2016.

Ulrich, G. (1984). Chapter 6: manufacturing cost estimation. In G. Ulrich (Ed.), A guide to chemical engineering process design and economics (pp. 324–342). New York: John Wiley & Sons Ltd..

USA EIA. (2016). Electricity: https://www.eia.gov/electricity/data.cfm#sales. Accessed 15 Jul 2016.

USDA ERS. (2016). United States Department of Agriculture Economic Research Service. Oil Crops Yearbook: http://www.ers.usda.gov/data-products/oil-crops-yearbook.aspx. Accessed 13 Nov 2016.

Valentova, O., Novotna, Z., Svoboda, Z., Schwartz, W., & Kas, J. (2000). Microwave heating and γ-irradiation treatment of rapeseed (Brassica napus). Journal of Food Lipids, 7, 237–245.

Wood, C., Rosentrater, K., & Muthukumarappan, K. (2014). Techno-economic modeling of a corn based ethanol plant in 2011/2012. Industrial Crops and Products, 56, 145–155.

Wu, J., Johnson, L., & Jung, S. (2009). Demulsification of oil-rich emulsion from enzyme-assisted aqueous extraction of extruded soybean flakes. Bioresource Technology, 100(2), 527–523.

Yusoff, M., Gordon, M., & Niranjan, K. (2015). Aqueous enzyme assisted oil extraction from oilseeds and emulsion de-emulsifying methods: a review. Trends in Food Science and Technology, 41(1), 60–82.

Acknowledgments

We would like to thank the Center for Crops Utilization Research (CCUR), Iowa State University, for their assistance.

Funding

This project was funded by the United States Department of Agriculture (USDA) Award 2013-67021-21083.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 136 kb)

Rights and permissions

About this article

Cite this article

Cheng, MH., Rosentrater, K.A., Sekhon, J. et al. Economic Feasibility of Soybean Oil Production by Enzyme-Assisted Aqueous Extraction Processing. Food Bioprocess Technol 12, 539–550 (2019). https://doi.org/10.1007/s11947-018-2228-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2228-9