Abstract

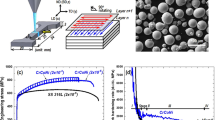

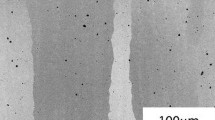

Materials with low stacking fault energies have been long sought for their many desirable mechanical attributes. Although there have been many successful reports of low stacking fault alloys (for example Cu-based and Mg-based), many have lacked sufficient strength to be relevant for structural applications. The recent discovery and development of multicomponent equiatomic alloys (or high-entropy alloys) that form as simple solid solutions on ideal lattices has opened the door to investigate changes in stacking fault energy in materials that naturally exhibit high mechanical strength. We report in this article our efforts to determine the stacking fault energies of two- to five-component alloys. A range of methods that include ball milling, arc melting, and casting, is used to synthesize the alloys. The resulting structure of the alloys is determined from x-ray diffraction measurements. First-principles electronic structure calculations are employed to determine elastic constants, lattice parameters, and Poisson’s ratios for the same alloys. These values are then used in conjunction with x-ray diffraction measurements to quantify stacking fault energies as a function of the number of components in the equiatomic alloys. We show that the stacking fault energies decrease with the number of components. Nonequiatomic alloys are also explored as a means to further reduce stacking fault energy. We show that this strategy leads to a means to further reduce the stacking fault energy in this class of alloys.

Similar content being viewed by others

References

Y.H. Zhao, Y.T. Zhu, X.Z. Liao, Z. Horita, and T.G. Langdon, Appl. Phys. Lett. 89, 121906 (2006).

Y.L. Gong, C.E. Wen, Y.C. Li, X.X. Wu, L.P. Cheng, X.C. Han, and X.K. Zhu, Mater. Sci. Eng. A 569, 144 (2013).

P.-L. Sun, Y.H. Zhao, J.C. Cooley, M.E. Kassner, Z. Horita, T.G. Langdon, E.J. Lavernia, and Y.T. Zhu, Mater. Sci. Eng. A 525, 83 (2009).

K. Youssef, M. Sakaliyska, H. Bahmanpour, R. Scattergood, and C. Koch, Acta Mater. 59, 5758 (2011).

H. Bahmanpour, A. Kauffmann, M.S. Khoshkhoo, K.M. Youssef, S. Mula, J. Freudenberger, J. Eckert, R.O. Scattergood, and C.C. Koch, Mater. Sci. Eng. A 529, 230 (2011).

Z.W. Wang, Y.B. Wang, X.Z. Liao, Y.H. Zhao, E.J. Lavernia, Y.T. Zhu, Z. Horita, and T.G. Langdon, Scripta Mater. 60, 52 (2009).

X.H. An, Q.Y. Lin, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, N. Gao, and T.G. Langdon, Scripta Mater. 64, 954 (2011).

G.E. Dieter, Mechanical Metallurgy, 3rd ed. (New York: McGraw-Hill, 1986), pp. 135–157.

Y. Zhang, N.R. Tao, and K. Lu, Scripta Mater. 60, 211 (2009).

W.W. Jian, G.M. Cheng, W.Z. Xu, H. Yuan, M.H. Tsai, Q.D. Wang, C.C. Koch, Y.T. Zhu, and S.N. Mathaudhu, Mater. Res. Lett. 1, 61 (2013).

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

S. Guo and C. Liu, Prog. Nat. Sci.: Mater. Int. 21, 433 (2011).

F. Otto, Y. Yang, H. Bei, and E.P. George, Acta Mater. 61, 2628 (2013).

S. Guo, C. Ng, J. Lu, and C.T. Liu, J. Appl. Phys. 109, 103505 (2011).

R.J.D. Tilley, Understanding Solids: The Science of Materials (Hoboken: Wiley, 2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004).

M. Leoni, T. Confente, and P. Scardi, Z. Kristallogr 23, 249 (2006).

G.K. Williamson and W.H. Hall, Acta Metall. 1, 22 (1953).

H.P. Klug and L.E. Alexander, X-Ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed. (New York: Wiley, 1974), pp. 660–662.

R.E. Schramm and R.P. Reed, Metall. Trans. A 7A, 359 (1976).

L. Vitos, Phys. Rev. B 64, 014107 (2001).

L. Vitos, Computational Quantum Mechanics for Materials Engineers: The EMTO Method and Applications (London: Springer, 2007).

P. Soven, Phys. Rev. 156, 809 (1967).

L. Vitos, I. Abrikosov, and B. Johansson, Phys. Rev. Lett. 87, 156401 (2001).

G. Kresse and J. Hafner, Phys. Rev. B 47, 558 (1993).

G. Kresse and J. Furthmüller, Phys. Rev. B 54, 11169 (1996).

G. Kresse and J. Furthmüller, Comput. Mater. Sci. 6, 15 (1996).

G. Kresse and J. Hafner, Phys. Rev. B 49, 14251 (1994).

A. Zunger, S.-H. Wei, L.G. Ferreira, and J.E. Bernard, Phys. Rev. Lett. 65, 353 (1990).

A. van de Walle, M. Asta, and G. Ceder, CALPHAD 26, 539 (2002).

O. Andersen, O. Jepsen, and G. Krier, Lectures on Methods of Electronic Structure Calculations, ed. V. Kumar, O.K. Andersen, and A. Mookerjee (Singapore: World Scientific, 1994).

L. Vitos, P. Korzhavyi, and B. Johansson, Phys. Rev. Lett. 88, 13 (2002).

L. Vitos, P.A. Korzhavyi, J.-O. Nilsson, and B. Johansson, Phys. Scripta 77, 065703 (2008).

J. Perdew, K. Burke, and M. Ernzerhof, Phys. Rev. Lett. 77, 3865 (1996).

J. Perdew, K. Burke, and M. Ernzerhof, Phys. Rev. Lett. 78, 1396 (1997).

B.L. Gyorffy, A.J. Pindor, J. Staunton, G.M. Stocks, and H. Winter, J. Phys. F: Met. Phys. 15, 1337 (1985).

P. Blöchl, Phys. Rev. B 50, 17953 (1994).

G. Kresse and D. Joubert, Phys. Rev. B 59, 1758 (1999).

C. Jiang, L. Chen, and Z.-K. Liu, Acta Mater. 53, 2643 (2005).

J. Pezold, A. Dick, M. Friák, and J. Neugebauer, Phys. Rev. B 81, 094203 (2010).

S. Lu, Q.-M. Hu, E.K. Delczeg-Czirjak, B. Johansson, and L. Vitos, Acta Mater. 60, 4506 (2012).

L. Vitos, J.-O. Nilsson, and B. Johansson, Acta Mater. 54, 3821 (2006).

M.S. Lucas, L. Mauger, J.A. Muñoz, Y. Xiao, A.O. Sheets, S.L. Semiatin, J. Horwath, and Z. Turgut, J. Appl. Phys. 109, 07E307 (2011).

S. Vives, E. Gaffet, and C. Meunier, Mater. Sci. Eng. A 336, 229 (2004).

M.J. Mehl, J.E. Osburn, D.A. Papaconstantopoulos, and B.M. Klein, Phys. Rev. B 41, 10311 (1990).

F. Tian, L.K. Varga, N. Chen, L. Delczeg, and L. Vitos, Phys. Rev. B 87, 075144 (2013).

G. Grimvall, Thermophysical Properties of Materials (Amsterdam: North-Holland, 1999).

H.M. Ledbetter and R.P. Reed, J. Phys. Chem. Ref. Data 2, 531 (1973).

C.B. Carter and S.M. Holmes, Philos. Mag. 35, 1161 (1977).

R.E. Schramm and R.P. Reed, Metall. Trans. A 6, 1345 (1975).

M.F. Denanot and J.P. Villain, Phys. Status Solidi A 8, K125 (1971).

A. Gali and E.P. George, Intermetallics 39, 74 (2013).

Acknowledgements

The work reported in this manuscript was made possible through support from the National Science Foundation from the Metals and Metallic Nanostructures program under grant DMR-1104930. D.L.I. and C.N. would also like to acknowledge Levente Vitos for sharing his EMTO-CPA code for work on this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zaddach, A.J., Niu, C., Koch, C.C. et al. Mechanical Properties and Stacking Fault Energies of NiFeCrCoMn High-Entropy Alloy. JOM 65, 1780–1789 (2013). https://doi.org/10.1007/s11837-013-0771-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-013-0771-4