Abstract

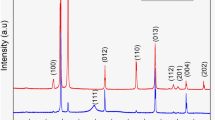

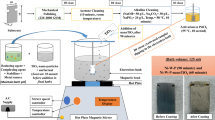

This study aims to analyse and forecast the significance of input process parameters to obtain a better ENi-P-TiO2 coated surface using artificial neural networks (ANN). By varying the four process parameters with the Taguchi L9 design, forty-five numbers of AH36 steel specimens are coated with ENi-P-TiO2 composites, and their microhardness values are determined. The ANN model was formulated using the input and output data obtained from the 45 specimens. The optimal design was developed based on mean squared error (MSE) and R2 values. The experimentally measured values were compared with their predicted values to determine the ANN model’s predictability. The efficiency of the ANN model is evaluated with an R2 value of 0.959 and an MSE value of 34.563 4. The authors have concluded that the developed model is suitable for designing and predicting ENi-P-TiO2 composite coatings to avoid extensive experimentation with economic production. Scanning Electron Microscope (SEM) and X-ray diffraction analysis (XRD) are also utilised to compare the base metal and optimal coated surface.

Similar content being viewed by others

References

Agarwala RC, Agarwala V (2003) Electroless alloy/composite coatings: A review. Sadhana-Academy Proceedings in Engineering Sciences 28: 475–493. https://doi.org/10.1007/BF02706445

Anthoni Sagaya Selvan R, Thakur DG, Seeman M, Muraliraja R, Ansari MI (2022) Modelling and optimisation of ENi-P-TiO2 coatings synthesised with Zwitterionic surfactant on naval grade AH36 Steel. Sådhanå 47(3): 1–13. https://doi.org/10.1007/s12046-022-01890-7

Beygi H, Vafaeenezhad H, Sajjadi SA (2012) Modeling the electroless nickel deposition on aluminum nanoparticles. Applied Surface Science 258: 7744–7750. https://doi.org/10.1016/j.apsusc.2012.04.132

Bückle H (1959) Progress in micro-indentation hardness testing. Metallurgical Reviews 4: 49–100. https://doi.org/10.1179/095066059790421746

Duncan RN (1996) The metallurgical structure of electroless nickel deposits: Effect on coating properties. Plating and Surface Finishing 83: 65–69

Duren CF (1990) Prediction of the hardness in the HAZ of HSLA steels by means of the carbon equivalent. Hardenability of Steels-Select Conference, Derby, UK, 51–62

Fotovvati B, Namdari N, Dehghanghadikolaei A (2019) On coating techniques for surface protection: A review. Journal of Manufacturing and Materials Processing 3(1): 28. https://doi.org/10.3390/jmmp3010028

Gadhari P, Sahoo P (2016) Electroless nickel-phosphorus composite coatings: A review. International Journal of Manufacturing, Materials, and Mechanical Engineering 6: 14–50. https://doi.org/10.4018/IJMMME.2016010102

Gadhari P, Sahoo P (2015) Improvement in tribological performance of Ni-P-TiO2 composite coatings using taguchi technique with grey relational analysis. Indian Journal of Materials Science 2015: 1–10. https://doi.org/10.1155/2015/104187

Ger MD, Hwang BJ (2002) Effect of surfactants on codeposition of PTFE particles with electroless Ni-P coating. Materials Chemistry and Physics 76: 38–45. https://doi.org/10.1016/S0254-0584(01)00513-2

Gerberich WW, Tymiak NI, Grunlan JC, Horstemeyer MF, Baskes MI (2002) Interpretations of indentation size effects. Journal of Applied Mechanics, Transactions ASME 69: 433–442. https://doi.org/10.1115/1.1469004

Golnaraghi S, Zangenehmadar Z, Moselhi O, Alkass S, Vosoughi AR (2019) Application of artificial neural network(s) in predicting formwork labour productivity. Advances in Civil Engineering 2019: 5972620. https://doi.org/10.1155/2019/5972620

Igi S, Inohara Y, Hirai T (2005) High performance steel plates for shipbuilding-Life cycle cost reduction technology of JFE Steel. JFE Technical Report 5: 16–23

Jha A, Chandrasekaran A, Kim C, Ramprasad R (2019) Impact of dataset uncertainties on machine learning model predictions: The example of polymer glass transition temperatures. Modelling and Simulation in Materials Science and Engineering 27: 024002. https://doi.org/10.1088/1361-651X/aaf8ca

Juneja R, Yumnam G, Satsangi S, Singh AK (2019) Coupling the high-throughput property map to machine learning for predicting lattice thermal conductivity. Chemistry of Materials 31: 5145–5151. https://doi.org/10.1021/acs.chemmater.9b01046

Lavesson N, Davidsson P (2006) Quantifying the impact of learning algorithm parameter tuning. Proceedings of the National Conference on Artificial Intelligence 1: 395–400

Liu Y, Zhao T, Ju W, Shi S (2017) Materials discovery and design using machine learning. Journal of Materiomics 3: 159–177. https://doi.org/10.1016/j.jmat.2017.08.002

Mallory GO (1990) The electroless nickel plating bath: effect of variables on the process. Electroless Plating: Fundamentals and Applications 57–101.

Mantovani RG, Rossi ALD, Vanschoren J, Bischl B, Carvalho AC-PLF (2015) To tune or not to tune: Recommending when to adjust SVM hyper-parameters via meta-learning. Proceedings of the International Joint Conference on Neural Networks, Killarney, Ireland, 1–8. https://doi.org/10.1109/IJCNN.2015.7280644

Muraliraja R, Elansezhian R (2014) Effect of zwitterionic surfactant on tribological behaviour of electroless plating. Surface Engineering 30: 752–757. https://doi.org/10.1179/1743294414Y.0000000321

Muraliraja R, Elansezhian R, Patterson K (2014) Optimization of reducing agent and key parameters effect on the efficiency of electroless Ni-P plating by Taguchi method. Procedia Materials Science 5: 2478–2486. https://doi.org/10.1016/j.mspro.2014.07.499

Muraliraja R, Elansezhian R, Sudagar J, Raviprakash AV (2016) Influence of a zwitterionic surfactant on the surface properties of electroless Ni-P coating on mild steel. Journal of Surfactants and Detergents 19: 1081–1088. https://doi.org/10.1007/s11743-016-1858-z

Pancrecious JK, Ulaeto SB, Ramya R, Rajan TPD, Pai BC, Pancrecious JK, Ulaeto SB, Ramya R, Rajan TPD (2018) Metallic composite coatings by electroless technique-a critical review. International Materials Reviews 63(10): 1–25. https://doi.org/10.1080/09506608.2018.1506692

Probst P, Boulesteix AL, Bischl B (2019) Tunability: Importance of hyperparameters of machine learning algorithms. Journal of Machine Learning Research 20: 1–32.

Sahoo P, Das SK (2011) Tribology of electroless nickel coatings — A review. Materials and Design 32: 1760–1775. https://doi.org/10.1016/j.matdes.2010.11.013

Shozib IA, Ahmad A, Rahaman MSA, Abdul-Rani AM, Alam MA, Beheshti M, Taufiqurrahman I (2021) Modelling and optimization of microhardness of electroless Ni-P-TiO2 composite coating based on machine learning approaches and RSM. Journal of Materials Research and Technology 12: 1010–1025. https://doi.org/10.1016/j.jmrt.2021.03.063

Srinivasa Pai P, Mathew MT, Stack MM, Rocha LA (2008) Some thoughts on neural network modelling of microabrasion-corrosion processes. Tribology International 41: 672–681. https://doi.org/10.1016/j.triboint.2007.11.015

Swetlana S, Khatavkar N, Singh AK (2020) Development of Vickers hardness prediction models via microstructural analysis and machine learning. Journal of Materials Science 55: 15845–15856. https://doi.org/10.1007/s10853-020-05153-w

Taheri R (2003) Electroless depostion of nickel. Modern Electroplating 1: 262.

Vaghefi SYM, Vaghefi SMM (2011) Prediction of phosphorus content of electroless nickel-phosphorous coatings using artificial neural network modeling. Neural Computing and Applications 20: 1055–1060. https://doi.org/10.1007/s00521-010-0473-6

Van Rijn JN, Hutter F (2018) Hyperparameter importance across datasets. Proceedings of the ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, London, 2367–2376. https://doi.org/10.1145/3219819.3220058

Vander Voort GF, Fowler R (2012) Low-load vickers microindentation hardness testing. Advanced Materials and Processes 170: 28–33.

Wen C, Zhang Y, Wang C, Xue D, Bai Y, Antonov S, Dai L, Lookman T, Su Y (2019) Machine learning assisted design of high entropy alloys with desired property. Acta Materialia 170: 109–117. https://doi.org/10.1016/j.actamat.2019.03.010

Wen G, Guo ZX, Davies CKL (1999) Electroless plating for the enhancement of material performance. Materials Technology 14: 210–217. https://doi.org/10.1080/10667857.1999.11752841

Reidel W (1991) Electroless nickel plating. ASM International, Metals Park, Ohio, 50–55

Yating W, Bin S, Lei L, Wenbin H (2008) Artificial neural network modelling of plating rate and phosphorus content in the coatings of electroless nickel plating. Journal of Materials Processing Technology 205: 207–213. https://doi.org/10.1016/j.jmatprotec.2007.11.095

Zhang P, Li SX, Zhang ZF (2011) General relationship between strength and hardness. Materials Science and Engineering A 529: 62–73. https://doi.org/10.1016/j.msea.2011.08.061

Zhang R, Somasundaran P (2006) Advances in adsorption of surfactants and their mixtures at solid/solution interfaces. Advances in Colloid and Interface Science 123–126: 213–229. https://doi.org/10.1016/j.cis.2006.07.004

Zou XF, Hu YJ, Long XB, Huang LY (2020) Prediction and optimization of phosphorus content in electroless plating of Cr12MoV die steel based on PSO-BP model. Surfaces and Interfaces 18: 100443. https://doi.org/10.1016/j.surfin.2020.100443

Acknowledgement

R. Anthoni Sagaya Selvan, one of the authors, would like to express gratitude to DIG Aedavalli Amarender Reddy, Chief Staff Officer (Tech), CGC (Eastern Seabaord), Indian Coast Guard, Visakhapatnam, India. Without his motivation, nurturing, and active participation in all aspects of the author’s life, it would not have been possible to successfully complete this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Article Highlights

• Environmental friendly Electroless ENi-P composite coatings are deposited on AH36 steel to increase its surface hardness for marine applications.

• Using the experimental data for training and validation, an ANNbased prediction model was devised.

• The ANN model was optimised by tuning hyperparameters and a sustainable model was produced to achieve a more accurate prediction of output based on the input parameters of the bath.

• The prediction performance of an artificial neural network (ANN) model is evaluated using experimental data, and three bath factors are analysed to comprehend its substantial contribution to obtaining better coating hardness.

• Through prediction, the devised model can be utilised to generate the input bath parameters for the required hardness value, saving time and chemicals.

Rights and permissions

About this article

Cite this article

Selvan, R.A.S., Thakur, D.G., Seeman, M. et al. Surface Modification of AH36 Steel Using ENi-P-nano TiO2 Composite Coatings Through ANN-Based Modelling and Prediction. J. Marine. Sci. Appl. 21, 193–203 (2022). https://doi.org/10.1007/s11804-022-00288-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11804-022-00288-5