Abstract

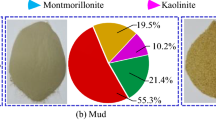

The grout-rock interfacial property is one of the key factors associated with the strength of grouted rock masses. In this study, direct shear tests and nanoindentation tests were adopted to investigate the mechanical properties of the grout-rock interface at both the macroscale and microscale. The cohesion of the cement specimens was higher than that of the grout-infilled joint specimens, while their internal friction angle was lower than that of the grout-infilled joint specimens. A “separation method” for identifying the different phases according to the qualitative and quantitative estimations was introduced, and the irregular interfacial transition zone (ITZ) thickness and elastic modulus were estimated. The ITZ thickness of the grout-infilled sandstone specimen ranged from 0 to 30 µm, whereas it was within the range of 10–40 µm for the grout-infilled mudstone specimen. The average elastic modulus of the ITZ in grout-infilled sandstone and mudstone specimens was approximately 58.2% and 54.1% lower than that of the bulk grout, respectively. Regarding the incidence of the rock type, the interlacing between the grout and sandstone was better developed. The ITZ with a higher porosity and lower modulus had a significant effect on the mechanical properties of the grout-infilled specimens.

摘要

浆-岩界面性质是影响注浆岩体强度的关键因素之一。本文采用直剪试验和纳米压痕试验研究了浆-岩界面的宏观和微观力学特性。结果表明,水泥试件的粘聚力高于浆液充填岩样,而内摩擦角较低。提出了一种从定性和定量角度识别不同相的“分离方法”,并估计了不规则界面过渡区(ITZ)的厚度和弹性模量。浆液充填砂岩岩样的ITZ 厚度为0∼30 µm,而浆液充填泥岩岩样的ITZ 厚度为10∼40 µm,浆液充填砂岩岩样和泥岩岩样ITZ 的平均弹性模量分别比水泥浆液的平均弹性模量低58.2%和54.1%。相比浆液充填泥岩岩样,浆液和砂岩之间的粘结效果较好。具有较高孔隙率和较低弹性模量的ITZ对浆液充填岩样的力学性能有显著影响。

Similar content being viewed by others

References

BAHAADDINI M, HAGAN P C, MITRA R, et al. Parametric study of smooth joint parameters on the shear behaviour of rock joints [J]. Rock Mechanics and Rock Engineering, 2015, 48(3): 923–940. DOI: https://doi.org/10.1007/s00603-014-0641-6.

JIANG Bang-you, GU Shi-tan, WANG Lian-guo, et al. Strainburst process of marble in tunnel-excavation-induced stress path considering intermediate principal stress [J]. Journal of Central South University, 2019, 26(4): 984–999. DOI: https://doi.org/10.1007/s11771-019-4065-z.

WANG Xiao, WEN Zhi-jie, JIANG Yu-jing, et al. Experimental study on mechanical and acoustic emission characteristics of rock-like material under non-uniformly distributed loads [J]. Rock Mechanics and Rock Engineering, 2018, 51(3): 729–745. DOI: https://doi.org/10.1007/s00603-017-1363-3.

LIU Yu-bing, YIN Guang-zhi, ZHANG Dong-ming, et al. Directional permeability evolution in intact and fractured coal subjected to true-triaxial stresses under dry and water-saturated conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 119: 22–34. DOI: https://doi.org/10.1016/j.ijrmms.2019.04.007.

ZHANG Fu-ping, LI Dian-qing, CAO Zi-jun, et al. Revisiting statistical correlation between Mohr-Coulomb shear strength parameters of Hoek-Brown rock masses [J]. Tunnelling and Underground Space Technology, 2018, 77: 36–44. DOI: https://doi.org/10.1016/j.tust.2018.03.018.

SUN Shang-qu, HE Peng, WANG Gang, et al. Shape characterization methods of irregular cavity using Fourier analysis in tunnel [J]. Mathematics and Computers in Simulation, 2021, 187: 191–214. DOI: https://doi.org/10.1016/j.matcom.2021.02.015.

CHEN Miao, YANG Sheng-qi, RANJITH P G, et al. Cracking behavior of rock containing non-persistent joints with various joints inclinations [J]. Theoretical and Applied Fracture Mechanics, 2020, 109: 102701. DOI: https://doi.org/10.1016/j.tafmec.2020.102701.

FENG Qiang, JIN Ji-chao, ZHANG Shuang, et al. Study on a damage model and uniaxial compression simulation method of frozen — thawed rock [J]. Rock Mechanics and Rock Engineering, 2022, 55(1): 187–211. DOI: https://doi.org/10.1007/s00603-021-02645-2.

MA Hao, LIU Quan-sheng. Prediction of the peak shear strength of sandstone and mudstone joints infilled with high water-cement ratio grouts [J]. Rock Mechanics and Rock Engineering, 2017, 50(8): 2021–2037. DOI: https://doi.org/10.1007/s00603-017-1225-z.

ZOLFAGHARI A, BIDAR A S, MALEKI J M R, et al. Evaluation of rock mass improvement due to cement grouting by Q-system at Bakhtiary Dam Site [J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 74: 38–44. DOI: https://doi.org/10.1016/j.ijrmms.2014.12.004.

KANG Yong-shui, LIU Quan-sheng, GONG Guang-qing, et al. Application of a combined support system to the weak floor reinforcement in deep underground coal mine [J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 71: 143–150. DOI: https://doi.org/10.1016/j.ijrmms.2014.03.017.

KOUPOULI N J F, BELEM T, RIVARD P, et al. Direct shear tests on cemented paste backfill-rock wall and cemented paste backfill-backfill interfaces [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2016, 8(4): 472–479. DOI: https://doi.org/10.1016/j.jrmge.2016.02.001.

SHE Cheng-xue, SUN Fu-ting. Study of the peak shear strength of a cement-filled hard rock joint [J]. Rock Mechanics and Rock Engineering, 2018, 51(3): 713–728. DOI: https://doi.org/10.1007/s00603-017-1358-0.

SHRIVASTAVA A K, RAO K S. Physical modeling of shear behavior of infilled rock joints under CNL and CNS boundary conditions [J]. Rock Mechanics and Rock Engineering, 2018, 51(1): 101–118. DOI: https://doi.org/10.1007/s00603-017-1318-8.

MOHAMD E T. Grouting rock fractures with cement grout [J]. Rock Mechanics and Rock Engineering, 2012, 45(4): 547–561. DOI: https://doi.org/10.1007/s00603-012-0235-0.

LIU Quan-sheng, LEI Guang-feng, PENG Xing-xin, et al. Rheological characteristics of cement grout and its effect on mechanical properties of a rock fracture [J]. Rock Mechanics and Rock Engineering, 2018, 51(2): 613–625. DOI: https://doi.org/10.1007/s00603-017-1340-x.

LEE J S, BANG C S, MOK Y J, et al. Numerical and experimental analysis of penetration grouting in jointed rock masses [J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(7): 1027–1037. DOI: https://doi.org/10.1016/S1365-1609(00)00040-X.

SALIMIAN M H, BAGHBANAN A, HASHEMOLHOSSEINI H, et al. Effect of grouting on shear behavior of rock joint [J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 98: 159–166. DOI: https://doi.org/10.1016/j.ijrmms.2017.07.002.

LU Yin-long, WANG Lian-guo, LI Zhao-lin, et al. Experimental study on the shear behavior of regular sandstone joints filled with cement grout [J]. Rock Mechanics and Rock Engineering, 2017, 50(5): 1321–1336. DOI: https://doi.org/10.1007/s00603-016-1154-2.

LI Zhao-feng, LI Shu-cai, LIU Ren-tai, et al. Grouting reinforcement experiment for water-rich broken rock mass [J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(1): 198–207. DOI: https://doi.org/10.13722/j.cnki.jrme.2016.0119. (in Chinese)

ZHANG Yi-huai, LEBEDEV M, AL-YASERI A, et al. Characterization of nanoscale rockmechanical properties and microstructures of a Chinese sub-bituminous coal [J]. Journal of Natural Gas Science and Engineering, 2018, 52: 106–116. DOI: https://doi.org/10.1016/j.jngse.2018.01.037.

CHUN C N W, TAJARUDIN H A, ISMAIL N, et al. Elucidation of mechanical, physical, chemical and thermal properties of microbial composite films by integrating sodium alginate with bacillus subtilis sp [J]. Polymers, 2021, 13(13): 2103. DOI: https://doi.org/10.3390/polym13132103.

CONSTANTINIDES G, ULM F J. The effect of two types of C-S-H on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling [J]. Cement and Concrete Research, 2004, 34(1): 67–80. DOI: https://doi.org/10.1016/S0008-8846(03)00230-8.

ZHU Wen-zhong, HUGHES J J, BICANIC N, et al. Nanoindentation mapping of mechanical properties of cement paste and natural rocks [J]. Materials Characterization, 2007, 58(11, 12): 1189–1198. DOI: https://doi.org/10.1016/j.matchar.2007.05.018.

HU Chuan-lin, LI Zong-jin. A review on the mechanical properties of cement-based materials measured by nanoindentation [J]. Construction and Building Materials, 2015, 90: 80–90. DOI: https://doi.org/10.1016/j.conbuildmat.2015.05.008.

SHAIKH F U A, SUPIT S W M, BARBHUIYA S. Microstructure and nanoscaled characterization of HVFA cement paste containing nano-SiO2 and nano-CaCO3 [J]. Journal of Materials in Civil Engineering, 2017, 29(8): 04017063. DOI: https://doi.org/10.1061/(asce)mt.1943-5533.0001898.

ZHANG Yi-huai, LEBEDEV M, AL-YASERI A, et al. Nanoscale rock mechanical property changes in heterogeneous coal after water adsorption [J]. Fuel, 2018, 218: 23–32. DOI: https://doi.org/10.1016/j.fuel.2018.01.006.

LIU Kou-qi, OSTADHASSAN M. Microstructural and geomechanical analysis of bakken shale at nanoscale [J]. Journal of Petroleum Science and Engineering, 2017, 153: 133–144. DOI: https://doi.org/10.1016/j.petrol.2017.03.039.

MANJUNATH G L, JHA B. Geomechanical characterization of Gondwana shale across nano-micro-meso scales [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 119: 35–45. DOI: https://doi.org/10.1016/j.ijrmms.2019.04.003.

LU Yun-hu, LI Yu-cheng, WU Yong-kang, et al. Characterization of shale softening by large volume-based nanoindentation [J]. Rock Mechanics and Rock Engineering, 2020, 53(3): 1393–1409. DOI: https://doi.org/10.1007/s00603-019-01981-8.

MA Zhao-yang, PATHEGAMA GAMAGE R, ZHANG Cheng-peng. Application of nanoindentation technology in rocks: A review [J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2020, 6(4): 1–27. DOI: https://doi.org/10.1007/s40948-020-00178-6.

OLLIVIER J P, MASO J C, BOURDETTE B. Interfacial transition zone in concrete [J]. Advanced Cement Based Materials, 1995, 2(1): 30–38. DOI: https://doi.org/10.1016/1065-7355(95)90037-3.

NILI M, EHSANI A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume [J]. Materials & Design, 2015, 75: 174–183. DOI: https://doi.org/10.1016/j.matdes.2015.03.024.

VARGAS P, RESTREPO-BAENA O, TOBÓN J I. Microstructural analysis of interfacial transition zone (ITZ) and its impact on the compressive strength of lightweight concretes [J]. Construction and Building Materials, 2017, 137: 381–389. DOI: https://doi.org/10.1016/j.conbuildmat.2017.01.101.

WANG Xiao-hui, JACOBSEN S, HE Jian-ying, et al. Application of nanoindentation testing to study of the interfacial transition zone in steel fiber reinforced mortar [J]. Cement and Concrete Research, 2009, 39(8): 701–715. DOI: https://doi.org/10.1016/j.cemconres.2009.05.002.

XIAO Jian-zhuang, LI Wen-gui, SUN Zhi-hui, et al. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation [J]. Cement and Concrete Composites, 2013, 37: 276–292. DOI: https://doi.org/10.1016/j.cemconcomp.2013.01.006.

XU Jing, WANG Bin-bin, ZUO Jun-qing. Modification effects of nanosilica on the interfacial transition zone in concrete: A multiscale approach [J]. Cement and Concrete Composites, 2017, 81: 1–10. DOI: https://doi.org/10.1016/j.cemconcomp.2017.04.003.

LI V C, STANG H. Interface property characterization and strengthening mechanisms in fiber reinforced cement based composites [J]. Advanced Cement Based Materials, 1997, 6(1): 1–20. DOI: https://doi.org/10.1016/S1065-7355(97)90001-8.

ZHU Xing-yi, YUAN Ying, LI Li-han, et al. Identification of interfacial transition zone in asphalt concrete based on nanoscale metrology techniques [J]. Materials & Design, 2017, 129: 91–102. DOI: https://doi.org/10.1016/j.matdes.2017.05.015.

LIU Quan-sheng, TIAN Yong-chao, LIU Dong-feng, et al. Updates to JRC-JCS model for estimating the peak shear strength of rock joints based on quantified surface description [J]. Engineering Geology, 2017, 228: 282–300. DOI: https://doi.org/10.1016/j.enggeo.2017.08.020.

WANG Jin-an, WANG Yu-xi, CAO Qiu-ju, et al. Behavior of microcontacts in rock joints under direct shear creep loading [J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 78: 217–229. DOI: https://doi.org/10.1016/j.ijrmms.2015.05.002.

LI Shu-cai, SHA Fei, LIU Ren-tai, et al. Investigation on fundamental properties of microfine cement and cement-slag grouts [J]. Construction and Building Materials, 2017, 153: 965–974. DOI: https://doi.org/10.1016/j.conbuildmat.2017.05.188.

MILLER M, BOBKO C, VANDAMME M, et al. Surface roughness criteria for cement paste nanoindentation [J]. Cement and Concrete Research, 2008, 38(4): 467–476. DOI: https://doi.org/10.1016/j.cemconres.2007.11.014.

LEE H, VIMONSATIT V, CHINDAPRASIRT P. Mechanical and micromechanical properties of alkali activated fly-ash cement based on nano-indentation [J]. Construction and Building Materials, 2016, 107: 95–102. DOI: https://doi.org/10.1016/j.conbuildmat.2015.12.013.

BARBHUIYA S, CHOW P, MEMON S. Microstructure, hydration and nanomechanical properties of concrete containing metakaolin [J]. Construction and Building Materials, 2015, 95: 696–702. DOI: https://doi.org/10.1016/j.conbuildmat.2015.07.101.

OLIVER W C, PHARR G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments [J]. Journal of Materials Research, 1992, 7(6): 1564–1583. DOI: https://doi.org/10.1557/jmr.1992.1564.

YANG Sheng-qi, RANJITH P G, GUI Yi-lin. Experimental study of mechanical behavior and X-ray micro CT observations of sandstone under conventional triaxial compression [J]. Geotechnical Testing Journal, 2015, 38(2): 20140209. DOI: https://doi.org/10.1520/gtj20140209.

PICHLER C, LACKNER R. Upscaling of viscoelastic properties of highly-filled composites: Investigation of matrix-inclusion-type morphologies with power-law viscoelastic material response [J]. Composites Science and Technology, 2009, 69(14): 2410–2420. DOI: https://doi.org/10.1016/j.compscitech.2009.06.008.

CONSTANTINIDES G, ULM F J. The nanogranular nature of C-S-H [J]. Journal of the Mechanics and Physics of Solids, 2007, 55(1): 64–90. DOI: https://doi.org/10.1016/j.jmps.2006.06.003.

NĚMEČEK J. Creep effects in nanoindentation of hydrated phases of cement pastes [J]. Materials Characterization, 2009, 60(9): 1028–1034. DOI: https://doi.org/10.1016/j.matchar.2009.04.008.

HUSSIN A, POOLE C. Petrography evidence of the interfacial transition zone (ITZ) in the normal strength concrete containing granitic and limestone aggregates [J]. Construction and Building Materials, 2011, 25(5): 2298–2303. DOI: https://doi.org/10.1016/j.conbuildmat.2010.11.023.

NASIR O, FALL M. Shear behaviour of cemented pastefill-rock interfaces [J]. Engineering Geology, 2008, 101(3, 4): 146–153. DOI: https://doi.org/10.1016/j.enggeo.2008.04.010.

Author information

Authors and Affiliations

Contributions

JIANG Bang-you and GU Shi-tan provided the concept. LI Wen-shuai carried out the experiment and wrote the draft of the manuscript. YANG Xu-xu analyzed the experimental data. Faiz U.A. SHAIKH reviewed the manuscript. LI Wen-shuai and JIANG Bang-you replied to reviewers’ comments and revised the manuscript.

Corresponding authors

Additional information

Conflict of interest

LI Wen-shuai, JIANG Bang-you, GU Shi-tan, YANG Xu-xu, and Faiz U.A. SHAIKH declare that they have no conflict of interest.

Foundation item: Project(52004144) supported by the National Natural Science Foundation of China; Project supported by the Shandong Province Higher Educational Young Innovative Talent Introduction and Cultivation Team, China

Rights and permissions

About this article

Cite this article

Li, Ws., Jiang, By., Gu, St. et al. Experimental study on the shear behavior of grout-infilled specimens and micromechanical properties of grout-rock interface. J. Cent. South Univ. 29, 1686–1700 (2022). https://doi.org/10.1007/s11771-022-5026-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5026-5