Abstract

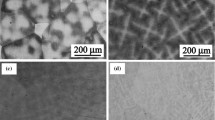

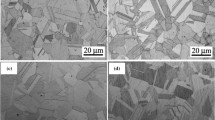

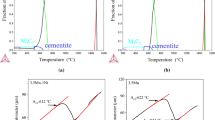

In order to improve the low ductility of the Mo-Ni alloy, Fe is added and the effects of Ni/Fe mass ratio on the densification behavior, microstructure evolution and mechanical properties of alloy were investigated. The experimental results show that when iron is added to 95Mo-5Ni alloy, the formation of brittle intermetallic phase δ-MoNi at the grain boundary is avoided. Meanwhile, the grain growth of Mo is also effectively inhibited in the sintering process. However, the addition of iron reduces the degree of densification of alloy since the activation effect of Ni is superior to that of Fe. From the experimental results, it could be concluded that the maximum hardness and bending strength are achieved by 95Mo-1.5Ni-3.5Fe alloy, which are HV 614 and 741 MPa, respectively. Combined with the analyses of bending fracture mechanism, the improvement relative to Mo-Ni alloy is likely attributed to the inhibition of the brittle phase.

摘要

为了改善Mo-Ni合金的低塑性,在合金中加入Fe,并研究了Ni/Fe质量比对合金致密化行为、 组织演变和力学性能的影响。结果表明,在95Mo-5Ni 合金中加入Fe,可避免晶界处脆性金属中间相 δ-MoNi 的形成,同时在烧结过程中也可以有效抑制Mo的晶粒长大。但是由于Ni 的活化效果优于Fe, Fe 的加入降低了合金的致密化程度。实验结果显示:95Mo-1.5Ni-3.5Fe 合金的硬度和抗弯强度最高, 分别为HV 614 和741 MPa。结合弯曲断裂机理分析,相对于Mo-Ni合金,性能的改善可能归因于抑制 脆性相的形成。

Similar content being viewed by others

References

MADAY M F, GIORGI R, DIKONIMOS-MAKRIS T. Correlations between the electrochemical behaviour and surface film composition of TZM alloy exposed to divertor water coolant environments [J]. Journal of Nuclear Materials, 1997, 246(1): 70–76. DOI: https://doi.org/10.1016/S0022-3115(97)00020-2.

DIMIDUK D M, PEREPEZKO J H. Mo-Si-B alloys: Developing a revolutionary turbine-engine material [J]. MRS Bulletin, 2003, 28(9): 639–645. DOI: https://doi.org/10.1557/mrs2003.191.

EL-GENK M S, TOURNIER J M. A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems [J]. Journal of Nuclear Materials, 2005, 340(1): 93–112. DOI: https://doi.org/10.1016/j.jnucmat.2004.10.118.

KASERER L, BRAUN J, STAJKOVIC J, et al. Fully dense and crack free molybdenum manufactured by Selective Laser Melting through alloying with carbon [J]. International Journal of Refractory Metals and Hard Materials, 2019, 84: 105000. DOI: https://doi.org/10.1016/j.ijrmhm.2019.105000.

LIU G, ZHANG G J, JIANG F, et al. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility [J]. Nature Materials, 2013, 12(4): 344–350. DOI: https://doi.org/10.1038/nmat3544.

GARG P, PARK S J, GERMAN R M. Effect of Die compaction pressure on densification behavior of molybdenum powders [J]. International Journal of Refractory Metals and Hard Materials, 2007, 25(1): 16–24. DOI: https://doi.org/10.1016/j.ijrmhm.2005.10.014.

ZOVAS P E, GERMAN R M. Retarded grain boundary mobility in activated sintered molybdenum [J]. Metallurgical and Materials Transactions A, 1984, 15(6): 1103–1110. DOI: https://doi.org/10.1007/BF02644704.

GERMAN R M, MUNIR Z A. Heterodiffusion model for the activated sintering of molybdenum [J]. Journal of the Less Common Metals, 1978, 58(1): 61–74. DOI: https://doi.org/10.1016/0022-5088(78)90071-1.

GERMAN R M, RABIN B H. Enhanced sintering through second phase additions [J]. Powder Metallurgy, 1985, 28(1): 7–12. DOI: https://doi.org/10.1179/pom.1985.28.1.7.

ZOVAS P E, GERMAN R M, HWANG K S, et al. Activated and liquid-phase sintering—Progress and problems [J]. JOM, 1983, 35(1): 28–33. DOI: https://doi.org/10.1007/BF03338181.

HOFMANN H, GROSSKOPF M, HOFMANN-AMTENBRINK M, et al. Sintering behaviour and mechanical properties of activated sintered molybdenum [J]. Powder Metallurgy, 1986, 29(3): 201–206. DOI: https://doi.org/10.1179/pom.1986.29.3.201.

LEE D D, KANG S J L, YOON D N. A direct observation of the grain shape accommodation during liquid phase sintering of Mo-Ni alloy [J]. Scripta Metallurgica et Materialia, 1990, 24(5): 927–930. DOI: https://doi.org/10.1016/0956-716X(90)90139-8.

PANICHKINA V V, SKOROKHOD V V, KHRIENKO A F. Activated sintering of tungsten and molybdenum powders [J]. Soviet Powder Metallurgy and Metal Ceramics, 1967, 6(7): 558–560. DOI: https://doi.org/10.1007/BF00774073.

GERMAN R M. Sintering theory and practice [M]. New York: Wiley-Interscience, 1996.

GERMAN R M, SURI P, PARK S J. Review: Liquid phase sintering [J]. Journal of Materials Science, 2009, 44(1): 1–39. DOI: https://doi.org/10.1007/s10853-008-3008-0.

WADSWORTH J, NIEH T G, STEPHENS J J. Recent advances in aerospace refractory metal alloys [J]. International Materials Reviews, 1988, 33(1): 131–150. DOI: https://doi.org/10.1179/imr.1988.33.1.131.

COCKERAM B V. The fracture toughness and toughening mechanism of commercially available unalloyed molybdenum and oxide dispersion strengthened molybdenum with an equiaxed, large grain structure [J]. Metallurgical and Materials Transactions A, 2009, 40(12): 2843–2860. DOI: https://doi.org/10.1007/s11661-009-9919-9.

SCHNEIBEL J H, BRADY M P, KRUZIC J J, et al. On the improvement of the ductility of molybdenum by spinel (MgAl2O4) particles [J]. Zeitschrift Für Metallkunde, 2005, 96(6): 632–637. DOI: https://doi.org/10.3139/146.101081.

ASKILL J. Tracer diffusion data for metals, alloys, and simple oxides [M]. New York: Plenum Press, 1970.

HWANG K S, HUANG H S. Identification of the segregation layer and its effects on the activated sintering and ductility of Ni-doped molybdenum [J]. Acta Materialia, 2003, 51(13): 3915–3926. DOI: https://doi.org/10.1016/S1359-6454(03)00216-7.

CHURN K S, GERMAN R M. Fracture behavior of W-Ni-Fe heavy alloys [J]. Metallurgical Transactions A, 1984, 15(2): 331–338. DOI: https://doi.org/10.1007/BF02645119.

HUBER A, SIGL L S. On the sintering of molybdenum with two liquid phases [J]. Materialia, 2020, 9: 100600. DOI: https://doi.org/10.1016/j.mtla.2020.100600.

HWANG K S, HUANG H S. Ductility improvement of Ni-added molybdenum compacts through the addition of Cu and Fe powders [J]. International Journal of Refractory Metals and Hard Materials, 2004, 22(4, 5): 185–191. DOI: https://doi.org/10.1016/j.ijrmhm.2004.06.003.

SAKAMOTO T. Effect of Ni-Fe and Ni-Cr alloys addition on sintering of molybdenum powders [J]. Journal of the Japan Society of Powder and Powder Metallurgy, 1997, 44(7): 689–693. DOI: https://doi.org/10.2497/jjspm.44.689.

PRABHU G, KUMAR R A, NANDY T K. Effect of cyclic heat treatment on the microstructure and mechanical properties of W-Ni-Co alloys [J]. International Journal of Refractory Metals and Hard Materials, 2019, 82: 31–42. DOI: https://doi.org/10.1016/j.ijrmhm.2019.03.024.

SAKAMOTO T, HONDA T, MIURA H, et al. Effect of Ni and Ni3Al additions on sintering of molybdenum powders [J]. Materials Transactions, JIM, 1997, 38(4): 326–333. DOI: https://doi.org/10.2320/matertrans1989.38.326.

JOHNSON J L, GERMAN R M. Role of solid-state skeletal sintering during processing of Mo-Cu composites [J]. Metallurgical and Materials Transactions A, 2001, 32(3): 605–613. DOI: https://doi.org/10.1007/s11661-001-0077-y.

JOHNSON J L, GERMAN R M. Solid-state contributions to densification during liquid-phase sintering [J]. Metallurgical and Materials Transactions B, 1996, 27(6): 901–909. DOI: https://doi.org/10.1007/s11663-996-0003-1.

HWANG K S, HUANG H S. The liquid phase sintering of molybdenum with Ni and Cu additions [J]. Materials Chemistry and Physics, 2001, 67(1–3): 92–100. DOI: https://doi.org/10.1016/S0254-0584(00)00425-9.

YE Lei, HAN Yong, FAN Jing-lian, et al. Fabrication of ultrafine-grain and great-performance W-Ni-Fe alloy with medium W content [J]. Journal of Alloys and Compounds, 2020, 846: 156237. DOI: https://doi.org/10.1016/j.jallcom.2020.156237.

LASSNER E, SCHUBERT W. Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds [M]. New York: Kluwer Academic, 1999. DOI: 978-0-306-45053-2.

WANG Da-hang, SUN Guo-dong, ZHANG Guo-hua. Preparation of ultrafine Mo powders via carbothermic pre-reduction of molybdenum oxide and deep reduction by hydrogen [J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 70–77. DOI: https://doi.org/10.1016/j.ijrmhm.2018.04.002.

SUN Guo-dong, ZHANG Guo-hua, CHOU K C. An industrially feasible pathway for preparation of Mo nanopowder and its sintering behavior [J]. International Journal of Refractory Metals and Hard Materials, 2019, 84: 105039. DOI: https://doi.org/10.1016/j.ijrmhm.2019.105039.

ZHANG He, LI Zhi-bo, ZHANG Guo-hua, et al. A novel method for preparing ultrafine molybdenum powder [J]. International Journal of Refractory Metals and Hard Materials, 2021, 96: 105491. DOI: https://doi.org/10.1016/j.ijrmhm.2021.105491.

SWARTZENDRUBER L J, ITKIN V P, ALCOCK C B. The Fe-Ni (iron-nickel) system [J]. Journal of Phase Equilibria, 1991, 12(3): 288–312. DOI: https://doi.org/10.1007/BF02649918.

BOSE A, SIMS D, GERMAN R M. Test temperature and strain rate effects on the properties of a tungsten heavy alloy [J]. Metallurgical Transactions A, 1988, 19(3): 487–494. DOI: https://doi.org/10.1007/BF02649263.

FRISK K. An experimental and theoretical study of the phase equilibria in the Fe-Mo-Ni system [J]. Metallurgical Transactions A, 1992, 23(2): 639–649. DOI: https://doi.org/10.1007/BF02801181.

ZHOU S H, WANG Y, JIANG C, et al. First-principles calculations and thermodynamic modeling of the Ni-Mo system [J]. Materials Science and Engineering A, 2005, 397(1, 2): 288–296. DOI: https://doi.org/10.1016/j.msea.2005.02.037.

HIRAOKA Y, OGUSU T, YOSHIZAWA N. Decrease of yield strength in molybdenum by adding small amounts of Group VIII elements [J]. Journal of Alloys and Compounds, 2004, 381(1, 2): 192–196. DOI: https://doi.org/10.1016/j.jallcom.2004.03.112.

HEIJLEGEN G P, RIECK G D. Diffusion in the Mo-Ni, Mo-Fe and Mo-Co slstems [J]. Acta Metallurgica, 1974, 22(10): 1269–1281. DOI: https://doi.org/10.1016/0001-6160(74)90140-0.

MIL’MAN Y V, RISTIĆ M M, GRIDNEVA I V, et al. Structure and hardness of sintered Mo-Ni alloys [J]. Soviet Powder Metallurgy and Metal Ceramics, 1987, 26(2): 144–148. DOI: https://doi.org/10.1007/BF00794133.

SAKAMOTO T, NISHIDA M, OKAZAKI K. Microstructure of Mo powders sintered with Ni and Ni3Al powders [J]. Journal of the Japan Society of Powder and Powder Metallurgy, 1999, 46(12): 1221–1225. DOI: https://doi.org/10.2497/jjspm.46.1221.

CHOU T C, LINK L. Solid-state interdiffusion in Ni-Mo diffusion couples at high temperatures [J]. Scripta Materialia, 1996, 34(5): 831–838. DOI: https://doi.org/10.1016/1359-6462(95)00601-X.

HWANG N M, PARK Y J, KIM D Y, et al. Activated sintering of nickel-doped tungsten: Approach by grain boundary structural transition [J]. Scripta Materialia, 2000, 42(5): 421–425. DOI: https://doi.org/10.1016/S1359-6462(99)00344-9.

YU Yang, REN Chao-yuan, ZHANG Wen-cong. Compressive behavior of liquid phase sintered 90 W-7Ni-3Fe heavy alloy at high temperature and low strain rate condition [J]. International Journal of Refractory Metals and Hard Materials, 2018, 76: 149–157. DOI: https://doi.org/10.1016/j.ijrmhm.2018.06.006.

LI Zhi-bo, ZHANG Guo-hua, CHOU K C. Densification behavior of ultrafine W-Ni-Fe composite powders produced by a two-stage reduction process [J]. Powder Technology, 2020, 360: 430–443. DOI: https://doi.org/10.1016/j.powtec.2019.11.019.

KENEL C, DAVENPORT T, LI X, et al. Kinetics of alloy formation and densification in Fe-Ni-Mo microfilaments extruded from oxide- or metal-powder inks [J]. Acta Materialia, 2020, 193: 51–60. DOI: https://doi.org/10.1016/j.actamat.2020.04.038.

RAJKUMAR V B, HARI KUMAR K C. Thermodynamic modeling of the Fe-Mo system coupled with experiments and ab initio calculations [J]. Journal of Alloys and Compounds, 2014, 611: 303–312. DOI: https://doi.org/10.1016/j.jallcom.2014.05.030.

SMITH J T. Diffusion mechanism for the nickel-activated sintering of molybdenum [J]. Journal of Applied Physics, 1965, 36(2): 595–598. DOI: https://doi.org/10.1063/1.1714036.

HALL E O. The deformation and ageing of mild steel: III discussion of results [J]. Proceedings of the Physical Society Section B, 1951, 64(9): 747–753. DOI: https://doi.org/10.1088/0370-1301/64/9/303.

Author information

Authors and Affiliations

Contributions

LIU Jun-ru, ZHANG Guo-hua and CHOU Kuo-chih developed the overarching research goal. LIU Jun-ru, LI Zhi-bo and CHEN Ben conducted the experiments, analyzed the test data, and wrote the initial draft of the manuscript.

Corresponding author

Additional information

Conflict of interest

LIU Jun-ru, LI Zhi-bo, CHEN Ben, CHOU Kuo-chih and ZHANG Guo-hua declare that they have no conflict of interest.

Foundation item: Project(51734002) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Liu, Jr., Li, Zb., Chen, B. et al. Effect of Ni/Fe ratio on activation sintering and mechanical properties of molybdenum nickel iron alloy. J. Cent. South Univ. 29, 1423–1436 (2022). https://doi.org/10.1007/s11771-022-5014-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5014-9