Abstract

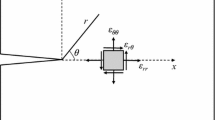

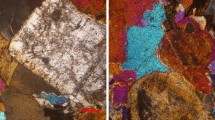

The asymmetric semi-circular bend (ASCB) specimen has been proposed to investigate the cracking behavior in different geo and construction materials and attracted the attention of researchers due to its advantages. However, there are few studies on the fracture toughness determination of rock materials. In this work, a series of fracture tests were performed with the ASCB specimens made of granite. The onset of fracture, crack initiation angle and crack propagating trajectory was analyzed in detail combined with several mixed mode fracture criteria. The influence of the crack length on the mode I/II fracture toughness was studied. A comparison between the fracture toughness ratios predicted by varying criteria and experimental results was conducted. The relationship between experimentally determined crack initiation angles and curves of the generalized maximum tangential stress (GMTS) criterion was obtained. The fracture process of the specimen was recorded with the high-speed camera. The shortcomings of the ASCB specimens for the fracture toughness determination of rock materials were discussed. The results may provide a reference for analysis of mixed mode I and II fracture behavior of brittle materials.

摘要

非对称半圆弯曲试件(ASCB)以结构简单、加工经济、实验实施便利等优点广泛应用于建筑材料 的断裂力学行为研究, 然而, 目前很少使用ASCB试件测定岩石的断裂特征. 本文采用不同裂纹长度 的花岗岩ASCB试样, 研究花岗岩的断裂韧度值、裂纹开裂角以及裂纹扩展轨迹等断裂力学行为. 首 先, 分析裂纹长度对纯I/II 型断裂韧度的影响. 然后, 结合多种混合断裂理论, 分析对比断裂韧度比 值理论值与试验值的差异, 以及断裂理论预测开裂角及实验测量值的差异, 得到了预测混合断裂韧度 及裂纹断裂角的最优准则. 最后, 探讨了半圆弯曲、非对称半圆弯曲试件测量岩石材料断裂力学特性 时存在的不足之处. 研究发现, 当断裂过程区尺寸为2.6 mm时, 采用广义最大环向拉应力准则能够很 好地预测裂纹断裂角. 在使用非对称半圆弯曲试件执行岩石断裂实验时, 应把预制裂纹切割更深, 即 调整裂纹长度与试件半径的比值达到更大. 本文的研究结果将为工程岩体断裂失稳机制的研究提供 参考.

Similar content being viewed by others

References

WU Qiu-hong, WENG Lei, ZHAO Yan-lin, et al. Influence of infilling stiffness on mechanical and fracturing responses of hollow cylindrical sandstone under uniaxial compression tests [J]. Journal of Central South University, 2021, 28(8): 2485–2498. DOI: https://doi.org/10.1007/s11771-021-4781-z.

JIA P, YANG T H, YU Q L. Mechanism of parallel fractures around deep underground excavations [J]. Theoretical and Applied Fracture Mechanics, 2012, 61: 57–65. DOI: https://doi.org/10.1016/j.tafmec.2012.08.007.

BIDGOLI M N, ZHAO Zhi-hong, JING Lan-ru. Numerical evaluation of strength and deformability of fractured rocks [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2013, 5(6): 419–430. DOI: https://doi.org/10.1016/j.jrmge.2013.09.002.

PAKDAMAN A M, MOOSAVI M, MOHAMMADI S. Experimental and numerical investigation into the methods of determination of mode I static fracture toughness of rocks [J]. Theoretical and Applied Fracture Mechanics, 2019, 100: 154–170. DOI: https://doi.org/10.1016/j.tafmec.2019.01.001.

OUCHTERLONY F. Suggested methods for determining the fracture toughness of rock [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1988, 25(2): 71–96. DOI: https://doi.org/10.1016/0148-9062(88)91871-2.

BUSH A J. Experimentally determined stress-intensity factors for single-edge-crack round bars loaded in bending [J]. Experimental Mechanics, 1976, 16(7): 249–257. DOI: https://doi.org/10.1007/BF02321148.

CHONG K P, KURUPPU M D. New specimens for mixed mode fracture investigations of geomaterials [J]. Engineering Fracture Mechanics, 1988, 30(5): 701–712. DOI: https://doi.org/10.1016/0013-7944(88)90160-9.

KURUPPU M D, OBARA Y, AYATOLLAHI M R, et al. ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen [J]. Rock Mechanics and Rock Engineering, 2014, 47(1): 267–274. DOI: https://doi.org/10.1007/s00603-013-0422-7.

KURUPPU M. Fracture toughness measurement using chevron notched semi-circular bend specimen [J]. International Journal of Fracture, 1997, 86(4): L33–L38.

AWAJI H, SATO S. Combined mode fracture toughness measurement by the disk test [J]. Journal of Engineering Materials and Technology, 1978, 100(2): 175–182. DOI: https://doi.org/10.1115/1.3443468.

WANG Qi-zhi, XING Lei. Determination of fracture toughness KIC by using the flattened Brazilian disk specimen for rocks [J]. Engineering Fracture Mechanics, 1999, 64(2): 193–201. DOI: https://doi.org/10.1016/S0013-7944(99)00065-X.

PEI Peng-da, DAI Feng, LIU Yi, et al. Dynamic tensile behavior of rocks under static pre-tension using the flattened Brazilian disc method [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 126: 104208. DOI: https://doi.org/10.1016/j.ijrmms.2019.104208.

FOWELL R J. Suggested method for determining mode I fracture toughness using cracked chevron notched Brazilian disc (CCNBD) specimens [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1995, 32(1): 57–64. DOI: https://doi.org/10.1016/0148-9062(94)00015-U.

YANG S, TANG Tian-xi, ZOLLINGER D G, et al. Splitting tension tests to determine concrete fracture parameters by peak-load method [J]. Advanced Cement Based Materials, 1997, 5(1): 18–28. DOI: https://doi.org/10.1016/S1065-7355(97)90011-0.

ALIHA M R M, BAHMANI A. Rock fracture toughness study under mixed mode I/III loading [J]. Rock Mechanics and Rock Engineering, 2017, 50(7): 1739–1751. DOI: https://doi.org/10.1007/s00603-017-1201-7.

ALIHA M R M, SARBIJAN M J, BAHMANI A. Fracture toughness determination of modified HMA mixtures with two novel disc shape configurations [J]. Construction and Building Materials, 2017, 155: 789–799. DOI: https://doi.org/10.1016/j.conbuildmat.2017.08.093.

BAHMANI A, FARAHMAND F, JANBAZ M R, et al. On the comparison of two mixed-mode I + III fracture test specimens [J]. Engineering Fracture Mechanics, 2021, 241: 107434. DOI: https://doi.org/10.1016/j.engfracmech.2020.107434.

TANG Tian-xi, BAŽANT Z P, YANG S, et al. Variable-Notch one-size test method for fracture energy and process zone length [J]. Engineering Fracture Mechanics, 1996, 55(3): 383–404. DOI: https://doi.org/10.1016/0013-7944(96)00030-6.

WENG Lei, WU Qiu-hong, ZHAO Yan-lin, et al. Dynamic response and failure of rock in initial gradient stress field under stress wave loading [J]. Journal of Central South University, 2020, 27(3): 963–972. DOI: https://doi.org/10.1007/s11771-020-4344-8.

WU Qiu-hong, CHEN Lu, SHEN Bao-tang, et al. Experimental investigation on rockbolt performance under the tension load [J]. Rock Mechanics and Rock Engineering, 2019, 52(11): 4605–4618. DOI: https://doi.org/10.1007/s00603-019-01845-1.

WU Qiu-hong, WENG Lei, ZHAO Yan-lin, et al. On the tensile mechanical characteristics of fine-grained granite after heating/cooling treatments with different cooling rates [J]. Engineering Geology, 2019, 253: 94–110. DOI: https://doi.org/10.1016/j.enggeo.2019.03.014.

AMERI M, MANSOURIAN A, PIRMOHAMMAD S, et al. Mixed mode fracture resistance of asphalt concrete mixtures [J]. Engineering Fracture Mechanics, 2012, 93: 153–167. DOI: https://doi.org/10.1016/j.engfracmech.2012.06.015.

FATTAHI AMIRDEHI H R, ALIHA M R M, MONIRI A, et al. Using the generalized maximum tangential stress criterion to predict mode II fracture of hot mix asphalt in terms of mode I results—A statistical analysis [J]. Construction and Building Materials, 2019, 213: 483–491. DOI: https://doi.org/10.1016/j.conbuildmat.2019.04.067.

ALIHA M R M, HOSSEINPOUR G R, AYATOLLAHI M R. Application of cracked triangular specimen subjected to three-point bending for investigating fracture behavior of rock materials [J]. Rock Mechanics and Rock Engineering, 2013, 46(5): 1023–1034. DOI: https://doi.org/10.1007/s00603-012-0325-z.

TUTLUOGLU L, KELES C. Mode I fracture toughness determination with straight notched disk bending method [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(8): 1248–1261. DOI: https://doi.org/10.1016/j.ijrmms.2011.09.019.

LIM I L, JOHNSTON I W, CHOI S K. Stress intensity factors for semi-circular specimens under three-point bending [J]. Engineering Fracture Mechanics, 1993, 44(3): 363–382. DOI: https://doi.org/10.1016/0013-7944(93)90030-V.

AYATOLLAHI M R, ALIHA M R M, HASSANI M M. Mixed mode brittle fracture in PMMA—An experimental study using SCB specimens [J]. Materials Science and Engineering A, 2006, 417(1, 2): 348–356. DOI: https://doi.org/10.1016/j.msea.2005.11.002.

AYATOLLAHI M R, ALIHA M R M. Wide range data for crack tip parameters in two disc-type specimens under mixed mode loading [J]. Computational Materials Science, 2007, 38(4): 660–670. DOI: https://doi.org/10.1016/j.commatsci.2006.04.008.

LIM I L, JOHNSTON I W, CHOI S K, et al. Fracture testing of a soft rock with semi-circular specimens under three-point bending. Part 1—mode I [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1994, 31(3): 185–197. DOI: https://doi.org/10.1016/0148-9062(94)90463-4.

AYATOLLAHI M R, ALIHA M R M, SAGHAFI H. An improved semi-circular bend specimen for investigating mixed mode brittle fracture [J]. Engineering Fracture Mechanics, 2011, 78(1): 110–123. DOI: https://doi.org/10.1016/j.engfracmech.2010.10.001.

MARSAVINA L, CONSTANTINESCU D M, LINUL E, et al. Refinements on fracture toughness of PUR foams [J]. Engineering Fracture Mechanics, 2014, 129: 54–66. DOI: https://doi.org/10.1016/j.engfracmech.2013.12.006.

ALIHA M R M, BEHBAHANI H, FAZAELI H, et al. Study of characteristic specification on mixed mode fracture toughness of asphalt mixtures [J]. Construction and Building Materials, 2014, 54: 623–635. DOI: https://doi.org/10.1016/j.conbuildmat.2013.12.097.

ALIHA M R M, RAZMI A, MANSOURIAN A. The influence of natural and synthetic fibers on low temperature mixed mode I + II fracture behavior of warm mix asphalt (WMA) materials [J]. Engineering Fracture Mechanics, 2017, 182: 322–336. DOI: https://doi.org/10.1016/j.engfracmech.2017.06.003.

ALIHA M R M. On predicting mode II fracture toughness (kIIC) of hot mix asphalt mixtures using the strain energy density criterion [J]. Theoretical and Applied Fracture Mechanics, 2019, 99: 36–43. DOI: https://doi.org/10.1016/j.tafmec.2018.11.001.

FAKHRI M, AMOOSOLTANI E, ALIHA M R M. Crack behavior analysis of roller compacted concrete mixtures containing reclaimed asphalt pavement and crumb rubber [J]. Engineering Fracture Mechanics, 2017, 180: 43–59. DOI: https://doi.org/10.1016/j.engfracmech.2017.05.011.

RAZAVI S M J, ALIHA M R M, BERTO F. Application of an average strain energy density criterion to obtain the mixed mode fracture load of granite rock tested with the cracked asymmetric four-point bend specimens [J]. Theoretical and Applied Fracture Mechanics, 2018, 97: 419–425. DOI: https://doi.org/10.1016/j.tafmec.2017.07.004.

WANG Yu-suo, HU Xiao-zhi. Determination of tensile strength and fracture toughness of granite using notched three-point-bend samples [J]. Rock Mechanics and Rock Engineering, 2017, 50(1): 17–28. DOI: https://doi.org/10.1007/s00603-016-1098-6.

WENG Lei, LI Xi-bing, TAHERI A, et al. Fracture evolution around a cavity in brittle rock under uniaxial compression and coupled static — dynamic loads [J]. Rock Mechanics and Rock Engineering, 2018, 51(2): 531–545. DOI: https://doi.org/10.1007/s00603-017-1343-7.

COTTERELL B, RICE J R. Slightly curved or kinked cracks [J]. International Journal of Fracture, 1980, 16(2): 155–169. DOI: https://doi.org/10.1007/BF00012619.

KHAN K, AL-SHAYEA N A. Effect of specimen geometry and testing method on mixed mode I–II fracture toughness of a limestone rock from Saudi Arabia [J]. Rock Mechanics and Rock Engineering, 2000, 33(3): 179–206. DOI: https://doi.org/10.1007/s006030070006.

CHANG S H, LEE C I, JEON S. Measurement of rock fracture toughness under modes I and II and mixed-mode conditions by using disc-type specimens [J]. Engineering Geology, 2002, 66(1, 2): 79–97. DOI: https://doi.org/10.1016/S0013-7952(02)00033-9.

WANG Jun-jie, HUANG Shi-yuan, GUO Wan-li, et al. Experimental study on fracture toughness of a compacted clay using semi-circular bend specimen [J]. Engineering Fracture Mechanics, 2020, 224: 106814. DOI: https://doi.org/10.1016/j.engfracmech.2019.106814.

SARKAR S, KUMAR R, MURTHY V M S R. Experimental and numerical simulation of crack propagation in sandstone by semi circular bend test [J]. Geotechnical and Geological Engineering, 2019, 37(4): 3157–3169. DOI: https://doi.org/10.1007/s10706-019-00833-0.

BAŽANT Z P. Size effect on structural strength: A review [J]. Archive of Applied Mechanics, 1999, 69(9, 10): 703–725. DOI: https://doi.org/10.1007/s004190050252.

PALANISWAMY K, KNAUSS W G. Propagation of a crack under general, in-plane tension [J]. International Journal of Fracture Mechanics, 1972, 8(1): 114–117. DOI: https://doi.org/10.1007/BF00185207.

HUSSAIN M, PU L, UNDERWOOD J. Strain energy release rate for a crack under combined mode I and mode II. Fracture analysis [C]// Proceedings of the 1973 National Symposium on Fracture Mechanics: Part II. ASTM International,1974.

UEDA Y, IKEDA K, YAO T, et al. Characteristics of brittle fracture under general combined modes [C]// Proceedings of ICF International Symposium on Fracture Mechanics. Beijing: Science Press, 1983.

SIH G C. Strain-energy-density factor applied to mixed mode crack problems [J]. International Journal of Fracture, 1974, 10(3): 305–321. DOI: https://doi.org/10.1007/BF00035493.

ERDOGAN F, SIH G C. On the crack extension in plates under plane loading and transverse shear [J]. Journal of Basic Engineering, 1963, 85(4): 519–525. DOI: https://doi.org/10.1115/1.3656897.

KHAN S M A, KHRAISHEH M K. Analysis of mixed mode crack initiation angles under various loading conditions [J]. Engineering Fracture Mechanics, 2000, 67(5): 397–419. DOI: https://doi.org/10.1016/S0013-7944(00)00068-0.

JANSSEN M, ZUIDEMA J, WANHILL R. Fracture Mechanics [M]. CRC Press, 2004. DOI: https://doi.org/10.1201/9781482265583.

AYATOLLAHI M R, ALIHA M R M. On determination of mode II fracture toughness using semi-circular bend specimen [J]. International Journal of Solids and Structures, 2006, 43(17): 5217–5227. DOI: https://doi.org/10.1016/j.ijsolstr.2005.07.049.

ALIHA M R M, AYATOLLAHI M R. Analysis of fracture initiation angle in some cracked ceramics using the generalized maximum tangential stress criterion [J]. International Journal of Solids and Structures, 2012, 49(13): 1877–1883. DOI: https://doi.org/10.1016/j.ijsolstr.2012.03.029.

SMITH D J, AYATOLLAHI M R, PAVIER M J. The role of T-stress in brittle fracture for linear elastic materials under mixed-mode loading [J]. Fatigue & Fracture of Engineering Materials & Structures, 2001, 24(2): 137–150. DOI: https://doi.org/10.1046/j.1460-2695.2001.00377.x.

SCHMIDT R A. A microcrack model and its significance to hydraulic fracturing and fracture toughness testing [C]// The 21st US Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association, 1980.

AYATOLLAHI M R, SISTANINIA M. Mode II fracture study of rocks using Brazilian disk specimens [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(5): 819–826. DOI: https://doi.org/10.1016/j.ijrmms.2011.04.017.

C L C, J W. On crack initiation angle of mixed mode ductile fracture with continuum damage mechanics [J]. Engineering Fracture Mechanics, 1989, 32(4): 601–612. DOI: https://doi.org/10.1016/0013-7944(89)90194-X.

HORII H, NEMAT-NASSER S. Compression-induced microcrack growth in brittle solids: Axial splitting and shear failure [J]. Journal of Geophysical Research: Solid Earth, 1985, 90(B4): 3105–3125. DOI: https://doi.org/10.1029/JB090iB04p03105.

Brittle failure in compression: Splitting faulting and brittle-ductile transition [J]. Philosophical Transactions of the Royal Society of London Series A, Mathematical and Physical Sciences, 1986, 319(1549): 337–374.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Projects(52004182, 51804110, 51904101) supported by the National Natural Science Foundation of China; Project (2020JJ5188) supported by the Natural Science Foundation of Hunan Province, China

Contributors

WU Qiu-hong provided the concept and edited the draft of manuscript. XIE You-sheng conducted the literature review and wrote the first draft of the manuscript. LIU Jie and WENG Lei analyzed the measured data. ZHAO Yan-lin and LI Xue-feng edited the draft of manuscript. XIE Cheng-long conducted numerical simulations. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

WU Qiu-hong, XIE Cheng-long, XIE You-sheng, ZHAO Yan-lin, LI Xue-feng, LIU Jie and WENG Lei declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wu, Qh., Xie, Cl., Xie, Ys. et al. Extending application of asymmetric semi-circular bend specimen to investigate mixed mode I/II fracture behavior of granite. J. Cent. South Univ. 29, 1289–1304 (2022). https://doi.org/10.1007/s11771-022-4989-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4989-6

Key words

- asymmetric semi-circular bend specimen

- rock fracture toughness

- crack growth trajectory

- crack initiation angle

- semi-circular bending

- generalized maximum tangential stress criterion