Abstract

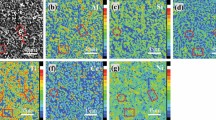

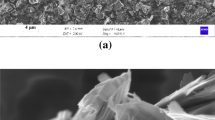

The effects of hot extrusion and addition of Al2O3p on both microstructure and tribological behavior of 7075 composites were investigated via optical microscopy (OM), scanning electron microscopy (SEM), energy dispersive spectrometry (EDS), and transmission electron microscopy (TEM). The experimental consequences reveal that the optimal addition of Al2O3p was 2 wt%. After hot extrusion, the Mg(Zn,Cu,Al)2 phases partially dissolve into the matrix and generate many uniformly distributed aging precipitation particles, the Al7Cu2Fe phases are squeezed and broken, and the Al2O3p become uniform distribution. The microhardness of as-extruded 2 wt% Al2O3p/7075 composites reaches HV 170.34, increased by 41.5% than as-cast composites. The wear rate of as-extruded 2 wt% Al2O3p/7075 composites is further lower than that of as-cast composites under the same condition. SEM-EDS analyses reveal that the reinforced wear resistance of composites can put down to the protective effect of the Al2O3p reinforced transition layer. After hot extrusion, the transition layer becomes stable, which determines the reinforced wear resistance of the as-extruded composites.

摘要

通过光学显微镜(OM)、扫描电子显微镜(SEM)、能谱仪(EDS)和透射电子显微镜(TEM)研究了热 挤压和Al2O3p 的添加对7075 复合材料的微观结构和摩擦学行为的影响。实验结果表明,Al2O3p 的最 佳添加量为2%(质量分数)。经热挤压后,Mg(Zn,Cu,Al)2 相部分溶解到基体中,并且产生了许多均匀 分布的时效析出颗粒,Al7Cu2Fe 相被挤压并破碎,Al2O3p 分布变得均匀。2%质量分数的Al2O3p/7075 复合材料的显微硬度达到HV 170.34,相比铸态复合材料提高了41.5%。在相同条件下,挤压态2%质 量分数的Al2O3p/7075 复合材料的磨损率比铸态复合材料的磨损率更低。SEM-EDS 分析表明,复合材 料耐磨性的增强主要取决于Al2O3p 增强的过渡层的保护作用。经过热挤压后,摩擦过渡层变得稳定, 这使得挤压态复合材料的耐磨性增强。

Similar content being viewed by others

References

SOLTANI N, PECH-CANUL M I, BAHRAMI A. Effect of 10Ce-TZP/Al2O3 nanocomposite particle amount and sintering temperature on the microstructure and mechanical properties of Al/(10Ce-TZP/Al2O3) nanocomposites [J]. Materials and Design, 2013, 50: 85–91. DOI: https://doi.org/10.1016/j.matdes.2013.03.001.

SOLTANI N, BAHRAMI A, PECH-CANUL M I. The effect of Ti on mechanical properties of extruded in-situ Al-15 pct Mg2Si composite [J]. Metallurgical and Materials Transactions A, 2013, 44: 4366–4373. DOI: https://doi.org/10.1007/s11661-013-1747-2.

KALA H, MER K, KUMAR S A. A Review on mechanical and tribological behaviors of stir cast aluminum matrix composites [J]. Procedia Materials Science, 2014, 6: 1951–1960. DOI: https://doi.org/10.1016/j.mspro.2014.07.229.

TENG Jie, Li Hua-pei, CHEN Gang. Wear mechanism for spray deposited Al-Si/SiCp composites under dry sliding condition [J]. Journal of Central South University, 2015, 22(8): 2875–2882. DOI: https://doi.org/10.1007/s11771-015-2820-3.

DEAQUINO L R, SOLTANI N, BAHRAMI A, GUTIERREZ C E, GARCIA S E, HERNANDEZ R M A L. Tribological characterization of Al7075-graphite composites fabricated by mechanical alloying and hot extrusion [J]. Materials and Design, 2015, 67: 224–231. DOI: https://doi.org/10.1016/j.matdes.2014.11.045.

BAHRAMI A, SOLTANI N, PECH-CANUL M I. Effect of sintering temperature on tribological behavior of Ce-TZP/Al2O3-aluminum nanocomposite [J]. Journal of Composite Materials, 2015, 49(28): 3507–3514. DOI: https://doi.org/10.1177/0021998314567010.

BAHRAMI A, SOLTANI N, SADRNEZHAAD S K. Manufacturing wear-resistant 10Ce-TZP/Al2O3 nanoparticle aluminum composite by powder metallurgy processing [J]. Materials and Manufacturing Processes, 2014, 29: 1237–1244. DOI: https://doi.org/10.1080/10426914.2014.930954.

SAJJADI S A, EZATPOUR H R, BEYGI H. Microstructure and mechanical properties of Al-Al2O3 micro and nanocomposites fabricated by stir casting [J]. Materials Science and Engineering A, 2011, 528(29, 30): 8765–8771. DOI: https://doi.org/10.1016/j.msea.2011.08.052.

BARADESWARAN A, ELAYA PERUMAL A. Study on mechanical and wear properties of Al 7075/Al2O3/graphite hybrid composites [J]. Composites Part B, 2014, 56: 464–471. DOI: https://doi.org/10.1016/j.compositesb.2013.08.013.

PANWAR N, CHAUHAN A. Fabrication methods of particulate reinforced aluminium metal matrix composite—A review [J]. Materials Today: Proceedings, 2017, 5(2): 5933–5939. DOI: https://doi.org/10.1016/j.matpr.2017.12.194.

RADHIKA N, SAM M. Tribological and wear performance of centrifuge cast functional graded copper based composite at dry sliding conditions [J]. Journal of Central South University, 2019, 26(11): 2961–2973. DOI: https://doi.org/10.1007/s11771-019-4228-y.

KANDPAL B C, KUMAR J, SINGH H. Manufacturing and technological challenges in stir casting of metal matrix composites—A review [J]. Materials Today: Proceedings, 2018, 5(1): 5–10. DOI: https://doi.org/10.1016/j.matpr.2017.11.046.

AKHLAGHI F, LAJEVARDI A, MAGHANAKI H M. Effects of casting temperature on the microstructure and wear resistance of compocast A356/SiCp composites: A comparison between SS and SL routes [J]. Journal of Materials Processing Technology, 2004, 155–156: 1874–1880. DOI: https://doi.org/10.1016/j.jmatprotec.2004.04.328.

LIOYD D J. Particle reinforced aluminium and magnesium matrix composites [J]. International Material Review, 1994, 39(1): 1–23. DOI: https://doi.org/10.1179/095066094790150982.

HAN Jian-min, WU Zhao-ling, CUI Shi-hai, LI Wei-jing, DU Yong-ping. Investigation of defects in SiCp/A356 composites made by a stir casting method [J]. Journal of Ceramic Processing Research, 2007, 8(1): 74–77. DOI: https://doi.org/10.1111/j.1744-7402.2007.02157.x.

MOHANAKUMARA K C, RAJASHEKAR H, GHANARAJA S, AJITPRASAD S L. Development and mechanical properties of SiC reinforced cast and extruded Al based metal matrix composite [J]. Procedia Materials Science, 2014, 5: 934–943. DOI: https://doi.org/10.1016/j.mspro.2014.07.381.

BORREGO A, FERNÁNDEZ R, CRISTINA M D C, IBÁÑEZ J, GONZÁLEZ-DONCEL G. Influence of extrusion temperature on the microstructure and the texture of 6061Al-15 vol.% SiCw PM composites [J]. Composites Science and Technology, 2002, 62(6): 731–742. DOI: https://doi.org/10.1016/S0266-3538(02)00043-X.

GHANARAJA S, VINUTH KUMAR K, RAJU H P, RAVIKUMAR K S. Processing and mechanical properties of hot extruded Al(Mg)-Al2O3 composites [J]. Materials Today: Proceedings, 2015, 2(4, 5): 1291–1300. DOI: https://doi.org/10.1016/j.matpr.2015.07.045.

SOLTANI N, JAFARI NODOOSHAN H R, BAHRAMI A, PECH-CANUL M I, LIU Wen-cai, WU Gou-hua. Effect of hot extrusion on wear properties of Al-15 wt.% Mg2Si in situ metal matrix composites [J]. Materials and Design, 2014, 53: 774–781. DOI: https://doi.org/10.1016/j.matdes.2013.07.084.

ZHANG Peng-xiang, YAN Hong, LIU Wei, ZHOU Xiu-liang, TANG Bin-bin. Effect of T6 heat treatment on microstructure and hardness of nanosized Al2O3 reinforced 7075 aluminum matrix composites [J]. Metals, 2019, 9(1): 44. DOI: https://doi.org/10.3390/met9010044.

DENG Yun-lai, WAN Li, WU Li-hui, ZHANG Yun-ya, ZHANG Xin-ming. Microstructural evolution of Al-Zn-Mg-Cu alloy during homogenization [J]. Journal of Materials Science, 2011, 46(4): 875–881. DOI: https://doi.org/10.1007/s10853-010-4828-2.

LEI Zhi-bo, ZHAO Ke, WANG Yi-guang, AN Li-nan. Thermal expansion of Al matrix composites reinforced with hybrid micro-/nano-sized Al2O3 particles [J]. Journal of Materials Science & Technology, 2014, 30(1): 61–64. DOI: https://doi.org/10.1016/j.jmst.2013.04.022.

MA Ka-ka, WEN Hai-ming, HU Tao, TOPPING T D, ISHEIM D, SEIDMAN D N, LAVERNIA E J, SCHOENUNG J M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy [J]. Acta Materialia, 2014, 62: 141–155. DOI: https://doi.org/10.1016/j.actamat.2013.09.042.

NES E. Recovery revisited [J]. Acta Metallurgica et Materialia, 1995, 43(6): 2189–2207. DOI: https://doi.org/10.1016/0956-7151(94)00409-9.

YANG Zi-run, SUN Yu, LI Xin-xing, WANG Shu-qi, MAO Tao-jie. Dry sliding wear performance of 7075 Al alloy under different temperatures and load conditions [J]. Rare Metals, 2015. DOI: 10.1007/s12598-015-0504-7 doi.

RAO R N, DAS S. Effect of matrix alloy and influence of SiC particle on the sliding wear characteristics of aluminium alloy composites [J]. Materials and Design, 2010, 31(3): 1200–1207. DOI: https://doi.org/10.1016/j.matdes.2009.09.032.

WANG Lei, DONG Bai-xin, QIU Feng, GENG Run, ZOU Qian, YANG Hong-yu, LI Qing-yuan, XU Zi-han, ZHAO Qing-long, JIANG Qi-chuan. Dry sliding friction and wear characterization of in situ TiC/Al-Cu3.7-Mg1.3 nanocomposites with nacre-like structures [J]. Journal of Materials Research and Technology, 2020, 9(1): 641–653. DOI: https://doi.org/10.1016/j.jmrt.2019.11.005.

NEMATI N, KHOSROSHAHI R, EMAMY M, ZOLRIASATEIN A. Investigation of microstructure, hardness and wear properties of Al-4.5 wt.% Cu-TiC nanocomposites produced by mechanical milling [J]. Materials & Design, 2011, 32(7): 3718–3729. DOI: https://doi.org/10.1016/j.matdes.2011.03.056.

SAMEEZADEH M, EMAMY M, FARHANGI H. Effects of particulate reinforcement and heat treatment on the hardness and wear properties of AA 2024-MoSi2 nanocomposites [J]. Materials and Design, 2011, 32(4): 2157–2164. DOI: https://doi.org/10.1016/j.matdes.2010.11.037.

YUAN Lin-lin, HAN Jing-tao, LIU Jing, JIANG Zheng-yi. Mechanical properties and tribological behavior of aluminum matrix composites reinforced with in-situ AlB2 particles [J]. Tribology International, 2016, 98: 41–47. DOI: https://doi.org/10.1016/j.triboint.2016.01.046.

ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics, 1953, 24(8): 981–988. DOI: https://doi.org/10.1063/1.1721448.

WILSON S, ALPAS A T. Wear mechanism maps for metal matrix composites [J]. Wear, 1997, 212(1): 41–49. DOI: https://doi.org/10.1016/S0043-1648(97)00142-7.

LIU Wei, YAN Hong, ZHU Jian-bin. Effect of the addition of rare earth element La on the tribological behaviour of AlSi5Cu1Mg alloy [J]. Applied Sciences, 2018, 8(2): 163. DOI: https://doi.org/10.1016/S0043-1648(97)00142-7.

Author information

Authors and Affiliations

Contributions

The overarching research goals were developed by YAN Hong, LEI Yu-shun and WEI Zhi-fan. LEI Yu-shun and WEI Zhi-fan provided the measured microstructure and tribological behavior data, and analyzed the measured data with XIONG Jun-jie and ZHANG Peng-xiang. WAN Jian-ping and WANG Zhi-lu have provided the corresponding materials and equipment. The initial draft of the manuscript was written by LEI Yu-shun, WEI Zhi-fan. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

LEI Yu-shun, YAN Hong, WEI Zhi-fan, XIONG Jun-jie, ZHANG Peng-xiang, WAN Jianping and WANG Zhi-lu declare that they have no conflict of interest.

Foundation item: Project(51965040) supported by the National Natural Science Foundation of China; Project(20181BAB206026) supported by the National Science Foundation of Jiangxi Province, China

Rights and permissions

About this article

Cite this article

Lei, Ys., Yan, H., Wei, Zf. et al. Effect of hot extrusion on microstructure and tribological behavior of Al2O3p reinforced 7075 aluminum-matrix composites. J. Cent. South Univ. 28, 2269–2284 (2021). https://doi.org/10.1007/s11771-021-4768-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4768-9