Abstract

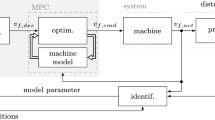

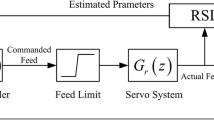

Today, powerful process simulation tools allow an offline process planning and optimization of metal cutting processes. The quality of the optimization strongly depends on the model and its parameters. Real cutting processes are influenced by uncertainties such as tool wear status or material properties, which are both unknown. To overcome this limitation, sensors and process control systems are used. Model-based Predictive Control (MPC) was developed in the 1970s for the chemical process industry. This control method was found to be very suitable to control complex manufacturing processes such as milling processes. Using MPC in metal cutting processes allows considering technological boundary conditions explicitly. Adapting the feed velocity and thus the process force increases the productivity and process stability in milling. A core element of the MPC is the use of a reference trajectory representing the time-dependent set point value in the optimization procedure. The tool path information, however, is given position-based. Thus, calculating the reference trajectory is not trivial and strongly influences the control quality. This paper presents two methods for determining the reference trajectory. The first method is based on an adaptive signal filter. For the second method the MPC is extended to a two-layer MPC: the first layer calculates an optimal reference trajectory; the second layer controls the machine tool.

Similar content being viewed by others

References

Zuperl U, Kiker E, Jezernik K Adaptive force control in high-speed machining by using a system of neural networks. In: 2006 IEEE international symposium on industrial electronics, pp 148–153

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design, 2nd edn. Cambridge University Press, Cambridge

Weinert K, Zabel A, Rautenberger J (2006) Modelling tool wear in milling by design of experiments. Prod Eng 13:21–24

Adams O (2016) Modellbasierte prädiktive Kraftregelung beim Fräsen, 1. Auflage. Ergebnisse aus der Produktionstechnik. Apprimus Verlag, Aachen

Centner RM, Idelsohn JM (1964) Adaptive controller for a metal cutting process. IEEE Trans Appl Ind 83(72):154–161. doi:10.1109/TAI.1964.5407783

Carrillo FJ, Rotella F (1997) A robust adaptive controller for constant turning force regulation. Control Eng Pract 5(12):1673–1682. doi:10.1016/S0967-0661(97)10021-1

Budak E, Kops L (2000) Improving productivity and part quality in milling of titanium based impellers by chatter suppression and force control. CIRP Ann Manuf Technol 49(1):31–36. doi:10.1016/S0007-8506(07)62890-X

Nouri M, Fussell BK (2013) Real-time milling force control and tool wear monitoring using constraint-based feedrates. In: Proceedings of the north american manufacturing research institution, vol 41, University of Wisconsin, Madison, 10–14 June 2013

Pien P, Tomizuka M (1992) Adaptive force control of two dimensional milling. American Control Conference, Chicago, pp 399–403

Nolzen H, Isermann R (1995) Fast adaptive cutting force control for milling operation. In: International conference on control applications, pp 760–765

Nolzen H, Isermann R (1995) Adaptive control of the cutting power for milling operation. In: 1995 American control conference—ACC’95, pp 2185–2189

Richalet J, Rault A, Testud JL, Papon J (1978) Model predictive heuristic control. Automatica 14(5):413–428. doi:10.1016/0005-1098(78)90001-8

Cutler CR, Ramaker BL (1980) Dynamic matrix control—a computer control algorithm. Joint automatic control conference

Prett DM, Gilette RD (1980) Optimization and constrained multivariable control of a catalytic cracking unit. Jt Autom Control Conf vol 17. doi:10.1109/JACC.1980.4232010

García CE, Prett DM, Morari M (1989) Model predictive control: theory and practice—a survey. Automatica 25(3):335–348. doi:10.1016/0005-1098(89)90002-2

Maciejowski JM (2002) Predictive control: with constraints. Prentice Hall, Harlow

Rawlings JB (2000) Tutorial overview of model predictive control. IEEE Control Syst Mag 20(3):38–52. doi:10.1109/37.845037

Brecher et al (2016) Self-optimizing production technologies. In: Integrative production technology: theory and applications. Springer

Stemmler S, Abel D, Adams O, Klocke F (2016) Model predictive feed rate control for a milling machine. IFAC-PapersOnLine 49(12):11–16. doi:10.1016/j.ifacol.2016.07.542

Adams O, Klocke F, Schwenzer M, Stemmler S, Abel D (2016) Model-based predictive force control in milling—system identification. Proced Technol 26:214–220. doi:10.1016/j.protcy.2016.08.029

Ying C-M, Joseph B (1999) Performance and stability analysis of LP-MPC and QP-MPC cascade control systems. AIChE J 45(7):1521–1534. doi:10.1002/aic.690450714

Scattolini R (2009) Architectures for distributed and hierarchical model predictive control—a review. J Process Control 19(5):723–731. doi:10.1016/j.jprocont.2009.02.003

Acknowledgements

The authors would like to thank the German Research Foundation DFG for the kind support within the Cluster of Excellence “Integrative Production Technology for High-Wage Countries”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schwenzer, M., Adams, O., Klocke, F. et al. Model-based predictive force control in milling: determination of reference trajectory. Prod. Eng. Res. Devel. 11, 107–115 (2017). https://doi.org/10.1007/s11740-017-0721-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0721-z