Abstract

Five out of ten welded disk bellows manufactured of AM350 stainless steel for the control rod drive mechanism of the fast breeder test reactor showed an increase in leak rate using helium leak testing from 10−9 to 10−4 Pa-m3/s during storage. Though the leak rate is so small that no leak can be detected by soap bubble test, it is more than the acceptable value for deploying in reactor (10−8 Pa-m3/s). This paper presents the results of a systematic failure analysis carried out and recommendations to prevent similar failures in the future. In service, the bellows are deployed in subcooled and tempered (SCT) condition conforming to SCT1000 condition in ASTM A693. The effectiveness of the heat treatment was verified by mechanical properties and x-ray diffraction investigations and compared with the values reported in the standard. Confocal and scanning electron microscopy of the failed bellows at the location of the failure was carried out and few pits were observed on the failed bellows both on the base metal and the weld. Confocal microscopy of the bellows from the other lot did not show significant pits. The potentiodynamic anodic polarization studies of AM350 indicate that AM350 in the solution annealed condition possesses less pitting resistance compared to that in the SCT1000 condition. This also explains the reason for the failure of bellows manufactured in a specific lot with a significant delay between the manufacturing to the heat treatment. This paper also presents recommendations to prevent similar failures in the future.

Similar content being viewed by others

References

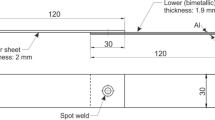

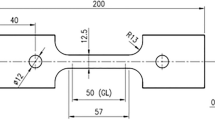

S.C.S.P. Kumar Krovvidi, E. Ramesh, S. Verma, R. Giribabu, S, Chandramouli, Y. Bhat, S. Sundarraj, A. Babu, B. Sreedhar, B.K. Nashine, K. Sureshkumar, S. Raghupathy, Design, manufacturing and in-sodium testing of AM350-welded disc bellows for FBTR control rod drive mechanism, in Proceedings of international conference on fast reactors and related fuel cycles: sustainable clean energy for the future (FR22) (Vienna, Austria, 2022)

E. Ramesh, S.C.S.P. Kumar Krovvidi, Quality assurance in manufacturing of welded disc bellows, in Proceedings of NDE (2018)

S.C.S.P. Kumar Krovvidi, C.R. Das, S. Goyal et al., Influence of heat treatment condition on tensile properties of AM350 stainless steel. Trans Indian Inst Met. (2022). https://doi.org/10.1007/s12666-022-02726-y

ASTM A693-19, Standard specifications for plate, strip for precipitation hardend stainless steel (2019)

ASTM E498, Standard practice for leaks using the mass spectrometer leak detector or residual gas analyzer in the tracer probe mode, Test Method A

ASTM E499, American Society for Testing and Materials, Standard practice for leaks using the mass spectrometer leak detector in the detector probe mode, Method A, Direct Probing

H. Shaikh, H.S. Khatak, R.K. Dayal, A. Sur, Failure analysis of AM 350 steel bellows. Prakt. Metallogr. 28(3), 143–150 (1991)

H. Shaikh, H.S. Khatak, Failure analysis of an AM 350 steel bellows. J. Eng. Fail. Anal. 8(6), 571–576 (2001)

Standards of Expansion joint manufacturer’s association (EJMA-10), 2015, USA

ASTM G5-14, Standard reference test method for making potentiodynamic anodic polarization measurements (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Krovvidi, S.C.S.P.K., Das, C.R., Toppo, A. et al. Failure Analysis of Large Stroke Welded Disk Bellows in Storage. J Fail. Anal. and Preven. 23, 245–257 (2023). https://doi.org/10.1007/s11668-022-01570-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01570-y