Abstract

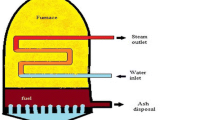

There are distinct types of boilers, such as fire tube boilers, water tube boilers, pulverized fuel boilers, grate furnace boiler, oil and gas-fired boilers, fluidized bed combustion boilers, and waste heat boilers. These boilers are employed in distinct industries such as chemical, fertilizer, refinery, cement, textile, pharmaceutical, steel, sugar, pulp and paper, food, and thermal power plants. But these boilers are subjected to various types of failures and pose a severe threat to the efficiency of the plant/industries. Hence, this manuscript aims to provide an overview of various causes of boiler failures, including caustic embrittlement, oxygen pitting, fouling, agglomeration, hydrogen damage, stress corrosion cracking, slagging, fatigue failure, hot corrosion, oxidation, erosion, etc. Finally, various preventive measures, including surface modification techniques, are discussed. So, by developing more advanced coating material combinations and methods/preventive measure, it is possible to improve the qualities of protection for futuristic applications.

Similar content being viewed by others

References

M.C. Barma, R. Saidur, S.M.A. Rahman, A. Allouhi, B.A. Akash, S.M. Sait, A review on boilers energy use, energy savings, and emissions reductions. Renew. Sustain. Energy Rev. 79, 970–983 (2017)

G.C. Wood, High-temperature oxidation of alloys. Oxid. Met. 2(1), 11–57 (1970). https://doi.org/10.1007/BF00603581

J. Stringer, High temperature corrosion issues in energy-related systems. Mater. Res. 7, 01–19 (2004). https://doi.org/10.1590/S1516-14392004000100002

S. Chaudhuri, R. Singh, High temperature boiler tube failures–case studies. in Proceeding COFA@NML Jamshdpur (1997), pp. 107-120. https://core.ac.uk/download/pdf/297711125.pdf

S.K. Dhua, Metallurgical investigation of failed boiler water-wall tubes received from a thermal power station. Eng. Fail. Anal. 17(7), 1572–1579 (2010). https://doi.org/10.1016/j.engfailanal.2010.06.004

J. Ahmad, J. Purbolaksono, L.C. Beng, A.Z. Rashid, A. Khinani, A.A. Ali, Failure investigation on rear water wall tube of boiler. Eng. Fail. Anal. 16(7), 2325–2332 (2009). https://doi.org/10.1016/j.engfailanal.2009.03.012

J. Ahmad, J. Purbolaksono, Hydrogen damage in a rear riser water wall tube of a power plant. Eng. Fail. Anal. 17(5), 1239–1245 (2010). https://doi.org/10.1016/j.engfailanal.2010.01.005

S.W. Liu, W.Z. Wang, C.J. Liu, Failure analysis of the boiler water-wall tube. Case Stud. Eng. Fail. Anal. 9, 35–39 (2017). https://doi.org/10.1016/j.csefa.2017.06.002

S. Kumar, P. Tadge, A. Mondal, N. Hussain, S. Ray, A. Saha, Boiler tube failures in thermal power plant: two case studies. Mater. Today Proc. (2022). https://doi.org/10.1016/j.matpr.2022.06.254

D.J. Benac, Failure avoidance brief: estimating heater tube life. J Fail. Anal. Preven. 9(1), 5–7 (2009). https://doi.org/10.1007/s11668-008-9190-1

J.J. Perdomo, T.D. Spry, An overheat boiler tube failure. J Fail. Anal. Preven. 5(2), 25–28 (2005). https://doi.org/10.1361/15477020522997

P.M. Singh, J. Mahmood, Stress assisted corrosion of waterwall tubes in recovery boiler tubes: failure analysis. J. Fail. Anal. Preven. 7(5), 361–370 (2007). https://doi.org/10.1007/s11668-007-9063-z

S. Chaudhuri, Some aspects of metallurgical assessment of boiler tubes—basic principles and case studies. Mater. Sci. Eng. A. 432(1), 90–99 (2006). https://doi.org/10.1016/j.msea.2006.06.026

N.-H. Lee, S. Kim, B.-H. Choe, K.-B. Yoon, D. Kwon, Failure analysis of a boiler tube in USC coal power plant. Eng. Fail. Anal. 16(7), 2031–2035 (2009). https://doi.org/10.1016/j.engfailanal.2008.12.006

S. Prakash, Hot corrosion of alloys and coatings. Develop. High Temp. Corr. Prot. Mater. (2008). https://doi.org/10.1533/9781845694258.1.164

P. Hancock, Vanadic and chloride attack of superalloys. Mater. Sci. Technol. 3(7), 536–544 (1987). https://doi.org/10.1080/02670836.1987.11782265

V. Chawla, A. Chawla, D. Puri, S. Prakash, P.G. Gurbuxani, B.S. Sidhu, Hot corrosion and erosion problems in coal based power plants in India and possible solutions—a review. JMMCE. 10(04), 367–386 (2011). https://doi.org/10.4236/jmmce.2011.104027

J.J. Wells, F. Wigley, D.J. Foster, W.R. Livingston, W.H. Gibb, J. Williamson, The nature of mineral matter in a coal and the effects on erosive and abrasive behaviour. Fuel Process. Technol. 86(5), 535–550 (2005). https://doi.org/10.1016/j.fuproc.2004.04.002

B.S. Sidhu, S. Prakash, Evaluation of the behavior of shrouded plasma spray coatings in the platen superheater of coal-fired boilers. Metall. Mater. Trans. A. 37(6), 1927–1936 (2006). https://doi.org/10.1007/s11661-006-0135-6

V.H. Hidalgo, J.B. Varela, A.C. Menéndez, S.P. Martinez, High temperature erosion wear of flame and plasma-sprayed nickel–chromium coatings under simulated coal-fired boiler atmospheres. Wear. 247(2), 214–222 (2001). https://doi.org/10.1016/S0043-1648(00)00540-8

I. Hutchings, P. Shipway, Surface Engineering, in Tribology, 2nd edn. ed. by I. Hutchings, P. Shipway (Butterworth-Heinemann, UK, 2017)

Y. Sasikumar, K. Indira, N. Rajendran, Surface modification methods for titanium and its alloys and their corrosion behavior in biological environment: a review. J. Bio. Tribo. Corr. 5(2), 36 (2019). https://doi.org/10.1007/s40735-019-0229-5

M. Sathish, N. Radhika, B. Saleh, A critical review on functionally graded coatings: methods, properties, and challenges. Compos. B Eng. 225, 109278 (2021). https://doi.org/10.1016/j.compositesb.2021.109278

S. Kumar, R. Kumar, Influence of processing conditions on the properties of thermal sprayed coating: a review. Surf. Eng. 37(11), 1339–1372 (2021). https://doi.org/10.1080/02670844.2021.1967024

R. Kumar, Thermal spray coating: a study. 2018. https://doi.org/10.5281/ZENODO.1207005

S. Kumar, M. Kumar, A. Handa, Combating hot corrosion of boiler tubes—a study. Eng. Fail. Anal. 94, 379–395 (2018). https://doi.org/10.1016/j.engfailanal.2018.08.004

S. Kumar, M. Kumar, N. Jindal, Overview of cold spray coatings applications and comparisons: a critical review. World J. Eng. 17(1), 27–51 (2020). https://doi.org/10.1108/WJE-01-2019-0021

R. Huang, H. Fukanuma, Future Trends in Cold Spray Techniques, in Future Development of Thermal Spray Coatings. ed. by N. Espallargas (Woodhead Publishing, UK, 2015)

L. Singh, V. Chawla, J.S. Grewal, A review on detonation gun sprayed coatings. JMMCE. 11(03), 243–265 (2012). https://doi.org/10.4236/jmmce.2012.113019

V.A.D. Souza, A. Neville, Aspects of microstructure on the synergy and overall material loss of thermal spray coatings in erosion–corrosion environments. Wear. 263(1), 339–346 (2007). https://doi.org/10.1016/j.wear.2007.01.071

G. Sundararajan, D.S. Rao, G. Sivakumar, S.V. Joshi, Detonation Spray Coatings, in Encyclopedia of Tribology. ed. by Q.J. Wang, Y.-W. Chung (Springer, Boston, 2013)

J.H. Kim, M.C. Kim, C.G. Park, Evaluation of functionally graded thermal barrier coatings fabricated by detonation gun spray technique. Surf. Coat. Technol. 168(2), 275–280 (2003). https://doi.org/10.1016/S0257-8972(03)00011-2

D.V. Rosato, D.V. Rosato, M.V. Rosato, 10—Coating, in Plastic Product Material and Process Selection Handbook. ed. by D.V. Rosato, D.V. Rosato, M.V. Rosato (Elsevier, Oxford, 2004)

M.R. Dorfman, Thermal Spray Coatings, in Handbook of Environmental Degradation of Materials, 3rd edn. ed. by M. Kutz (William Andrew Publishing, Norwich, 2018)

S. Kumar, A. Handa, V. Chawla, N.K. Grover, R. Kumar, Performance of thermal-sprayed coatings to combat hot corrosion of coal-fired boiler tube and effect of process parameters and post-coating heat treatment on coating performance: a review. Surf. Eng. 37(7), 833–860 (2021). https://doi.org/10.1080/02670844.2021.1924506

K. Sunitha, H. Vasudev, A short note on the various thermal spray coating processes and effect of post-treatment on Ni-based coatings. Mater. Today: Proc. 50, 1452–1457 (2022). https://doi.org/10.1016/j.matpr.2021.09.017

R. Kumar, R. Kumar, S. Kumar, Erosion corrosion study of HVOF sprayed thermal sprayed coatings on boiler tubes: a review. IJSMS. (2018). https://doi.org/10.51386/25815946/ijsms-v1i3p101

K.E. Fox, N.L. Tran, T.A. Nguyen, T.T. Nguyen, P.A. Tran, 8—Surface Modification of Medical Devices at Nanoscale—Recent Development and Translational Perspectives, in Biomaterials in Translational Medicine. ed. by L. Yang, S.B. Bhaduri, T.J. Webster (Academic Press, Cambridge, 2019)

U. Gunputh, H. Le, 6—Composite Coatings for Implants and Tissue Engineering Scaffolds, in Biomedical Composites, 2nd edn. ed. by L. Ambrosio (Woodhead Publishing, UK, 2017)

S. Devaraj, B. Anand, M. Gibbons, A. McDonald, S. Chandra, Thermal spray deposition of aluminum and zinc coatings on thermoplastics. Surf. Coat. Technol. 399, 126114 (2020). https://doi.org/10.1016/j.surfcoat.2020.126114

A. Scrivani, U. Bardi, L. Carrafiello, A. Lavacchi, F. Niccolai, G. Rizzi, A comparative study of high velocity oxygen fuel, vacuum plasma spray, and axial plasma spray for the deposition of CoNiCrAlY bond coat alloy. J. Therm. Spray Technol. 12, 504–507 (2003). https://doi.org/10.1361/105996303772082242

S. Kumar, M. Kumar, A. Handa, Erosion corrosion behaviour and mechanical properties of wire arc sprayed Ni-Cr and Ni-Al coating on boiler steels in a real boiler environment. Mater. High Temp. 37(6), 370–384 (2020). https://doi.org/10.1080/09603409.2020.1810922

S. Kumar, M. Kumar, A. Handa, Comparative study of high temperature oxidation behavior and mechanical properties of wire arc sprayed NiCr and NiAl coatings. Eng. Fail. Anal. 106, 104173 (2019). https://doi.org/10.1016/j.engfailanal.2019.104173

S. Kumar, M. Kumar, A. Handa, High temperature oxidation and erosion-corrosion behaviour of wire arc sprayed Ni-Cr coating on boiler steel. Mater. Res. Express. 6(12), 125533 (2020). https://doi.org/10.1088/2053-1591/ab5fae

M. Kumar, S. Kant, S. Kumar, Corrosion behavior of wire arc sprayed Ni-based coatings in extreme environment. Mater. Res. Express. 6(10), 106427 (2019). https://doi.org/10.1088/2053-1591/ab3bd8

V. Sharma, S. Kumar, M. Kumar, D. Deepak, High temperature oxidation performance of Ni-Cr-Ti and Ni-5Al coatings. Mater. Today: Proc. 26, 3397–3406 (2020). https://doi.org/10.1016/j.matpr.2019.11.048

P. Chivavibul et al., Development of WC-Co coatings deposited by warm spray process. J. Therm. Spray Tech. 17(5), 750–756 (2008). https://doi.org/10.1007/s11666-008-9271-4

N. Bala, H. Singh, S. Prakash, Accelerated hot corrosion studies of cold spray Ni–50Cr coating on boiler steels. Mater. Des. 31(1), 244–253 (2010). https://doi.org/10.1016/j.matdes.2009.06.033

B.S. Sidhu, S. Prakash, Studies on the behaviour of Stellite-6 as plasma sprayed and laser remelted coatings in molten salt environment at 900 °C under cyclic conditions. J. Mater. Process. Technol. 172(1), 52–63 (2006). https://doi.org/10.1016/j.jmatprotec.2005.08.018

A. Mangla, V. Chawla, G. Singh, Comparative study of hot corrosion behavior of HVOF and plasma sprayed Ni20Cr coating on SA213 (T22) boiler steel in Na2SO4–60% V2O5 environment. Inte. J. Eng. Sci. Res. Technol. 4(11), 2348–8034 (2017)

A. Rani, N. Bala, C.M. Gupta, Accelerated hot corrosion studies of D-gun-sprayed Cr2O3–50% Al2O3 coating on boiler steel and Fe-based superalloy. Oxid. Met. 88(5), 621–648 (2017). https://doi.org/10.1007/s11085-017-9759-8

M. Tiainen, J. Daavitsainen, R.S. Laitinen, The role of amorphous material in ash on the agglomeration problems in fb boilers. a powder XRD and SEM-EDS study. Energy Fuels. 16(4), 871–877 (2002). https://doi.org/10.1021/ef010269j

E.J. Anthony, L. Jia, Agglomeration and strength development of deposits in CFBC boilers firing high-sulfur fuels. Fuel. 79(15), 1933–1942 (2000). https://doi.org/10.1016/S0016-2361(00)00054-5

M. Öhman, A. Nordin, The role of kaolin in prevention of bed agglomeration during fluidized bed combustion of biomass fuels 2000. Energy Fuels. 14(3), 737–737 (2000). https://doi.org/10.1021/ef000065n

M. Theis, B.-J. Skrifvars, M. Zevenhoven, M. Hupa, H. Tran, Fouling tendency of ash resulting from burning mixtures of biofuels. Part 2: deposit chemistry. Fuel. 14–15(85), 1992–2001 (2006). https://doi.org/10.1016/j.fuel.2006.03.015

N. Hare, M. Rasul, S. Moazzem, A review on boiler deposition/foulage prevention and removal techniques for power plant. in EE’10: Proceedings of the 5th IASME/WSEAS international conference on Energy & environment (2010), pp. 217-222. https://dl.acm.org/doi/10.5555/1807906.1807947

E. Raask, Mineral impurities in coal combustion: behavior, problems, and remedial measures. (1985). Available: https://www.osti.gov/biblio/5693722

R.W. Bryers, Fireside slagging, fouling, and high-temperature corrosion of heat-transfer surface due to impurities in steam-raising fuels. Prog. Energy Combust. Sci. 22(1), 29–120 (1996). https://doi.org/10.1016/0360-1285(95)00012-7

F. Wigley, J. Williamson, Modelling fly ash generation for pulverised coal combustion. Prog. Energy Combust. Sci. 24(4), 337–343 (1998). https://doi.org/10.1016/S0360-1285(98)00005-7

A.R. McLennan, G.W. Bryant, C.W. Bailey, B.R. Stanmore, T.F. Wall, An experimental comparison of the ash formed from coals containing pyrite and siderite mineral in oxidizing and reducing conditions. Energy Fuels. 14(2), 308–315 (2000). https://doi.org/10.1021/ef990092h

D. Zhang, Ash fouling, deposition and slagging in ultra-supercritical coal power plants. Ultra-Supercrit. Coal Power Plants Mater. Technol. Optim. (2013). https://doi.org/10.1533/9780857097514.2.133

A.L. Robinson, H. Junker, L.L. Baxter, Pilot-scale investigation of the influence of coal−biomass cofiring on ash deposition. Energy Fuels. 16(2), 343–355 (2002). https://doi.org/10.1021/ef010128h

F. Frandsen, Ash formation, deposition and corrosion when utilizing straw for heat and power production. Doctoral thesis, DTU Chemical Engineering (2010). https://orbit.dtu.dk/files/6228196/prod21319533943894.Doc_Thesis_V7.0PC_Publishable_Version.pdf

I. Panagiotidis, K. Vafiadis, A. Tourlidakis, A. Tomboulides, Study of slagging and fouling mechanisms in a lignite-fired power plant. Appl. Therm. Eng. 74, 156–164 (2015). https://doi.org/10.1016/j.applthermaleng.2014.03.043

P.P. Płaza, The development of a slagging and fouling predictive methodology for large scale pulverised boilers fired with coal/biomass blends. PhD Thesis, Cardiff University (2013). https://orca.cardiff.ac.uk/id/eprint/58453/1/2014PlazaPPPhD.pdf

Rakhoh, Caustic Embrittlement in Steam Boilers | Causes and Prevention—Boilers and Steam Boiler Manufacturer in Maharashtra, Pune (2022). https://rakhoh.com/en/caustic-embrittlement-in-steam-boilers-causes-and-prevention/

E.W. Colbeck, L. Powell, S.H. Smith, Caustic embrittlement. Proc. Inst. Mech. Eng. 149(1), 63–73 (1943). https://doi.org/10.1243/PIME_PROC_1943_149_019_02

R.K. Singh Raman, Role of caustic concentration and electrochemical potentials in caustic cracking of steels. Mater. Sci. Eng.: A. 441(1), 342–348 (2006). https://doi.org/10.1016/j.msea.2006.08.041

H.H. Krause, High temperature corrosion problems in waste incineration systems. JMES. 7(4), 322–332 (1986). https://doi.org/10.1007/BF02833571

P. Haribhakti, P.B. Joshi, R. Kumar, Failure Investigation of Boiler Tubes: A Comprehensive Approach. (ASM International, Almere, 2018)

RAKHOH, Causes and prevention of boiler tube failures in fireside of Steam boilers. Boilers and Steam Boiler Manufacturer in Maharashtra, Pune, (2021). https://rakhoh.com/en/causes-and-prevention-of-boiler-tube-failures-in-fireside-of-steam-boilers/

S.L. Meiley, Cause and prevention of fatigue failures in boiler tubing. in ASM failure analysis case histories: power generating equipment (2019). https://doi.org/10.31399/asm.fach.power.c9001569

S. J Maddox, Fatigue Strength of Welded Structures, 2nd edn. Woodhead Publishing Series in Welding and Other Joining Technologies (1991). https://www.elsevier.com/books/fatigue-strength-of-welded-structures/maddox/978-1-85573-013-7

Oxygen attack in boilers—Lenntech. https://www.lenntech.com/applications/process/boiler/oxygen-attack.htm

D.D.N. Singh, Various forms of water side corrosion: causes and prevention. in National conference on boiler corrosion (NML Jamshepur, 1995), pp. 1–14. https://eprints.nmlindia.org/3557/1/H1-H14.PDF

RAKHOH, Corrosion in Steam Boiler: Causes and its Solution. Boilers and Steam Boiler Manufacturer in Maharashtra, Pune, (2021). https://rakhoh.com/en/corrosion-in-steam-boiler-causes-and-its-solution/

Different Types of Corrosion: Stress Corrosion Cracking (SCC)—Causes and Prevention, WebCorr Corrosion Consulting Services, Corrosion Short Courses and Corrosion Expert Witness, WEBCORR The corrosion clinic (1995), pp. 1–2. https://www.corrosionclinic.com/types_of_corrosion/stress_corrosion_cracking.htm

Y.S. Kim, W.C. Kim, J. Jain, E.-W. Huang, S.Y. Lee, Hydrogen embrittlement of a boiler water wall tube in a district heating system. Metals. 12(8), 8 (2022). https://doi.org/10.3390/met12081276

P.F. Timmins, Solutions to Hydrogen Attack in Steels. (ASM International, Materials Park, 1997)

R.K. Dayal, N. Parvathavarthini, Hydrogen embrittlement in power plant steels. Sadhana. 28(3), 431–451 (2003). https://doi.org/10.1007/BF02706442

Acknowledgments

The authors are highly thankful to R&D department of Chandigarh University Gharuan and Chandigarh Group of Colleges, Landran, Mohali, Punjab (India).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, K., Kumar, S. & Gill, H.S. Role of Surface Modification Techniques to Prevent Failure of Components Subjected to the Fireside of Boilers. J Fail. Anal. and Preven. 23, 1–15 (2023). https://doi.org/10.1007/s11668-022-01556-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01556-w