Abstract

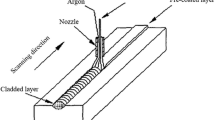

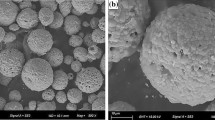

The high-purity MAX phase coatings with thickness lower than 10 μm are mainly deposited by physical vapor deposition. Still, they typically fail to meet the long-term stability demand of heavy load and high-temperature applications. In the present study, a process for in situ synthesis of Cr2AlC MAX phase coating based on plasma transferred arc cladding directly from pure Cr, Al and Cr3C2 powder has been proposed for the first time. The as-received powders were mixed at a molar ration Cr:Al:C = 2:1.1:1 in a mortar manually for 1800s. To reveal the possible in situ synthesis mechanism, the effects of the plasma gas flux on the phase formation and microstructure evolution of coatings were investigated. The results indicated that a Cr2AlC gradient coating with a 1 mm high-purity Cr2AlC top layer was formed on low-carbon steel by plasma gas flux 0.03 and 0.04 L/s. If plasma gas flux continued to increase to 0.05 L/s, no Cr2AlC MAX phase was observed in the coating. The study proved the possibility of in situ synthesis of Cr2AlC coating by plasma transferred arc cladding and revealed the in situ synthesis mechanism.

Similar content being viewed by others

References

M.W. Barsoum, The MN+1AXN Phases: A New Class of Solids: Thermodynamically Stable Nanolaminates, Prog. Solid State Chem., 2000, 28, p 201-281.

Z.M. Sun, Progress in Research and Development on MAX Phases: A Family of Layered Ternary Compounds, Int. Mater. Rev., 2011, 56, p 143-166.

M. Sokol, V. Natu, S. Kota and M.W. Barsoum, On the Chemical Diversity of the MAX Phases, Trends Chem., 2019, 1, p 210-223.

J. Gonzalez-Julian, Processing of MAX Phases: from Synthesis to Applications, J. Am. Ceram. Soc., 2021, 104, p 659-690.

E.N. Hoffman, D.W. Vinson, R.L. Sindelar, D.J. Tallman, G. Kohse and M.W. Barsoum, MAX Phase Carbides and Nitrides Properties for Future Nuclear Power Plant In-core Applications and Neutron Transmutation Analysis, Nucl. Eng. Des., 2012, 244, p 17-24.

H. Rueß, J. Werner, Y. Unutulmazsoy, J.W. Gerlach, X. Chen, B. Stelzer, D. Music, S. Kolozsvari, P. Polcik, T.E. Weirich and J.M. Schneider, Effect of Target Peak Power Density on the Phase Formation, Microstructure Evolution, and Mechanical Properties of Cr2AlC MAX-Phase Coatings, J. Eur. Ceram. Soc., 2021, 41, p 1841-1847.

M. Imtyazuddin, A.H. Mir, M.A. Tunes and V.M. Vishnyakov, Radiation Resistance and Mechanical Properties of Magnetron-Sputtered Cr2AlC Thin Films, J. Nucl. Mater., 2019, 526, 151742.

B. Völker, B. Stelzer, S. Mráz, H. Rueß, R. Sahu, C. Kirchlechner, G. Dehm and J.M. Schneider, On the Fracture Behavior of Cr2AlC Coatings, Mater. Design, 2021, 206, 109757.

Y.M. Li, G.R. Zhao, Y.H. Qian, J.J. Xu and M.S. Li, Deposition of Phase-pure Cr2AlC Coating by DC Magnetron Sputtering and Post Annealing Using Cr-Al-C Targets with Controlled Elemental Composition but Different Phase Compositions, J. Mater. Sci. Technol., 2018, 34, p 466-471.

Z.Y. Wang, W.T. Li, C.C. Wang, H.C. Wu, P.L. Ke and A.Y. Wang, Transforming the Amorphous Ti-Al-C Coatings to High-Purity Ti2AlC MAX Phase Coatings by Prolonged Annealing at 550 °C, Mater. Lett., 2020, 261, 127160.

M. Ougier, A. Michau, F. Schuster, H. Maskrot and M.L. Schlegel, Effects of HiPIMS Discharges and Annealing on Cr-Al-C Thin Films, Surf. Coat. Technol., 2020, 399, 126141.

J. Gonzalez-Julian, G. Mauer, D. Sebold, D.E. Mack and R. Vassen, Cr2AlC MAX Phase as Bond Coat for Thermal Barrier Coatings: Processing, Testing Under Thermal Gradient Loading, and Future Challenges, J. Am. Ceram. Soc., 2020, 103, p 2362-2375.

F.Y. Zhang, S. Yan, C. Li, Y. Ding, J.N. He and F.X. Yin, Synthesis and Characterization of MAX Phase Cr2AlC Based Composite Coatings by Plasma Spraying and Post Annealing, J. Eur. Ceram. Soc., 2019, 39, p 5132-5139.

Z. Zhang, S.H. Lim, J.W. Chai, D.M.Y. Lai, A.K.H. Cheong, K.L. Cheong, S.J. Wang, H.M. Jin and J.S. Pan, Plasma Spray of Ti2AlC MAX Phase Powders: Effects of Process Parameters on Coatings’ Properties, Surf. Coat. Technol., 2017, 325, p 429-436.

N. Markocsan, D. Manitsas, J. Jiang and S. Björklund, MAX-Phase Coatings Produced by Thermal Spraying, J. Superhard Mater., 2017, 39, p 355-364.

M. Sonestedt, J. Frodelius, J.P. Palmquist, H. Högberg, L. Hultman and K. Stiller, Microstructure of High Velocity Oxy-Fuel Sprayed Ti2AlC Coatings, J. Mater. Sci., 2010, 45, p 2760-2769.

Z. Zhang, S.H. Lim, J. Chai, D.M.Y. Lai, P.C. Lim, A.K.H. Cheong, S. Wang, H. Jin and J. Pan, Kerosene-Fuelled High Velocity Oxy-fuel (HVOF) Spray of Ti2AlC MAX Phase Powders, J. Alloys. Compd., 2018, 735, p 377-385.

T. Go, Y.J. Sohn, G. Mauer, R. Vaßen and J. Gonzalez-Julian, Cold Spray Deposition of Cr2AlC MAX Phase for Coatings and Bond-Coat Layers, J. Eur. Ceram. Soc., 2019, 39, p 860-867.

A. Elsenberg, M. Busato, F. Gärtner, A. List, A. Bruera, G. Bolelli, L. Lusvarghi and T. Klassen, Influence of MAX-Phase Deformability on Coating Formation by Cold Spraying, J. Therm. Spray Tech., 2021, 30, p 617-642.

A. Loganathan, A. Sahu, C. Rudolf, C. Zhang, S. Rengifo, T. Laha, B. Boesl and A. Agarwal, Multi-scale Tribological and Nanomechanical Behavior of Cold Sprayed Ti2AlC MAX Phase Coating, Surf. Coat. Technol., 2018, 334, p 384-393.

H.X. Zhang, J.J. Dai, C.X. Sun, Z.W. Ma, X.Y. Wang and J.J. Du, Fabrication of TiC/TiB/Ti3AlC2 Phases Reinforced Coatings on Ti-6Al-4V Substrate, Mater. Manuf. Process., 2017, 33, p 1037-1042.

Y. Zhu, X.B. Liu, Y.F. Liu, G. Wang, Y. Wang, Y. Meng and J. Liang, Development and Characterization of Co-Cu/Ti3SiC2 Self-lubricating Wear Resistant Composite Coatings on Ti6Al4V Alloy by Laser Cladding, Surf. Coat. Technol., 2021, 424, 127664.

H. Yan, K.W. Liu, P.L. Zhang, J. Zhao, Y. Qin, Q.H. Lu and Z.S. Yu, Fabrication and Tribological Behaviors of Ti3SiC2/Ti5Si3/TiC/Ni-Based Composite Coatings by Laser Cladding for Self-lubricating Applications, Opt. Laser Technol., 2020, 126, 106077.

E.I. Zamulaev, E.A. Levashov, E.A. Skryleva, T.A. Sviridova and Ph.V. Kiryukhantsev-Korneev, Conditions for Formation of MAX Phase Cr2AlC in Electrospark Coatings Deposited onto Titanium Alloy, Surf. Coat. Technol., 2016, 298, p 15-23.

L.O. Xiao, S.B. Li, G.M. Song and W.G. Sloof, Synthesis and Thermal Stability of Cr2AlC, J. Eur. Ceram. Soc., 2011, 31, p 1497-1502.

P. Richardson, D. Cuskelly, M. Brandt and E. Kisi, Microstructural Analysis of In-situ Reacted Ti2AlC MAX Phase Composite Coating by Laser Cladding, Surf. Coat. Technol., 2020, 385, 125360.

F.Y. Zhang, J.W. Chen, S. Yan, G.X. Yu, J.N. He and F.X. Yin, Plasma Spraying Ti-Al-C Based Composite Coatings from Ti/Al/Graphite Agglomerates: Synthesis, Characterization and Reaction Mechanism, Vacuum, 2022, 200, 111036.

S. Oukach, B. Pateyron and L. Pawłowski, Physical and Chemical Phenomena Occurring Between Solid Ceramics and Liquid Metals and Alloys at Laser and Plasma Composite Coatings Formation: A Review, Surf. Sci. Rep., 2019, 74, p 213-241.

Z.M. Liu, S.L. Cui, Z. Luo, C.Z. Zhang, Z.M. Wang and Y.C. Zhang, Plasma Arc Welding: Process Variants and its Recent Developments of Sensing, Controlling and Modeling, J. Manuf. Process., 2016, 23, p 315-327.

Y.L. Yuan and Z.G. Li, A Novel Approach of In-situ Synthesis of WC Particulate-Reinforced Fe-30Ni Ceramic Metal Coating, Surf. Coat. Technol., 2017, 328, p 256-265.

T. Zhao, S. Zhang, F.Q. Zhou, H.F. Zhang, C.H. Zhang and J. Chen, Microstructure Evolution and Properties of In-Situ TiC Reinforced Titanium Matrix Composites Coating by Plasma Transferred Arc Welding (PTAW), Surf. Coat. Technol., 2021, 424, 127637.

M.L. Wang, H.Z. Cui, N. Wei, L. Ding, X.J. Zhang, Y. Zhao, C.M. Wang and Q. Song, A New Design of In-Situ Ti(C, N) Reinforced Composite Coatings and Their Microstructures, Interfaces and Wear Resistances, ACS Appl. Mater. Interfaces., 2018, 10, p 4250-4265.

Z.C. Feng, Y.F. Liu, Y. Li, G.B. Sun, Z. Zhang and C.X. Shi, Microstructure and High Temperature Reciprocating Sliding Wear Properties of MoSi2/TiC/γ-Ni Composite Coating In-situ Synthesized by Co-Axial Powder Feeding Plasma Transferred Arc Cladding, Tribol. Int., 2019, 129, p 82-91.

Z.J. Lin, Y.C. Zhou and M.S. Li, Synthesis, Microstructure, and Property of Cr2AlC, J. Mater. Sci. Technol., 2007, 23, p 721-746.

Z. Z. Zhang, C. Chen, Y. J. Li, Z. J. Feng, Y. Lan, J. H. Lan, Z. Y. Lin, Q. Y. Lin, Z. Pan, R. G. Gan, H. Z. Liang, Z. G. Li and H. Lin, One Kind of Powder Feeding System for Plasma Transferred arc Clading, CN216274372U (2022)

J. Wilden, J.P. Bergmann and H. Frank, Plasma Transferred Arc Welding-Modeling and Experimental Optimization, J. Therm. Spray Tech., 2006, 15, p 779-784.

P.L. Fauchais, J.V.R. Heberlein and M.I. Boulos, Plasma-Transferred Arc, Thermal Spray Fundamentals. Springer, Boston, 2014, p 631-673

H.C. Oh, S.H. Lee and S.C. Choi, The Reaction Mechanism for the Low Temperature Synthesis of Cr2AlC Under Electronic Field, J. Alloys Compd., 2014, 587, p 296-302.

D. Nýblová, P. Billik, J. Noga, E. Šimon, R. Bystrický, M. Čaplovičová and M. Nosko, Degradation of Al4C3 Due to Atmospheric Humidity, JOM, 2018, 70, p 2378-2384.

Acknowledgments

This work is supported by the Central Guide the Special Fund for Local Development of China (GuiKe ZY19183018) and Science and Technology Planning Project of Administration for Market Regulation of Guangxi Zhuang Autonomous Region (GXSJKJ2022-4).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Chen, H., Zhang, Z. et al. In Situ Synthesis of Cr2AlC Gradient Coating by Plasma Transferred Arc Cladding. J Therm Spray Tech 32, 1378–1388 (2023). https://doi.org/10.1007/s11666-023-01530-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01530-4