Abstract

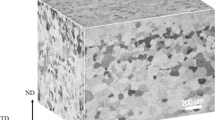

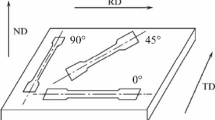

In the present study, the through-thickness texture evolution and grain colony distribution in ferritic stainless steel under two different cold-rolling processes have been investigated with the aim to enhance deep drawability. It was shown that in the case of conventional cold-rolling process, at the surface, mid-thickness between the surface and the center, and center layers, all the textures consisted of very sharp α-fiber and weak γ-fiber with a peak at {111}〈110〉 after cold rolling, and non-uniform γ-fiber recrystallization textures were formed after final annealing. In case of two-step cold-rolling process, by contrast, all the textures were dominated by sharp α-fiber and weak γ-fiber after cold rolling to 50% reduction, and {111}〈112〉 became the prominent component after subsequent annealing. The α-fiber and γ-fiber with a peak at {111}〈112〉 were intensified after cold rolling to 60% reduction, resulting in the formation of uniform γ-fiber recrystallization textures after final annealing. Furthermore, after two-step cold-rolling process, the final sheet exhibited a more homogeneous distribution of grain colonies. Therefore, the deep drawability of final sheet was significantly improved after two-step cold-rolling process. It was elucidated that the selective growth mechanism was responsible for the characteristics of γ-fiber recrystallization texture under conventional cold-rolling process, whereas γ-fiber recrystallization texture development was controlled by the oriented nucleation mechanism in the two-step cold-rolling process.

Similar content being viewed by others

References

K.H. Lo, C.H. Shek, and J.K.L. Lai, Recent developments in stainless steels, Mater. Sci. Eng. R, 2009, 65, p 39–104

S.M. Kim, Y.S. Chun, S.Y. Won, Y.H. Kim, and C.S. Lee, Hydrogen embrittlement behavior of 430 and 445NF ferritic stainless steels, Metall. Mater. Trans. A, 2013, 44A, p 1331–1339

F. Gao, Z.Y. Liu, H.T. Liu, and G.D. Wang, Toughness under different rolling processes in ultra purified Fe-17 wt.% Cr alloy steels, J. Alloy. Compd., 2013, 567, p 141–147

F. Gao, Z.Y. Liu, R.D.K. Misra, H.T. Liu, and F.X. Yu, Constitutive modeling and dynamic softening mechanism during hot deformation of an ultra-pure 17%Cr ferritic stainless steel stabilized with Nb, Met. Mater. Int., 2014, 20, p 939–951

M.-Y. Huh, J.-H. Lee, S.H. Park, O. Engler, and D. Raabe, Effect of through-thickness macro and micro-texture gradients on ridging of 17%Cr ferritic stainless steel, Steel Res. Int., 2005, 76, p 797–806

S.H. Park, K.Y. Kim, Y.D. Lee, and C.G. Park, Evolution of microstructure and texture associated with ridging in ferritic stainless steel, ISIJ Int., 2002, 42, p 100–105

H.J. Shin, J.K. An, S. Park, and D.N. Lee, The effect of texture on ridging of ferritic stainless steel, Acta Mater., 2003, 51, p 4693–4706

D. Raabe and K. Lücke, Textures of ferritic stainless steel, Mater. Sci. Technol., 1993, 9, p 302–312

H.T. Liu, Z.Y. Liu, and G.D. Wang, Texture development and formability of strip cast 17%Cr ferritic stainless steel, ISIJ Int., 2009, 49, p 890–896

Y. Nakagawa, T. Sakamoto, I. Yamauchi, T. Yamazaki, and M. Ueno, Effect of hot rolling process on deep drawability and ridging tendency of Ti stabilized 17%Cr stainless steel, Tetsu-to-Hagane, 1980, 66, p 657–666

M.Y. Huh and O. Engler, Effect of intermediate annealing on texture, formability and ridging of 17%Cr ferritic stainless steel sheet, Mater. Sci. Eng. A, 2001, 308, p 74–87

H. Miyamoto, T. Xiao, T. Uenoya, and M. Hatano, Effect of simple shear deformation prior to cold rolling on texture and ridging of 16%Cr ferritic stainless steel sheets, ISIJ Int., 2010, 50, p 1653–1659

T. Kaneko, H. Utsunomiya, Y. Saito, T. Sakai, and N. Furushiro, Improvement of ridging behaviour of ferritic stainless steel by spread rolling method, Tetsu-to-Hagane, 2003, 89, p 653–658

D. Raabe, F. Reher, M. Hölscher, and K. Lücke, Textures of strip cast Fe16%Cr, Scripta Metall. Mater., 1993, 29, p 113–116

H.T. Yan, H.Y. Bi, X. Li, and Z. Xu, Effect of two-step cold rolling and annealing on texture, grain boundary character distribution and r-value of Nb + Ti stabilized ferritic stainless steel, Mater. Charact., 2009, 60, p 65–68

I. Jung, J. Mola, D. Chae, and B.C. De Cooman, Influence of the cold rolling and annealing sequence on the ridging behaviour of Ti-stabilized 18% Cr ferritic stainless steel, Steel Res. Int., 2010, 81, p 1089–1096

H.T. Liu, Study of microstructure, texture and formability of Cr17 ferritic stainless steel, Ph.D. Thesis, Northeastern University, 2009

M.R. Barnett and J.J. Jonas, Influence of ferrite rolling temperature on microstructure and texture in deformed low C and IF steels, ISIJ Int., 1997, 37, p 697–705

D. Vanderschueren, N. Yoshinaga, and K. Koyama, Recrystallization of Ti IF steel investigated with electron back-scattering pattern (EBSP), ISIJ Int., 1996, 36, p 1046–1054

J.J. Jonas, Effects of shear band formation on texture development in warm-rolled IF steels, J. Mater. Process. Technol., 2001, 117, p 293–299

M.Y. Huh, Y.S. Cho, J.S. Kim, and O. Engler, Effect of lubrication on the evolution of through-thickness textures gradients in cold rolled and recrystallized low carbon steel, Z. Metallkd., 1990, 90, p 124–131

R.K. Ray, J.J. Jonas, and R.E. Hook, Cold rolling and annealing textures in low carbon and extra low carbon steels, Int. Mater. Rev., 1994, 39, p 129–172

M. Hölscher, D. Raabe, and K. Lücke, Relationship between rolling textures and shear textures in f.c.c. and b.c.c. metals, Acta Metall. Mater., 1994, 42, p 879–886

R.P. Siqueira, H.R.Z. Sandim, T.R. Oliveira, and D. Raabe, Composition and orientation effects on the final recrystallization texture of coarse-grained Nb-containing AISI, 430 ferritic stainless steels, Mater. Sci. Eng. A, 2011, 528, p 3513–3519

D. Raabe, Z. Zhao, S.J. Park, and F. Roters, Theory of orientation gradients in plastically strained crystals, Acta Mater., 2002, 50, p 421–440

H. Inagaki, Fundamental aspect of texture formation in low carbon steel, ISIJ Int., 1994, 34, p 313–321

I. Tikhovskiy, D. Raabe, and F. Roters, Simulation of the deformation texture of a 17%Cr ferritic stainless steel using the texture component crystal plasticity FE method considering texture gradients, Scripta Mater., 2006, 54, p 1537–1542

S.-H. Hong and D.N. Lee, Recrystallization textures in cold-rolled Ti bearing IF steel sheets, ISIJ Int., 2002, 42, p 1278–1287

D. Raabe, Textures of strip cast and hot rolled ferritic and austenitic stainless steel, Mater. Sci. Technol., 1995, 11, p 461–468

D. Raabe and K. Lücke, Selective particle drag during primary recrystallization of Fe-Cr alloys, Scripta Metall., 1992, 26, p 19–24

M. Sánchez-Araiza, S. Godet, P.J. Jacques, and J.J. Jonas, Texture evolution during the recrystallization of a warm-rolled low-carbon steel, Acta Metall., 2006, 54, p 3085–3093

Z.D. Wang, Y.H. Guo, D.Q. Sun, X.H. Liu, and G.D. Wang, Texture comparison of an ordinary if steel and a high-strength IF steel under ferritic rolling and high-temperature coiling, Mater. Charact., 2006, 57, p 402–407

W.C. Jeong, Effect of hot-rolling temperature on microstructure and texture of an ultra-low carbon Ti-interstitial-free steel, Mater. Lett., 2008, 62, p 91–94

M.P. Butron-Guillen and J.J. Jonas, Effect of finishing temperature on hot band textures in an IF steel, ISIJ Int., 1996, 36, p 68–73

T. Senuma, H. Yada, R. Shimizu, and J. Harase, Textures of low carbon and titanium bearing extra low carbon steel sheets hot rolled below their A R3 temperatures, Acta Metall. Mater., 1990, 38, p 2673–2681

K. Verbeken, L. Keatens, and J.J. Jonas, Microtextural study of orientation change during nucleation and growth in a cold rolled ULC steel, Scripta Mater., 2003, 48, p 1457–1462

J.-I. Hamada, N. Ono, and H. Inoue, Effect of texture on r-value of ferritic stainless steel sheets, ISIJ Int., 2011, 51, p 1740–1748

S.Y. Li, X.M. Zhang, and G. Gottstein, Analysis and prediction of earing behavior in cup drawing of BCC metals by use of crystallographic method, ISIJ Int., 1999, 39, p 501–508

D. Raabe, Y. Wang, and F. Roters, Crystal plasticity simulation study on the influence of texture on earing in steel, Comp. Mater. Sci., 2005, 34, p 221–234

D. Daniel and J.J. Jonas, Measurement and prediction of plastic anisotropy in deep-drawing steels, Metall. Trans. A, 1990, 21, p 331–343

J.-I. Hamada, K. Agata, and H. Inoue, Estimation of planar anisotropy of the r-value in ferritic stainless steel sheets, Mater. Trans., 2009, 50, p 752–758

Acknowledgment

The present study is supported by the National Science & Technology Pillar Program during the Twelfth Five-Year Plan Period (No. 2012BAE04B02) and the National Natural Science Foundation of China (Nos. 51271050 and 51004035). RDKM gratefully acknowledges support from the University of Texas at El Paso, USA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, F., Yu, Fx., Misra, R.D.K. et al. Microstructure, Texture, and Deep Drawability Under Two Different Cold-Rolling Processes in Ferritic Stainless Steel. J. of Materi Eng and Perform 24, 3862–3880 (2015). https://doi.org/10.1007/s11665-015-1689-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1689-5