Abstract

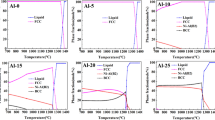

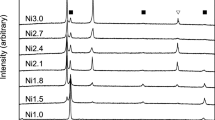

A newly designed composition of non-equiatomic Fe40Cr25Ni15Al15Co5 medium-entropy alloy (MEA) was produced by induction melting (IM). The as-cast alloy was found to consist of a two-phase microstructure of BCC (2.87 ± 0.01 Å) and ordered B2 (2.88 ± 0.02 Å) type phases. The structures of these phases were confirmed through X-ray diffraction (XRD) and transmission electron microscopy (TEM) techniques. It was observed that the Ni-Al-enriched ordered B2 phase of cuboidal shapes (~ 100 to 200 nm) is homogeneously distributed in Fe-Cr-rich BCC matrix with a cube-on-cube orientation relationship. The formation of the columnar dendrites (width 50 to 100 μm) was identified through optical microscopy (OM). The structural and microstructural stability of the alloy was investigated by heat-treating the alloy through different schedules. Heat-treated samples at different temperatures (< 1273 K) exhibit a similar type of two-phase microstructure with columnar dendrites. However, compositional rearrangement takes place during long time exposure to develop polymorphically related phases. The alloy was observed to possess a high compressive yield strength and hardness, i.e., ~ 1047 MPa and 391 ± 9 HV, respectively, at room temperature. Heat-treated samples at 600 °C and 900 °C (873 K and 1173 K) showed an increase in yield strength and ultimate strength with a significant increase in plasticity due to the increase in volume fraction of B2 phase and softening of the BCC matrix phase. The thermal stability and high strength of this alloy may open new avenues for high-temperature applications.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299–303.

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Mater. Sci. Eng. A, 2004, vol. 375–377, pp. 213–8.

E.J. Pickering and N.G. Jones: Int. Mater. Rev., 2016, vol. 61, pp. 183–202.

Y. Zhang, T. Ting, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z. Ping: Prog. Mater. Sci., 2014, vol. 61, pp. 1–93.

N.K. Mukhopadhyay: Curr. Sci., 2015, vol. 109, pp. 665–67.

J.W. Yeh: JOM, 2013, vol. 65, pp. 1759–71.

V. Shivam, Y. Shadangi, J. Basu, and N.K. Mukhopadhyay: J. Mater. Res., 2019, vol. 35, pp. 787–95.

W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai, and J.-W. Yeh: Intermetallics, 2012, vol. 26, pp. 44–51.

M. Vaidya, G.M. Muralikrishna, and B.S. Murty: J. Mater. Res., 2019, vol. 34, pp. 664–86.

T. Borkar, B. Gwalani, D. Choudhuri, C. V Mikler, C.J. Yannetta, X. Chen, R. V Ramanujan, M.J. Styles, M.A. Gibson, and R. Banerjee: Acta Mater., 2016, vol. 116, pp. 63–76.

F. Otto, Y. Yang, H. Bei, and E.P. George: Acta Mater., 2013, vol. 61, pp. 2628–38.

A.S. Sharma, S. Yadav, K. Biswas, and B. Basu: Mater. Sci. Eng. R, 2018, vol. 131, pp. 1–42.

M.H. Tsai and J.W. Yeh: Mater. Res. Lett., 2014, vol. 2, pp. 107–23.

D.B. Miracle and O.N. Senkov: Acta Mater., 2017, vol. 122, pp. 448–511.

C.Y. Hsu, T.S. Sheu, J.W. Yeh, and S.K. Chen: Wear, 2010, vol. 268, pp. 653–9.

S. Yadav, A. Kumar, and K. Biswas: Mater. Chem. Phys., 2018, vol. 210, pp. 222–32.

S. Praveen, J. Basu, S. Kashyap, and R.S. Kottada: J. Alloys Compd., 2016, vol. 662, pp. 361–7.

J. Chen, X. Zhou, W. Wang, B. Liu, Y. Lv, W. Yang, D. Xu, and Y. Liu: J. Alloys Compd., 2018, vol. 760, pp. 15–30.

Y. Zou, J.M. Wheeler, H. Ma, P. Okle, and R. Spolenak: Nano Lett., 2017, vol. 17, pp. 1569–74.

Y. Liang, L. Wang, Y. Wen, B. Cheng, Q. Wu, T. Cao, Q. Xiao, Y. Xue, G. Sha, Y. Wang, Y. Ren, X. Li, L. Wang, F. Wang, and H. Cai: Nat. Commun. 2018, 9, pp. 1–8.

D.G. Shaysultanov, G.A. Salishchev, Y. V Ivanisenko, S. V Zherebtsov, M.A. Tikhonovsky, and N.D. Stepanov: J. Alloys Compd., 2017, vol. 705, pp. 756–63.

Y. Ma, Q. Wang, B.B. Jiang, C.L. Li, J.M. Hao, X.N. Li, C. Dong, and T.G. Nieh: Acta Mater., 2018, vol. 147, pp. 213–25.

A. Munitz, S. Salhov, S. Hayun, and N. Frage: J. Alloys Compd., 2016, 683, pp. 221–30.

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi, and N.K. Mukhopadhyay: Adv. Powder Technol., 29(9), 2221-2230, 2018. doi:10.1016/j.apt.2018.06.006.

C.M. Lin and H.L. Tsai: Intermetallics, 2011, vol. 19, pp. 288–94.

J. Hao, Y. Ma, Q. Wang, C. Zhang, C. Li, C. Dong, Q. Song, and P.K. Liaw: Jounal Alloy. Compd., 2019, vol. 780, pp. 408–21.

F. Meng, J. Qiu, and I. Baker: Mater. Sci. Eng. A, 2013, vol. 586, pp. 45–52.

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, and Z.P. Lu: Acta Mater., 2016, vol. 102, pp. 187–96.

H. Jain, Y. Shadangi, V. Shivam, and D. Chakravarty, D Mukhopadhya, N.K Kumar: J. Alloys Compd. 2020, vol. 834, p. 155013.

A.R. Miedema, P.F. de Châtel, and F.R. de Boer: Phys. B, 1980, vol. 100, pp. 1–28.

S. Guo and C.T. Liu: Prog. Nat. Sci. Mater. Int., 2011, vol. 21, pp. 433–46.

M.J. Yao, K.G. Pradeep, C.C. Tasan, and D. Raabe: Scr. Mater., 2014, vol. 72–73, pp. 5–8.

S. Ghosh, J. Basu, D. Ramachandran, E. Mohandas, and M. Vijayalakshmi: Intermetallics, 2012, vol. 23, pp. 148–57.

E.A. Marquis and D.N. Seidman: Acta Mater., 2001, vol. 49, pp. 1909–19.

M.E. Thompson, C.S. Su, and P.W. Voorhees: Acta Metall., 1994, vol. 42, pp. 2107–22.

B.. Murty: High Entropy Alloy, 2014.

J. Basu and S. Ranganathan: Sadhana, 2003, vol. 28, pp. 783–98.

J. Basu and S. Ranganathan: Acta Mater., 2008, vol. 56, pp. 1899–907.

J. Basu and S. Ranganathan: Intermetallics, 2009, vol. 17, pp. 128–35.

J. Basu and S. Ranganathan: Intermetallics, 2004, vol. 12, pp. 1045–50.

Y. Zhou, X. Jin, L. Zhang, X. Du, and B. Li: Mater. Sci. Eng. A, 2018, vol. 716, pp. 235–9.

Acknowledgments

The authors are thankful to Prof. R.K Mandal, Dr. Manish Kumar Singh, Yagnesh Shadangi and Priyatosh Pradhan for their help and stimulating discussion during the course of this work. The authors are also grateful to the Advanced Research Centre for Iron and Steel (ARCIS) of the Institute funded by the Steel Development Fund, Ministry of Steel, India, for providing melting and XRD facilities. The authors would also like to acknowledge the DST-FIST funding for providing the electron microscopy facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 29, 2020; accepted February 7, 2021.

Rights and permissions

About this article

Cite this article

Shivam, V., Basu, J., Manna, R. et al. Local Composition Migration Induced Microstructural Evolution and Mechanical Properties of Non-equiatomic Fe40Cr25Ni15 Al15Co5 Medium-Entropy Alloy. Metall Mater Trans A 52, 1777–1789 (2021). https://doi.org/10.1007/s11661-021-06188-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06188-7