Abstract

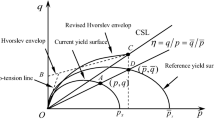

The results of a series of laboratory tests on unimproved and cement-improved specimens of two clays are presented, and the ability of a bounding surface elastoplastic constitutive model to predict the observed behavior is investigated. The results of the oedometer, triaxial compression, extension, and cyclic shear tests demonstrated that the unimproved soil behavior is similar to that of soft clays. Cement-improved specimens exhibited peak/residual behavior and dilation, as well as higher strength and stiffness over unimproved samples in triaxial compression. Two methods of accounting for the artificial overconsolidation effect created by cement improvement are detailed. The apparent preconsolidation pressure method is considerably easier to use, but the fitted OCR method gave better results over varied levels of confining stresses. While the bounding surface model predicted the monotonic behavior of unimproved soil very well, the predictions made for cyclic behavior and for improved soils were only of limited success.

Similar content being viewed by others

Abbreviations

- A c :

-

Shape parameter defining hyperbola section of bounding surface in compression

- A e :

-

Shape parameter defining hyperbola section of bounding surface in extension

- a w :

-

Cement content

- C :

-

Projection center parameter

- C c :

-

Virgin compression index

- C r :

-

Recompression index

- C C :

-

Coefficient of curvature

- C U :

-

Coefficient of uniformity

- D 50 :

-

Diameter in the grain size distribution curve corresponding to 50% passing

- e :

-

Void ratio

- h 2 :

-

Shape hardening parameter for states in immediate vicinity of I axis

- h c :

-

Shape hardening parameter in triaxial compression

- h e :

-

Shape hardening parameter in triaxial extension

- M c :

-

Slope of the critical state line in compression

- M e :

-

Slope of the critical state line in extension

- \(p^{{\prime }}\) :

-

Mean effective stress

- q :

-

Deviatoric stress

- \(q_{\text{n}}\) :

-

Normalized deviatoric stress

- R c :

-

Shape parameter defining ellipse 1 section of bounding surface in compression

- R e :

-

Shape parameter defining ellipse 1 section of bounding surface in extension

- S :

-

Elastic nucleus parameter

- S g :

-

Specific gravity

- T :

-

Shape parameter defining ellipse 2 section of bounding surface

- u :

-

Excess pore water pressure

- u n :

-

Normalized excess pore water pressure

- V soil :

-

Volume of soil solids

- W c :

-

Mass of cement

- W s :

-

Mass of soil solids

- W w,mix :

-

Mass of water in total improved soil sample

- W w,slurry :

-

Mass of water in slurry

- w:c :

-

Water-to-cement ratio

- w T:c :

-

Total water-to-cement ratio

- α :

-

Cement factor

- ε a :

-

Axial strain

- κ :

-

Slope of the recompression line in e versus ln(\(p^{{\prime }}\)) space

- λ :

-

Slope of the virgin compression line in e versus ln(\(p^{{\prime }}\)) space

- ν :

-

Poisson’s ratio

- σ b :

-

Back pressure

- \(\sigma_{ 1}^{{\prime }}\) :

-

Effective axial stress

- \(\sigma_{ 3}^{{\prime }}\) :

-

Effective confining stress

- \(\sigma_{\text{c}}^{{\prime }}\) :

-

Effective consolidation stress

- \(\sigma_{\text{p}}^{{\prime }}\) :

-

Effective preconsolidation pressure

- \(\sigma_{\text{v}}^{{\prime }}\) :

-

Effective vertical stress

- Apparent preconsolidation pressure:

-

The yield stress determined from improved specimen oedometer test results

- Fitted overconsolidation ratio (OCR):

-

The OCR value calibrated using test results by treating it as a constitutive model parameter

- Imposed OCR:

-

The OCR calculated from the maximum confining stress imposed during the consolidation phase and the confining stress prior to the start of the shear phase in a triaxial test

References

Abu-Farsakh M, Dhakal S, Chen Q (2015) Laboratory characterization of cementitiously treated/stabilized very weak subgrade soil under cyclic loading. Soils Found 55(3):504–516

Ahnberg H (2007) On yield stresses and the influence of curing stresses on stress paths and strength measured in triaxial testing of stabilized soils. Can Geotech J 44:54–66. doi:10.1139/t06-096

Andromalos K, Hegaxy Y, Jasperse B (2001) Stabilization of soft soils by soil mixing. In: Soft ground technology (GSP 112), pp 194–205. doi:10.1061/40552(301)16

Arroyo M, Ciantia M, Castellanza R, Gens A, Nova R (2012) Simulation of cement-improved clay structures with a bonded elasto-plastic model: a practical approach. Comput Geotech 45:140–150

Arroyo M, Castellanza MC, Gens A (2011) A soft-rock model for cement-improved clays. In: 15th European conference of soil mechanics and foundation engineering, pp 501–506

Asaoka A, Nakano M, Nora T (2000) Superloading yield surface concept for highly structured soil behaviour. Soils Found 40(2):99–110

Baudet B, Stallebrass S (2004) A constitutive model for saturated clays. Géotechnique 54(4):269–278

Bruce MEC, Berg RR, Collin JG, Filz GM, Terashi M, Yang DS (2013) Federal Highway Administration design manual: deep mixing for embankment and foundation support, Report No. FHWA-HRT-13-046. Federal Highway Administration, Washington

Dafalias YF, Herrmann LR (1986) Bounding surface plasticity II: application to isotropic cohesive soils. J Eng Mech 112(12):1263–1291. doi:10.1061/(ASCE)0733-9399(1986)112:12(1263)

Filz GM, Hodges DE, Weatherby DE, Marr WA (2005) Standardized definitions and laboratory procedures for soil–cement specimens applicable to the wet method of deep mixing. In: Innov grouting soil improv (GSP 136), pp 1–13. doi:10.1061/40783(162)1

Fleming BJ, Sritharan S, Miller GA, Muraleetharan KK (2016) Full-scale seismic testing of piles in improved and unimproved soft clay. Earthq Spectra 32(1):239–265. doi:10.1193/012714EQS018M

Gonzalez NA, Gens A, Arroyo M, Rouainia M (2011) A structured constitutive model for simulating the behaviour of an overconsolidated bonded clay. In: 9th international conference on computational plasticity, fundamentals and applications, pp 2–12

Hodges DK, Filz GM, Weatherby DE (2008) Laboratory mixing, curing, and strength testing of soil–cement specimens applicable to the wet method of deep mixing, CGPR Report No. 48. Virginia Tech Center for Geotechnical Practice and Research, Blacksburg, Virginia

Horpibulsuk S, Liu MD, Liyanapathirana DS, Suebsuk J (2010) Behaviour of cemented clay simulated via the theoretical framework of the structured Cam clay model. Comput Geotech 37:1–9

Japanese Geotechnical Society (2000) Practice for making and curing stabilized soil specimens without compaction, JGS T 0821-2000. Japanese Geotechnical Society, Tokyo

Kaliakin VN, Dafalias YF, Herrmann LR (1987) Time dependent bounding surface model for isotropic cohesive soils: notes for a short course. In: Second International Conference on Constitutive Laws for Engineering Materials: THEORY and APPLICATION, Tucson, Arizona

Kamruzzaman AHM, Chew SH, Lee FH (2009) Structuration and destructuration behavior of cement-treated Singapore marine clay. J Geotech Geoenviron Eng 135:573–589. doi:10.1061/(ASCE)1090-0241(2009)135:4(573)

Kasama K, Ochiai H, Yasufuku N (2000) On the stress–strain behaviour of lightly cemented clay based on an extended critical state concept. Soils Found 40(5):37–47

Kavvadas M, Amorosi A (2000) A constitutive model for structured soils. Géotechnique 50(3):263–273

Kirupakaran K, Cerato AB, Liu C, Miller GA, Muraleetharan KK, Pinilla JD, Price S, Thompson ZM (2010) Simulation of a centrifuge model test of pile foundations in CDSM improved soft clays. In: GeoFlorida 2010: adv anal, model des (GSP 199), pp 1583–1591

Lapointe E, Fannin J, Wilson B (2012) Cement-treated soil: variation of UCS with soil type. In: Grouting deep mixing 2012 (GSP 228), pp 512–521. doi:10.1061/9780784412350.0037

Lee K, Chan D, Lam K (2004) Constitutive model for cement treated clay in a critical state framework. Soils Found 44(3):69–77

Lee KH, Lee S (2002) Mechanical Properties of Weakly Bonded Cement Stabilized Kaolin. KSCE J Civ Eng 6(4):389–398. doi:10.1007/BF02841993

Liu MD, Carter JP (2000) Modelling the destructuring of soils during virgin compression. Géotechnique 50(4):479–483

Liu C, Soltani H, Muraleetharan KK, Cerato AB, Miller GA, Sritharan S (2016) Cyclic and seismic response of single piles in improved and unimproved soft clays. Acta Geotech 11:1431–1444. doi:10.1007/s11440-016-0504-2

Liu C, Soltani H, Pinilla JD, Muraleetharan KK, Cerato AB, Miller GA (2011) Centrifuge investigation of seismic behavior of pile foundations in soft clays. Geo-Frontiers 2011:585–594. doi:10.1061/41165(397)61

Liu MD, Carter JP, Horpibulsuk S, Liyanapathirana DS (2006) Modelling the behavior of cemented clay. In: Ground modif seism mitig (GSP 152), pp 65–72

Liu C, Soltani H, Muraleetharan K, Cerato C, Miller GA, Sritharan S (2014) Cyclic loading of single piles—centrifuge model No. 1. Network for earthquake engineering simulation (distributor), Dataset. doi:10.4231/D3S46H66Q

Liu C, Soltani H, Muraleetharan K, Cerato A, Miller GA, Sritharan S (2014) Dynamic loading of single piles—centrifuge model No. 2. Network for earthquake engineering simulation (distributor), Dataset. doi:10.4231/D31N7XN5R

Lorenzo GA, Bergado DT (2004) Fundamental parameters of cement-admixed clay—new Approach. J Geotech Geoenviron Eng 130:1042–1050. doi:10.1061/(ASCE)1090-0241(2004)130:10(1042)

Miura N, Horpibulsuk S, Nagaraj TS (2001) Engineering behavior of cement stabilized clay at high water content. Soils Found 45(5):33–45

Muraleetharan KK, Ravichandran N, Taylor LM (2003) TeraDysac: TeraScale dynamic soil analysis code. Computer Code, School of Civil Engineering and Environmental Science, University of Oklahoma, Norman

Nguyen LD, Fatahi B, Khabbaz H (2014) A constitutive model for cemented clays capturing cementation degradation. Int J Plast 56:1–18

Nova R, Castellanza R, Tamagnini C (2003) A constitutive model for bonded geomaterials subject to mechanical and/or chemical degradation. Int J Numer Anal Methods Geomech 27(9):705–732

Panico F, Viana da Fonseca A (2016) Long term cyclic response of a soil–cement mixture: experimental study and modelling. Procedia Eng 143:178–186. doi:10.1016/j.proeng.2016.06.023

Porbaha A, Shibuya S, Kishida T (2000) State of the art in deep mixing technology. Part III: geomaterial characterization. Ground Improv 4(3):91–110. doi:10.1680/grim.2000.4.3.91

Porbaha A, Tanaka H, Kobayashi M (1998) State of the art in deep mixing technology: part II. Applications. Ground Improv 2(3):125–139. doi:10.1680/gi.1998.020303

Porbaha AA (2006) Recent advances in deep mixing research and development in the USA. In: Ground modif seism mitig (GSP 152), pp 45–50. doi:10.1061/40864(196)7

Quiroga AJ (2013) Modeling of pile foundations in unimproved and cement-improved soft clays: laboratory testing and field validation. Thesis, University of Oklahoma

Ravichandran N (2005) A framework-based finite element approach for solving large deformation problems in multi-phase porous media. Dissertation, School of Civil Engineering and Environmental Science, University of Oklahoma

Rouainia M, Muir Wood D (2000) A kinematic hardening constitutive model for natural clays with loss of structure. Géotechnique 50(2):153–164

Sheeran DE, Krizek RJ (1971) Preparation of homogeneous soil samples by slurry consolidation. J Mater 6(2):356–373

Shen S, Xu Y, Han J, Zhang J (2012) A ten-year review on the development of soil mixing technologies in China. In: Grouting deep mixing 2012 (GSP 228), pp 343–356. doi:10.1061/9780784412350.0020

Shrestha R, Al-Tabbaa A (2012) Development of predictive models for cement stabilized soils. In: Grouting deep mixing 2012 (GSP 228), pp 221–230. doi:10.1061/9780784412350.0008

Suebsuk J, Horpibulsuk S, Liu MD (2010) Modified structured Cam clay: a generalized critical state model for destructured, naturally structured and artificially structured clays. Comput Geotech 37:956–968

Suebsuk J, Horpibulsuk S, Liu MD (2011) A critical state model for overconsolidated structured clays. Comput Geotech 38:648–658

Taghavi A, Miller G, Muraleetharan K (2010) NEES-pilEs full-scale field testing in Miami, Oklahoma: geotechnical site investigation report, technical report. School of Civil Engineering and Environmental Science, University of Oklahoma, Norman

Taghavi A, Muraleetharan KK, Miller GA, Cerato AB (2016) Centrifuge modeling of laterally loaded pile groups in improved soft clay. J Geotech Geoenviron Eng 142(4):1–13. doi:10.1061/(ASCE)GT.1943-5606.0001443

Taghavi A, Muraleetharan K, Miller G, Cerato A (2013) Seismic and cyclic lateral load tests of pile groups and single piles—centrifuge model No. 4. Network for earthquake engineering simulation (distributor), Dataset. doi:10.4231/D39P2W61H

Taghavi A (2015) Seismic and quasi-static lateral load behavior of groups in improved soft clay: centrifuge and numerical modeling. Dissertation, University of Oklahoma

Taiebat M, Dafalias YF, Peek R (2010) A destructuration theory and its application to SANICLAY model. Int J Numer Anal Methods Geomech 34:1009–1040

Tatsuoka F, Kobayashi A (1983) Triaxial strength characteristics of cement-treated soft clay. In: Proceedings of the 8th European conference of SMFE, pp 421–426

Thompson ZM (2011) Stress–Strain behavior of unimproved and cement-improved soft clays. Thesis, University of Oklahoma

Uddin K, Balasubramaniam AS, Bergado DT (1997) Engineering behavior of cement-treated Bangkok soft clay. Geotech Eng 28(1):89–119

Upadhyaya S, Tiwari B, Olgun G (2016) Static and dynamic properties of compacted soil–cement mixtures. Geotech Struct Eng Congr 2016:1646–1654

Vatsula A, Nova R, Srinivasa M (2001) Elastoplastic model for cemented soils. J Geotech Geoenviron Eng 127(8):679–687

Viana da Fonseca A, Rios S, Amaral MF, Panico F (2013) Fatigue cyclic tests on artificially cemented soil. Geotech Test J 36(2):227–235. doi:10.1520/GTJ20120113

Xiao H, Lee FH, Liu Y (2016) Bounding surface Cam-clay model with cohesion for cement-admixed clay. Int J Geomech 17:04016026

Yin JH (2001) Stress–strain–strength characteristics of soft Hong Kong marine deposits without or with cement treatment. Lowl Technol Inst 3(1):1–13

Acknowledgements

This project was funded by a U.S. National Science Foundation (NSF) George E. Brown, Jr. Network for Earthquake Engineering Simulation Research (NEESR) Grant (Grant No. CMMI-0830328). The first author was also funded by two fellowships from NSF (through Grant Nos. HRD-1249206 and HRD-0902027). This support from NSF is gratefully acknowledged. Any opinions, findings, and conclusions or recommendations expressed in this paper are those of the authors and do not necessarily reflect the views of NSF. Hoda Soltani’s contribution to some of the laboratory tests presented in this paper is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quiroga, A.J., Thompson, Z.M., Muraleetharan, K.K. et al. Stress–strain behavior of cement-improved clays: testing and modeling. Acta Geotech. 12, 1003–1020 (2017). https://doi.org/10.1007/s11440-017-0529-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-017-0529-1