Abstract

Purpose

End-of-life (EoL) modelling in life cycle assessment has already been broadly discussed within several studies. However, no consensus has been achieved on how to model recycling in LCA, even though several approaches have been developed. Within this paper, results arising from the application of two new EoL formulas, the product environmental footprint (PEF) and the multi-recycling-approach (MRA) ones, are compared and discussed. Both formulas consider multiple EoL scenarios such as recycling, incineration and landfill.

Methods

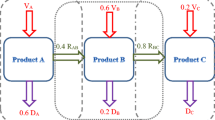

The PEF formula has been developed within the PEF programme whose intent is to define a harmonized methodology to evaluate the environmental performance of products. The formula is based on a 50:50 allocation approach, as burdens and benefits associated with recycling are accounted for a 50% rate. The MRA formula has been developed to change focus from products to materials. Recycling cycles and material losses over time are considered with reference to material pools. Allocation between systems is no longer needed, as the actual number of potential life cycles for a certain material is included in the calculation. Both the approaches have been tested within two case studies.

Results and discussion

Methodological differences could thereof be determined, as well as applicability concerns, due to the type of data required for each formula. As far as the environmental performance is concerned, impacts delivered by MRA are lower than those delivered by PEF for aluminium, while the opposite happens for plastic and rubber due to the higher share of energy recovery accounted in PEF formula. Stainless steel impacts are almost the same.

Conclusions and recommendations

The application of the two formulas provides some inputs for the EoL dilemma in LCA. The use of a wider perspective, better reflecting material properties all over the material life cycle, is of substantial importance to properly represent recycling situations. In MRA, such properties are treated and less data are required compared to the PEF formula. On the contrary, the PEF model better accommodates the modelling of products whose materials, at end of life, can undertake the route of recycling or recovery (or landfill), depending on country-specific EoL management practices. However, its application requires more data.

Similar content being viewed by others

References

Allacker K, Mathieux F, Manfredi S et al (2014) Allocation solutions for secondary material production and end of life recovery: proposals for product policy initiatives. Resour Conserv Recycl 88:1–12

Ardente F, Cellura M (2012) Economic allocation in life cycle assessment. J Ind Ecol 16:387–398

Ardente F, Wolf M (2011) Integration of resource efficiency and waste management criteria in the implementing measures under the ecodesign directive. Final Exec Summ. doi:10.2788/72577

Baumann H, Tillman A-M (2004) The hitch hiker’s guide to LCA. An orientation in life cycle assessment methodology and application. External organization

Brems A, Baeyens J, Dewil R (2012) Recycling and recovery of post-consumer plastic solid waste in a European context. Therm Sci 16:669–685

British Glass (2007) GLASS : Society and the Environment

Buchert T, Steingrimsson JG, Neugebauer S et al (2015) Design and manufacturing of a sustainable pedelec. Procedia CIRP 29:579–584

Bundesverband Sekundärrohstoffe und Entsorgung e.V (2011) Market report plastics

Buxmann K, Furrer P, Gerber J, et al. (2006) Aluminium recycling in Europe. In: Eur. Alum. Assoc

Calkins M (2008) Materials for sustainable sites. John Wiley & Sons, Inc., Hoboken, New Jersey

Chang RJ, Mori H, Yang W (2010) Polyphenylene Sulfide (Pps) Market Study

Chatterjee K K. (2007) Uses of metals and metallic minerals. New age international publishers

Cherry CR, Weinert JX, Xinmiao Y (2009) Comparative environmental impacts of electric bikes in China. Transp Res Part D Transp Environ 14:281–290

Dufour D (2010) Promoting cycling for everyone as a daily transport mode

Dufrene M, Zwolinski P, Brissaud D (2013) CIRP Annals - Manufacturing Technology An engineering platform to support a practical integrated eco-design methodology. CIRP Ann - Manuf Technol 1016–1019

Dunn JB, Gaines L, Barnes M, Sullivan J, Wang M (2013) Material and energy flows in the materials production, assembly, and end-of-life stages of the automotive lithium-ion battery life cycle. J Chem Inf Model 53:1689–1699

European aluminium association (2013) Sustainability of the European aluminium industry

European Commission (2006) Regulation (EC) concerning the registration, evaluation, authorisation and restriction of chemicals (REACH), establishing a European chemicals agency, amending directive 1999/45/EC and repealing council regulation (EEC) no 793/93 and commission regulation. Off J Eur Union l396/1. doi: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:396:0001:0849:EN:PDF

European Commission (2009) Directive 2009/125/EC of the European Parliament and the council of 21 October 2009 establishing a framework for the setting of ecodesign requirements for energy-related products (recast) (Text. Off J Eur Union 26

European Commission (2010) International reference life cycle data system (ILCD) handbook—general guide for life cycle assessment—detailed guidance

European Commission (2011) EC communication: roadmap to a resource efficient europe. 32. doi: COM(2011) 571 final

European Commission (2013) Commission recommendation of 9 April 2013 on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations. Off J Eur Union 210

European Commission (2014) Guidance for the implementation of the EU product environmental footprint (PEF) during the environmental footprint (EF) pilot phase. 1–55

European Parliament (2011) Directive 2011/65/EU of the European Parliament and of the council of 8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS). Off J Eur Union 54:88–110

European Parliament (2012) Directive 2012/19/EU of the European Parliament and of the council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off J Eur Union 38–71

European Tyre & Rubber manufacturers association (Etrma) (2011) End of life tyres—a valuable resource with growing potential

Eurostat (2010) Treatment of waste

Eurostat (2014) Price developments and volume trade of paper waste EU-28. http://epp.eurostat.ec.europa.eu/portal/page/portal/waste/documents/websheet_paper_15042014.pdf

Finkbeiner M (2013) Product environmental footprint—breakthrough or breakdown for policy implementation of life cycle assessment? Int J Life Cycle Assess 19:266–271

Finkbeiner M (2014) Background and future prospects in life cycle assessment. In: Klöpffer W (ed). Springer Netherlands, Dordrecht, pp 85–106

Finkbeiner M, Neugebauer S, Berger M (2013) Carbon footprint of recycled biogenic products: the challenge of modelling CO2 removal credits. Int J Sustain Eng 6:66–73

Finkbeiner M, Ackermann R, Bach V et al. (2014) Background and future prospects in life cycle assessment. In: Klöpffer W (ed). Springer Netherlands, Dordrecht, pp 207–258

Finnveden G, Hauschild MZ, Ekvall T et al (2009) Recent developments in life cycle assessment. J Environ Manag 91:1–21

Frischknecht R (2010) LCI modelling approaches applied on recycling of materials in view of environmental sustainability, risk perception and eco-efficiency. Int J Life Cycle Assess 15:666–671

Galatola M, Pant R (2014) Reply to the editorial “product environmental footprint—breakthrough or breakdown for policy implementation of life cycle assessment?” written by Prof. Finkbeiner (Int J life cycle assess 19(2):266-271). Int J Life Cycle Assess 19:1356–1360

Glass for Europe (2010) Recyclable waste flat glass in the context of the development of end-of-waste criteria glass

Glass for Europe (2012) Europe’s flat glass industry in a competitive low carbon economy

Glass for Europe (2014a) EU waste legislation & building glass recycling

Glass for Europe (2014b) Glass for Europe’s industrial renaissance

Graedel TE, Julian A, Jean-Pierre B, et al. (2011) Recycling rates of metals—a status report

Green Public Procurement (2010) Windows technical background report

Hashimoto S, Daigo I, Eckelman M, Reck B (2010) Measuring the status of stainless steel use in the Japanese socio-economic system. Resour Conserv Recycl 54:737–743

ISO (2006a) ISO 14040:2006, Environmental management—life cycle assessment—principles and framework. 40

ISO (2006b) ISO 14044:2006 Environmental management—life cycle assessment—requirements and guidelines. Environ Manag - Life cycle Assess - Princ Framew 46

ISO (2012) Environmental labels and declarations—self-declared environmental claims (type II environmental labelling) (ISO 14021:2012)

Karak T, Bhagat RM, Bhattacharyya P (2012) Municipal solid waste generation, composition, and management: the world scenario. Crit Rev Environ Sci Technol 42:1509–1630

Kaufman AS, Meier PJ, Sinistore JC, Reinemann DJ (2010) Applying life-cycle assessment to low carbon fuel standards-how allocation choices influence carbon intensity for renewable transportation fuels. Energy Policy 38:5229–5241

Kiwa (2010) Rubber consultancy & lifetime prediction

Krömer S, Kreipe E, Reichenbach D, Stark R (1999) Life cycle assessment of a car tyre

Kuhlke B, Walsh T World plastic market review

Kumar H, Azapagic A, Schepelmann P, Ritthoff M (2010) Options for broadening and deepening the LCA approaches. J Clean Prod 18:120–127

Liu S, Cao W, Fang J, Shang S (2009) Variance analysis and performance evaluation of different crumb rubber modified (CRM) asphalt. Constr Build Mater 23:2701–2708

Menzie WD, Soto-Viruet Y, Bermudez-Lugo O et al. (2013) Review of selected global mineral industries in 2011 and an outlook to 2017. 33

Morris J (1996) Recycling versus incineration: an energy conservation analysis. J Hazard Mater 47:277–293

Muchová L, Eder P (2010) End-of-waste Criteria for Iron and Steel Scrap: Technical Proposals

Nakamura S, Kondo Y, Matsubae K et al (2012) Quality- and dilution losses in the recycling of ferrous materials from end-of-life passenger cars: input-output analysis under explicit consideration of scrap quality. Environ Sci Technol 46:9266–9273

Neugebauer S, Finkbeiner M (2012) The multi-recycling-approach as a new option to deal with end-of-life allocation dilemma

Neugebauer S, Chang Y, Maliszewski M et al. (2013a) Life cycle sustainability assessment & sustainable product development: a case study on pedal electric cycles (pedelec). Proc of11th glob conf sustain manuf 549–554

Neugebauer S, Finkbeiner M, Volkhausen W, Mecke SGE (2013b) Umweltbewertung von Stahl – neue Ökobilanz berücksichtigt Multirecycling des Werkstoffs, Stahl und Eisen. Stahlleisen 7:49–55

Nordelöf A, Messagie M, Tillman AM et al (2014) Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—what can we learn from life cycle assessment? Int J Life Cycle Assess 19:1866–1890

Pelletier N, Tyedmers P (2011) An ecological economic critique of the use of market information in life cycle assessment research. J Ind Ecol 15:342–354

PlasticsEurope (2015) ISSUU—plastics—the facts 2014/2015 by PlasticsEurope. 1–34

Ramani K, Ramanujan D, Bernstein WZ et al (2010) Integrated sustainable life cycle design: a review. J Mech Des 132:091004. doi:10.1115/1.4002308

Reale F, Buttol P, Cortesi S et al (2015) Dealing with LCA modeling for the end of life mechatronic products. Environ Eng Manag J 14:1691–1704

Rebitzer G, Ekvall T, Frischknecht R et al (2004) Life cycle assessment part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30:701–720

Reck BK, Chambon M, Hashimoto S, Graedel TE (2010) Global stainless steel cycle exemplifies China’s rise to metal dominance. Environ Sci Technol 44:3940–3946

Saner D, Walser T, Vadenbo CO (2012) End-of-life and waste management in life cycle assessment—Zurich, 6 December 2011. Int J Life Cycle Assess 17:504–510

Schluep M, Streicher M, Morf L, Buser A (2009) Recycling of plastics from waste electrical and electronic equipment (WEEE)—tentative results of a Swiss study

Shaw BD, Staff ERJ (2011) Why is recycled rubber not used in tyres? pp 34–37

Singapore Exchange (2014) Modification of SICOM TSR20 rubber futures contract, SICOM RSS3 rubber futures contract and SICOM OTC TSR20 rubber contract

Steel Recycling Institute (2012) Steel takes LEED® with recycled content modern steel production technologies. www.recycle-steel.org

Steel Recycling Institute (2013) 2013 steel recycling rates steel: North America’s most recycled material 2013 steel reinforcement rate. http://www.recycle-steel.org/∼/media/Files/SRI/Releases/Steel Recycling Rates Sheet.pdf?la = en

UNEP, Reuter M (2013) Metal recycling: opportunities, limits, infrastructure

United States Environmental Protection Agency (2012) Municipal solid waste generation, recycling, and disposal in the United States: facts and figures for 2012. 1–14

Vefago LHM, Avellaneda J (2013) Recycling concepts and the index of recyclability for building materials. Resour Conserv Recycl 72:127–135

Velis CA (2014) Global recycling markets—plastic waste: a story for one player—China. Report prepared by FUELogy and formatted by D-waste on behalf of International Solid Waste Association—Globalisation and Waste Management Task Force

Verhoef EV, Dijkema GPJ, Reuter MA (2004) Process knowledge, system dynamics, and metal ecology. J Ind Ecol 8:23–43

Vieitez ER, Eder P, Villanueva A et al. (2011) End-of-waste criteria for glass cullet: technical proposals

Visvanathan C (2004) Mechanical biolgical pre-treatment of solid waste prior to landfill. 1–10

Wäger PA, Hischier R, Eugster M (2011) Environmental impacts of the Swiss collection and recovery systems for waste electrical and electronic equipment (WEEE): a follow-up. Sci Total Environ 409:1746–1756

Wardenaar T, Van Ruijven T, Beltran AM et al (2012) Differences between LCA for analysis and LCA for policy: a case study on the consequences of allocation choices in bio-energy policies. Int J Life Cycle Assess 17:1059–1067

Worldsteel Association (2014) World steel in figures. 29

Zeng X, Li J, Singh N (2014) Recycling of spent lithium-ion battery: a critical review. Crit Rev Environ Sci Technol 44:1129–1165

Acknowledgements

The paper has been possible thanks to the research project G.EN.ESI funded by the European Community’s 7th Framework Programme (NMP.2011.3.1-1-280371—www.genesi-fp7.eu).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Hans-Jürgen Garvens

Rights and permissions

About this article

Cite this article

Mengarelli, M., Neugebauer, S., Finkbeiner, M. et al. End-of-life modelling in life cycle assessment—material or product-centred perspective?. Int J Life Cycle Assess 22, 1288–1301 (2017). https://doi.org/10.1007/s11367-016-1237-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-016-1237-z