Abstract

The solid particle erosion of polymers occurs in a wide variety of industries and has been extensively studied experimentally. However, numerical models capable of accurately simulating the associated material removal mechanisms and predicting erosion rate do not yet exist. In this paper, a coupled smoothed particle hydrodynamics (SPH)/finite element (FE) model was developed to simulate the erosion of an epoxy by successive overlapping impacts of angular 22 µm, 97 µm and 152 µm silicon carbide particles at various angles of attack. The epoxy was modeled using a strain-rate-dependent elastic–plastic material model that fails at a critical plastic strain. It was found that, once the critical plastic strain was calibrated using a single experiment, the numerical model could predict both the length of the incubation period and the steady-state erosion rate to within 6% and 11%, respectively, of the measured values. It was found that fundamental material removal mechanisms such as cutting, ploughing and the accumulation of plastic deformation due to multiple overlapping impacts were all successfully simulated. Overall, it has been demonstrated that numerical models can be used to investigate the effect of influential parameters on the solid particle erosion of a polymer. This may have important implications for the development of effective methods to improve the erosion resistance of polymers.

[38]

Similar content being viewed by others

References

Tilly, G.P.: Erosion caused by airborne particles. Wear 14, 63–79 (1969)

Fried, J.R.: Polymers in Aerospace Applications. Smithers Rapra, Shrewsbury (2010)

Bull, S.J.: Tribological and micro-tribological phenomena in coatings. In: Materials Science Forum, pp. 105–152. Trans Tech Publ, Uetikon (1997)

Miyazaki, N.: Solid particle erosion of composite materials: a critical review. J. Compos. Mater. 27, 1–8 (2015)

Ratner, S.B., Styller, E.E.: Characteristics of impact friction and wear of polymeric materials. Wear 73, 213–234 (1981)

Rajesh, J.J., Bijwe, J., Tewari, U.S., Venkataraman, B.: Erosive wear behavior of various polyamides. Wear 249, 702–714 (2001)

Barkoula, N.-M., Gremmels, J., Karger-Kocsis, J.: Dependence of solid particle erosion on the cross-link density in an epoxy resin modified by hygrothermally decomposed polyurethane. Wear 247, 100–108 (2001)

Böhm, H., Betz, S., Ball, A.: The wear resistance of polymers. Tribol. Int. 23, 399–406 (1990)

Brandstädter, A., Goretta, K.C., Routbort, J.L., Groppi, D.P., Karasek, K.R.: Solid-particle erosion of bismaleimide polymers. Wear 147, 155–164 (1991)

Wang, Y.-F., Yang, Z.-G.: A coupled finite element and meshfree analysis of erosive wear. Tribol. Int. 42, 373–377 (2009)

Wang, Y.F., Yang, Z.G.: Finite element model of erosive wear on ductile and brittle materials. Wear 265, 871–878 (2008)

Liu, Z.G., Wan, S., Nguyen, V.B., Zhang, Y.W.: A numerical study on the effect of particle shape on the erosion of ductile materials. Wear 313, 135–142 (2014)

Hutchings, I.M.: Deformation of metal surfaces by the oblique impact of square plates. Int. J. Mech. Sci. 19, 45–52 (1977)

Papini, M., Spelt, J.K.: Impact of rigid angular particles with fully-plastic targets. Part II: parametric study of erosion phenomena. Int. J. Mech. Sci. 42, 1007–1025 (2000)

Papini, M., Spelt, J.K.: Impact of rigid angular particles with fully-plastic targets. Part I: analysis. Int. J. Mech. Sci. 42, 991–1006 (2000)

Takaffoli, M., Papini, M.: Numerical simulation of solid particle impacts on Al6061-T6 part I: three-dimensional representation of angular particles. Wear 292–293, 100–110 (2012)

Takaffoli, M., Papini, M.: Numerical simulation of solid particle impacts on Al6061-T6 Part II: materials removal mechanisms for impact of multiple angular particles. Wear 296, 648–655 (2012)

Leguizamón, S., Jahanbakhsh, E., Alimirzazadeh, S., Maertens, A., Avellan, F.: FVPM numerical simulation of the effect of particle shape and elasticity on impact erosion. Wear 430–431, 108–119 (2019)

Zhang, N., Yang, F., Li, L., Shen, C., Castro, J., Lee, L.J.: Thickness effect on particle erosion resistance of thermoplastic polyurethane coating on steel substrate. Wear 303, 49–55 (2013)

Ashrafizadeh, H., McDonald, A., Mertiny, P.: Development of a finite element model to study the effect of temperature on erosion resistance of polyurethane elastomers. Wear 390–391, 322–333 (2017)

Patnaik, A., Kaundal, R., Satapathy, A., Biswas, S., Kumar, P.: Solid particle erosion of particulate filled short glass fiber reinforced polyester resin composites. Adv. Mater. Res. 123–125, 213–216 (2010)

Deliwala, A.A., Peter, M.R., Yerramalli, C.S.: A multiple particle impact model for prediction of erosion in carbon-fiber reinforced composites. Wear 406–407, 185–193 (2018)

Tewari, U.S., Harsha, A.P., Häger, A.M., Friedrich, K.: Solid particle erosion of carbon fibre–and glass fibre–epoxy composites. Compos. Sci. Technol. 63, 549–557 (2003)

Dorogoy, A., Rittel, D., Brill, A.: Experimentation and modeling of inclined ballistic impact in thick polycarbonate plates. Int. J. Impact Eng. 38, 804–814 (2011)

Dar, U.A., Zhang, W.: Polymer based aerospace structures under high velocity impact applications; experimental, constitutive and finite element analysis. J. Mech. Sci. Technol. 29, 4259–4265 (2015)

Duan, Y., Saigal, A., Greif, R., Zimmerman, M.A.: A uniform phenomenological constitutive model for glassy and semicrystalline polymers. Polym. Eng. Sci. 41, 1322–1328 (2001)

Johnson, G.R.: A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In: Proceedings of the 7th Internatonal Symposium on Ballistics, pp. 541–547 (1983)

G’sell, C., Jonas, J.J.: Determination of the plastic behaviour of solid polymers at constant true strain rate. J. Mater. Sci. 14, 583–591 (1979)

Matsuoka, S.: Nonlinear viscoelastic stress—strain relationships in polymeric solids. In: Failure of Plastics, pp. 24–59. Carl Hanser Verlag, Munich (1986)

Brooks, J.W.: Processing wrought nickel and titanium superalloy, thermo-mechanical processing: theory, modeling and practice. In: A conference organized in celebration of the 75th anniversary of the Swedish Society for Material Technology (1996)

Louche, H., Piette-Coudol, F., Arrieux, R., Issartel, J.: An experimental and modeling study of the thermomechanical behavior of an ABS polymer structural component during an impact test. Int. J. Impact Eng. 36, 847–861 (2009)

Arani, N.H., Rabba, W., Papini, M.: Solid particle erosion of epoxy matrix composites reinforced by Al2O3 spheres. Tribol. Int. 136, 432–445 (2019)

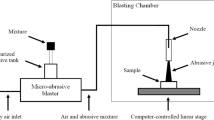

Ghobeity, A., Getu, H., Krajac, T., Spelt, J.K., Papini, M.: Process repeatability in abrasive jet micro-machining. J. Mater. Process. Technol. 190, 51–60 (2007)

Dehnadfar, D., Friedman, J., Papini, M.: Laser shadowgraphy measurements of abrasive particle spatial, size and velocity distributions through micro-masks used in abrasive jet micro-machining. J. Mater. Process. Technol. 212, 137–149 (2012)

Walley, S.M., Field, J.E.: The erosion and deformation of polyethylene by solid-particle impact. Philos. Trans. R. Soc. Lond. Ser. A 321, 277–303 (1987)

Takaffoli, M., Papini, M.: Material deformation and removal due to single particle impacts on ductile materials using smoothed particle hydrodynamics. Wear 274–275, 50–59 (2012)

Halquist, J.: LS-DYNA keyword user’s manual version 971. Livermore, California (2007)

Jordan, J.L., Foley, J.R., Siviour, C.R.: Mechanical properties of Epon 826/DEA epoxy. Mech. Time-Dependent Mater. 12, 249–272 (2008)

Iwamoto, T., Nagai, T., Sawa, T.: Experimental and computational investigations on strain rate sensitivity and deformation behavior of bulk materials made of epoxy resin structural adhesive. Int. J. Solids Struct. 47, 175–185 (2010)

Poulain, X., Benzerga, A.A., Goldberg, R.K.: Finite-strain elasto-viscoplastic behavior of an epoxy resin: experiments and modeling in the glassy regime. Int. J. Plast. 62, 138–161 (2014)

Goglio, L., Peroni, L., Peroni, M., Rossetto, M.: High strain-rate compression and tension behaviour of an epoxy bi-component adhesive. Int. J. Adhes. Adhes. 28, 329–339 (2008)

Hadavi, V., Moreno, C.E., Papini, M.: Numerical and experimental analysis of particle fracture during solid particle erosion, part I: modeling and experimental verification. Wear 356, 135–145 (2016)

Hadavi, V., Michaelsen, B., Papini, M.: Measurements and modeling of instantaneous particle orientation within abrasive air jets and implications for particle embedding. Wear 336–337, 9–20 (2015)

Hadavi, V., Arani, N.H., Papini, M.: Numerical and experimental investigations of particle embedment during the incubation period in the solid particle erosion of ductile materials. Tribol. Int. 129, 38–45 (2019)

McKellop, H., Clarke, I., Markolf, K., Amstutz, H.: Friction and wear properties of polymer, metal, and ceramic prosthetic joint materials evaluated on a multichannel screening device. J. Biomed. Mater. Res. 15, 619–653 (1981)

Burzynski, T., Papini, M.: Analytical models of the interference between incident and rebounding particles within an abrasive jet: comparison with computer simulation. Wear 263, 1593–1601 (2007)

Miyazaki, N., Hamao, T.: Solid particle erosion of thermoplastic resins reinforced by short fibers. J. Compos. Mater. 28, 871–883 (1994)

Chen, J., Hutchings, I.M., Deng, T., Bradley, M.S.A., Koziol, K.K.K.: The effect of carbon nanotube orientation on erosive wear resistance of CNT-epoxy based composites. Carbon N. Y. 73, 421–431 (2014)

Stack, M.M., Pungwiwat, N.: Slurry erosion of metallics, polymers, and ceramics: particle size effects. Mater. Sci. Technol. 15, 337–344 (1999)

Marei, A.I., Izvozchikov, P.V: Determination of the wear of rubbers in a stream of abrasive particles. In: Abrasion of Rubber. pp. 274–280. MacLaren London, London (1967)

Barkoula, N.M., Karger-Kocsis, J.: Processes and influencing parameters of the solid particle erosion of polymers and their composites. J. Mater. Sci. 37, 3807–3820 (2002)

Rao, P.V., Buckley, D.H.: Angular particle impingement studies of thermoplastic materials at normal incidence. ASLE Trans. 29, 283–298 (1986)

Stachowiak, G.W., Batchelor, A.W.: Engineering Tribology. Butterworth-Heinemann, Oxford (2000)

Dhar, S., Krajac, T., Ciampini, D., Papini, M.: Erosion mechanisms due to impact of single angular particles. Wear 258, 567–579 (2005)

Arjula, S., Harsha, A.P., Ghosh, M.K.: Solid-particle erosion behavior of high-performance thermoplastic polymers. J. Mater. Sci. 43, 1757–1768 (2008)

Acknowledgements

The authors gratefully acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC Grant # RGPIN-2019-04633), and Ontario Graduate Scholarships.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heydarzadeh Arani, N., Eghbal, M. & Papini, M. Numerical Simulation of Solid Particle Erosion of Epoxy by Overlapping Angular Particle Impacts. Tribol Lett 68, 66 (2020). https://doi.org/10.1007/s11249-020-01305-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-01305-w