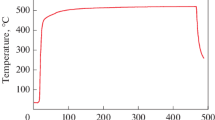

Using X-ray diffraction analysis, the effect of Ar+ ions with an energy of 15−20 keV (at ion current densities of 100−300 μA/cm2) on the microstructure, the level of internal microstresses and the texture of cold rolled ribbons of alloy Ni – 13.9 wt.% W is studied. It is found out that short-term irradiation of 80 μm thick ribbons with a fluence of 3.1·1016 cm–2 (for 50 s) at temperatures T ≤ 370°C and T = 630°C leads to a decrease in microstresses in their entire volume, while the original texture is retained. With an increase in the fluence to 9.7·1017 cm–2 at T = 630°C, the texture changes from (220) to (200). Changes in microstresses and texture on the irradiated and non-irradiated sides of 80-μm-thick ribbons are comparable to each other, despite the fact that the projected range of Ar+ ions with an energy of 15−20 keV in the alloy is only ~7 nm. It is known that annealing of such ribbons in an oven (700°C, 30 min) does not cause their recrystallization. At 850°C, the microstresses are relieved and the texture dramatically changes from (220) to (200) both as a result of annealing in a furnace (15 s) and as a result of irradiation with a fluence of 3.2·1016 cm–2 for 17 s, but the effect of stress removal in the course of furnace annealing is 3 times lower than that of irradiation. Thus, the following facts have been established: 1) the occurrence of recrystallization processes in the alloy under study during irradiation at a temperature lower than the temperature of the onset of thermally activated recrystallization and 2) a higher rate of microstress drop (and to lower values) in the course of irradiation than during furnace annealing. This indicates a significant role of nanoscale radiation-dynamic effects at the cascade-forming irradiation of metastable media.

Similar content being viewed by others

References

Second-generation HTS conductors (Ed. A. Goyal) [Russian Translation edited by Prof. A.R. Kaul.], LKI, Moscow (2009).

А. А. Molodyk and A. R. Kaul, Rossiyskii Khim. Zhurnal, 7, No. 6, 48 (2013).

C. Senatore, M. Alessandrini, A. Lucarelli, et al., Supercond. Sci. Technol., 27, No. 10, 103001 (2014).

D. P. Norton, A. Goyal, J. D. Budai, et al., Science, 274, 755 (1996).

D. P. Rodionov, I. V. Gervasyeva, and Yu. V. Khlebnikova, Textured Nickel-Alloy Substrates [in Russian], RIO UrB RAS, Ekaterinburg (2012).

A. A. Nikonov, Physics of Metals and Metallogr., 119 , No. 1, 6 (2018).

Yu. V. Khlebnikova, D. P. Rodionov, I. V. Gervasyeva, et al., Physics of Metals and Metallogr., 117 , No. 11, 1129 (2016).

Yu. V. Khlebnikova, D. P. Rodionov, L. Yu. Egorova, and T. R. Suaridze, Physics of Metals and Metallogr., 117 , No. 5, 500 (2017).

Yu. V. Khlebnikova, T. R. Suaridze, D. P. Rodionov, et al., Physics of Metals and Metallogr., 118 , No. 10, 982 (2017).

M. V. Kravtsova, V. A. Drobyshev, Yu. I. Chistov, et al., Problems of Atomic Science and Technology. Materials Technology and New Materials Series” (PAST), 76, No. 1, 62 (2014).

M. S. Sungurov, V. V. Derevyanko, S. A. Leonov, et al., Pis’ma ZhTF, 40, Iss. 18, 47 (2014).

A. V. Borisov, D. N. Rakov, I. M. Abdyukhanov, et al., At. Energy, 119, 326 (2016).

I. A. Chernykh, Multilayer epitaxial superconductor–interlayer structures for increasing the current-conducting capacity of the second-generation ribbons. Author’s abstract of Cand. Phys.-Math. Sci. Thesis [in Russian], Moscow (2015).

M. Ya. Chernykh, T. S. Krylova, I. V. Kulikov, et al., Physics of Metals and Metallogr., 119 , No. 3, 267 (2018).

D. P. Rodionov, I. V. Gervasyeva, Yu. V. Khlebnikova, et al., Physics of Metals and Metallogr., 111 , No. 6, 601 (2011).

V. V. Ovchinnikov, N. V. Gushchina, F. F. Maknin’ko, et al., Russ. Phys. J., 50, No. 2, 177 (2007).

I. Yu. Romanov, N. V. Gushchina, V. V. Ovchinnikov, et al., Russ. Phys. J., 60, No. 10, 1823 (2018).

V. V. Ovchinnikov, Surf. Coat. Technol, 355, 65 (2018).

N. V. Gavrilov, G. A. Mesyats, S. P. Nikulin, et al., J. Vac. Sci. Technol., A14, 1050 (1996).

H. M. Rietveld, J. Appl. Crystallogr., 2, No. 2, 65 (1969).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 1, pp. 112–118, January, 2022.

Rights and permissions

About this article

Cite this article

Guschina, N.V., Voronin, V.I., Proskurnina, N.V. et al. The Effect of Ion Irradiation (Аr+, E = 15−20 keV) on the Microstructure of the Deformed Ni – 13.9 wt.% W Alloy. Russ Phys J 65, 123–130 (2022). https://doi.org/10.1007/s11182-022-02614-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-022-02614-4