Abstract

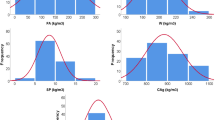

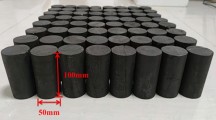

The coal ash fusion characteristics are a significant factor to consider while designing a boiler to match a coal or different coal range. Characterization of coal ash provides the fundamental mechanism that controls the heating efficiency of the coal in a pulverized coal-fired boiler, regarding the coal minerals association. Changes in coal properties could lead to changes in ash properties, i.e., ash fusion temperatures (AFT) and ash elemental composition, which could lead to slagging or fouling issues inside the boiler. The main cause could be attributed to the high temperature of the combustion process and the low melting point of ash, or vice versa. This study aimed to develop AFT prediction models using coal samples from different coalfields to predict the initial deformation temperature (DT), softening temperature (ST), hemispherical temperature (HT) and fluid temperature (FT) of coal ash. The artificial neural network (ANN), Gaussian process regression (GPR) and support vector regression (SVR) are the three machine learning tools used in this modeling. The resulting AFT predictive models indicated that the ANN model predicted DT, ST, HT and FT more adequately and reliably than the GPR and SVR. The Taylor’s diagram, which enabled easy identification of the closeness of the model predictions to the measured data, also indicated that the ANN outperformed all the other models.

Similar content being viewed by others

References

ASTM, D-3682-13. (2013). Standard Test Methods for ash in the analysis sample of coal and coke from coal. ASTM International.

Baek, S. H., Park, H. Y., & Ko, S. H. (2014). The effect of the coal blending method in a coal fired boiler on carbon in ash and NOx emission. Fuel, 128, 62–70.

Ceylan, Z., & Sungur, B. (2020). Estimation of coal elemental composition from proximate analysis using machine learning techniques. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects., 1, 5. https://doi.org/10.1080/15567036.2020.1790696

Gao, F., Han, P., & Zhai, Y. J. (2011). Application of support vector machine and ant colony algorithm in optimization of coal ash fusion temperature. In Proceedings of the 2011 international conference on machine learning and cybernetics, Guilin.

Goni, C., Helle, S., Garcia, X., Gordon, A., Parra, R., Kelm, U., Jimenez, R., & Alfaro, G. (2003). Coal blend combustion: Fusibility ranking from mineral matter composition. Fuel, 82, 2087–2095.

Hasanipanah, M., Jamei, M., Mohammed, A. S., Amar, M. N., Ouaer, H., & Khedher, K. (2022). Intelligent prediction of rock mass deformation modulus through three optimized cascaded forward neural network models. Earth Science Informatics, 15(3), 1659–1669.

Heckmeier, F. M., & Breitsamter, C. (2020). Aerodynamic probe calibration using Gaussian process regression. Measurement Science and Technology, 31, 1–16.

Huggins, F. E., Kosmack, D. A., & Huffman, G. P. (1981). Correlation between ash-fusion temperatures and ternary equilibrium phase diagrams. Fuel, 60, 577–584.

Hurst, H. J., Novak, F., & Patterson, J. H. (1996). Phase diagram approach to the fluxing effect of additions of CaCO3 on Australian coal ashes. Energy and Fuels, 10, 1215–1219.

ISO 540. (2008). Hard coal and coke—Determination of ash fusibility.

Jak, E. (2002). Prediction of coal AFTs with the FACT Thermodynamic computer package. Fuel, 81, 1655–1668.

Jamei, M., Hasanipanah, M., Karbsi, M., Ahmadianfar, I., & Taherifar, S. (2021). Prediction of flyrock induced by mine blasting using a novel kernel-based extreme learning machine. Journal of Rock Mechanics and Geotechnical Engineering, 13(6), 1438–1451.

Jamei, M., Mohammed, A. S., Ahmadianfar, I., Sabri, M. M., Karbasi, M., & Hasanipanah, M. (2022). Predicting rock brittleness using a robust evolutionary programming paradigm and regression-based feature selection model. Applied Sciences, 12(14), 7101.

Kucukbayrak, S., Ersoy-Mericboyu, A., Haykiri-Acma, H., Guner, H., & Urkan, K. (1993). Investigation of the relation between chemical composition and ash fusion temperatures for soke Turkish lignites. Fuel Science and Technology International, 1(9), 1231–1249.

Lawal, A. I., & Kwon, S. (2020). Application of artificial intelligence in rock mechanics: An overview. Journal of Rock Mechanics and Geotechnical Engineering, 13, 248–266.

Lawal, A. I., & Kwon, S. (2022). Development of mathematically motivated hybrid soft computing models for improved predictions of ultimate bearing capacity of shallow foundations. Journal of Rock Mechanics and Geotechnical Engineering. https://doi.org/10.1016/j.jrmge.2022.04.005

Lawal, A. I., Kwon, S., Aladejare, A. E., & Oniyide, G. O. (2022). Prediction of the static and dynamic mechanical properties of sedimentary rock using GPR, ANN, and response surface method. Geomechanics and Engineering, 28(3), 4547–4563.

Lawal, A. I., Olajuyi, S. I., Kwon, S., Aladejare, A. E., & Edo, T. M. (2021). Prediction of blast-induced ground vibration using GPR and blast-design parameters optimization based on novel grey-wolf optimization algorithm. Acta Geophysica, 69(4), 1313–1324.

Liu, B., He, Q., Jiang, Z., Xu, R., & Hu, B. (2013). Relationship between coal ash composition and AFTs. Fuel, 105, 293–300.

Liu, Y. P., Wu, M. G., & Qian, J. X. (2007). Predicting coal ash fusion temperature based on its chemical composition using ACO-BP neural network. Thermochimica Acta, 454, 64–68.

Lolja, S. A., Haxhi, H., Dhimitri, R., Drushku, S., & Malja, A. (2002). Correlation between AFTs and chemical composition in Albanian coal ashes. Fuel, 81(17), 2257–2261.

Ozbayoglu, G., & Ozbayoglu, M. E. (2006). A new approach for the prediction of AFT: A case study using Turkish lignites. Fuel, 85, 545–552.

Qi, X., Song, W., & Song, G. (2021). Influence of ashing temperature on predicting slagging characteristics of Xinjiang high-sodium low-rank coal and strategy of using mineral additives as potential slagging preventatives. ACS Omega, 6, 8850–8861.

Qian, X., Lee, S., Soto, A., & Chen, G. (2018). Regression model to predict the higher heating value of poultry waste from proximate analysis. Resources, 7(3), 39.

Rushdi, A., Sharma, A., & Gupta, R. (2004). An experimental study of the effect of coal blending on ash deposition. Fuel, 83(4–5), 495–506.

Seggiani, M. (1999). Empirical correlations of the ash fusion temperatures and temperature of critical viscosity for coal and biomass ashes. Fuel, 78, 1121–1125.

Seggiani, M., & Pannocchia, G. (2003). Prediction of coal ash thermal properties using partial least-squares regression. Industrial and Engineering Chemistry Research, 42, 4919–4926.

Shen, M. K., Huang, Z. Y., Wang, Z. H., & Zhou, J. H. (2014). Prediction of coal ash deformation temperature based on cuckoo algorithm and BP neural network. Journal of Fuel Chemistry and Technology, 42, 1423–1430.

Smola, A. J., & Schölkopf, B. (2004). A tutorial on support vector regression. Statistics and Computing, 14, 199–222.

Song, W. J., Tang, L. H., Zhu, X. D., Wu, Y. Q., Zhu, Z. B., & Koyama, S. (2010). Effect of coal ash composition on AFTs. Energy and Fuels, 24(1), 182–189.

van Dyk, J. C., & Waanders, F. B. (2007). Manipulation of gasification coal feed in order to increase the ash fusion temperature of the coal enabling the gasifiers to operate at higher temperatures. Fuel, 86, 2728–2735.

Vassilev, S. V., Kitano, K., Takeda, S., & Tsurue, T. (1995). Influence of mineral and chemical composition of coal ashes on their fusibility. Fuel Processing and Technology, 45, 27–51.

Wall, T. F., Creelman, R. A., Gupta, R. P., Gupta, S. K., Coin, C., & Lowe, A. (1998). Coal ash fusion temperatures-new characterization techniques, and implications for slagging and fouling. Progress Energy and Combustion Science, 24, 345–353.

Wang, C. L., Zhou, H., Li, G. N., Qiu, K. Z., & Qian, K. F. (2007). Combining support vector machine and genetic algorithm to predict ash fusion temperature. Proceedings of the CSEE, 27, 11–15.

Wang, Q., Zhang, L., Sato, A., Ninomiya, Y., & Yamashita, T. (2008). Effects of coal blending on the reduction of PM10 during high-temperature combustion 1. Mineral transformations. Fuel, 87(13–14), 2997–3005.

Winegartner, E. C., & Rhodes, B. T. (1975). An empirical study of the relation of chemical properties to ash fusion temperatures. Journal of Engineering for Gas and Power, 97, 395–406.

Xu, J., Song, X., Yu, G., & Du, C. (2020). Investigating the effect of flux on ash fusibility of high-calcium coal. ACS Omega, 5, 11361–11368.

Xu, Z. M., Zhao, Y. P., Wen, X. Q., Chen, P., & Yuan, S. (2011). A new method to predict deformation temperature of coal ash. Proceedings of the CSEE, 31, 38–43.

Yin, C., Luo, Z., Ni, M., & Cen, K. (1998). Predicting coal ash fusion temperature with a back propagation neural network model. Fuel, 77, 1777–1782.

Yun, Y., Yoo, Y. D., & Chung, S. W. (2007). Selection of IGCC candidate coals by pilot-scale gasifier production. Fuel Processing Technologies, 88, 107–116.

Zeng, J., Jamei, M., Amar, M. N., Hasanipanah, M., & Bayat, P. (2022). A novel solution for simulating air overpressure resulting from blasting using an efficient cascaded forward neural network. Engineering with Computers, 38, 2069–2081.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lawal, A.I., Onifade, M., Bada, S.O. et al. Prediction of Thermal Coal Ash Behavior of South African Coals: Comparative Applications of ANN, GPR, and SVR. Nat Resour Res 32, 1399–1413 (2023). https://doi.org/10.1007/s11053-023-10192-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-023-10192-6