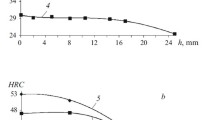

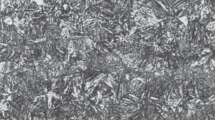

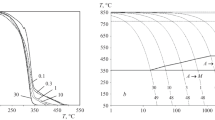

The structure and tensile mechanical properties of sparingly alloyed steel 20Kh3 are studied after quenching and tempering at different temperatures. Comparative analysis of the load-extension curves in individual deformation stages and of the fracture zones after tempering at 250 – 650°C is performed. It is shown that the low ductility margin of steel 20Kh3 after high-temperature tempering is a result of precipitation of special carbides controlling the density and mobility of dislocations both inside grains (Cr7C3) and over grain boundaries (Cr7C3, Cr23C6 ).

Similar content being viewed by others

References

S. S. Wang, D. L. Peng, L. Chang, and X. D. Hui, “Enhanced mechanical properties induced by refined heat treatment for 9Cr – 0.5Mo – 1.8W martensitic heat resistant steel,” Mater. Design, 50, 174 – 180 (2013).

N. Sainia, Ch. Pandey, M. M. Mahapatra, and R. S. Mulik, “Evolution of nano-size precipitates during tempering of 9Cr – 1Mo – 1W – V – Nb steel and their influence on mechanical properties,” Mater. Sci. Eng. A, 711, 37 – 43 (2018).

S. K. Bonagani, B. Vishwanadh, S. Tenneti, et al., “Influence of tempering treatments on mechanical properties and hydrogen embrittlement of 13 wt.% Cr martensitic stainless steel,” Int. J. Pressure Vessels and Piping, 176, 103069 (2019).

API spec 5CT. Specification for Casting and Tubing, eff. date Jul. 1 (2019).

S. M. Bitykov, K. A. Laev, M. N. Lefler, et al., “Martensitic steel with 13% C for corrosion-resistant oil pipe,” Steel Trans., 41(2), 171 – 174 (2011).

J. Li, Ch. Zhang, and Y. Liu, “Influence of carbides on the high-temperature tempered martensite embrittlement of martensitic heat-resistant steels,” Mater. Sci. Eng. A, 670, 256 – 263 (2016).

L. Xia, Y. Li, L. Ma, et al., “Influence of O2 on the erosion-corrosion performance of 3Cr steels in CO2 containing environment,” Materials, 13, 791 – 802 (2020).

B. Kermani, T. Perez, C. Morales, et al., “Window of application and operational track record of low carbon 3Cr steel tubular,” in: Proc. 61st NACE Anneal Conf., San Diego, CA, USA, 12 – 16 March (2006).

V. M. Farber and V. A. Khotinov, “Characteristics of stages (periods) of stress–strain curve of structural steels,” Metalloved. Term. Obrab. Met., No. 4, 14 – 20 (2021).

M. I. Goldshtein and V. M. Farber, Precipitation Hardening of Steel [in Russian], Metallurgiya, Moscow (1979).

R. W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, John Wiley & Sons Inc. (1996), 810 p.

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 15 – 20, August, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Selivanova, O.V., Khotinov, V.A., Ovsyannikov, A.B. et al. Tensile Deformation Behavior of Steel 20Kh3 After Quenching and Tempering. Met Sci Heat Treat 64, 436–440 (2022). https://doi.org/10.1007/s11041-022-00826-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00826-6