Abstract

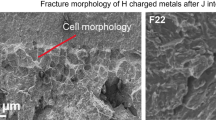

We study the tendency of corrosion-proof steels of the martensitic, martensite-ferritic, austenitic, austenite-martensitic, and ferrite-austenitic classes to corrosion cracking in hydrogen-sulfide-containing media. We have established that austenitic chromium-nickel-molybdenum (08Kh17N15M13T and 10Kh17N13M2T) and ferrite-austenitic (12Kh21N5T and 02Kh22N6AM3 steels are the most resistant to fracture: the threshold stresses in NACE solution (5% NaCl solution + 0.5% CH3 COOH saturated with H2S, 20±2°C, pH ∼ 3) are not less than 90% of the yield point.

Similar content being viewed by others

References

I. Ya. Sokol, E. A. Ul’yanin, É. G. Fel’dgandler, et al., Structure and Corrosion of Metals and Alloys: Atlas and Handbook [in Russian], Metallurgiya, Moscow (1989).

A. Gigada, T. Pastore, P. Pedeferri, and V. Vicentini, “The sulfide stress corrosion cracking of high alloy stainless steels for oil and wells,” Corros. Sci., 27, No. 10/11, 1213–1223 (1987).

R. K. Melekhov, A. M. Krutsan, O. N. Romaniv, et al., MR 185-86. Methodical Recommendations. Calculations and Tests for the Tendency of Steels and Alloys to Corrosion Cracking in Liquid Media [in Russian], VNIINMASh, Moscow (1986).

NACE Standard TM-0177-90. Standard Test Method of Laboratory Testing of Metals for Resistance to Sulfide Stress Corrosion Cracking in H2S Environments, National Association of Corrosion Engineers (NACE), Houston, Tx (1990).

V. I. Pokhmurs’kyi, R. K. Melekhov, H. M. Krutsan, and V. H. Zdanovs’kyi, Stress Corrosion Fracture of Welded Constructions [in Ukrainian], Naukova Dumka, Kyiv (1995).

R. K. Melekhov, A. I. Radkevich, L. M. Karvatskii, and A. M. Krutsan, “On the resistance of home-produced structural steels against sulfide cracking,” Zashch. Met., 33, No. 5, 493–497 (1997).

G. V. Chumalo and S. I. Girnyi, “Sulfide cracking of austenitic chromium-manganese-nickel and chromium-manganese steels,” Fiz.-Khim. Mekh. Mater., 24, No. 3, 113–115 (1988).

B. Graig, “Limitations of alloying to improve the threshold for hydrogen stress cracking of steels,” in: Hydrogen Effects on Material Behaviour. Proceedings of the 4th International Conf. on Effect of Hydrogen on the Behaviour of Materials (Wyoming, Sep. 12–15, 1989) (1989), pp. 223–230.

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 41, No. 6, pp. 103–107, November–December, 2005.

Rights and permissions

About this article

Cite this article

Krutsan, H., Radkevych, O., Melekhov, R. et al. Evaluation of the resistance of corrosion-proof steels to corrosion cracking in hydrogen sulfide solutions. Mater Sci 41, 833–838 (2005). https://doi.org/10.1007/s11003-006-0049-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11003-006-0049-x