Abstract

Microporous silica particles that are monodispersed and have submicrometer diameters are attracting much attention in many applications, including medicine, environmental technology, cosmetics, and electronics. However, the production of microporous silica particles on an industrial scale comes with some difficulties. We have recently reported that the efficient synthesis of monodisperse and microporous silica particles can be achieved by the gradual injection of reactants into the reaction system. In the present study, we examined the effect of template molecules on the particle morphology via the gradual injection of reactants method. The use of the primary amines is mandatory to obtain the microporous silica particles. Furthermore, the solubility of amines in the reaction solution plays a critical role in the synthesis of monodispersed and microporous silica particles of 100 nm in diameter. Monodisperse silica particles 100 nm in diameter and with a specific surface area of 500 m2/g could be obtained with decylamine as a surfactant. The results indicate that the present synthetic approach is useful for efficient and large-scale production of monodisperse and microporous silica particles with the designated surface area.

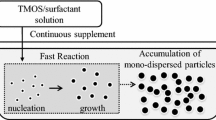

Graphical Abstract

Microporous silica particles of 100 nm in diameter can be prepared in an industrial scale by the gradual injection of reagent approach. Good dispersibility of particle diameter and effective production can be achieved at the same time.

Similar content being viewed by others

References

Barbé C, Bartlett J, Kong L, Finnie K, Lin HQ, Larkin M, Calleja S, Bush A, Calleja G (2004) Adv Mater 16:1959–1966

Lu J, Liong M, Zink JI, Tamanoi F (2007) Small 3(8):1341–1346

Liong M, Lu J, Kovochich M, Xia T, Ruehm SG, Nel AE, Tamanoi F, Zink JI (2008) ACS Nano 2(5):889–896

Lu F, Wu S-H, Hung Y, Mou C-Y (2009) Small 5(12):1408–1413

Du X, He J (2011) Nanoscale 3:3984–4002

Urata C, Yamada H, Wakabayashi R, Aoyama Y, Hirosawa S, Arai S, Takeoka S, Yamauchi Y, Kuroda K (2011) J Am Chem Soc 133:8102–8105

Yamada H, Urata C, Aoyama Y, Osada S, Yamauchi Y, Kuroda K (2012) Chem Mater 24:1462–1471

Lin Y-S, Hurley KR, Haynes CL (2012) J Phys Chem Lett 3:364–374

Yang P, Gaib S, Lin J (2012) Chem Soc Rev 41:3679–3698

Kwon S, Singh RK, Perez RA, Neel EAA, Kim H-W, Chrzanowski W (2013) J Tissue Eng 4:1–18

Prevo BG, Hwang Y, Velev OD (2005) Chem Mater 17:3642–3651

Kobler J, Bein T (2008) ACS Nano 11:2324–2330

Hoshikawa Y, Yabe H, Nomura A, Yamaki T, Shimojima A, Okubo T (2010) Chem Mater 22:12–14

Katagiri K, Yamazaki S, Inumaru K, Koumoto K (2015) Polym J 47:190–194

Nooney RI, Thirunavukkarasu D, Chen Y, Josephs R, Ostafin AE (2002) Chem Mater 12:4721–4728

Ikari K, Suzuki K, Imai H (2004) Langmuir 20:11504–11508

Suzuki K, Ikari K, Imai H (2004) J Am Chem Soc 126:462–463

Ikari K, Suzuki K, Imai H (2006) Langmuir 22:802–806

Yano K, Suzuki N, Akimoto Y, Fukushima Y (2002) Bull Chem Soc Jpn 75:1977–1982

Yano K, Fukushima Y (2003) J Mater Chem 13:2577–2581

Yano K, Fukushima Y (2004) J Mater Chem 14:1579–1584

Yamada Y, Yano K (2006) Micro Meso Mater 93:190–198

Mizutani M, Yamada Y, Nakamura T, Yano K (2008) Chem Mater 20:4777–4782

Yano K, Katz MB, Pan X, Tatsuda N (2014) J Colloid Interface Sci 418:61–65

Urata C, Aoyama Y, Tonegawa A, Yamauchi Y, Kuroda K (2009) Chem Commun 34:5094–5096

Yamada H, Urata C, Ujiie H, Yamauchi Y, Kuroda K (2013) Nanoscale 5:6145–6153

Kuroda K, Shimojima A, Kawahara K, Watabayashi R, Yamura Y, Asakura Y, Kitahara M (2014) Chem Mater 26:211–220

Möller K, Kobler J, Bein T (2007) Adv Funct Mater 17:605–612

Qiao Z-A, Zhang L, Guo M, Liu Y, Huo Q (2009) Chem Mater 21:3823–3829

Zhang K, Xu LL, Jiang JG, Calin N, Lam KF, Zhang SJ, Wu HH, Wu GD, Albela B, Bonneviot L, Wu P (2013) J Am Chem Soc 135:2427–2430

Wu S-H, Mou C-Y, Lin H-P (2013) Chem Soc Rev 42(9):3862–3875

Shimogaki T, Tokoro H, Tabuchi M, Koike N, Yamashina Y, Takahashi M (2015) J Sol-Gel Sci Technol 74:109–113

Stöber W, Fink A (1968) J Colloid Interface Sci 26:62–69

Shimogaki T, Tokoro H, Tabuchi M, Koike N, Yamashina Y, Takahashi M (2015) J Sol–Gel Sci Technol 76:156–163

Brinker CJ, Scherer GW (1990) Sol–gel science: the physics and chemistry of sol-gel processing. Academic Press, Boston

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shimogaki, T., Tokoro, H., Tabuchi, M. et al. Large-scale preparation of morphology-controlled microporous silica particles via gradual injection of reactants with different surfactants. J Sol-Gel Sci Technol 79, 440–446 (2016). https://doi.org/10.1007/s10971-015-3942-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3942-7