Abstract

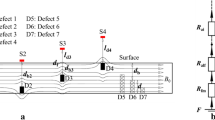

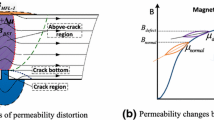

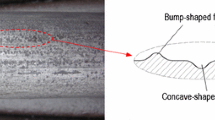

Magnetic flux leakage (MFL) testing has been widely used as an efficient non-destructive testing method to detect damage in ferromagnetic materials. It’s of great importance to improve the testing capability of MFL sensors. In this paper, a micro magnetic bridge method in MFL of high sensitivity is proposed to detect micro-cracks. This method consists of a micro magnetic bridge core and an induction coil. Furthermore, a novel micro magnetic bridge probe (MMBP) of higher spatial resolution is designed and developed with \(10~\upmu \hbox {m}\) width between the two sides of this MMBP in the testing magnetic bridge. The lift-off effect of this new MMBP is studied via finite element method and experimental verification. The results show this MMBP can achieve high sensitivity only when working with a micro-lift-off value. To examine the detecting capability of this MMBP, micro-cracks in magnetic particle inspection sensitivity testing pieces are all inspected, and the lowest depth value is only \(7~\upmu \hbox {m}\). The MMBP in this paper improves the testing capability of MFL to the micrometre scale and can be widely used to detect grinding micro-cracks in bearing rings.

Similar content being viewed by others

References

Wang, Z.D., Gu, Y., Wang, Y.S.: A review of three magnetic NDT technologies. J. Magn. Magn. Mater. 324(4), 382–388 (2012)

Sumyong, N., Prateepasen, A., Kaewtrakulpong, P.: Influence of scanning velocity and gap distance on magnetic flux leakage measurement. ECTI Trans. Electr. Eng. Electron. Commun. 5(1), 118–122 (2007)

Xu, F., Wang, X., Wu, H.: Inspection method of cable-stayed bridge using magnetic flux leakage detection: principle, sensor design, and signal processing. J. Mech. Sci. Technol. 26(3), 661–669 (2012)

Chen, L., Li, X., Qin, G., et al.: Signal processing of magnetic flux leakage surface flaw inspect in pipeline steel. Russ. J. Nondestruct. Test. 44(12), 859–867 (2008)

Förster, F.: New findings in the field of non-destructive magnetic leakage field inspection. NDT Int. 19(1), 3–14 (1986)

Sun, Y., Kang, Y.: Magnetic mechanisms of magnetic flux leakage nondestructive testing. Appl. Phys. Lett. 103(18), 184104 (2013)

Sun, Y., Kang, Y.: High-speed MFL method and apparatus based on orthogonal magnetisation for steel pipe. Insight Non-Destruct. Test. Cond. Monit. 51(10), 548–552 (2009)

Sun, Y., Kang, Y.: High-speed magnetic flux leakage technique and apparatus based on orthogonal magnetization for steel pipe. Mater. Eval. 68(4), 452–458 (2010)

Sun, Y., Feng, B., Liu, S., et al.: A methodology for identifying defects in the magnetic flux leakage method and suggestions for standard specimens. J. Nondestruct. Eval. 34(3), 1–9 (2015)

Li, Y., Tian, G.Y., Ward, S.: Numerical simulation on magnetic flux leakage evaluation at high speed. NDT E Int. 39(5), 367–373 (2006)

Wu, J.B., Tu, J., Yang, Y., et al.: Signal acquisition analysis in Hi-speed and Hi-precision MFL testing for steel pipe. In: Advanced Materials Research, vol. 718, pp. 875–880. Trans Tech Publications (2013)

Wu, J., Sun, Y., Kang, Y., et al.: Theoretical analyses of MFL signal affected by discontinuity orientation and sensor-scanning direction. IEEE Trans. Magn. 51(1), 1–7 (2015)

Jianbo, W., Hui, F., Jie, W., et al.: The influence of non-uniform wall thickness on MFL testing for a steel pipe. Insight Non-Destruct. Test. Cond. Monit. 57(12), 703–708 (2015)

Wu, J., Sun, Y., Feng, B., et al.: The effect of motion-induced eddy current on circumferential magnetization in MFL testing for a steel pipe. IEEE Trans. Magn. 53, 1–6 (2017)

Chen, L., Que, P.W., Jin, T.: A giant-magnetoresistance sensor for magnetic-flux-leakage nondestructive testing of a pipeline. Russ. J. Nondestruct. Test. 41(7), 462–465 (2005)

Kataoka, Y., Murayama, S., Wakiwaka, H., et al.: Application of GMR line sensor to detect the magnetic flux distribution for nondestructive testing. Int. J. Appl. Electromagn. Mech. 15(1–4), 47–52 (2001)

Singh, W.S., Rao, B.P.C., Vaidyanathan, S., et al.: Detection of leakage magnetic flux from near-side and far-side defects in carbon steel plates using a giant magneto-resistive sensor. Meas. Sci. Technol. 19(1), 015702 (2007)

Singh, W.S., Rao, B.P.C., Thirunavukkarasu, S., et al.: Flexible GMR sensor array for magnetic flux leakage testing of steel track ropes. J. Sens. 2012 (2012)

Park, G.S., Park, E.S.: Improvement of the sensor system in magnetic flux leakage-type nondestructive testing (NDT). IEEE Trans. Magn. 38(2), 1277–1280 (2002)

Wu, J., Fang, H., Li, L., et al.: A lift-off-tolerant magnetic flux leakage testing method for drill pipes at wellhead. Sensors 17(1), 201 (2017)

Sun, Y., Kang, Y.: A new MFL principle and method based on near-zero background magnetic field. NDT E Int. 43(4), 348–353 (2010)

Zuoying, H., Peiwen, Q., Liang, C.: 3D FEM analysis in magnetic flux leakage method. NDT e Int. 39(1), 61–66 (2006)

Al-Naemi, F.I., Hall, J.P., Moses, A.J.: FEM modelling techniques of magnetic flux leakage-type NDT for ferromagnetic plate inspections. J. Magn. Magn. Mater. 304(2), e790–e793 (2006)

Cui, Z., Wang, X., Li, Y., et al.: High sensitive magnetically actuated micromirrors for magnetic field measurement. Sens. Actuators A: Phys. 138(1), 145–150 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, E., Kang, Y., Tang, J. et al. A New Micro Magnetic Bridge Probe in Magnetic Flux Leakage for Detecting Micro-cracks. J Nondestruct Eval 37, 46 (2018). https://doi.org/10.1007/s10921-018-0499-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-018-0499-8