Abstract

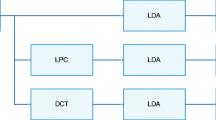

Nondestructive testing is widely used to detect and to size up discontinuities embedded in a material. Among the several ultrasonic techniques, time of flight diffraction (TOFD) combines high speed inspection, high sizing reliability and low rate of incorrect results. However, the classification of defects through ultrasound signals acquired by the TOFD technique depends heavily on the knowledge and experience of the operator and thus, this classification is still frequently questioned. Besides, this task requires long processing time due to the large amount of data to be analyzed. Nevertheless, computational tools for pattern recognition can be employed to analyze a high amount of data with large efficiency. In the present work, simulation of ultrasound propagation in two-dimensional media containing, each one, different kinds of modeled discontinuities which mimic defects in welded joints were performed. Clustering (k-means) and classification (principal component analysis and k-nearest neighbors) algorithms were employed to associate each simulated ultrasound signal with its corresponding modeled defects. The results for each method were analyzed, discussed and compared. The results are very promising.

Similar content being viewed by others

References

Kaufman, Leonard, Rousseeuw, Peter J.: Finding Groups in Data: An Introduction to Cluster Analysis, vol. 344. Wiley, New York (2009)

Haykin, S.S.: Neural Networks and Learning Machines, vol. 3. Pearson, Upper Saddle River, NJ (2009)

Webb, Andrew R.: Statistical Pattern Recognition. Wiley, New York (2003)

Silk, M.G., Lidington, B.H.: Defect sizing using an ultrasonic time-delay approach. Br. J. Non-Destr. Test. 17(2), 33–36 (1975)

Wooh, Shi-Chang, Shi, Yijun: A simulation study of the beam steering characteristics for linear phased arrays. Non-Destr. Eval. 18(2), 39–57 (1999)

Ogilvy, J.A., Temple, J.A.G.: Diffraction of elastic waves by cracks: application to time-of-flight inspection. Ultrasonics 21(6), 259–269 (1983)

Temple, J.A.G.: Predicted ultrasonic responses for pulse-echo inspections. Br. J. Non-Destr. Test. 28(3), 145–154 (1986)

Baskaran, G., Lakshmana Rao, C., Balasubramaniam, K.: Simulation of the tofd technique using the finite element method. Insight-Non-Destr. Test. Cond. Monit. 49(11), 641–646 (2007)

Ghose, B., Balasubramaniam, K., Krishnamurthy, C.V.,Rao, A.S.: Two dimensional fem simulation of ultrasonic wave propagation in isotropic solid media using comsol. In COMSOL Conference (2010)

Orfanidis, S.J.: Introduction to Signal Processing. Prentice-Hall, Inc., Upper Saddle River (1995)

de Moura, E.P., Siqueira, M.H.S., da Silva, R.R., Rebello, J.M.A.: Welding defect pattern recognition in tofd signals part 2. Non-linear classifiers. Insight-Non-Destr. Test. Cond. Monit. 47(12), 783–787 (2005)

Jolliffe, Ian: Principal Component Analysis. Wiley Online Library, New York (2002)

Varella, C.A.A.: Análise de componentes principais. Universidade Federal Rural do Rio de Janeiro, Rio de Janeiro (2008)

de Moura, E.P., Vieira, A.P., Gonçalves, L.L.: Fluctuation analyses for pattern classification in nondestructive materials inspection. EURASIP J. Adv. Signal Process. 1, 262869 (2010)

Rousseeuw, P.J.: Rousseeuw. Silhouettes: a graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 20, 53–65 (1987)

Davies, D.L., Bouldin, D.W.: A cluster separation measure. IEEE Trans. Pattern Anal. Mach. Intell. 2, 224–227 (1979)

Anil, K.: Jain. Data clustering: 50 years beyond k-means. Pattern recognition letters 31(8), 651–666 (2010)

Petrovic, S.: A comparison between the silhouette index and the davies-bouldin index in labelling ids clusters. In Proceedings of the 11th Nordic Workshop of Secure IT Systems, pp 53–64 (2006)

Dimitriadou, E., Dolničar, S., Weingessel, A.: An examination of indexes for determining the number of clusters in binary data sets. Psychometrika 67(1), 137–159 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Murta, R.H.F., Vieira, F.d.A., Santos, V.O. et al. Welding Defect Classification from Simulated Ultrasonic Signals. J Nondestruct Eval 37, 40 (2018). https://doi.org/10.1007/s10921-018-0496-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-018-0496-y