Abstract

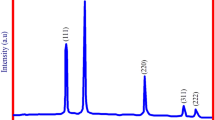

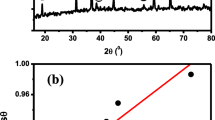

In this research, we used a fast and simple method for synthesis of calcium titanate (CaTiO3) and calcium ferrite (CaFe2O4) nanostructures: microwave assisted co-precipitation method. The effect of time, microwave radiation power and type of solvent on the morphology of magnetic nanoparticles was studied. Calcium ferrite/calcium titanate (CaFe2O4/CaTiO3) nanocomposite was prepared by the same method. The morphology and particles size of samples were studied by scanning electron microscopy. The porous nanostructure of CaTiO3 and CaFe2O4/CaTiO3 were ideal for photocatalytic behavior. The crystallographic properties of products were analyzed using X-ray diffraction technique. The purity of the samples confirmed by Fourier transform infrared spectroscopy. The magnetic property of CaFe2O4 and CaFe2O4/CaTiO3 nanoparticles was determined by vibrating sample magnetometry. Both products had ferromagnetic properties with nanocomposite being a hard ferromagnetic sample. The photocatalytic behavior of CaTiO3 and prepared nanocomposite was studied by measuring degradation efficiency of three different acidic dyes irradiated under UV–Visible light in different initial conditions. The results confirmed that both products have photocatalytic properties, but the CaFe2O4/CaTiO3 has a higher photocatalytic activity due to coupling of two semiconductors, which can be employed for effective charge separation and increase of lifetime in the charge carriers.

Similar content being viewed by others

References

Y. Hou, W. Chu, and M. Ma (2012). J. Environ. Sci. 24 (7), 1204. https://doi.org/10.1016/S1001-0742(11)61006-1.

M. O. Ansari, M. M. Khan, S. A. Ansari, and M. H. Cho (2015). J. Saudi Chem. Soc. 19, 494. https://doi.org/10.1016/j.jscs.2015.06.004.

Y. Zhang, W. Bing, X. Hui, L. Hui, W. Minglu, H. Yixuan, and P. Bingcai (2016). Nano Impact 3, 22. https://doi.org/10.1021/es3000504.

Y. Lixing, W. Dan, H. Jianfeng, C. Liyun, O. Haibo, and Y. Xiang (2016). J. Alloys Compd. 664, 476. https://doi.org/10.1016/j.jallcom.2015.10.281.

Y. Liu, J. Li, B. Zhou, Sh. Lv, X. Li, H. Chen, Q. Chen, and W. Cai (2012). Appl. Catal. B: Environ. 111–112, 485. https://doi.org/10.1016/j.apcatb.2011.10.038.

P. Satishkumar, R. V. Mangalaraja, S. Anandan, and M. Ashokkumar (2013). Chem. Eng. J. 220, 302. https://doi.org/10.1016/j.cej.2013.01.036.

F. J. Chen, Y. L. Cao, and D. Z. Jia (2013). Chem. Eng. J. 234, 223. https://doi.org/10.1016/j.cej.2013.08.075.

S. Zinatloo-Ajabshir and M. Salavati-Niasari (2017). Sep. Purif. Technol. 179, 77. https://doi.org/10.1016/j.matlet.2016.05.094.

S. Masoumi, G. Nabiyouni, and D. Ghanbari (2016). J. Mater. Sci. Mater. Electron. 27, 9962. https://doi.org/10.1007/s10854-016-5067-3.

S. Zinatloo-Ajabshir, S. Mortazavi-Derazkola, and M. Salavati-Niasari (2017). J. Mater. Sci.: Mater. Electron. 28 (23), 17849. https://doi.org/10.1007/s10854-017-7726-4.

S. Vilhunen, M. Bosund, M. L. Kaariainen, D. Cameron, and M. Sillanpaa (2009). Sep. Purif. Technol. 66, 130. https://doi.org/10.1016/j.seppur.2008.11.004.

M. Muruganandham, R. Amutha, E. Repo, M. Sillanpaa, Y. Kusumoto, and A. Al-Mamun (2010). J. Photochem. Photobiol. A 216, 133. https://doi.org/10.1016/j.jphotochem.2010.06.008.

J. Y. Park, S. J. Park, J. H. Lee, C. H. Hwang, K. J. Hwang, S. Jin, D. Y. Choi, S. D. Yoon, and I. H. Lee (2014). Mater. Lett. 121, 97. https://doi.org/10.1016/j.matlet.2014.01.012.

M. Pelaez, N. T. Nolan, S. C. Pillai, M. K. Seery, P. Falaras, A. G. Kontos, P. S. M. Dunlop, J. W. J. Hamilton, J. A. Byrne, and K. Oshea (2012). Appl. Catal. B 125, 331. https://doi.org/10.1016/j.apcatb.2012.05.036.

S. A. Ansari, S. G. Ansari, H. Foaud, and M. H. Cho (2017). New J. Chem. 41, 9314. https://doi.org/10.1039/C6NJ04070E.

B. I. Stefanov, D. Lebrun, A. Mattsson, C. G. Granqvist, and L. Osterlund (2015). J. Chem. Educ. 92 (4), 678. https://doi.org/10.1021/ed500604e.

L. Yang, L. Ding, F. Deng, X. B. Luo, and S. L. Luo, in X. Luo and F. Deng (eds.), Nanomaterial for the Removal of Pollutants and Resource Reutilization (Elsevier, Amsterdam, 2019), pp. 1–23.

S. A. Ansari, Z. Khan, M. O. Ansari, and M. H. Cho (2016). RSC Adv. 6, 44616. https://doi.org/10.1039/C6RA06145A.

T. R. Cook, D. K. Dogutan, S. Y. Reece, Y. Surendranath, T. S. Teets, and D. G. Nocera (2010). Chem. Rev. 110, 6474. https://doi.org/10.1021/cr100246c.

M. Masjedi-Arani and M. Salavati-Niasari (2017). Int. J. Hydrog. Energy 42, 17184. https://doi.org/10.1016/j.ijhydene.2017.05.118.

A. Salehabadi, M. Salavati-Niasari, and M. Ghiyasian-Arani (2018). J. Alloys Compd. 745, 789. https://doi.org/10.1016/j.jallcom.2018.02.242.

A. D. McNaught and A. Wilkinson, IUPAC. Compendium of chemical terminology, 2nd ed. (Blackwell Scientific Publications, Oxford, 1997).

D. H. Zhang, G. D. Li, J. X. Lia, and J. S. Chen (2008). Chem. Commun. 29, 3414. https://doi.org/10.1039/B805737K.

P. Kanhere and Z. Chen (2014). Molecules 19, 19995. https://doi.org/10.3390/molecules191219995.

S. Parsons, Advanced Oxidation Processes for Water and Wastewater Treatment. (IWA Publishing, London, 2004), pp. 1–347.

G. Ferreira Teixeira, E. Silva Jr., R. Vilela, M. A. Zaghete, and F. Colmati (2019). Catalysts 9, 721. https://doi.org/10.3390/catal9090721.

A. S. Bhalla, R. Guo, and R. Roy (2000). Mat. Res. Innov. 4, 3. https://doi.org/10.1007/s100190000062.

M. Kharaziha and M. H. Fathi (2009). Ceram. Int. 35, 2449. https://doi.org/10.1016/j.ceramint.2009.02.001.

T. Kokubo, T. Matsushita, and H. Takadama (2007). J. Eur. Ceram. Soc. 27, 1553. https://doi.org/10.1016/j.jeurceramsoc.2006.04.015.

T. Inadome, K. Hayashi, Y. Nakashima, H. Tsumura, and Y. Sugioka (1995). J. Biomed. Mater. Res. 29, 19. https://doi.org/10.1002/jbm.820290104.

N. Keyvani, A. Azarniya, H. R. MadaahHosseini, M. Abedi, and D. Moskovskikh (2019). Mater. Chem. Phys. 223, 202. https://doi.org/10.1016/j.matchemphys.2018.10.060.

T. Ohno, T. Tsubota, Y. Nakamura, and K. Sayama (2005). Appl. Catal. Gen. 288, 74. https://doi.org/10.1016/j.apcata.2005.04.035.

S. Preda, C. Anastasescu, I. Balint, P. Umek, M. Sluban, C. C. Negrila, D. G. Angelescu, V. Bratan, A. Rusu, and M. Zaharescu (2019). Appl. Surf. Sci. 470, 1053. https://doi.org/10.1016/j.apsusc.2018.11.194.

M. Morin, L. Torres-Martinez, D. Sanchez-Martinez, and C. Gomez-Solis (2017). Mat. Res. 20, 1322. https://doi.org/10.1590/1980-5373-MR-2016-0615.

C. Suryanarayana (2001). Prog. Mater. Sci. 46 (1–2), 1. https://doi.org/10.1016/S0079-6425(99)00010-9.

D. Zhang, M. Wang, G. J. Ren, and E. J. Song (2013). Mater. Sci. Eng. 33 (8), 4677. https://doi.org/10.1016/j.msec.2013.07.030.

M. S. Sadjadi, K. Zare, S. Khanahmadzadeh, and M. Enhessari (2008). Mater. Lett. 62 (21–22), 3679. https://doi.org/10.1016/j.matlet.2008.04.028.

X. Tang and K. Hu (2006). J. Mater. Sci. 41 (23), 8025. https://doi.org/10.1007/s10853-006-0908-8.

S. H. Chuang, M. L. Hsieh, S. C. Wu, H. C. Lin, T. S. Chao, and T. H. Hou (2011). J. Am. Ceram. Soc. 94 (1), 250. https://doi.org/10.1111/j.1551-2916.2010.04037.x.

M. Enhessari, S. N. Moqhadam, M. K. Razi, S. Ghezelbashi, and M. H. Tootkani (2010). Int. J. Nano Dimens. 1 (2), 125. https://doi.org/10.7508/IJND.2010.02.005.

Y. J. Lin, Y. H. Chang, W. D. Yang, and B. S. Tsai (2006). J. Non-Cryst. Solids 352 (8), 789. https://doi.org/10.1016/j.jnoncrysol.2006.02.001.

M. L. Moreira, E. C. Paris, G. S. Nascimento, V. M. Longo, J. R. Sambrano, V. R. Mastelaro, M. I. B. Bernardi, A. Juan, J. A. Varela, and E. Longo (2009). Acta Mater. 57, 5174. https://doi.org/10.1016/j.actamat.2009.07.019.

M. L. Moreira, J. R. Bordin, J. Andrés, J. A. Varela, and E. Longo (2020). Mol. Syst. Des. Eng. 7, 1255. https://doi.org/10.1039/D0ME00043D.

A. Kiani, Gh. Nabiyouni, Sh. Masoumi, and D. Ghanbari (2019). Compos. B 175, 17080. https://doi.org/10.1016/j.compositesb.2019.107080.

S. Mortazavi-Derazkola, M. Salavati-Niasari, O. Amiri, and A. Abbasi (2017). J. Energy Chem. 26, 17. https://doi.org/10.1016/j.jechem.2016.10.015.

F. Ansari, A. Sobhani, and M. Salavati-Niasari (2018). J. Colloid Interface Sci. 514, 723. https://doi.org/10.1016/j.jcis.2017.12.083.

Z. L. Lu, P. Z. Gao, R. X. Ma, Y. K. Sun, and D. Y. Li (2016). Eng. Mater. 680, 272. https://doi.org/10.4028/www.scientific.net/KEM.680.272.

M. Etminan, Gh. Nabiyouni, and D. Ghanbari (2018). J. Mater. Sci. Mater. Electron. 29, 1766. https://doi.org/10.1007/s10854-017-8085-x.

N. Eskandari, G. Nabiyouni, S. Masoumi, and D. Ghanbari (2019). Compos. Part B: Eng. 176, 107343. https://doi.org/10.1016/j.compositesb.2019.107343.

M. Joulaei, K. Hedayati, and D. Ghanbari (2019). Compos. Part B: Eng. 176, 107345. https://doi.org/10.1016/j.compositesb.2019.107345.

F. Beshkar, H. Khojasteh, and M. Salavati-Niasari (2017). J. Colloid Interface Sci. 497, 57. https://doi.org/10.1016/j.jcis.2017.02.016.

M. Kubota, Y. Kanazawa, K. Nasu, S. Moritake, H. Kawaji, T. Atake, and Y. Ichiyanagi (2008). J. Therm. Anal. Calorim. 92, 461. https://doi.org/10.1007/s10973-007-8971-1.

J. Chandradass, A. H. Jadhav, K. H. Kim, and H. Kim (2012). J. Alloys Compd. 517, 164. https://doi.org/10.1016/j.jallcom.2011.12.071.

J. Yunas, N. H. Sulaiman, and M. J. Ghazali (2018). IEEE Int. Conf. Semicond. Electron. (ICSE) 978, 1. https://doi.org/10.1109/SMELEC.2018.8481301.

N. H. Sulaiman, M. J. Ghazali, J. Yunas, A. Rajabi, B. Y. Majlis, and M. Razali (2018). Ceram. Int. 44, 46. https://doi.org/10.1016/j.ceramint.2017.08.203.

P. Shankar, S. Bhavyashri, R. S. Raveendra, A. Jayasheelan, C. S. Prakash, B. M. Nagabhushana, H. Nagabhushana, and B. Daruka-Prasad (2015). Int. J. Adv. Sci. Tech. Res. 4 (1), 445.

B. M. Patil, R. S. Srinivasa, and S. R. Dharwadkar (2007). Bull. Mater. Sci. 30, 225. https://doi.org/10.1007/s12034-007-0040-7.

V. S. Marques, L. S. Cavalcante, J. C. Sczancoski, D. P. Volanti, J. W. M. Espinosa, M. R. Joya, M. R. M. C. Santos, P. S. Pizani, J. A. Varela, and E. Longo (2008). Solid State Sci. 10, 1056. https://doi.org/10.1016/j.solidstatesciences.2007.11.004.

P. Hu, H. Jiao, C.-H. Wang, X. Wang, S. Ye, X.-P. Jing, F. Zhao, and Z.-X. Yue (2011). Mater. Sci. Eng. B 176, 401. https://doi.org/10.1016/j.solidstatesciences.2007.11.004.

A. Krause, W. M. Weber, D. Pohl, and B. Rellinghaus (2015). J. Phys. D: Appl. Phys. 48 (41), 415304. https://doi.org/10.1088/0022-3727/48/41/415304.

F. Maghazeii, M. Baghernezhad, and D. Ghanbari (2018). Adv. Mater. Novel Coat. 26, 1815.

M. Karbasi, F. Maghazeii, and D. Ghanbari (2019). J. Nanostruct. 9 (2), 365. https://doi.org/10.22052/JNS.2019.02.018.

F. Maghazeii, D. Ghanbari, and L. Lotfi (2020). J. Nanostruct. 10 (3), 434. https://doi.org/10.22052/JNS.2020.03.001.

F. Maghazeii and D. Ghanbari (2020). Adv. Mater. Novel Coat. 34, 2462.

H. P. Klug and L. Alexander, X-ray Diffraction Procedure (Wiley, New York, 1954).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abdi, Z., Maghazeii, F. & Ghanbari, D. The Effect of Calcium Perovskite and Newly Developed Magnetic CaFe2O4/CaTiO3 Perovskite Nanocomposite on Degradation of Toxic Dyes Under UV–Visible Radiation. J Clust Sci 33, 2475–2487 (2022). https://doi.org/10.1007/s10876-021-02168-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-021-02168-4