Abstract

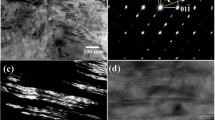

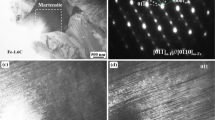

Systematical transmission electron microscopy (TEM) studies of the martensitic substructure in quenched Fe–C binary alloys have revealed that the initially formed martensite has twinning structure, and the twin is body-centered cubic {112}<111>-type twin regardless of the carbon concentrations. A metastable hexagonal ω-Fe(C) phase with an ultrafine particle-like morphology is distributed at the twin boundary region. In order to explore the common existence of the ω-Fe in nitrogen steels, the martensitic substructures in high-nitrogen martensitic stainless steels at various conditions (as-quenched, subzero-treated and tempered) have been investigated in detail by means of TEM. The ω-Fe with an ultrafine particle size of 1–3 nm has been observed in all the samples. TEM tilting experiment and electron diffraction analysis have revealed that each martensitic lath or plate is composed of {112}<111>-type twin structure with the ω particles at the twin boundary region. The martensite morphology and the relationship between the twin and the ω phase particles have been discussed crystal geometrically. The ω particle size variation with subzero and tempering treatment has also been discussed based on a proposed dilation and split mechanism. The existence of large amount of twins up to 550 °C simply suggests that the nitrogen atoms have much stronger effect than carbon atoms on the ω phase stability. The present investigation will provide a very clear image about the martensitic substructure in high-nitrogen martensitic stainless steels.

Similar content being viewed by others

References

Byrnes MLG, Grujicic M, Owen WS (1987) Nitrogen strengthening of a stable austenitic stainless steel. Acta Metall 35:1853–1862. https://doi.org/10.1016/0001-6160(87)90131-3

Stein G, Menzel J (1995) Nitrogen alloyed steels—a new generation of materials with extraordinary properties. Int J Mater Prod Technol 10:290–302. https://doi.org/10.1504/IJMPT.1995.036456

Simmons JW (1996) Overview: high-nitrogen alloying of stainless steels. Mater Sci Eng, A 207:159–169. https://doi.org/10.1016/0921-5093(95)09991-3

Berns H (1996) Manufacture and application of high nitrogen steels. ISIJ Int 36:909–914. https://doi.org/10.2355/isijinternational.36.909

Li CX, Bell T (2006) Corrosion properties of plasma nitride AISI 410 martensitic stainless steel in 3.5% NaCl and 1% HCl aqueous solutions. Corros Sci 48:2036–2049. https://doi.org/10.1016/j.corsci.2005.08.011

Lopez D, Falleiros NA, Tschiptschin AP (2007) Corrosion-erosion behavior of austenitic and martensitic high nitrogen stainless steels. Wear 263:347–354. https://doi.org/10.1016/j.wear.2007.01.053

Ono AA, Alonso N, Tschiptschin AP (1996) The corrosion resistance of nitrogen bearing martensitic stainless steels. ISIJ Int 36:813–817. https://doi.org/10.2355/isijinternational.36.813

Lee TH, Oh CS, Kim SJ, Takaki S (2007) Deformation twinning in high-nitrogen austenitic stainless steel. Acta Mater 55:3649–3662. https://doi.org/10.1016/j.actamat.2007.02.023

Bahrami F, Hendry A (1995) Microstructure and mechanical behavior of nitrogen alloyed martensitic stainless-steel. Mater Sci Technol 11:488–497

Berns H, Gavriljuk V (1997) Tempering of martensitic stainless steel with 0.6 w/o nitrogen and/or carbon. J Phys IV 7(C5):263–268. https://doi.org/10.1051/jp4:1997541

Shimizu T, Koga T, Noda T, Okabe M, Sugiyama T, Shibata T (2002) Properties of a low carbon and high nitrogen martensitic stainless steel melted in a pressurized induction furnace. Trans Indian Inst Metals 55:161–164

Ma XP, Wang LJ, Qin B, Liu CM, Subramanian SV (2012) Effect of N on microstructure and mechanical properties of 16Cr5Ni1Mo martensitic stainless steel. Mater Des 34:74–81. https://doi.org/10.1016/j.matdes.2011.07.064

Onomoto T, Terazawa Y, Tsuchiyama T, Takaki S (2009) Effect of grain refinement on tensile properties in Fe–25Cr–1 N alloy. ISIJ Int 49:1246–1252

Mitsui H, Kurihana S (2007) Solution nitriding treatment of Fe–Cr alloys under pressurized nitrogen gas. ISIJ Int 47:479–485. https://doi.org/10.2355/isijinternational.47.479

Oshima T, Habara Y, Kuroda K (2007) Efforts to save nickel in austenitic stainless steels. ISIJ Int 47:359–364. https://doi.org/10.2355/isijinternational.47.359

Kaluba WJ, Kaluba T, Taillard R (1999) The austenitizing behavior of high-nitrogen martensitic stainless steels. Scr Mater 41:1289–1293. https://doi.org/10.1016/S1359-6462(99)00281-X

Beneteau A, Aeby-Gautier E, Geandier G, Weisbecker P, Rediaimia A, Appolaire B (2014) Tempering of a martensitic stainless steel: investigation by in situ synchrotron X-ray diffraction. Acta Mater 81:30–40. https://doi.org/10.1016/j.actamat.2014.07.050

Behjati P, Kermanpur A, Najafizadeh A, Baghbadorani HS, Karjalainen LP, Jung JG, Lee YK (2014) Effect of nitrogen content on grain refinement and mechanical properties of a reversion-treated Ni-free 18Cr–12Mn austenitic stainless steel. Metall Mater Trans A 45A:6317–6328. https://doi.org/10.1007/s11661-014-2595-4

Sun J, Zhang YT, Wang P, Ye ZF, Li DZ (2014) Effect of N on the microstructure and mechanical properties of high Si martensitic heat-resistance steels. Acta Metall Sin (Eng Lett) 27:573–584. https://doi.org/10.1007/s40195-014-0095-6

Zhou QG, Zhang WF, Yan W, Wang W, Sha W, Shan YY, Yang K (2012) Microstructure and mechanical properties of a nitride-strengthened reduced activation ferritic/martensitic steel. Metall Mater Trans A 43A:5079–5087. https://doi.org/10.1007/s11661-012-1311-5

Krauss G (1999) Martensite in steel: strength and structure. Mater Sci Eng, A 273–275:40–57. https://doi.org/10.1016/S0921-5093(99)00288-9

Cohen M (1962) Strengthening of steel. Trans TMS AIME 224:638–657

O’Neill H (1935) Twinning in alpha iron. Nature 135:1076–1077. https://doi.org/10.1038/1351076d0

Greninger AB (1935) Twinning in alpha iron. Nature 135:916–917. https://doi.org/10.1038/135916c0

Kelly PM, Nutting J (1960) The martensite transformation in carbon steels. Proc R Soc A 259:45. https://doi.org/10.1098/rspa.1960.0210

Nutting J (1969) Physical metallurgy of alloy steels. J Iron Steel Inst 207:872–877

Crocker AG (1962) Twinned martensite. Acta Metall 10:113. https://doi.org/10.1016/0001-6160(62)90056-1

Sherby OD, Wadsworth J, Lesuer DR, Syn CK (2008) Revisiting the structure of martensite in iron-carbon steels. Mater Trans 49:2016–2027. https://doi.org/10.2320/matertrans.MRA2007338

Ping DH, Liu TW, Ohnuma M, Ohmura T, Abe T, Onodera H (2017) Microstructural evolution and carbides in quenched ultra-low carbon (Fe–C) alloys. ISIJ Int 57:1233–1240. https://doi.org/10.2355/isijinternational.ISIJINT-2016-624

Ping DH, Geng WT (2013) A popular metastable omega phase in body-centered cubic steels. Mater Chem Phys 139:830–835. https://doi.org/10.1016/j.matchemphys.2013.02.040

Ping DH (2014) Review on omega phase in body-centered cubic metals and alloys. Acta Metall Sin (Eng Lett) 27:1–11. https://doi.org/10.1007/s40195-013-0014-2

Liu TW, Zhang DX, Liu Q, Zheng YJ, Su YJ, Zhao XQ, Yin J, Song M, Ping DH (2015) A new nanoscale metastable iron phase in carbon steels. Sci Rep 5:15331. https://doi.org/10.1038/srep15331

Ping DH, Singh A, Guo SQ, Ohmura T, Ohnuma M, Abe T, Onodera H (2018) A simple method for observing ω-Fe electron diffraction spots from <112>α-Fe directions of quenched Fe–C twinned martensite. ISIJ Int. https://doi.org/10.2355/isijinternational.isijint-2017-270

Liu TW, Ping DH, Ohmura T, Ohnuma M (2018) Electron diffraction characterization of quenched Fe–C martensite. J Mater Sci 53:2976–2984. https://doi.org/10.1007/s10853-017-1731-0

Silcock JM (1958) An X-ray examination of the omega-phase in TiV, TiMo and TiCr alloys. Acta Metall 6:481–493. https://doi.org/10.1016/0001-6160(58)90111-1

Sass SL (1969) Omega phase in a Zr-25 at.% Ti alloy. Acta Metall 17:813–820. https://doi.org/10.1016/0001-6160(69)90100-X

De Fontaine D (1970) Mechanical instabilities in the B.C.C. lattice and the beta to omega phase transformation. Acta Metall 18:275–279. https://doi.org/10.1016/0001-6160(70)90035-0

Sikka SK, Vohra YK, Chidambaram R (1982) Omega phase in materials. Prog Mater Sci 27:245–310. https://doi.org/10.1016/0079-6425(82)90002-0

Bahrami F, Hendry A (1995) Microstructure and mechanical-behavior of nitrogen alloyed martensitic stainless steel. Mater Sci Technol 11:488–497

Gavriljuk VG, Berns H (1999) High nitrogen steels. Springer, Berlin, p 1

Toro A, Misiolek WZ, Tschiptschin AP (2003) Correlations between microstructure and surface properties in a high nitrogen martensitic stainless steel. Acta Mater 51:3363–3374. https://doi.org/10.1016/S1359-6454(03)00107-1

Mola J, De Cooman BC (2013) Quenching and partitioning (Q&P) processing of martensitic stainless steels. Metal Mater Trans A 44:946–967. https://doi.org/10.1007/s11661-012-1420-1

Böttger A, Van Genderen MJ, Sijbrandij SJ, Mittemeijer EJ, Smith GDW (1996) Atom-probe and X-ray diffraction analysis of the composition and structure of precipitates formed on tempering of ternary iron-carbon-nitrogen martensites. ISIJ Int 36:764–767. https://doi.org/10.2355/isijinternational.36.764

Ojima M, Ohnuma M, Suzuki J, Ueta S, Narita S, Shimizu T, Tomota Y (2008) Origin of the enhanced hardness of a tempered high-nitrogen martensitic steel. Scr Mater 59:313–316. https://doi.org/10.1016/j.scriptamat.2008.03.030

Sleeswyk AW, Helle JN (1961) Zigzag configurations of twins in alpha-iron. Acta Metall 9:344–351. https://doi.org/10.1016/0001-6160(61)90228-0

Umemoto M, Hyodo T, Maeda T, Tamura I (1984) Electron-microscopy studies of butterfly martensite. Acta Metall 32:1191–1203. https://doi.org/10.1016/0001-6160(84)90126-3

Ping DH (2015) Understanding solid-solid (fcc → ω + bcc) transition at atomic scale. Acta Metall Sin (Engl Lett) 28:663–670. https://doi.org/10.1007/s40195-015-0283-z

Ping DH, Cui CY, Yin FX, Yamabe-Mitarai Y (2006) TEM investigations on martensite in a Ti–Nb-based shape memory alloy. Scr Mater 54:1305–1310. https://doi.org/10.1016/j.scriptamat.2005.12.022

Cui CY, Ping DH (2009) Microstructural evolution and ductility improvement of a Ti–30Nb alloy with Pd addition. J Alloys Compd 471:248–252. https://doi.org/10.1016/j.jallcom.2008.03.057

Zywicki P, Ping DH, Abe T, Garbacz H, Yamabe-Mitarai Y, Kurzydlowski KJ (2015) Effect of Pd addition on the microstructure of Ti–30Nb alloy. Met Mater Int 21:617–622. https://doi.org/10.1007/s12540-015-4593-5

Hickman BS (1969) The formation of omega phase in titanium and zirconium alloys: a review. J Mater Sci 4:554–563. https://doi.org/10.1007/BF00550217

Dawson CW, Sass SL (1970) As-quenched form of omega phase in Zr–Nb alloys. Metall Trans 1:2225–2233. https://doi.org/10.1007/BF02643439

Cook HE (1973) Nature of omega ransformation. Acta Metall 21:1445–1449. https://doi.org/10.1016/0001-6160(73)90093-X

Moffat DL, Larbalestier DC (1988) The competition between martensite and omega in quenched Ti-Nb alloys. Metall Trans A 19A:1677–1686. https://doi.org/10.1007/BF02645135

Ivanisenko Y, Kilmametov A, Rösner H, Valiev RZ (2008) Evidence of α → ω phase transition in titanium after high pressure torsion. Int J Mater Res 99:36–41. https://doi.org/10.3139/146.101606

Straumal BB, Kilmametov AR, Ivanisenko Y, Gornakova AS, Mazilkin AA, Kriegel MJ, Fabrichnaya OB, Baretzky B, Hahn H (2015) Phase transformation in Ti–Fe alloys induced by high pressure torsion. Adv Eng Mater 17:1835–1841. https://doi.org/10.1002/adem.201500143

Kilmametov AR, Ivanisenko Y, Mazilkin AA, Straumal BB, Gornakova AS, Fabrichnaya OB, Kriegel MJ, Rafaja D, Hahn H (2018) The α → ω and β → ω phase transformations in Ti-Fe alloys under high-pressure torsion. Acta Mater 144:337–351. https://doi.org/10.1016/j.actamat.2017.10.051

Stiegler JO, Houston JT, Picklesimer ML (1964) Transmission electron microscopy of omega-phase in a Zr–15%Nb alloy. J Nucl Mater 11:32–40. https://doi.org/10.1016/0022-3115(64)90118-7

Dobromyslov AV, Elkin VA (1999) β → α″ and β → ω transformations in Ti-Os alloys. Metall Mater Trans A 30A:231–233. https://doi.org/10.1007/s11661-999-0211-9

Ikeda Y, Tanaka I (2016) Omega structure in steel: a first-principle study. J Alloys Compd 684:624–627. https://doi.org/10.1016/j.jallcom.2016.05.211

De Fontaine D, Paton NE, Williams JC (1971) Omega phase transformation in titanium alloys as an example of displacement controlled reactions. Acta Metall 19:1153–1162. https://doi.org/10.1016/0001-6160(71)90047-2

Hennig RG, Trinkle DR, Bouchet J, Srinivasan SG, Albers RC, Wilkins JW (2005) Impurities block the α to ω martensitic transformation in titanium. Nat Mater 4:129–133. https://doi.org/10.1038/nmat1292

Wu SQ, Ping DH, Yamabe-Mitarai Y, Xiao WL, Yang Y, Hu QM, Li GP, Yang R (2014) {112} <111>twinning during ω to body-centered cubic transition. Acta Mater 62:122–128. https://doi.org/10.1016/j.actamat.2013.09.040

Acknowledgements

The authors would like to gratefully acknowledge Dr. S. Ueta in Daido Steel Co., Ltd., for providing the high-nitrogen-containing steel studied in the present work. This work was supported by JSPS KAKENHI Grant number JP15H02304.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ping, D.H., Ohnuma, M. ω-Fe particle size and distribution in high-nitrogen martensitic steels. J Mater Sci 53, 5339–5355 (2018). https://doi.org/10.1007/s10853-017-1938-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1938-0