Abstract

The flame behaviors in a narrow gap with low-velocity airflow are significantly different from buoyancy-controlled flames in open areas. The conditions experienced by microgravity flame may be reproduced in a narrow gap environment where the buoyancy is limited. This work studies the behaviors of near-limit concurrent flame spread over a thick solid fuel in an oxygen-limited narrow channel with 3 mm and 5 mm heights. As the concurrent airflow and oxygen concentration decrease below a critical value, the flame spread transitions to the fuel-regression mode, burning like a candle flame. Further reducing the oxygen, the flame tip tilts towards the inflow like the flame in the opposed flow. A flammability map is found to define three regimes (1) concurrent flame spread, (2) fuel regression, and (3) extinction. The fuel-regression regime is characterized by a fuel regression angle of over 30° and a global flame equivalence ratio of over 1.9. The existence of the fuel-regression mode extends the low-flow flammability limit in the concurrent flow. The ‘round-trip’ flame phenomenon is observed where the 1st-stage near-limit opposed flame spread transitions to the 2nd-stage fuel regression in the concurrent flow. This work provides new insights into the concurrent flame-spread and extinction behavior under oxygen-limited and microgravity environments.

Similar content being viewed by others

References

Williams FA (1977) Mechanisms of fire spread. Symp Combust 16:1281–1294

Gollner MJ, Miller CH, Tang W, Singh AV (2017) The effect of flow and geometry on concurrent flame spread. Fire Saf J 91:68–78

T’ien JS, Shih HY, Jiang CB, Ross HD, Miller FJ, Fernandez-Pello AC et al (2001) Mechanisms of flame spread and smolder wave propagation. In: Ross HD (ed) Microgravity combustion: fire in free fall. Academic Press, Massachusetts, pp 299–418

Fernandez-Pello AC (1984) Flame spread modeling. Combust Sci Technol 39:119–134

Loh HT, Fernandez-Pello AC (1985) A study of the controlling mechanisms of flow assisted flame spread. Symp Combust 20:1575–1582

Osorio AF, Fernandez-Pello C, Urban DL, Ruff GA (2012) External radiant flux and oxygen concentration as conditions for concurrent flame spread in fabrics. 42nd International Conference on Environmental Systems 2012:3538

Thomsen M, Fernandez-Pello C, Ruff GA, Urban DL (2019) Buoyancy effects on concurrent flame spread over thick PMMA. Combust Flame 199:279–291

Zhou L, Fernandez-Pello AC (1991) Concurrent turbulent flame spread. Symp Combust 23:1709–1714

Zhu F, Lu Z, Wang S (2016) Flame spread and extinction over a thick solid fuel in low-velocity opposed and concurrent flows. Microgravity Sci Technol 28:87–94

Thomsen M, Huang X, Fernandez-Pello C, Urban DL, Ruff GA (2019) Concurrent flame spread over externally heated Nomex under mixed convection flow. Proc Combust Inst 37: 3801–3808

Thomsen M, Fernandez-Pello C, Urban DL, Ruff GA, Olson SL (2019) On simulating concurrent flame spread in reduced gravity by reducing ambient pressure. Proc Combust Inst 37:3793–3800

NASA Technical Standard (1998) Flammability, odor, offgassing, and compatibility requirements and test procedures for materials in environments that support combustion

Center ESNEENE space research and technology (2014) Space product assurance - Flammability testing for the screening of space materials. EN 16602–70–21

ISO 11925–2 (2002) Reaction to fire tests-Ignitability of building products subjected to direct impingement of flame-Part 2: Single-flame source test

Zhu N, Huang X, Fang J, Yang L, Hu L (2021) Transitional flame-spread and fuel-regression behaviors under the change of concurrent wind. Fire Saf J 120:103015

Olson SL, Ferkul PV, Marcum JW (2019) High-speed video analysis of flame oscillations along a PMMA rod after stagnation region blowoff. Proc Combust Inst 37:1555–1562

Marcum JW, Ferkul PV, Olson SL (2019) PMMA rod stagnation region flame blowoff limits at various radii, oxygen concentrations, and mixed stretch rates. Proc Combust Inst 37:4001–4008

Tseng Y-T, Tien JS (2010) Limiting length, steady spread, and nongrowing flames in concurrent flow over solids. J Heat Transfer 132:091201

Olson SL, Ruff GA, Ferkul PV, Owens JC, Easton J, Liao YT, et al (2023) The effect of duct size, sample size, and fuel composition on concurrent flame spread over large cellulose samples in microgravity. Combust Flame 248:112559

Urban DL, Ferkul P, Olson S, Ruff GA, Easton J, T’ien JS et al (2019) Flame spread: effects of microgravity and scale. Combust Flame 199:168–182

Ivanov AV, Balashov YV, Andreeva TV, Melikhov AS (1999) Experimental Flammability Verification in Space of Material NASA/CR-1999–209405

Olson SL, Miller FJ, Jahangirian S, Wichman IS (2009) Flame spread over thin fuels in actual and simulated microgravity conditions. Combust Flame 156:1214–1226

Zhang X, Yu Y (2011) Experimental studies on the three-dimensional effects of opposed-flow flame spread over thin solid materials. Combust Flame 158:1193–1200

Hossain S, Wichman IS, Sidebotham GW, Olson SL, Miller FJ (2018) Influence of gap height and flow field on global stoichiometry and heat losses during opposed flow flame spread over thin fuels in simulated microgravity. Combust Flame 193:133–144

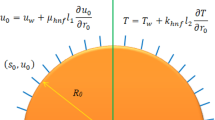

Hossain S, Wichman IS, Miller FJ, Olson SL (2020) Opposed flow flame spread over thermally thick solid fuels: buoyant flow suppression, stretch rate theory, and the regressive burning regime. Combust Flame 219:57–69

Zhu F, Wang S, Lu Z (2018) A comparative study of near-limit flame spread over a thick solid in space- and ground-based experiments. Microgravity Sci Technol 30:943–949

Zhu F, Wang S, Lu Z, Wu C (2021) Opposed flame spread over thick solid fuels under influence of sub-atmospheric pressure and low-velocity flow. Fire Saf J 125:103430

Vetturini A, Cui W, Liao YT, Olson S, Ferkul P (2020) Flame spread over ultra-thin solids: effect of area density and concurrent-opposed spread reversal phenomenon. Fire Technol 56:91–111

Olson SL, Miller FJ (2009) Experimental comparison of opposed and concurrent flame spread in a forced convective microgravity environment. Proc Combust Inst 32:2445–2452

Zhu F, Lu Z, Wang S, Yin Y (2019) Microgravity diffusion flame spread over a thick solid in step-changed low-velocity opposed flows. Combust Flame 205:55–67

Zhou S, Qi X, Gao J, Huang X, Zhang D (2022) Countercurrent flame propagation and quenching behaviour in a packed bed of spherical PMMA beads in an upward flow of pure oxygen. Combust Sci Technol (in press)

Matsuoka T, Nakashima K, Nakamura Y, Noda S (2017) Appearance of flamelets spreading over thermally thick fuel. Proc Combust Inst 36:3019–3026

Wang SF, Zhu F, Lu ZB (2016) Near-limit flame spread over thick solid fuels. J Combust Sci Technol 22:402–407

Wang S, Wang S, Zhu K, Xiao Y, Lu Z (2016) Near quenching limit instabilities of concurrent flame spread over thin solid fuel. Combust Sci Technol 188:451–471

Olson SL, Urban DL, Ruff GA, Ferkul PV, Toth B, Eigenbrod C et al (2020) Concurrent flame spread over two-sided thick PMMA Slabs in microgravity. Fire Technol 56:49–69

Jiang L, He JJ, Sun JH (2018) Sample width and thickness effects on upward flame spread over PMMA surface. J Hazard Mater 342:114–120

Huang X, Link S, Rodriguez A, Thomsen M, Olson S, Ferkul P, et al (2019) Transition from opposed flame spread to fuel regression and blow off: Effect of flow, atmosphere, and microgravity. Proc Combust Inst 37:4117–4126

Olson SL (1991) Mechanisms of microgravity flame spread over a thin solid fuel: oxygen and opposed flow effects. Combust Sci Technol 76:233–249

Carmignani L, Rhoades B, Bhattacharjee S (2018) Correlation of burning rate with spread rate for downward flame spread over PMMA. Fire Technol 54:613–624

Thomsen M, Fernandez-Pello C, Huang X, Olson S, Ferkul P (2020) Buoyancy effect on downward flame spread over PMMA cylinders. Fire Technol 56:247–269

Fujita O (2015) Solid combustion research in microgravity as a basis of fire safety in space. Proc Combust Inst 35:2487–2502

Kumar A, Shih HY, T’ien JS (2003) A comparison of extinction limits and spreading rates in opposed and concurrent spreading flames over thin solids. Combust Flame 132:667–677

Lyons KM (2007) Toward an understanding of the stabilization mechanisms of lifted turbulent jet flames: experiments. Prog Energy Combust Sci 33:211–231

Huang X, Rein G (2019) Upward-and-downward spread of smoldering peat fire. Proc Combust Inst 37:4025–4033

Gao J, Qi X, Zhang D, Matsuoka T, Nakamura Y (2021) Propagation of glowing combustion front in a packed bed of activated carbon particles and the role of CO oxidation. Proc Combust Inst 38:5023–5032

Acknowledgements

This work is supported by the National Key R&D Program of China (Grant No. 2021YFA0716203), the Opening Fund of State Key Laboratory of Fire Science (SKLFS) under Grant No. HZ2021-KF12, and the National Natural Science Foundation of China under Grant No. U1738117.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file1 Near-limit flames in concurrent airflow (MP4 659 KB)

Supplementary file2 Near-limit flames in the concurrent flow with 18.1% oxygen concentration (MP4 827 KB)

Supplementary file3 Two-stage “round-trip” flame spread process in the concurrent airflow (MP4 603 KB)

Appendix

Appendix

The velocity profiles at the outlet of the narrow channel with a height of 5 mm are shown in Figure

12. The gas flow velocity near the wall is about 2 cm/s, slightly slower than that in the central region, mainly due to the effect of the boundary layer. The average velocity is close to the forced flow velocity. In general, it can be considered that the flow field around the sample is uniform.

The position of the pyrolysis front as a function of time is measured at various flow velocities under an air environment, as shown in Figure

13. It is seen that the pyrolysis front has a linear relationship with time, implying that the flame in the concurrent assistant flow environment is in a steady state.

Images of flame under 18.1% O2 with a flow velocity of 8 cm/s from the top view are shown in Figure

14. The time evolution of the flame base position is measured from the top-view images. The yellow line depicts the flame boundary.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, F., Huang, X., Chen, X. et al. Flame Spread Transition to Regression of Thick Fuel in Oxygen-Limited Concurrent Flow. Fire Technol 59, 827–845 (2023). https://doi.org/10.1007/s10694-023-01369-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-023-01369-9