Abstract

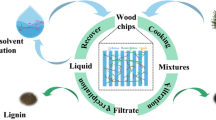

Chemical pulp was prepared by the low-temperature, atmospheric pressure, and short reaction time pulping of Eucalyptus wood chips using a high-boiling-point solvent. The pulping conditions and pulp properties were evaluated. After the digestion of the Eucalyptus chips, pulp containing 6% residual lignin was obtained in 59.6% yield. It exhibited a low shive content and a sufficiently pulped appearance. With subsequent digestion at 110 °C for 60 min, the shive content further decreased, and fiber bundles disintegrated by simple mechanical stirring. The fiber length and width of the pulp were 500–577 and 20.1–27.9 μm, respectively, and the fiber roughness was 8.8–16.8 mg/100 m. The degree of crystallization of the pulp proportionally increased with cooking temperature. The brightness of the pulp with ~ 6% residual lignin content was greater than 52% ISO, and the zero-span tensile strength and viscosity gradually increased with pulping time.

Similar content being viewed by others

References

Ahn EB, Hong SB, Kim KJ, Eom TJ (2015) Micro-fibrillated cellulose preparation with enzyme beating pretreatment and effect on paper strength improvement. J Korea TAPPI 47(6):57–65

Alaejos J, López F, Eugenio ME, Tapias R (2006) Soda-anthraquinone, kraft and organosolv pulping of holm oak trimmings. Biores Technol 97:2110–2116

Ali M, Emsley AM, Herman H, Heywood RJ (2001) Spectroscopic studies of the ageing of cellulosic paper. Polymer 42(7):2893–2900

Aziz S, Sarkanen K (1989) Organosolv pulping—a review. Tappi J 72(3):169–175

Dahlmann G, Schroeter MC (1990) The organocell process—pulping with the environment in mind. Tappi J 73(4):237–240

Eom TJ, Kim KJ (2015) Process for separating Lignocellulose components by using aliphatic glycol ether. Patent #KR1015264390000

Gierer J (1985) Chemistry of delignification part 1: general concept and reactions during pulping. Wood Sci Technol 19(4):289–312

Gustafson RR, Sleicher CA, Mckean WT, Finlayson BA (1983) Theoretical model of the Kraft pulping process. I&EC Process Des Dev 22:87–96

Hong SB, Jung SE, Kim KJ, Eom TJ (2016a) Characteristics of organosolv pulping method by high boiling point solvents. Pan Pacific Conf 2016:200–201

Hong SB, Kim KJ, Eom TJ (2016b) Delignification of pine wood meals using high boiling point solvents and acidic catalysts. J Korea TAPPI 48(6):119–126

Huang Y, Wang L, Chao Y, Nawawi DS, Akiyama T, Yokoyama T, Matsumoto Y (2012) Analysis of lignin aromatic structure in wood based on the IR spectrum. J Wood Chem Technol 32(4):294–303

International Standard Organization (ISO) (2010) Pulps-determination of limiting viscosity number in cupriethylenediamine (CED) solution. 5351:2010(E)

Johansson A, Aaltonen O, Ylinen P (1987) Organosolv pulping-methods and pulp properties. Biomass 13(1):45–65

Kajimoto J, Sano Y (2001) HBS pulping (3)—accelerated effect of RHBS on delignification. Jpn TAPPI J 55(10):114–123

Kajimoto J, Sano Y, Widodo WE, Kishimoto T, Uraki Y (2000) HBS pulping (1)—pulping of softwood. Jpn TAPPI J 54(9):88–95

Kim KJ, Jung JD, Jung SE, Hong SB, Eom TJ (2016) Delignification of lignocellulosic biomass with high-boiling point solvent and acidic catalyst. J Korea TAPPI 48(1):119–126

Neiva D, Fernandes L, Araújo S, Lourenço A, Gominho J, Simões R, Pereira H (2015) Chemical composition and kraft pulping potential of 12 eucalypt species. Ind Crops Prod 66:89–95

Roncero MB, Torres AL, Colom JF, Vidal T (2000) Effect of xylanase treatment on fibre morphology in totally chlorine free bleaching (TCF) of Eucalyptus pulp. Process Biochem 36(1–2):45–50

Schrems M, Liebner F, Betz N, Zeilinger M, Böhmdorfer S, Rosenau T, Potthast A (2012) Understanding the impact of supercritical carbon dioxide on the delignification mechanism during organosolv pulping: a model compound study. J Wood Chem Technol 32(3):225–234

Schroeter MC (1991) Possible lignin reactions in the organocell pulping process. Tappi J 74(10):197–200

Yousef MA, Shabaka AA, Nada AMA, AbdEl-Nour KN (1991) Physical properties and IR spectroscopy of thermally treated bagasse paper sheets. Indian J Pure Appl Phys 29:6–8

Zhao X, Li S, Wu R, Liu D (2017) Organosolv fractionating pre-treatment of lignocellulosic biomass for efficient enzymatic saccharification: chemistry, kinetics, and substrate structures. Biofuels Bioprod Biorefin 11(3):567–590

Acknowledgments

This study was supported by the 2016 Individual Basic Science Program (NRF-2016R1D1A3A03918987), hosted by the National Research Foundation (NRF), Ministry of Science, ICT and Future Planning, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, KJ., Hong, SB. & Eom, TJ. Preparation of Eucalyptus pulp by mild condition of low-temperature, atmospheric pressure, and short-reaction-time with high-boiling-point solvent and pulp properties. Cellulose 25, 753–761 (2018). https://doi.org/10.1007/s10570-017-1564-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1564-7