Abstract

Cotton fabrics were modified by xerogel coatings with dispersed particles of graphene (Gr) or reduced graphene oxide (RGO). To obtain a stable dispersion of Gr or RGO in organo-silicon sol, sodium lauryl sulfate as an anionic surfactant was used. The fabrics were padded with the organo-silicon sol containing dispersed Gr or RGO, forming a thin xerogel coating after drying. The fabrics coated with the xerogel containing 0.5–1.5 wt% of RGO or Gr were prepared and examined. The best anti-static properties were obtained for the coating with 1.5 wt% of Gr, whose surface resistance and volume resistance were on the order of 105 and 103 Ω, respectively. Such properties make the fabric suitable for protective cloths in the environment with explosive atmosphere.

Similar content being viewed by others

Introduction

The unique properties of graphene (Gr) and recent development of methods of its manufacture have caused strong interest in this novel material, particularly in its application in electronics (Mao et al. 2014; Randviir et al. 2014; Yuan et al. 2014). Few publications concern the use of Gr in textiles in the form of nanocomposites (Tang et al. 2014; Tian et al. 2014; Yuan et al. 2014; Zhang et al. 2013), as a yarn made from Gr flakes (Jalili et al. 2013; Tian et al. 2014) or using textiles as a support for Gr particles (Cheng et al. 2013; Karimi et al. 2015; Molina et al. 2013a; Neves et al. 2015) and are predominantly aimed at the potential applications of such materials in electronics. Rare applications of Gr for the modification of textiles can result from difficulties in its use in the form of aqueous dispersions. Because of that, surface modification of textiles is carried out mainly with graphene oxide (GO), where the structure and the presence of functional groups (hydroxyl, carboxyl, and epoxy) allow applying it in the form of aqueous dispersions and enable further modifications to achieve the desired properties (Sahito et al. 2015; Shateri-Khalilabad and Yazdanshenas 2013a; Tang et al. 2015; Tissera et al. 2015; Yaghoubidoust et al. 2014).

Imparting conductivity to textiles with deposited GO requires its reduction to reduced graphene oxide (RGO) by chemical and/or thermal methods (Shateri-Khalilabad and Yazdanshenas 2013b; Shen et al. 2016; Zhang et al. 2016). Those methods of making textiles electro-conducting encounter certain limitations. The efficiency of GO reduction depends on the type and concentration of the reducing agent and the conditions (for instance time and temperature) of the process. These factors may contribute to the deterioration of the strength of such modified textiles. If the high temperature necessary for GO reduction exceeds the degradation temperature of the textile (Cai et al. 2017; Konios et al. 2014; Shateri-Khalilabad and Yazdanshenas 2013a; Wang et al. 2017), the textile properties can be negatively affected.

Very interesting perspectives are created by immobilization of nanoparticles in the matrices of the silica thin films produced on the surface of fibers by the sol–gel method (Mahltig et al. 2005; Textor and Mahltig 2008). Because of their very small thickness and porosity, such coatings are flexible, physically bonded to the fiber surfaces, are transparent and colorless (Brzezinski et al. 2012; Textor and Mahltig 2008). This ensures retaining of the original “textile” character and appearance of coated textiles. At the same time, the silica matrices can be filled with nanoparticles (Abidi et al. 2009; Klemenčič et al. 2013; Kowalczyk et al. 2015a; Tarimala et al. 2006; Tomšič et al. 2009). Binding the thin coatings prepared by the sol–gel method to the fiber surface can be significantly improved by using to preparation of film-forming sols the proper organo-silicon precursors, having active functional groups capable of physical or chemical interactions with functional groups on fibers surfaces (Textor and Mahltig 2008), mainly hydroxyl groups in the case of cellulose and polyester fibers.

In our study we explored the possibility of modification of cotton textiles with RGO and Gr by dispersing them in nanocoatings, deposited on cotton fiber surface by the sol–gel method. The study aimed at obtaining anti-static properties of the textiles without necessity to reduce GO on fibers surface. The method of obtaining of stable dispersions of Gr and RGO in organo-silicon sol in the presence of anionic surfactant was elaborated. The sol, playing a role of matrix binding RGO and Gr to the fiber surface, was based on diethoxydimethylsilane, tetraethoxysilane, and (3-glycidoxypropyl)triethoxysilane. The effect of the thin-coating finishing of cotton woven fabrics using the organo-silicon sol modified with RGO or Gr particles on the electrostatic properties was examined.

Experimental

Materials

Woven fabrics

White plain weave cotton fabric (145 g/m2) 0.36 mm thick, with 205 threads/10 cm in the weft direction and 295 threads/10 cm in the warp direction, was used in this study. In order to remove all possible contaminants remaining in the fabric after manufacturing, prior to further modification the woven fabric was cleaned by diethyl ether and anhydrous ethanol extraction (Makowski et al. 2014).

Reduced graphene oxide (RGO)

RGO powder was provided by Nano Carbon Sp. z o.o., Poland. Elemental analysis (percentage by weight): C > 85%, H < 1%, N < 3.5%, O < 10%, others ~0.6%. Purity of 99.4% (XRF impurities analysis).

Graphene (Gr)

Gr powder with an average flake thickness of 8 nm (20–30 monolayers), an average particle (lateral) size of 550 nm (150–3000 nm), purity of 99.9%, and a specific surface area 100 m2/g was provided by Graphene Laboratories, Inc., USA.

Dispersing agent

Sodiumlauryl sulfate (SDS) as a dispersing agent of RGO and Gr, with purity of 99%, was provided by Carl Roth GmbH, Germany.

Reagents

Diethoxydimethylsilane (DEDMS) and (3-glycidoxypropyl)triethoxysilane (GPS), both with purity 97%, were purchased from ABCR. Tetraethoxysilane (TEOS) with purity 99% and aluminum isopropoxide with purity 98% were provided by Sigma Aldrich and poly(vinyl alcohol) (M W = 72,000) by Avantor Performance Materials Poland SA. All reagents were used without purification.

Preparation of organo-silicon sol

Quantities of 74.84 g (0.49 mol) of DEDMS, 158 mL of 2% aqueous solution of poly(vinyl alcohol), and 0.85 mL of aluminum isopropoxide solution in isopropanol (0.046 mol/L) were poured to 500 mL Erlenmeyer flask. The mixture was kept for 2 h at room temperature, and then 2.4 g (0.0115 mol) of TEOS and 12.4 g (0.039 mol) GPS were added. Solution was intensively mix on magnetic stirrer. The sol was ready to use after 8 h.

Preparation of dispersion of RGO or Gr in organo-silicon sol

In order to disperse RGO or Gr in the organo-silicon sol, the three-step method was used. At first RGO or G was dispersed in an aqueous solution of the dispersing agent: SDS. The concentration of RGO or Gr in the dispersion was 1.75%, and the weight ratio RGO/SDS or Gr/SDS was 1:3. The dispersion of RGO or Gr was homogenized using an ultrasonic homogenizer (power 200 W, amplitude 30%, frequency 50/60 Hz) at room temperature for 10 h. In the second step the organo-silicon sol was added to RGO/SDS or Gr/SDS suspensions and then homogenized using the ultrasonic homogenizer for 30 min, while the third step involved the addition of distilled water during continuous homogenization. The proper amounts of components were selected to obtain 0.5%, 1.0%, and 1.5 wt% of RGO or Gr in 10 wt% organo-silicon sol. The respective sols were denoted as for instance 1.5%RGO/sol or 1.5%Gr/sol.

Padding

The coating-forming Gr/sols or RGO/sols were applied on the fabric surface by the padding method using a laboratory double-roll padding machine with a horizontal position of the squeezing rollers from BENZ GmbH (Switzerland). The padding rate was 1 m/min with the squeezing roller pressure of 15 kG/cm along the roller contact line. The padding was repeated four times. After each padding-step the fabric was dried at 100 °C for 15 min. After four padding and drying cycles, some of the fabrics were rinsed in distilled water in ultrasonic bath for 15 min (power 70 W, frequency 50/60 Hz, Branson 1510E-DTH, USA), and then were dried at room temperature. Some of the unrinsed fabrics were subjected to calendering (pressure of 3.5 Torr, rate 3.5 m/min, Ramisch, Germany). The weight percentage of dry solid on fabrics (W) was determined by weighting the fabric before (W 0) and after padding and the subsequent thermal treatment (W 1). The W value was evaluated according to Eq. (1).

The W values for the fabrics with deposited RGO/sols were 2.8, 5.6, and 7.1 wt%, for RGO contents of 0.5, 1, and 1.5 wt% respectively, whereas for the fabrics with Gr/sols the W values were equal to 2.2, 5.5, and 6.4 wt%, for Gr contents of 0.5, 1, and 1.5 wt%, respectively.

Methods and apparatus

SEM/EDS analysis

The surface and chemical composition of the materials were examined by means of a scanning electron microscope (SEM), VEGA 3 (Tescan, Czech Republic) with an energy dissipative spectroscopy (EDS using an INCA energy microanalyser; Oxford Instruments Analytical, England). Prior to examination the sample surfaces were vacuum sputtered with gold using a coater (Quorum Technologies Ltd., England).

Raman analysis

The RGO and Gr powders were analyzed by means of a Raman dispersive spectrometer: Renishaw InVia Reflex (Renishaw, England) with λ = 785 nm laser excitation.

FTIR-ATR analysis

Attenuated total reflectance (ATR) Fourier transform infrared (FTIR) spectra were obtained with a spectrometer Vertex 70 (Bruker, Germany) in the 600–4000 cm−1 region with a resolution of 8 cm−1. Bruker OPUS software was used to record the spectra.

Electrokinetic analysis

The electrokinetic measurements were carried out using Zetasizer Nano ZS (Malvern Instruments Ltd., England) at 20 °C. The values of zeta potential (ζ) of the aqueous dispersions of Gr and RGO powders were determined from their electrophoretic mobilities (μ) in water according to the Smoluchowski equation (Eq. 2):

where η is the solution viscosity and ε is the dielectric constant of water, equal to 80.4.

Color analysis

The colorimetric analysis of the fabrics was recorded using a spectrophotometer, CM-2600d (Konica Minolta, Japan). The spectra were recorded in the wavelength range of 360–740 nm. Measurements were performed under standard illuminant D65, at a 10° observing angle and d/8 viewing geometry. The three coordinates (L*, a*, and b*) of the CIE Lab color system and the color difference (ΔE) of the fabrics were calculated by colorimetry software. The color differences (ΔE) were evaluated according to Eq. (3)

where ΔL*, Δa*, and Δb* are the differences between color values of the sample before and after padding.

Electrostatic analysis

The textiles were conditioned in a climatic chamber HCZ 0030 L(M) (HERAEUS, Germany) at 23 ± 1 °C and relative humidity of 25 ± 5% for 24 h and then their electrostatic properties were measured in the same conditions.

Surface resistance (R s) was measured according to standard (PN-EN 1149-1:2008). Volume resistance (R p ) was measured according to standard (PN-EN 1149-2:1999+Ap1:2001). The measurements were carried out with the use of a set of standardized measuring electrodes and a teraohm-meter 6206 (ELTEX, Germany).

Charge decay time (t 50) was measured according to standard (PN-EN 1149-3:2007). This method consists of directly positioning the electrode under the sample surface and supplying it with a voltage of 1200 V stepwise for 30 μs. A measuring probe located above the tested material recorded the field intensity changes caused by the presence of the sample. In this way the charge decay time, t 50 (time, at which the field intensity decreases to a half of the initial value) was determined.

Result and discussion

Characterization of RGO and Gr powders

SEM micrographs in Fig. 1 show that RGO and Gr were in the form of multilayered particles consisting of platelets; the platelets of RGO were wavy whereas those of Gr were flat and smooth.

Figure 2 shows FTIR-ATR spectra recorded for RGO and Gr. The weak peak at 1725 cm−1 visible on RGO spectrum reflects stretching vibrations in C=O group, and the peak near 1618 cm−1 is characteristic of aromatic carbon in C=C group. In addition, the broad peak near 1280 cm−1 is characteristic of stretching vibrations in C–OH group. The presence of peaks characteristic of oxygen containing groups on RGO spectrum evidences that the reduction was not complete. Those peaks are absent on the spectrum recorded for Gr, which exhibits only weak peaks near 1580 and 1025 cm−1 characteristic of skeletal vibrations of graphene platelets and stretching vibrations in C–O group, respectively (Guo et al. 2009; Molina et al. 2013b; Nethravathi and Rajamathi 2008).

The presence of oxygen (O) in the both materials was confirmed by elemental analysis. For RGO the average content of carbon and oxygen was 82.95 ± 1.07 and 17.05 ± 1.11 wt%, respectively. For Gr the respective numbers were 96.82 ± 0.35 and 3.18 ± 0.34 wt%. Hence, oxygen/carbon ratio was equal 0.21 and 0.03 by weight for RGO and Gr, respectively.

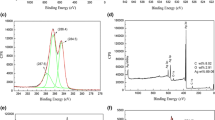

Differences between RGO and Gr were evidenced by Raman spectroscopy (Fig. 3). The RGO spectrum is featured by two strong peaks near 1315 and 1600 cm−1 corresponding to D and G bands. The Gr spectrum, besides the peaks near 1324 and 1584 cm−1 (D and G bands) exhibits the third peak near 2655 cm−1 (so-called 2D band). The D band originates from disordered structure of Gr. The G band originates from in-plane vibrations of sp 2 carbon atoms, whereas the 2D band is typical of out-of-plane vibrations of sp 2 carbon atoms and can serve for identification of single Gr platelets. The intensity ratio of D and G peaks, I D/I G, enables the estimation of degree of order of Gr and its derivatives. I D/I G is equal to 1.43 and 0.52 for RGO and Gr, respectively. The smaller I D/I G value obtained for Gr confirms its more ordered structure and lattice of conjugated sp 2 carbon atoms than in the case of RGO. Simultaneously, I 2D/I G ratio of 1/5 measured for Gr confirms its form as multi-platelet particles, since for single Gr platelets this ratio is equal to 4/1 (Faugeras et al. 2008; Wang et al. 2008).

Uniformity of padding textiles with RGO and Gr suspensions, necessary for uniform finishing, requires high stability of the suspensions. In order to estimate the stability of aqueous dispersions of RGO and Gr, zeta potential (ζ) was measured, which characterizes electrokinetic properties of the systems. For stable and unstable colloids, |ζ| > 30 mV and |ζ| < 30 mV, respectively; in the latter, particles agglomerate and sediment because of prevailing attractive forces (Hunter 1981; Vallar et al. 1999).

For the aqueous dispersions of RGO and Gr, the ζ values were equal to −25.1 ± 1.2 and −13.6 ± 0.6 mV, respectively, which confirms the instability of the dispersions. To improve the stability of negatively charged RGO and Gr dispersions, anionic surfactant SDS was used. Adsorption of SDS chains on RGO and Gr surfaces is physical and increases surface negative charge of the particles, which results in the ζ values in the range of −90 to −105 mV and in prevailing repulsive forces between the particles. As a consequence, the dispersions exhibited better electrokinetic stability in time (Fig. 4). The stability was also retained in the sol—padding bath.

Durable functionalization of textiles requires the use of stable RGO and Gr dispersions. To this end, the synthesis of organo-silicon sol, and the method of its filling with RGO and Gr dispersions containing SDS were elaborated.

Synthesis of organo-silicon sol

The synthesis of organo-silicon sol was carried out by co-hydrolysis and condensation of alkoxysilanes: TEOS, DEDMS, and GPS in the presence of a catalyst–aluminum isopropoxide. The resulting sol was highly stable over time. The mechanism of hydrolysis/condensation of alkoxysilanes with the alumina catalyst leading to organo-silicon sol is proposed in Fig. 5. Most probably, in the first step of the reaction the complex of the catalyst with the silane and water is formed. After the rearrangement, the OH group becomes bonded to the silicon atom with the simultaneous separation of ethanol. From the studies of others (Chojnowski et al. 1990; Kaźmierski et al. 1994) it follows that the hydrolysis of the first alkoxy group is the slowest, whereas the separation of the next alkoxy groups is much easier, and the respective hydrolysis rate constants differ by two orders of magnitude. In the present case the hydrolysis reaction occurs until the full conversion of all alkoxy groups into Si–OH. The resulting oligomeric silanols condense with each other and form a siloxane network, which is soluble in water due to the presence of OH groups.

All alkoxysilanes in the reaction mixture undergo hydrolysis and condensation reactions as it is described above. DEDMS in the sol allows to obtain long linear siloxane oligomers between the knots, thus forming a flexible siloxane network. Moreover, in the process conditions, epoxide ring opens in GPS and two OH groups are formed. These groups can participate in bonding the sol to surface of cotton fibers (Schottner 2001).

The organo-silicon sol deposited on a textile forms thin xerogel coating on surface of cotton fibers. It plays a role of a matrix for RGO and Gr particles and binds the particles to the fibers. The coating is strongly bonded to the fiber surface, is elastic and resistant to spalling. Moreover, it does not deteriorate the basic textile properties; neither causes stiffening nor color change of the textile.

Characteristics of cotton fabric with deposited RGO and Gr

Figure 6 presents SEM micrographs cotton fibers with xerogel coatings containing 1.5 wt% of RGO or Gr. The micrographs show RGO and Gr particles, adhering well to the fiber surface, and also loosely bonded particles forming agglomerates.

Depending on the particle type (RGO or Gr), as well as on the amount of deposited particles, the modified fabrics exhibited different intensity of darkening. The intensity were analysed based on color difference (ΔE) measured by colorimetric method; values of color coordinates L*, a*, and b* as well as ΔE are collected in Table 1.

ΔE increased with increasing RGO content in the xerogel coatings and ranged from 40.86 ± 0.44 to 57.06 ± 1.11. Similar tendency was observed for the coatings containing Gr. With increasing Gr content ΔE increased from 53.68 ± 0.56 to 58.03 ± 0.29. It appears that larger values of ΔE were measured for xerogel coatings obtained with Gr/sols than for those obtained with the corresponding RGO/sols, evidencing more intense darkening of the former most possibly due to larger content of sp 2 carbon. The results of the elemental analysis, which are listed in Table 2, confirmed that the fabrics with the Gr modified xerogel coatings contained from 2.3 to 3.5 wt% more of carbon than the fabrics with the corresponding xerogel coatings modified with RGO.

From the point of view of possible applications durability of adhesive bonding of RGO and Gr modified xerogel coatings of cotton fibers is important. To gain an insight into the durability, the modified fabrics were rinsed in an ultrasound bath for 30 min, dried at 100 °C for 15 min, and subjected to both colorimetric and elemental analysis (Tables 1, 2). It appears that ΔE decreased after rinsing, which is evidence that loosely bonded RGO and Gr particles were partially removed from the fibers surface. However, the changes in ΔE were smaller for the coatings containing Gr than for those with RGO that indicates that Gr particles were better bonded to the fabrics than RGO particles. This is most possibly related to the structure of the particles, as shown in Fig. 1. Gr particles consist of flat and smooth platelets, hence their contact surface area with the fibers is larger than in the case of wavy platelets of RGO. As a consequence, better bonding of Gr particles, dispersed in the xerogel coating, to the fibers was achieved.

The removal of loosely bonded RGO and Gr particles from the fibers surfaces was confirmed by elemental analysis. Simultaneously, the absence of silicon and sodium (Table 2) evidences that SDS surfactant was completely washed out from the fabric surface.

Electrostatic properties of fabrics with xerogel coatings containing Gr or RGO

Table 3 lists R s, R p , and t 50 values measured for the textiles. A cotton fabric is a dielectric and does not exhibit antistatic properties. R s and R p determined for the neat cotton fabric were equal to 3.6 × 1011 Ω ± 0.1 × 1011 Ω and 8.1 × 109 Ω ± 0.4 × 109 Ω, respectively, whereas its t 50 exceeded 30 s. Deposition of all three RGO/sols, despite the significant degree of reduction, did not change markedly electrostatic properties of the fabric. RGO did not form continuous conductive network permitting electric charge to flow. Similar result was obtained for the cotton fabric with the xerogel coating obtained with 0.5%Gr/sol, whose R s was close to that of the fabric coated with 1.5%RGO/sol. Enhancement of the properties was achieved only in the case of higher Gr content. R s of order 108 and 105 Ω was measured for the fabrics coated with 1.0%Gr/sol and 1.5%Gr/sol, respectively. The respective values of R p were of order of 105 and 104 Ω, respectively. A significant decrease of resistance of the fabric with xerogel coating obtained with 1.5%Gr/sol may show that the percolation threshold is reached and the conducting network is formed, as in the case of particles of other conducting materials.

It is worth noting that Kowalczyk et al. (2015b) modified polyester/cotton woven fabric with carbon nanotubes. R s of the modified fabric, measured according to PN-EN 1149-1:2008, was equal to 1.03 × 103 Ω. Surface resistance of 1.43 × 103 Ω cm−1 was reported for GO-dyed cotton fabric after seven dyeing cycles followed by reduction with Na2S2O4 (Shen et al. 2016). Shateri-Khalilabad and Yazdanshenas (2013b) also modified cotton fabric with GO, deposited by a dip-pad-dry method followed by reduction with ascorbic acid, and achieved surface resistivity of 9.18 × 104 Ω/sq.

After calendering both R p and R s values as well as t 50 decreased. Rinsing decreased R p and R s, and increased t 50. However, in the case of use of 1.5%Gr/sol the improved electrostatic properties were retained even after rinsing because of sufficient bonding of Gr particles to the fabric by xerogel coating permanently attached to the cotton fiber surface.

Obtaining a conductive network on fibers surfaces requires contacts between Gr flakes. To enhance the contact the modified textiles were subjected to calendaring. Figure 7 clearly shows that calendering resulted in smoothening and partial pressing of Gr flakes into the fabric. As a consequence, nearly twofold increase of conductivity of the fabric modified with Gr/sols was obtained. Nevertheless, the fabric modified with RGO/sols, despite the calendaring, retained the properties characteristic of a dielectric, with R s > 1010 Ω.

According to standard (PN-EN 1149-5:2009), in the environment with explosive atmosphere protective clothing should be used made of materials with R s < 2.5 × 109 Ω, tested in accordance with PN-EN 1149-1:2008 and/or t 50 < 4 s, tested in accordance with PN-EN 1149-3:2007. The R s and t 50 of the cotton fabric with xerogel coating prepared with 1.5%Gr/sol, even measured after rinsing, allow to use the fabric for protective cloths in such conditions.

Conclusion

The use of surfactant allowed obtaining stable aqueous dispersions of RGO and Gr. The elaborated sol based on diethoxydimethylsilane, tetraethoxysilane, and (3-glycidoxypropyl)triethoxysilane exhibited good stability and dilutability by water and could be filled with RGO or Gr particles. The obtained sol with Gr or RGO, after deposition on the cotton fabric by the padding method and drying, formed on fibers surface thin xerogel coating, which played a role of a matrix bonding RGO or Gr particles to the fibers surface.

The best anti-static properties were obtained for the fabric with the xerogel coating obtained with 1.5%Gr/sol. It was found that calendaring of the coated fabrics caused smoothening and flattening of Gr flakes, hence a decrease of distances between the flakes, which resulted in increased conductivity.

It was shown that the sol–gel method could be used for permanent attachment of RGO or Gr particles to the fibers surface and the possibility to apply calendering to improve conductivity was demonstrated. The anti-static properties of the Gr modified cotton fabric were reached without a reduction of GO on the fabric. The properties of the fabric with xerogel coating prepared with 1.5%Gr/sol made the fabric suitable for protective cloths in the environment with explosive atmosphere.

References

Abidi N, Cabrales L, Hequet E (2009) Functionalization of a cotton fabric surface with titania nanosols: applications for self-cleaning and UV-protection properties. ACS Appl Mater Interfaces 1:2141–2146. doi:10.1021/am900315t

Brzezinski S, Kowalczyk D, Borak B, Jasiorski M, Tracz A (2012) Applying the sol–gel method to the deposition of nanocoats on textiles to improve their abrasion resistance. J Appl Polym Sci 125:3058–3067. doi:10.1002/app.36353

Cai G, Xu Z, Yang M, Tang B, Wang X (2017) Functionalization of cotton fabrics through thermal reduction of grapheme oxide. Appl Surf Sci 393:441–448. doi:10.1016/j.apsusc.2016.10.046

Cheng H, Dong Z, Hu C, Zhao Y, Hu Y, Qu L, Chen N, Dai L (2013) Textile electrodes woven by carbon nanotube–graphene hybrid fibers for flexible electrochemical capacitors. Nanoscale 5:3428–3434. doi:10.1039/C3NR00320E

Chojnowski J, Cypryk M, Kaźmierski K, Rózga K (1990) The reactivity of monomeric silanol intermediates in the hydrolytic polycondensation of tetraethoxysilane in acidic media. J Non-Cryst Solids 125:40–49. doi:10.1016/0022-3093(90)90321-C

Faugeras C, Nerrière A, Potemski M, Mahmood A, Dujardin E, Berger C, de Heer WA (2008) Few-layer graphene on SiC, pyrolitic graphite, and graphene: a Raman scattering study. Appl Phys Lett 92:011914. doi:10.1063/1.2828975

Guo H-L, Wang X-F, Qian Q-Y, Wang F-B, Xia X-H (2009) A green approach to the synthesis of graphene nanosheets. ACS Nano 3:2653–2659. doi:10.1021/nn900227d

Hunter RJ (1981) Zeta potential in colloids science. Academic Press, New York

Jalili R, Aboutalebi SH, Esrafilzadeh D, Shepherd RL, Chen J, Aminorroaya-Yamini S, Konstantinov K, Minett AI, Razal JM, Wallace GG (2013) Scalable one-step wet-spinning of graphene fibers and yarns from liquid crystalline dispersions of graphene oxide: towards multifunctional textiles. Adv Funct Mater 23:5345–5354. doi:10.1002/adfm.201300765

Karimi L, Yazdanshenas ME, Khajavi R, Rashidi A, Mirjalili M (2015) Optimizing the photocatalytic properties and the synergistic effects of graphene and nano titanium dioxide immobilized on cotton fabric. Appl Surf Sci 332:665–673. doi:10.1016/j.apsusc.2015.01.184

Kaźmierski K, Chojnowski J, Mc Vie J (1994) The acid-catalyzed condensation of methyl substituted model oligosiloxanes bearing silanol and ethoxysilane functions. Eur Polym J 30:515–527. doi:10.1016/0014-3057(94)90054-X

Klemenčič D, Tomšič B, Kovač F, Žerjav M, Simončič A, Simončič B (2013) Antimicrobial wool, polyester and a wool/polyester blend created by silver particles embedded in a silicon matrix. Colloids Surf B 111:517–522. doi:10.1016/j.colsurfb.2013.06.044

Konios D, Stylianakis MM, Stratakis E, Kymakis E (2014) Dispersion behavior of grapheme oxide and reduced grapheme oxide. J Colloid Interface Sci 430:108–112. doi:10.1016/j.jcis.2014.05.033

Kowalczyk D, Brzeziński S, Kamińska I (2015a) Multifunctional bioactive and improving the performance durability nanocoatings for finishing PET/CO woven fabrics by the sol–gel method. J Alloys Compd 649:387–393. doi:10.1016/j.jallcom.2015.06.236

Kowalczyk D, Brzeziński S, Makowski T, Fortuniak W (2015b) Conductive hydrophobic hybrid textiles modified with carbon nanotubes. Appl Surf Sci 357:1007–1014. doi:10.1016/j.apsusc.2015.09.132

Mahltig B, Haufe H, Böttcher H (2005) Functionalisation of textiles by inorganic sol–gel coatings. J Mater Chem 15:4385–4398. doi:10.1039/B505177K

Makowski T, Kowalczyk D, Fortuniak W, Jeziorska D, Brzeziński S, Tracz A (2014) Superhydrophobic properties of cotton woven fabrics with conducting 3D networks of multiwall carbon nanotubes, MWCNTs. Cellulose 21:4659–4670. doi:10.1007/s10570-014-0422-0

Mao X, Rutledge GC, Hatton TA (2014) Nanocarbon-based electrochemical systems for sensing, electrocatalysis and energy storage. Nano Today 9:405–432. doi:10.1016/j.nantod.2014.06.011

Molina J, Fernández J, del Río AI, Bonastre J, Cases F (2013a) Chemical and electrochemical study of fabrics coated with reduced graphene oxide. Appl Surf Sci 279:46–54. doi:10.1016/j.apsusc.2013.04.020

Molina J, Fernández J, Inés JC, del Río AI, Bonastre J, Cases F (2013b) Electrochemical characterization of reduced graphene oxide-coated polyester fabrics. Electrochim Acta 93:44–52. doi:10.1016/j.electacta.2013.01.071

Nethravathi C, Rajamathi M (2008) Chemically modified graphene sheets produced by the solvothermal reduction of colloidal dispersions of graphite oxide. Carbon 46:1994–1998. doi:10.1016/j.carbon.2008.08.013

Neves AIS, Bointon TH, Melo LV, Russo S, de Schrijver I, Craciun MF, Alves H (2015) Transparent conductive graphene textile fibers. Sci Rep 5:9866. doi:10.1038/srep09866

PN-EN 1149-1:2008: Protective clothing. Electrostatic properties. Part 1: test method for measurement of surface resistivity

PN-EN 1149-2:1999+Ap1:2001: Protective clothing. Electrostatic properties. Part 2: test method for measurement of the electrical resistance through a material

PN-EN 1149-3:2007: Protective clothing. Electrostatic properties. Part 3: test methods for measurement of charge decay

PN-EN 1149-5:2009: Protective clothing. Electrostatic properties. Part 5: material performance and design requirements

Randviir EP, Brownson DAC, Banks CE (2014) A decade of graphene research: production, applications and outlook. Mater Today 17:426–432. doi:10.1016/j.mattod.2014.06.001

Sahito IA, Sun KC, Arbab AA, Qadir MB, Jeong SH (2015) Integrating high electrical conductivity and photocatalytic activity in cotton fabric by cationizing for enriched coating of negatively charged graphene oxide. Carbohydr Polym 130:299–306. doi:10.1016/j.carbpol.2015.05.010

Schottner G (2001) Hybrid sol–gel-derived polymers: applications of multifunctional materials. Chem Mater 13:3422–3435. doi:10.1021/cm011060m

Shateri-Khalilabad M, Yazdanshenas ME (2013a) Fabricating electroconductive cotton textiles using graphene. Carbohydr Polym 96:190–195. doi:10.1016/j.carbpol.2013.03.052

Shateri-Khalilabad M, Yazdanshenas ME (2013b) Preparation of superhydrophobic electroconductive graphene-coated cotton cellulose. Cellulose 20:963–972. doi:10.1007/s10570-013-9873-y

Shen W, Dong Y, Cui G, Li B (2016) Optimized preparation of electrically conductive cotton fabric by an industrialized exhaustion dyeing with reduced graphene oxide. Cellulose 23:3291–3300. doi:10.1007/s10570-016-1006-y

Tang Y, He Z, Mosseler JA, Ni Y (2014) Production of highly electro-conductive cellulosic paper via surface coating of carbon nanotube/graphene oxide nanocomposites using nanocrystalline cellulose as a binder. Cellulose 21:4569–4581. doi:10.1007/s10570-014-0418-9

Tang X, Tian M, Qu L, Zhu S, Guo X, Han G, Sun K, Hu X, Wang Y, Xu X (2015) Functionalization of cotton fabric with graphene oxide nanosheet and polyaniline for conductive and UV blocking properties. Synth Met 202:82–88. doi:10.1016/j.synthmet.2015.01.017

Tarimala S, Kothari N, Abidi N, Hequet E, Fralick J, Dai LL (2006) New approach to antibacterial treatment of cotton fabric with silver nanoparticle–doped silicon using sol–gel process. J Appl Polym Sci 101:2938–2943. doi:10.1002/app.23443

Textor T, Mahltig B (2008) Nanosols and textiles. World Scientific, Singapore

Tian M, Qu L, Zhang X, Zhang K, Zhu S, Guo X, Han G, Tang X, Sun Y (2014) Enhanced mechanical and thermal properties of regenerated cellulose/graphene composite fibers. Carbohydr Polym 111:456–462. doi:10.1016/j.carbpol.2014.05.016

Tissera ND, Wijesena RN, Perera JR, Nalin de Silva KM, Amaratunge GAJ (2015) Hydrophobic cotton textile surfaces using an amphiphilic graphene oxide (GO) coating. Appl Surf Sci 324:455–463. doi:10.1016/j.apsusc.2014.10.148

Tomšič B, Simončič B, Orel B, Žerjav M, Schroers H, Simončič A, Samardžija Z (2009) Antimicrobial activity of AgCl embedded in a silicon matrix on cotton fabric. Carbohydr Polym 75:618–626. doi:10.1016/j.carbpol.2008.09.013

Vallar S, Houivet D, El Fallah J, Kervadec D, Haussonne J-M (1999) Oxide slurries stability and powders dispersion: optimization with zeta potential and rheological measurements. J Eur Ceram Soc 19:1017–1021. doi:10.1016/S0955-2219(98)00365-3

Wang YY, Ni ZH, Yu T, Shen ZX, Wang HM, Wu YH, Chen W, Wee ATS (2008) Raman studies of monolayer graphene: the substrate effect. J Phys Chem C 112:10637–10640. doi:10.1021/jp8008404

Wang J, Salihi EC, Šiller L (2017) Green reduction of graphene oxide using alanine. Mater Sci Eng C 72:1–6. doi:10.1016/j.msec.2016.11.017

Yaghoubidoust F, Wicaksono DHB, Chandren S, Nur H (2014) Effect of graphene oxide on the structural and electrochemical behavior of polypyrrole deposited on cotton fabric. J Mol Struct 1075:486–493. doi:10.1016/j.molstruc.2014.07.025

Yuan WJ, Chen J, Shi GQ (2014) Nanoporous graphene materials. Mater Today 17:77–85. doi:10.1016/j.mattod.2014.01.021

Zhang Q, Li Y, Feng Y, Feng W (2013) Electropolymerization of graphene oxide/polyaniline composite for high-performance supercapacitor. Electrochim Acta 90:95–100. doi:10.1016/j.electacta.2012.11.035

Zhang H, Cao J, Wu W, Cao Z, Ma H (2016) Layer-by-layer assembly of graphene oxide on viscose fibers for the fabrication of flexible conductive devices. Cellulose 23:3761–3770. doi:10.1007/s10570-016-1088-6

Acknowledgments

The financial support from the National Science Centre, Poland (UMO-2014/15/B/ST8/04286) is acknowledged. The are grateful to Dorota Puchowicz and Stanisława Wróbel from Textile Research Institute for the Raman spectra and electrostatic properties measurements, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kowalczyk, D., Fortuniak, W., Mizerska, U. et al. Modification of cotton fabric with graphene and reduced graphene oxide using sol–gel method. Cellulose 24, 4057–4068 (2017). https://doi.org/10.1007/s10570-017-1389-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1389-4