Abstract

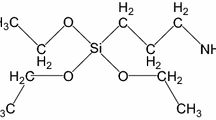

The microfibrilar structure and the morphology of the fibre are some of the most important characteristics that determine fibre performance during yarn making. This article is focused on understanding of morphological features of manmade cellulosic fibre and exploring an alternate way to alter fibre morphology. It is observed that though the chemical nature of different types of cellulose fibres viz. viscose, modal and lyocell is same; different processing routes lead to different cross-section and morphologies of fibres which leads to their characteristic properties and spinning behavior. A novel way is attempted to alter the fibre morphology of viscose fibre by changing the fibre regeneration kinetics and molecular weight distribution through addition of low molecular weight and branched structured hemicelluloses in spinning dope. Addition of hemicelluloses in the spinning dope prior to spinning and regeneration of viscose fibres is found to alter the morphology of the fibres without affecting tensile properties of the fibres.

Similar content being viewed by others

References

Carrillo F, Colom X, Sunol J, Saurina J (2004) Structural FTIR analysis and thermal characterization of lyocell and viscose-type fibres. Eur Polym J 40:2229–2234

Colom X, Carrillo F (2002) Crystallinity changes in lyocell and viscose type fibres by caustic treatment. Eur Polym J 38:2225–2230

Fidelis MEA, Pereira TVC, Gomes ODFM, Filho RDT (2013) The effect of fiber morphology on the tensile strength of natural fibers. J Mater Res Technol 2:149–157

Fink HP, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO solutions. Prog Polym Sci 26:1473–1524

Hermans PH, Weidinger A (1949) X-ray studies on the crystallinity of cellulose. J Polym Sci 4:135–144

Kadla JF, Gilbert RD (2000) Cellulose structure: a review. Cell Chem Technol 34:197–216

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Edit 44:3358–3393

Kreze T, Malej S (2003) Structural characteristics of new and conventional regenerated cellulose fibres. Text Res J 73:675–684

Lenz J, Schurz J, Wrentschur E (1988) The fibrillar structure of cellulosic man-made fibers spun from different solvent systems. J Appl Polym Sci 35:1987–2000

Li Z, Li Z, Ding R, Yu C (2016) Composition of ramie hemicelluloses and effect of polysaccharides on fiber properties. Text Res J 86:451–460

Mohanty AKM, Drzal LT, Selke SE, Harte BR, Hinrichsen G (2005) Natural fibers biopolymers and biocomposites. In: Mohanty AK, Misra M (eds) Natural fibers, biopolymers, and biocomposites. CRC Press, Florida, pp 1–36

Murugan R, Dasaradan BS (2008) Design and fabrication of crushing instrument to study influence of lateral deformation on fibrous assembly. Indian J Fibre Text Res 33:256–268

Roder T, Johann M, Gerhard K, Sandra S, Gerhard Z, Herbert S (2009) Comparative characteristics of man-made regenerated cellulosic fibers. Lenzing Ber 87:98–105

Roggenstein W (2011) Viscose fibres with new functional qualities. Lenzing Ber 89:72–77

Schild G, Liftinger E (2014) Xylan enriched viscose fibers. Cellulose 21:3031–3039

Schurz J, Lenz J (1994) Investigations on the structure of regenerated cellulose fibers. Macromol Symp 83:273–289

Sinoimeri A (2009) Friction in textile fibers and its role fibre processing. Wear 267:1619–1624

Smole MS, Persin Z, Kreze T, Kleinschek KS, Ribitsch V, Neumayer S (2003) X-ray study of pre-treated regenerated cellulose fibres. Mater Res Innov 7:275–282

Spiridon I, Popa VI (2008) Hemicelluloses: major sources properties and applications. In: Belgacem MN, Gandini A (eds) Monomers, polymers and composites from renewable sources. Elsevier, Oxford, pp 289–304

Timell TE (1965) Wood hemicelluloses II. Adv Carbohydr Chem 20:409–483

Viswanathan A (1965) Frictional forces in cotton and regenerated cellulosic fibres. J Text Inst Trans 57:T30–T41

Woodings C (2003) Cellulose fibers, regenerated. In: Mark HF, Kroschwitz JI (eds) Encyclopedia of polymer science and technology. Wiley, Michigan, pp 1–48

Acknowledgments

One of the authors (Saurabh Singh) duly acknowledges the support from Pulp and Fibre Innovation Centre, Grasim Industries, Mumbai, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S.C., Murthy, Z.V.P. Study of cellulosic fibres morphological features and their modifications using hemicelluloses. Cellulose 24, 3119–3130 (2017). https://doi.org/10.1007/s10570-017-1353-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1353-3