Abstract

NiMoS supported on ZSM-5 with different Si/Al ratio, crystallite size and pore structure was prepared by incipient impregnation method and applied in 1, 3, 5-trimethylbenzene (1, 3, 5-TMB) hydrodealkylation (HDAK). The physicochemical properties of samples were characterized by XRD, FTIR, SEM, N2 adsorption–desorption, NH3-TPD, Py-FTIR, H2-TPR, HRTEM and TGA. It is demonstrated that for microporous NiMoS/ZSM-5, acid amount and crystallite size of HZSM-5 are key factors affecting HDAK performance. The larger acid amount and smaller crystallite size can promote the conversion of 1, 3, 5-TMB, especially the dealkylation reaction, resulting in higher BTX yield. Compared to NiMoZ-3, mesopores in micro-mesoporous NiMoAKZ-3 are beneficial to accessibility of 1, 3, 5-TMB to NiMoS and acid sites in close proximity, and the diffusion of reactant and product molecules inside pores, thus resulting in superior HDAK performance of NiMoAKZ-3. Moreover, the reaction network of 1, 3, 5-TMB HDAK was revealed according to product distribution.

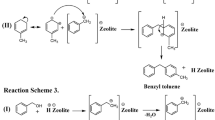

Graphic Abstract

NiMoS supported on ZSM-5 was developed for heavy aromatic hydrodealkylation (HDAK). Acid amount and crystallite size of microporous ZSM-5 are key factors affecting 1,3,5-trimethylbenzene (1,3,5-TMB) HDAK. Mesopores inside ZSM-5 facilitate accessibility of 1,3,5-TMB to NiMoS and acid sites in close proximity and improve HDAK performance.

Similar content being viewed by others

Data Availability

Manuscript including all data correct and unpublished.

References

Ali SA, Almulla FM, Jermy BR, Aitani AM, Abudawoud RH, AlAmer M, Qureshi ZS, Mohammad T, Alasiri HS (2021) J Ind Eng Chem 98:189–199

Margarit VJ, Portilla MT, Navarro MT, Abudawoud R, Al-Zahrani IM, Shaikh S, Martínez C, Corma A (2019) Appl Catal A 581:11–22

Kim T, Kim G-P, Jang J, Shim SE, Ahn W-S, Baeck S-H (2016) Catal Sci Technol 6:5599–5607

Lim D, Jang J, Kim T, Shim SE, Baeck S-H (2015) J Mol Catal A 407:147–151

Shen Q, Zhu X, Dong J, Zhu Z (2009) Catal Lett 129:170–180

Jin T, Xia DH, Xiang YZ, Zhou YL (2009) Pet Sci Technol 27:1821–1835

Serra JM, Guillon E, Corma A (2005) J Catal 232:342–354

Wang X, Xiao C, Alabsi MH, Zheng P, Cao Z, Mei J, Shi Y, Duan A, Gao D, Huang K-W, Xu C (2020). Green Energy Environ. https://doi.org/10.1016/j.gee.2020.1010.1012

Yang L, Song Z, Yu Y, Zhu L, Xia D (2020) Catal Surv Asia 24:104–114

Stanislaus A, Cooper BH (1994) Catal Rev 36:75–123

Wang H, Cheng X, Xiao B, Wang C, Zhao L, Zhu Y (2015) Catal Surv Asia 19:78–87

Tsai S-T, Chao P-H, Wang I, Tsai T-C (2010) Appl Catal A 385:73–79

Albahar M, Li C, Zholobenko VL, Garforth AA (2020) Microporous Mesoporous Mater 302:110221

Shang Y, Wang W, Zhai Y, Song Y, Zhao X, Ma T, Wei J, Gong Y (2019) Microporous Mesoporous Mater 276:173–182

Xu J, Huang T, Fan Y (2017) Appl Catal B 203:839–850

Wang Y, Yin C, Zhao X, Liu C (2017) Catal Commun 88:13–17

Subramanian V, Zholobenko VL, Cheng K, Lancelot C, Heyte S, Thuriot J, Paul S, Ordomsky VV, Khodakov AY (2016) ChemCatChem 8:380–389

Ma Z, Fu T, Wang Y, Shao J, Ma Q, Zhang C, Cui L, Li Z (2019) Ind Eng Chem Res 58:2146–2158

Han W, Yuan P, Fan Y, Liu H, Bao X (2012) J Mater Chem 22:12121–12127

Mohebbi S, Rostamizadeh M, Kahforoushan D (2020) Fuel 266:117063

López-Martín A, Caballero A, Colón G (2020) Mol Catal 486:110787

Chen Y, Zhang J, Jiang X, Wei L, Li Z, Liu C (2020) J Taiwan Inst Chem Eng 116:153–159

Pan M, Zheng J, Ou Y, Wang Q, Zhang L, Li R (2021) Microporous Mesoporous Mater 316:110983

Qiao K, Shi X, Zhou F, Chen H, Fu J, Ma H, Huang H (2017) Appl Catal A 547:274–282

Li B, Li S, Li N, Chen H, Zhang W, Bao X, Lin B (2006) Microporous Mesoporous Mater 88:244–253

Ma D, Zhang W, Shu Y, Liu X, Xu Y, Bao X (2000) Catal Lett 66:155–160

Li J, Wang L, Zhang D, Qian J, Liu L, Xing J (2019) J Fuel Chem Technol 47:957–963

Zhou W, Liu M, Zhang Q, Wei Q, Ding S, Zhou Y (2017) ACS Catal 7:7665–7679

Ye J, Bai L, Liu B, Tian H, Hu J, Pologarzon F, Mayes RT, Wu Z, Fang Y (2019) Ind Eng Chem Res 58:7094–7106

Dai Q, Zhu Q, Lou Y, Wang X (2018) J Catal 357:29–40

Čižmek A, Subotić B, Aiello R, Crea F, Nastro A, Tuoto C (1995) Microporous Mater 4:159–168

Cimek A, Subotic B, Smit I, Tonejc A, Aiello R, Crea F, Nastro A (1995) Microporous Mater 8:159–169

Liu Z, Han W, Hu D, Nie H, Wang Z, Sun S, Deng Z, Yang Q (2020) Catal Sci Technol 10:5218–5230

Toppi S, Thomas C, Sayag C, Brodzki D, Peltier FL, Travers C, Djéga-Mariadassou G (2002) J Catal 210:431–444

Sheng Q, Ling K, Li Z, Zhao L (2013) Fuel Process Technol 110:73–78

Chen T-S, Yang W-Y, Du Z-Y, Feng J, Li W-Y (2021) Catal Today 371:40–49

Ali SA, Ogunronbi KE, Al-Khattaf SS (2013) Chem Eng Res Des 91:2601–2616

Gao S, Zhai S, Yan J, Wang Z, Wang L (2015) Chem Eng Technol 38:497–503

Acknowledgements

The authors would like to acknowledge the support provided by Natural Science Research Project of Guangdong University of Petrochemical Technology (2017rc02 and 2017qn25), Science and Technology Planning Project of Maoming (2018022 & 2019400), Young Innovative Talents Project of Guangdong Province (2018KQNCX158 & 2020KQNCX051), Open fund of Key Laboratory of Low-carbon Chemistry & Energy Conservation of Guangdong Province, Guangdong Basic and Applied Basic Research Fund (2020A1515110729, 2020A1515110552 & 2021A1515010278), the Training Program for Guangdong Provincial Characteristic Innovation Projects of Universities (2018KTSCX149), and the Project of PhDs’ Start-up Research of Guangdong University of Petrochemical Technology (2020bs002).

Author information

Authors and Affiliations

Contributions

SS-conduct the experiment and write an original draft. YT-conduct the whole experiment. FC-writing, review, and editing. SW, RZ, YX, NL, XZ, CL-investigation. WY-review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Consent to Participate

All Authors are agreed for submission.

Consent for Publication

Agreed to submission.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shan, S., Tian, Y., Chen, F. et al. Acidity, Crystallite Size and Pore Structure as Key Factors Influencing 1,3,5-Trimethylbenzene Hydrodealkylation Performance of NiMoS/ZSM-5. Catal Surv Asia 26, 35–45 (2022). https://doi.org/10.1007/s10563-021-09344-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-021-09344-6