Abstract

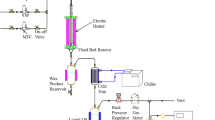

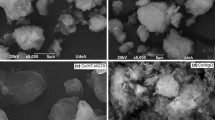

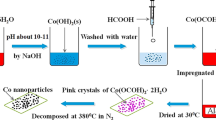

Three cobalt catalysts (Co) promoted by ruthenium supported on γ-Al2O3 were synthesized by incipient wetness co-impregnation (I/I), successive reduction (R/R), and a novel hybrid reduction–impregnation (R/I) methods. The Co loading in all of the present catalysts was 15.0 wt% and that of Ru was 0.15 wt%. To study the influence of the preparation methods on activity and selectivity of the Fischer–Tropsch synthesis, we used the prepared catalysts in a fixed-bed reactor. The different characteristic analysis tools such as X-ray diffraction, Transmission electron microscopy, Hydrogen temperature–programmed reduction, Brunauer–Emmett–Teller, Inductive Coupled Plasma and Energy–dispersive X-ray were carried out to determine the properties of the present prepared catalysts. The TPR peaks for Co⋅Ru/Al2O3(R/I) catalyst were presented significantly at lower temperatures than those obtained for the Co⋅Ru/Al2O3 (I/I) and Co⋅Ru/Al2O3 (R/R) catalysts. The average sizes of the cobalt oxide particle were calculated as 7.9, 17.2, and 37.3 nm for Co⋅Ru/Al2O3/R/R, Co⋅Ru/Al2O3 (R/I), and Co⋅Ru/Al2O3 (I/I), respectively, which are nearly consistent with those sizes obtained by TEM images. Using Co⋅Ru/Al2O3(R/I), the enhancement in CO conversion, C5+ selectivity, and chain–growth probability were 30, 18, 12.5%, respectively, in compared to those obtained by Co⋅Ru/Al2O3 (I/I) whereas the Co⋅Ru/Al2O3 (R/R) catalyst did not highly improve the FT performance with respect to Co⋅Ru/Al2O3 (I/I). Moreover, the highest CO conversion, C5+ selectivity, chain–growth probability factor and the lowest C1 selectivity belonged to the hybrid reduction–impregnation method. The effects of temperature (T = 210–230 °C) and pressure (P = 10–20 bar) were thoroughly investigated while H2/CO ratio and GHSV were kept 2 and 1800 per hour, respectively. Using the reaction yield of C5+ as a criterion, the Co⋅Ru/Al2O3(R/I) catalyst was selected to be the most productive catalyst at the optimum operating conditions 230 °C and 10 bars.

Graphical Abstract

Similar content being viewed by others

References

Parnian MJ, Khodadadi AA, Taheri Najafabadi A, Mortazavi Y (2014) Appl Catal A 470:221–231

van der Laan GP (1999) Kinetics, Selectivity and Scale up of the Fischer–Tropsch Synthesis, PhD thesis, University of Gorningen

Facchini M (2010) A study of cobalt catalyst for Fischer–Tropsch Synthesis, M.Sc. thesis, University of Glasgow

Wilhelm DJ, Simbeck DR, Karp AD, Dickenson RL (2001) Fuel Process Technol 71: 139–148

Feyzi M, Jafari F (2012) J Fuel Chem Technol 40:550–557

Fajin JLC., Cordeiro MNDS, Gomes JRB (2015) Catalysts 5:3–17

Nakanishi M, Uddin Md. A., Kato Y, Nishina Y, Hapipi AM (2017) Catal Today. doi:10.1016/j.cattod.2017.01.017

Guo X, Lv Y, Wu P, Zhang K, Liu Q, Luo M (2015) Chin J Chem Eng. doi:10.1016/j.cjche.2015.12.024

Ghampson IT, Newman C, Kong L, Pier E, Hurley KD, Pollock RA, Walsh BR, Goundie B, Wright J, Wheeler MC, Meulenberg RW, DeSisto WJ, Frederick BG, Austin RN (2010) Appl Catal A 388:57–67

Haghtalab A, Mosayebi A (2014) Int J Hydrog Energy 39:18882–18893

Tavasoli A, Sadagiani K, Khorashe F, Seifkordi AA, Rohani AA, Nakhaeipour A (2008) Fuel Process Technol 89:491–498

Kungurova OA, Khassin AA, Cherepanova SV, Saraev AA, Kaichev VV, Shtertser NV, Chermashentseva GK, Gerasimov EY, Paukshtis EA, Vodyankina OV, Minyukova TP, Abou-Jaoude G (2017) Appl Catal A 539:48–58

Parnian MJ, Najafabadi AT, Mortazavi Y, Khodadadi AA, Nazzari I (2014) Appl Surf Sci 313:183–195

Cruz MGA., de Oliveira AP S, Fernandes FAN, de Sousa FF, Oliveira AC, Filho JM, Campos AF, Rodriguez-Castellon E (2017) Chem Eng J 317:143–156

Satterfield CN (1991) Heterogeneous catalysis in industrial practice. McGraw-Hill, New York

Park JY, Lee YJ, Karandikar PR, Jun KW, Ha KS, Park HG (2012) Appl Catal A 411–412:15–23

Ueda K, Tabata H, Kawai T (2001) Appl Physics Let 79:7

Masuku CM, Hildebrandt D, Glasser D (2011) Chem Eng Sci 66:6254–6263

Carballo JMG, Yang J, Holmen A, Garcia-Rodriguez S, Rojas S, Ojeda M, Fierro JL G (2011) J Catal 284:102–108

Fraser I, Rabiu AM, Steen EV (2016) Energy Procedia 100:210–216

Jung JS, Lee JS, Choi G, Ramesh S, Moon DJ (2014) Fuel 001:0016–2361

Nauman EB (2008) Chemical reactor design, optimization, and scaleup. Wiley, Hoboken

Iglesia E, Soled SL, Fiato A, Grayson H (1993) J Catal 143:345–368

Mosayebi A, Haghtalab A (2015) Chem Eng J 259:191–204

Irankhah A, Haghtalab A (2008) Chem Eng Technol 31:525–536

Li C, Ying W, Cao F, Zhang H, Fang D (2008) Pet Sci Technol 31:704–716

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Irandoust, A., Haghtalab, A. A Hybrid Reduction–Impregnation Method in Preparation of Co–Ru/γ-Al2O3 Catalyst for Fischer–Tropsch Synthesis. Catal Lett 147, 2967–2981 (2017). https://doi.org/10.1007/s10562-017-2190-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-017-2190-6