Abstract

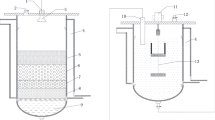

With an attempt to utilize bio-waste, oil palm empty fruit bunches (OPEFB) were investigated as feedstock for biogas production. Bench scale experiments were carried out employing a two-stage process for the digestion of pre-treated OPEFB with and without the addition of biodiesel waste glycerol (WG). Two continuous stirred tank reactors (CSTR) were operated for acid and methane production. Alkali pre-treated OPEFB were initially acidified to produce an acid hydrolysate solution. Different proportions of WG, between 0.4 and 0.8% (by volume of feed), were increased stepwise. The results indicated that the acidification of these pre-treated brunches generated approximately 4.25 g/L of volatile fatty acid at an optimum pre-treatment condition with soaking in 2% of NaOH for 48 h. This was an increase of 47% compared to the acidification of raw OPEFB. The maximum methane production was achieved with the addition of 0.4% WG, which yielded a gas production of 0.542 and 0.369 L g CODrem biogas and methane, respectively. These conditions can improve the gas yield of biogas and methane by a factor of 1.67 and 2.84, respectively. However, a higher supplementation of WG seemed to promote more instability, which was reflected by a lower methane concentration and organic removal efficiency.

Similar content being viewed by others

References

Wangrakdiskul U, Yodpijit N (2015) Trends analysis and future of sustainable palm oil in Thailand. Int J Appl Sci Technol 8:21–32

USDA (2012) Thailand biofuels annual 2012 foreign agricultural service, global agricultural information network

Chavalparit O, Ongwandee M, Trangkaprasith K (2013) Production of pelletized fuel from biodiesel-production wastes: oil palm fronds and crude glycerin. Eng J 17:61–70

Kelly-Yong TL, Lee KT, Mohamed AR, Bhatia S (2007) Potential of hydrogen from oil palm biomass as a source of renewable energy worldwide. Energy Policy 35:5692–5701

Raghareutai T, Chavalparit O, Ongwandee M (2010) Development of environmental sustainability for the biodiesel industry in Thailand. Int J Sust Dev World 17(5):363–369

Tan HT, Lee KT, Mohamed AR (2010) Second-generation bio-ethanol (SGB) from Malaysian palm empty fruit bunch: energy and exergy analyses. Bioresour Technol 101:5719–5727

Sudiyani Y (2009) Utilization of biomass waste empty fruit bunch fiber of palm oil for bioethanol production. In: Research workshop on Sustainable biofuel, Jakarta, Indonesia, pp 4–5

Piarpuzán D, Quintero JA, Cardona CA (2011) Empty fruit bunches from oil palm as a potential raw material for fuel ethanol production. Biomass Bioenerg 35(3):1130–1137

Yacob S, Shirai Y, Hassan MA, Wakisaka M, Subash S (2005) Baseline study of methane emission from open digesting tank of palm oil mill effluent. Chemosphere 59:1578–1581

Chavalparit O, Rulkens HW, Mol APJ, Khaodhiar S (2006) Options for environmental sustainability of the crude palm oil industry in thailand through environment of industrial ecosystem. Environ Dev Sustain 8(2):271–287

Purwandari FA, Sanjaya AP, Millati R, Cahyanto MN, Horváth IS, Niklasson C, Taherzadeh MJ (2013) Pretreatment of oil palm empty fruit bunch (OPEFB) by Nmethylmorpholine-N-oxide (NMMO) for biogas production: structural changes and digestion improvement. Bioresour Technol 128:461–466

Yu Y, Park B, Hwang S (2004) Co-digestion of lignocellulosics with glucose using thermophilic acidogens. Biochem Eng J 18:225–229

Speece RE (1996) Anaerobic biotechnology for industrial wastewater. (TN) Archae Press, Nashville, p 394

Nieves DC, Karimi K, Horvth IS (2011) Improvement of biogas production from oil palm empty fruit bunches (OPEFB). Ind Crops Prod 34:1097–1101

O-Thong S, Boe K, Angelidaki I (2012) Thermophilic anaerobic co-digestion of oil palm empty fruit bunches with palm oil mill effluent for efficient biogas production. Appl Energ 93:648–654

She P, Jahim J, Harun S (2013) Enhancement of batch biohydrogen production from prehydrolysate of acid treated oil palm empty fruit bunch. Int J Hydrogen Energy 38(22):9592–9599

Rebecca AS, Chen Y, Ratna RSS, Michael DB, Jason O (2007) A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour Technol 98:3000–3011

Macias-Corral M, Samani Z, Hanson A, Smith G, Funk P, Yu H, Longworth J (2008) Anaerobic digestion of municipal solid waste and agricultural waste and the effect of co-digestion with dairy cow manure. Bioresour Technol 99(17):8288–8293

El-Mashad HM, Zhang R (2010) Biogas production from co-digestion of dairy manure and food waste. Bioresour Technol 101(11):4021–4028

Chen G, Zheng Z, Yang S, Fang C, Zou X, Zhang J (2010) Improving conversion of Spartina alterniflora into biogas by co-digestion with cow feces. Fuel Process Technol 91(11):1416–1421

Diaz JP, Reyes IP, Lundin M, Horvath IS (2011) Co-digestion of different waste mixtures from agro-industrial activities; kinetic evaluation and synergetic effects. Bioresour Technol 102:10834–10840

Li C, Champagne P, Anderson BC (2014) Anaerobic co-digestion of municipal organic wastes and pre-treatment to enhance biogas production from waste. Water Sci Technol 69(2):443–449

Astals S, Nolla-Ardevol V, Mata-Alvarez J (2012) Anaerobic co-digestion of pig manure and crude glycerol at mesophilic conditions: biogas and digestate. Bioresour Technol 110:11063–11070

Amon T, Amon B, Kryvoruchko V, Bodiroza V, Potsch E, Zollitsch W (2006) Optimising methane yield from anaerobic digestion of manure: effects of dairy systems and of glycerine supplementation. Int Congr 1293:217–220

Alvarez JA, Otero L, Lema JM (2010) The methodology for optimizing feed composition for anaerobic co-digestion of agro-industrial waste. Bioresour Technol 101:1153–1158

Lovato G, Ratusznei SM, Rodrigues JAD (2016) Co-digestion of whey with glycerine in an AnSBBR for biomethane production. Appl Biochem Biotech 178:126–143

Kacprzak A, Krzystek L, Ledakowicz S (2010) Co-digestion of agricultural and industrial wastes. Chem Pap 64(2):127–131

Fountoulakis MS, Petousi I, Manios T (2010) Co-digestion of sewage sludge with glycerol to boost biogas production. Waste Manage 30(10):1849–1853

Holm-Nielsen JB, Lomborg CJ, Oleskowicz-Popiel P, Esbensen KH (2007) Online near infrared monitoring of glycerol-boosted anaerobic digestion processes: evaluation of process analytical technologies. Biotechnol Bioeng 99:302–313

APHA (2005) Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association (APHA). Washington, DC, USA

TAPPI Press (1991) T 230 om-88, Viscosity of pulp. In: Fibrous materials and pulp testing. TAPPI test methods, Vol. 1. Atlanta

Babel S, Fukushi K, Sitanrassamee B (2004) Effect of acid speciation on solid waste liquefaction in an anaerobic acid digester. Water Res 38(9):2417–2423

Feijoo G, Soto M, Mendez R, Lema JM (1995) Sodium inhibition in the anaerobic digestion process: antagonism and adaptation phenomina. Enzyme Microb Tech 17:180–188

Phukingngam D, Chavalparit O, Dararat S, Ongwandee M (2011) Anaerobic baffled reactor treatment of biodiesel-processing wastewater with high strength of methanol and glycerol: reactor performance and biogas production. Chem Pap 65(5):644–651

Acknowledgements

This research has been supported by the Ratchadapisek Sompoch Endowment Fund (2016), Chulalongkorn University (CU-59-002-IC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chavalparit, O., Sasananan, S., Kullavanijaya, P. et al. Anaerobic co-digestion of hydrolysate from alkali pre-treated oil palm empty fruit bunches with biodiesel waste glycerol. J Mater Cycles Waste Manag 20, 336–344 (2018). https://doi.org/10.1007/s10163-017-0585-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-017-0585-5