Abstract

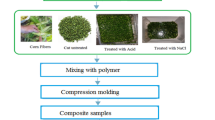

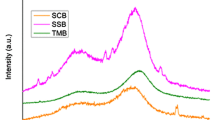

Pretreatment of lignocellulosic materials is a highly essential and critical task for the manufacturing of engineered composite panels. Recently, ionic liquids (ILs) have emerged as a promising green solvent for lignocellulosic biomass disintegration. In this work, the impact of IL pretreatment on the flexural and thermal properties of the thermo-molded biocomposite panels made from oil palm biomass residue and thermoplastic starch biopolymer as binder was studied. Oil palm fiber was pretreated with IL [emim][dep] (1-ethyl-3-methylimidazolium diethyl phosphate) and IL [bmim][Cl] (1-butyl-3-methylimidazolium chloride) prior to mixing with plasticized starch. The compounded mixture was then hot-pressed into composite panels. To understand the effect of IL pretreatment, lignocellulosic characterization, morphology, and thermogravimetric analysis of the untreated and treated fibers were performed. It was found that thermal stability of the oil palm biomass and the biocomposites was improved after IL pretreatment due to partial removal of hemicellulose and lignin from raw fiber. Moreover, pretreated biocomposites exhibited superior strength and modulus as compared to that of untreated sample as evidenced from flexural testing. The study plainly demonstrates that IL-assisted pretreatment could be an extremely attractive and clean technology for the efficient use of agro-based industrial waste in biocomposite field.

Similar content being viewed by others

References

Abdulkhani A, Marvast EH, Ashori A, Karimi AN (2013) Effects of dissolution of some lignocellulosic materials with ionic liquids as green solvents on mechanical and physical properties of composite films. Carbohydr Polym 95:57–63

Bauer A, Leonhartsberger C, Bösch P, Amon B, Friedl A, Amon T (2010) Analysis of methane yields from energy crops and agricultural by-products and estimation of energy potential from sustainable crop rotation systems in EU-27. Clean Technol Environ Policy 12:153–161

Brandt A, Gräsvik J, Hallett JP, Welton T (2013) Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem 15:550–583

Capello C, Fischer U, Hungerbühler K (2007) What is a green solvent? A comprehensive framework for the environmental assessment of solvents. Green Chem 9:927–934

Chum HL (2000) The importance of clean products and processes from alternative feedstocks. Clean Technol Environ Policy 2:127–128

Chum H, Black S, Johnson D, Sarkanen K, Robert D (1999) Organosolv pretreatment for enzymatic hydrolysis of poplars: isolation and quantitative structural studies of lignins. Clean Products Process 1:187–198

Couling DJ, Bernot RJ, Docherty KM, Dixon JK, Maginn EJ (2006) Assessing the factors responsible for ionic liquid toxicity to aquatic organisms via quantitative structure–property relationship modeling. Green Chem 8:82–90

Croitoru C, Patachia S, Cretu N, Boer A, Friedrich C (2011) Influence of ionic liquids on the surface properties of poplar veneers. Appl Surf Sci 257:6220–6225

Elgharbawy AA, Alam MZ, Moniruzzaman M, Goto M (2016) Ionic liquid pretreatment as emerging approaches for enhanced enzymatic hydrolysis of lignocellulosic biomass. Biochem Eng J 109:252–267

Estokova A, Porhincak M (2015) Environmental analysis of two building material alternatives in structures with the aim of sustainable construction. Clean Technol Environ Policy 17:75–83

Ewida K, El-Salmawy H, Atta N, Mahmoud M (2006) A sustainable approach to the recycling of rice straw through pelletization and controlled burning. Clean Technol Environ Policy 8:188–197

Financie R, Moniruzzaman M, Uemura Y (2016) Enhanced enzymatic delignification of oil palm biomass with ionic liquid pretreatment. Biochem Eng J. doi:10.1016/j.bej.2016.02.008

Forssell PM, Mikkilä JM, Moates GK, Parker R (1997) Phase and glass transition behaviour of concentrated barley starch-glycerol-water mixtures, a model for thermoplastic starch. Carbohydr Polym 34:275–282

Haque MM, Hasan M, Islam MS, Ali ME (2009) Physico-mechanical properties of chemically treated palm and coir fiber reinforced polypropylene composites. Bioresour Technol 100:4903–4906

Hulleman SH, Janssen FH, Feil H (1998) The role of water during plasticization of native starches. Polymer 39:2043–2048

Ibrahim H, Farag M, Megahed H, Mehanny S (2014) Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr Polym 101:11–19

Ibrahim F, Moniruzzaman M, Yusup S, Uemura Y (2015) Dissolution of cellulose with ionic liquid in pressurized cell. J Mol Liquids 1:370–372

Isaksson J, Åsblad A, Berntsson T (2014) Pretreatment methods for gasification of biomass and Fischer-Tropsch crude production integrated with a pulp and paper mill. Clean Technol Environ Policy 16:1393–1402

Izani MN, Paridah M, Anwar U, Nor MM, H’ng P (2013) Effects of fiber treatment on morphology, tensile and thermogravimetric analysis of oil palm empty fruit bunches fibers. Compos B Eng 45:1251–1257

Kaar WE, Holtzapple MT (2000) Using lime pretreatment to facilitate the enzymic hydrolysis of corn stover. Biomass Bioenergy 18:189–199

Kim TH, Lee Y (2006) Fractionation of corn stover by hot-water and aqueous ammonia treatment. Bioresour Technol 97:224–232

Klemeš JJ, Varbanov PS (2012) Efficient and clean production of fuels and biofuels: a summary. Clean Technol Environ Policy 14:371–375

Kravanja P, Könighofer K, Canella L, Jungmeier G, Friedl A (2012) Perspectives for the production of bioethanol from wood and straw in Austria: technical, economic, and ecological aspects. Clean Technol Environ Policy 14:411–425

Li B, Asikkala J, Filpponen I, Argyropoulos DS (2010) Factors affecting wood dissolution and regeneration of ionic liquids. Ind Eng Chem Res 49:2477–2484

Lu B, Xu A, Wang J (2014) Cation does matter: how cationic structure affects the dissolution of cellulose in ionic liquids. Green Chem 16:1326–1335

Mai NL, Ha SH, Koo Y-M (2014) Efficient pretreatment of lignocellulose in ionic liquids/co-solvent for enzymatic hydrolysis enhancement into fermentable sugars. Process Biochem 49:1144–1151

Maroušek J (2013a) Pretreatment of sunflower stalks for biogas production. Clean Technol Environ Policy 15:735–740

Maroušek J (2013b) Prospects in straw disintegration for biogas production. Environ Sci Pollut Res 20:7268–7274

Maroušek J (2013c) Removal of hardly fermentable ballast from the maize silage to accelerate biogas production. Ind Crops Prod 44:253–257

Mishra GS, Mitra A, Banerjee R, Ghangrekar M (2014) Comparative pretreatment method for efficient enzymatic hydrolysis of Salvinia cucullata and sewage treatment in ponds containing this biomass. Clean Technol Environ Policy 16:1787–1794

Moniruzzaman M, Ono T (2012) Ionic liquid assisted enzymatic delignification of wood biomass: a new ‘green’ and efficient approach for isolating of cellulose fibers. Biochem Eng J 60:156–160

Moniruzzaman M, Ono T (2013) Separation and characterization of cellulose fibers from cypress wood treated with ionic liquid prior to laccase treatment. Bioresour Technol 127:132–137

Nagarajan V, Mohanty AK, Misra M (2013) Sustainable green composites: value addition to agricultural residues and perennial grasses. ACS Sustain Chem Eng 1:325–333

Ninomiya K, Soda H, Ogino C, Takahashi K, Shimizu N (2013) Effect of ionic liquid weight ratio on pretreatment of bamboo powder prior to enzymatic saccharification. Bioresour Technol 128:188–192

Payal RS, Bejagam KK, Mondal A, Balasubramanian S (2015) Dissolution of cellulose in room temperature ionic liquids: anion dependence. J Phys Chem B 119:1654–1659

Polaskova M et al (2013) Preparation of microfibers from wood/ionic liquid solutions. Carbohydr Polym 92:214–217

Pourbafrani M, McKechnie J, Shen T, Saville BA, MacLean HL (2014) Impacts of pre-treatment technologies and co-products on greenhouse gas emissions and energy use of lignocellulosic ethanol production. J Clean Prod 78:104–111

Qureshi ZS, Deshmukh KM, Bhanage BM (2014) Applications of ionic liquids in organic synthesis and catalysis. Clean Technol Environ Policy 16:1487–1513

Rosa MF et al (2009) Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour Technol 100:5196–5202

Rout J, Misra M, Tripathy S, Nayak S, Mohanty A (2001) The influence of fibre treatment on the performance of coir-polyester composites. Compos Sci Technol 61:1303–1310

Sands JM, Fink BK, McKnight SH, Newton CH, Gillespie JW Jr, Palmese GR (2001) Environmental issues for polymer matrix composites and structural adhesives. Clean Products Process 2:228–235

Shibata M, Teramoto N, Nakamura T, Saitoh Y (2013) All-cellulose and all-wood composites by partial dissolution of cotton fabric and wood in ionic liquid. Carbohydr Polym 98:1532–1539

Shukla SK, Kumar A (2014) Polarity issues in room temperature ionic liquids. Clean Technol Environ Policy 17:1111–1116

Sugano M, Iwabuchi Y, Watanabe T, Kajita J, Iwata K, Hirano K (2010) Relations between thermal degradations of SBS copolymer and asphalt substrate in polymer modified asphalt. Clean Technol Environ Policy 12:653–659

Sun Y-G, Ma Y-L, Wang L-Q, Wang F-Z, Wu Q-Q, Pan G-Y (2015) Physicochemical properties of corn stalk after treatment using steam explosion coupled with acid or alkali. Carbohydr Polym 117:486–493

Swindall W (2004) Ionic liquids come of age-almost. Clean Technol Environ Policy 6:149–150

Tan HT, Lee KT (2012) Understanding the impact of ionic liquid pretreatment on biomass and enzymatic hydrolysis. Chem Eng J 183:448–458

Wechsler A et al (2013) Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil based sustainable particleboard: a comparison of its properties with conventional wood based particleboard. Mater Des 50:117–123

Weerachanchai P, Leong SSJ, Chang MW, Ching CB, Lee J-M (2012) Improvement of biomass properties by pretreatment with ionic liquids for bioconversion process. Bioresour Technol 111:453–459

Zavrel M, Bross D, Funke M, Büchs J, Spiess AC (2009) High-throughput screening for ionic liquids dissolving (ligno-) cellulose. Bioresour Technol 100:2580–2587

Zheng Y, Pan Z, Zhang R, Jenkins BM, Blunk S (2006) Properties of medium-density particleboard from saline Athel wood. Ind Crops Prod 23:318–326

Acknowledgments

This research work was supported by the University Research Internal Fund (URIF) under Grant Number 0153AA-B80, Universiti Teknologi PETRONAS, Malaysia for financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahmood, H., Moniruzzaman, M., Yusup, S. et al. Particulate composites based on ionic liquid-treated oil palm fiber and thermoplastic starch adhesive. Clean Techn Environ Policy 18, 2217–2226 (2016). https://doi.org/10.1007/s10098-016-1132-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1132-0