Abstract

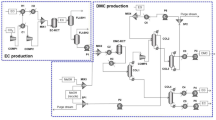

This work presents a preliminary screening of eco-technologies for dimethyl carbonate (DMC) production. Through sustainability metrics, the assessment of six different chemical routes allows comparisons according to economical and environmental criteria, to determine the most sustainable route. CO2 sequestration potential is also considered. The alternatives are scored according to the adopted metrics, leading to the decision of a suitable route based on economic and environmental grounds, prioritizing pollution-preventing technologies herein referred to as eco-technologies. Casting of technologies was based on alternatives available in the literature: Route 1 production of DMC from methanol and phosgene [Ono in Pure Appl Chem 68(2):367–375, 1996]; Route 2 production of DMC from methyl nitrite and CO [Ono in Pure Appl Chem 68(2):367–375, 1996]; Route 3 production of DMC from CO and methanol [Ono in Pure Appl Chem 68(2):367–375, 1996]; Route 4 production of DMC from urea and methanol (Wang et al. in Ind Eng Chem Res 46:8972–8979, 2007); Route 5 production of DMC from ethylene oxide and CO2 [Ono in Pure Appl Chem 68(2):367–375, 1996]; Route 6 production of DMC from CO2 and methanol (Choi et al. in Green Chem 4:230–234, 2002). The analysis shows that Routes 4 and 5 combine intermediate values of the total (sustainability) score, CO2 sequestration potential and industrial feasibility, therefore entitled as eco-technologies, based on the adopted metrics. Although the two technologies are potentially ecological, they are recommended for a more rigorous analysis on the grounds of process simulation and life cycle analysis.

Similar content being viewed by others

Abbreviations

- PP j :

-

Profit potential of Route j

- PPbest :

-

Best result obtained for routes profit potential

- PI j :

-

Profit index of Route j

- ν ji :

-

Stoichiometric coefficient of Chemical i on Route j

- P ji :

-

Price in US$/mol of Chemical i on Route j

- TX j :

-

Toxicity of Route j

- TXbest :

-

Best result obtained for routes’ toxicity

- tx ji :

-

Toxicity of Chemical i on Route j

- TXI j :

-

Toxicity index of Route j

- EI j :

-

Environmental impact of Route j

- EIbest :

-

Best result obtained for routes’ environmental impact

- ScoreTotal,j :

-

Total score or Route j

References

Anatas PT, Allen D (2002) Green chemistry. In: Allen DT (ed) Green engineering: environmentally conscious design of chemical processes. Prentice Hall PTR, New Jersey, pp 177–196

Aresta M, Galatola M (1999) Life cycle analysis applied to the assessment of the environmental impact of alternative synthetic processes. The dimethylcarbonate case: part 1. J Clean Prod 7:181–193

Aresta M, Dibenedetto A, Tommasi I (2001) Developing innovative synthetic technologies of industrial relevance based on carbon dioxide as raw material. Energy Fuels 15:269–273

Choi J et al (2002) Selective and high yield synthesis of dimethyl carbonate directly from carbon dioxide and methanol. Green Chem 4:230–234

EPA (2002) WAR version 1.0.15

Fan LT, Zhang T, Liu J, Schlup JR (2007) Assessment of sustainability-potential: hierarchical approach. Ind Eng Chem Res 46(13):4506–4516

Hossain KA, Khan FI, Hawboldt K (2007) E-Green—a robust risk-based environmental assessment tool for process industries. Ind Eng Chem Res 46:8787–8795

Jensen N, Coll N, Gani R (2003) An integrated computer-aided system for generation and evaluation of sustainable process alternatives. Clean Technol Environ Policy 5:209–225

Krotscheck C, Narodoslawsky M (1996) The sustainable process index—a new dimension in ecological evaluation. Ecol Eng 6:241–258

Ono Y (1996) Dimethyl carbonate for environmentally benign reactions. Pure Appl Chem 68(2):367–375

Wang F et al (2007) Modeling of the catalytic distillation process for the synthesis of dimethyl carbonate by urea methanolysis method. Ind Eng Chem Res 46:8972–8979

Xiaolu L et al (2006) Study of combustion and emission characteristics of a diesel engine operated with dimethyl carbonate. Energy Convers Manag 47:1438–1448

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monteiro, J.G.MS., de Queiroz Fernandes Araújo, O. & de Medeiros, J.L. Sustainability metrics for eco-technologies assessment, part I: preliminary screening. Clean Techn Environ Policy 11, 209–214 (2009). https://doi.org/10.1007/s10098-008-0189-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-008-0189-9