Abstract

The risk of excavation operations due to high capital costs can be reduced by correct estimation of machine performance. Many models have been proposed to study this issue, but considering the nature of the problem, it is rather difficult to estimate tunnel boring machine performance by simple linear prediction models. The purpose of the present study is to construct linear and non-linear multivariate prediction models to estimate TBM performance as a function of rock mass properties in granitic and mica-gniess rocks. For this purpose, rock properties and machine data were obtained from a historical TBM tunneling project in Norway and then the database was established to develop performance prediction models utilizing the linear and the non-linear multiple regression methods. This study proposes more accurate and practical statistical models compared to the previous ones based on multivariate regression analyses to estimate the performance of hard rock TBMs.

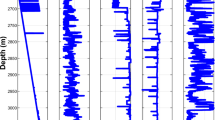

(Modified after NGU 2015)

Similar content being viewed by others

References

Aeberli U, Wanner WJ (1978) On the influence of discontinuities at the application of tunnelling machines. In: Proceedings of the 3rd International Congress IAEG, Madrid, Part III (2), p 7–14

Aune B (1993) Temperatur normaler, normalperiode 1961–90. Oslo: Den norske meteorologiske institutt, Rapport 02/93

Barton N (2000) TBM tunnelling in jointed and faulted rock. Balkema, Rotterdam

Bruland A (1998) Hard rock tunnel boring. Doctoral thesis, Norwegian University of Science and Technology, Trondheim

Cheema S (1999) Development of a rock mass boreability index for the performance of tunnel boring machines. PhD dissertation, Colorado School of Mines, Golden, CO

Deer DU (1981) Adverse geology and TBM tunneling problems. In: Proceedings of RETS. Society of Mining, pp 574–586

Delisio A, Zhao J, Einstein HH (2013) Analysis and prediction of TBM performance in blocky rock conditions at the Lotschberg Base Tunnel. Tunn Undergr Space Technol 33:131–142

Farmer IW, Glossop NH (1980) Mechanics of disc cutter penetration. Tunn Tunn Int 12:22–25

Farrokh E, Rostami J, Laughton C (2012) Study of various models for estimation of penetration rate of hard rock TBMs. Tunn Undergr Space Technol 30:110–123

Forland EJ (1993) Nedbornormaler normalperiode 1961–90. Oslo: Den norske meteorologiske institutt, Rapport 39/93

Gehring K (1994) Experience with TBM-application under extreme rock condition in a South-African project leads to development of high-performance disk cutters. In: Proceedings of the 7th international IAEG congress. Balkema, Rotterdam, pp 4243–4252

Gelman A, Hill J (2006) Data analysis using regression and multilevel/hierarchical models, 1st edn. Cambridge University Press, Cambridge, p 648

Gong QM, Zhao J (2007) Influence of rock brittleness on TBM penetration rate in Singapore Granite. Tunn Undergr Space Tech 22:317–324

Gong QM, Zhao J (2009) Development of a rock mass characteristics model for TBM penetration rate prediction. Int J Rock Mech Min Sci 46:8–18

Gong QM, Zhao J, Jiao YY (2005) Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Space Tech 20:183–191

Gong QM, Jiao YY, Zhao J (2006) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 21:46–55

Gong QM, Zhao J, Jiang YS (2007) In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunn Undergr Space Techn 22:303–316

Graham PC (1976) Rock exploration for machine manufacturers. In: Bieniawski ZT (ed) Exploration for rock engineering. Balkema, Johannesburg, pp 173–180

Hassanpour J, Rostami J, Khamehchiyan M, Bruland A (2009) Developing new equations for TBM performance prediction in carbonate-argillaceous rocks: a case history of Nowsood water conveyance tunnel. Geomech Geoeng Int J 4(4):287–297

Hassanpour J, Rostami J, Khamehchiyan M, Bruland A, Tavakoli HR (2010) TBM performance analysis in pyroclastic rocks: a case history of Karaj water conveyance tunnel. Rock Mech Rock Eng 43(4):427–445

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunn Undergr Space Technol 26:595–603

Hassanpour J, Rostami J, Zhao J, Tarigh Azali S (2015) TBM performance and disc cutter wear prediction based on ten years experience of TBM tunnelling in Iran. Geomechanik und Tunnelbau 8(3):239–247

Hassanpour J, Ghaedi Vanani AA, Rostami J, Cheshomi A (2016) Evaluation of common TBM performance prediction models based on field data from the second lot of Zagros water conveyance tunnel (ZWCT2). Tunn Undergr Space Technol 52:147–156

Hughes HM (1986) The relative cuttability of coal measures rock. Min Sci Technol 3:95–109

IBM SPSS Inc. (2011) SPSS regression models (Version 20.0)

Isaksen K, Hauck C, Gudevang E, Odegard RS, Sollid JL (2002) Mountain permafrost distribution in Dovrefjell and Jotunheimen, southern Norway, based on BTS and DC resistivity tomography data. Nor Geogr Tidsskr 56:122–136

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using Rock Mass Rating (RMR) system. Tunn Undergr Space Technol 25:333–345

Klein S, Schmoll M, Avery T (1995) TBM performance at four hard rock tunnels in California. In: Proceedings of the Rapid Excavation and Tunnelling Conference, pp 61–75 (Chapter 4)

Macias FJ, Jakobsen PD, Seo Y, Bruland A (2014) Influence of rock mass fracturing on the net penetration rates of hard rock TBMs. Tunn Undergr Space Technol 44:108–120

Matern N, Hjelmer A (1943) Forsok med pagrus (“Tests with Chippings”), Bulletin 65, Statens Vaginstitut, Stockholm, pp 65 (English summary, pp 56–60)

Mikaeil R, Zare Naghadehi M, Sereshki F (2009) Multifactorial fuzzy approach to the penetrability classification of TBM in hard rock conditions. Tunn Undergr Space Technol 24(5):500–505

Nelson PP (1993) TBM performance analysis with reference to rock properties. In: Hudson JA (ed) Comprehensive rock engineering, Chap 10, vol 4. Pergamon Press, pp 261–291

Norges Geologiske Undersokelse, NGU (2015) Produktark: Berggrunn N250 (M 1: 250,000), Norway, januar 2015

Oraee K, Salehi B (2013) Assessing prediction models of advance rate in tunnel boring machines-a case study in Iran. Arab J Geosci 6(2):481–489

Ramezanzadeh A (2005) Performance Analysis and Development of New Models for Performance Prediction of Hard Rock TBMs in Rock Mass, Ph.D. Thesis, INSA de Lyon, France, p 333

Ramezanzadeh A, Rostami J, Kastner R (2005) Influence of Rock Mass Properties on Performance of Hard Rock TBMs. RETC, June 27–29, Seattle, Washington, USA

Ramezanzadeh A, Rostami J, Tadic D (2008) Impact of rock mass characteristics on hard rock TBM performance. In: 13th Australian Tunneling Conference, Melbourne

Robbins (2015) Products catalogues. http://www.therobbinscompany.com/. Accessed June 2016

Rostami J (1997) Development of a force estimation model for rock fragmentation with disc cutters through theoretical modelling and physical measurement of crushed zone pressure. Doctoral Dissertation, Colorado School of Mines, Golden, CO

Rostami J, Ozdemir L (1993) A new model for performance perdiction of hard rock TBMs. In: RETC proceedings, p 793–809

Salimi A, Rostami J, Moormann C, Delisio A (2016) Application of non-linear regression analysis and artificial intelligence algorithms for performance prediction of hard rock TBMs. Tunn Undergr Space Technol 58:236–246

Sanio HP (1985) Prediction of the performance of disc cutters in anisotropic rock. Int J Rock Mech Min Sci 22:153–161

Sapigni M, Berti M, Bethaz E, Busillo A, Cardone G (2002) TBM performance estimation using rock mass classifications. Int J Rock Mech Min Sci 39:771–788

Sievers H (1950) Die Bestimmung des Bohrwiderstandes von Gesteinen, Glückauf 86: 37/38, pp 776–784 Glückauf G.M.B.H., Essen

Solheim O, Rake R, Kvarv P (1987) Fullprofilboring ved Jostedal-Anlegget (Fullfaceboring at the Jostedal Hydropower Project). In: (Asting G, Lauritzen R, Heltzen AM, Berg KR, eds) Fjellsprengningsteknikk-Bergmekanikk-Geoteknikk Conference, Oslo, Norway, Norwegian Geotechnical Institute. (In Norwegian)

Tarkoy PJ (1973) Predicting TBM penetration rate in selected rock type. In: Proceedings, Ninth Canadian Rock Mechanics Symposium, Montreal

Thuro K, Plinninger RJ (2003) Hard rock tunnel boring, cutting, drilling and blasting: rock parameters for excavatability. In: Proceedings of the 10th inter-national congress ISRM, South African Institute on Mineral Metallurgy, pp 1–7

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn Undergr Space Technol 23:326–339

Yagiz S, Ozdemir L (2001) Geotechnical parameters influencing the TBM performance in various rocks. In program with abstracts. 44th Annual Meeting of AEG. Technical Session 10; Engineering Geology for Construction Practices, St. Louis. MO, USA

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22:808–814

Yarali O, Kahraman S (2011) The drillability assessment of rocks using the different brittleness values. Tunn Undergr Space Technol 26:406–414

Zare Naghadehi M, Mikaeil R (2016) Optimization of tunnel boring machine (TBM) disc cutter spacing in jointed hard rock using a distinct element numerical simulation. Periodica Poltytechnica Civil Engineering, Accepted for publication

Acknowledgments

Special thanks and appreciation go to Professor Amund Bruland from the Department of Civil and Transport Engineering of the Norwegian University of Science and Technology (NTNU) for providing the authors with the in situ penetration test dataset and the related documents.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zare Naghadehi, M., Ramezanzadeh, A. Models for estimation of TBM performance in granitic and mica gneiss hard rocks in a hydropower tunnel. Bull Eng Geol Environ 76, 1627–1641 (2017). https://doi.org/10.1007/s10064-016-0950-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-016-0950-y