Abstract

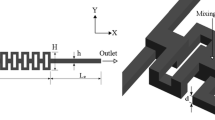

Three-dimensional CFD simulations carried to evaluate mixing performance of two designs of micromixers namely RB-TSAR and EB-TSAR. The results of flow physics analysis indicate that the interfacial area between the two flow fluids can be enhanced by creating a flow in transverse direction with the help of split and recombination of fluid streams by placing baffles in diffuser shaped mixing elements along the axial direction. Further, the simulation results indicate that at inlet Reynolds number below 1, the molecular diffusion is the most dominant mechanism of mixing, and the mixing index is almost the same for all cases. However at Re > 5, the secondary flow influencing the mixing process dramatically and thus mixing index is increased. The results also reveal that baffles can break the fluid streams, produce fluid convection and increase the contact area of the fluid by folding and deflecting which in turn helps to improve the mixing index. The split and recombination of the fluid streams and separation vortices play vital role in enhancing the mixing performance. The design configurations studied here showed mixing index higher than 0.85 for the Re in the range from 10 to 50.

Similar content being viewed by others

References

Afzal A, Kim KY (2012) Passive split and recombination micromixer with convergent–divergent walls. Chem Eng J 203:182–192

Ansari MA, Kim KY (2010) Mixing performance of unbalanced split and recombine micromixers with circular and rhombic sub-channels. Chem Eng J 162(2):760–767

Bothe D, Stemich C, Warnecke HJ (2006) Fluid mixing in a T-shaped micro-mixer. Chem Eng Sci 61(9):2950–2958

Chen X, Shen J (2017) Numerical and experimental investigation on splitting-and-recombination micromixer with E-shape mixing units. Microsyst Technol 23(10):4671–4677

Chen X, Zhao Z (2017) Numerical investigation on layout optimization of obstacles in a three-dimensional passive micromixer. Anal Chim Acta 964:142–149

Chen X, Li T, Hu Z (2016a) A novel research on serpentine microchannels of passive micromixers. Microsyst Technol 23(7):2649–2656

Chen X, Li T, Zeng H, Hu Z, Fu B (2016b) Numerical and experimental investigation on micromixers with serpentine microchannels. Int J Heat Mass Transf 98:131–140

Chen X, Zhang Z, Yi D, Hu Z (2017) Numerical studies on different two-dimensional micromixers basing on a fractal-like tree network. Microsyst Technol 23(3):755–763

Cheri MS, Latifi H, Moghaddam MS, Shahraki H (2013) Simulation and experimental investigation of planar micromixers with short-mixing-length. Chem Eng J 234:247–255

Chung CK, Shih TR (2007) A rhombic micromixer with asymmetrical flow for enhancing mixing. J Micromech Microeng 17(12):2495

Chung YC, Hsu YL, Jen CP, Lu MC, Lin YC (2004) Design of passive mixers utilizing microfluidic self-circulation in the mixing chamber. Lab Chip 4(1):70–77

Chung CK, Shih TR, Chang CK, Lai CW, Wu BH (2011) Design and experiments of a short-mixing-length baffled microreactor and its application to microfluidic synthesis of nanoparticles. Chem Eng J 168(2):790–798

Cortes-Quiroz CA, Zangeneh M, Goto A (2009) On multi-objective optimization of geometry of staggered herringbone micromixer. Microfluid Nanofluid 7(1):29–43

Cortes-Quiroz CA, Azarbadegan A, Zangeneh M (2014) Evaluation of flow characteristics that give higher mixing performance in the 3-D T-mixer versus the typical T-mixer. Sens Actuators B Chem 202:1209–1219

Falk L, Commenge JM (2010) Performance comparison of micromixers. Chem Eng Sci 65(1):405–411

Galletti C, Roudgar M, Brunazzi E, Mauri R (2012) Effect of inlet conditions on the engulfment pattern in a T-shaped micro-mixer. Chem Eng J 185:300–313

Gidde RR, Pawar PM (2019) Flow feature analysis of T-junction wavy micromixer for mixing application. Int J Chem React Eng. https://doi.org/10.1515/ijcre-2018-0306

Gidde RR, Pawar PM, Ronge BP, Misal ND, Kapurkar RB, Parkhe AK (2018a) Evaluation of the mixing performance in a planar passive micromixer with circular and square mixing chambers. Microsyst Technol 24(6):2599–2610

Gidde RR, Shinde AB, Pawar PM, Ronge BP (2018b) Design optimization of a rectangular wave micromixer (RWM) using Taguchi based grey relational analysis (GRA). Microsyst Technol 24(9):3651–3666

Gidde RR, Pawar PM, Ronge BP, Shinde AB, Misal ND, Wangikar SS (2018c) Flow field analysis of a passive wavy micromixer with CSAR and ESAR elements. Microsyst Technol 25(3):1017–1030

Gidde RR, Pawar PM, Gavali SR, Salunkhe SY (2019) Flow feature analysis of an eye shaped split and collision (ES-SAC) element based micromixer for lab-on-a-chip application. Microsyst Technol. https://doi.org/10.1007/s00542-018-4271-x

Gigras A, Pushpavanam S (2008) Early induction of secondary vortices for micromixing enhancement. Microfluid Nanofluid 5(1):89–99

Goet G, Baier T, Hardt S (2009) Micro contactor based on isotachophoretic sample transport. Lab Chip 9(24):3586–3593

Hardt S, Drese K, Hessel V, Schönfeld F (2004) Passive micro mixers for applications in the micro reactor and µTAS field. In: 2nd international conference on microchannels and minichannels, American Society of Mechanical Engineers, pp 45–55

Hossain S, Kim KY (2014) Mixing analysis of passive micromixer with unbalanced three-split rhombic sub-channels. Micromachines 5(4):913–928

Hossain S, Lee I, Kim SM, Kim KY (2017) A micromixer with two-layer serpentine crossing channels having excellent mixing performance at low Reynolds numbers. Chem Eng J 327:268–277

Huang SW, Wu CY, Lai BH, Chien YC (2017) Fluid mixing in a swirl-inducing microchannel with square and T-shaped crosssections. Microsyst Technol 23:1971–1981

Jain M, Rao A, Nandakumar K (2013) Numerical study on shape optimization of groove micromixers. Microfluid Nanofluid 15(5):689–699

Kim DS, Lee SH, Kwon TH, Ahn CH (2005) A serpentine laminating micromixer combining splitting/recombination and advection. Lab Chip 5(7):739–747

Kuo JN, Li YS (2017) Centrifuge-based micromixer with three-dimensional square-wave microchannel for blood plasma mixing. Microsyst Technol 23:2343–2354

Liu M (2011) Computational study of convective–diffusive mixing in a microchannel mixer. Chem Eng Sci 66(10):2211–2223

Nguyen NT, Wereley S (2006) Fundamentals and applications of microfluidics. Artech House, Boston, pp 293–341

Nguyen NT, Wu Z (2004) Micromixers—a review. J Micromech Microeng 15(2):R1

Oh DW, Jin JS, Choi JH, Kim HY, Lee JS (2007) A microfluidic chaotic mixer using ferrofluid. J Micromech Microeng 17(10):2077

Okuducu M, Aral M (2018) Performance analysis and numerical evaluation of mixing in 3-D T-shape passive micromixers. Micromachines 9(5):210

Okuducu MB, Aral MM (2019) Computational evaluation of mixing performance in 3-D swirl-generating passive micromixers. Processes 7(3):121

Ortega-Casanova J (2016) Enhancing mixing at a very low Reynolds number by a heaving square cylinder. J Fluids Struct 65:1–20

Posner JD, Santiago JG (2006) Convective instability of electrokinetic flows in a cross-shaped microchannel. J Fluid Mech 555:1–42

Pradeep A, Raveendran J, Ramachandran T, Nair BG (2016) Computational simulation and fabrication of smooth-edged passive micromixers with alternately varying diameter for efficient mixing. Microelectron Eng 165:32–40

Roudgar M, Brunazzi E, Galletti C, Mauri R (2012) Numerical study of split T-micromixers. Chem Eng Technol 35(7):1291–1299

Sahu PK, Golia A, Sen AK (2013) Investigations into mixing of fluids in microchannels with lateral obstructions. Microsyst Technol 19:493–501

Sarkar S, Singh KK, Shankar V, Shenoy KT (2015) CFD simulations to study the effects of wall protrusions on microfluidic mixing. J Micromech Microeng 25(8):084008

Shah I, Kim SW, Kim K, Doh YH, Choi KH (2019) Experimental and numerical analysis of Y-shaped split and recombination micro-mixer with different mixing units. Chem Eng J 358:691–706

Shih TR, Chung CK (2008) A high-efficiency planar micromixer with convection and diffusion mixing over a wide Reynolds number range. Microfluid Nanofluid 5(2):175–183

Suh YK, Kang S (2010) A review on mixing in microfluidics. Micromachines 1:82–111

The HL, Ta BQ, Thanh HL, Dong T, Thoi TN, Karlsen F (2015a) Geometric effects on mixing performance in a novel passive micromixer with trapezoidal-zigzag channels. J Micromech Microeng 25:094004

The HL, Thanh HL, Dong T, Ta BQ, Tran-Minh N, Karlsen F (2015b) An effective passive micromixer with shifted trapezoidal blades using wide Reynolds number range. Chem Eng Res Des 93:1–11

Tran-Minh N, Dong T, Karlsen F (2014) An efficient passive planar micromixer with ellipse-like micropillars for continuous mixing of human blood. Comput Methods Progr Biomed 117(1):20–29

Wang H, Iovenitti P, Harvey E, Masood S (2002) Optimizing layout of obstacles for enhanced mixing in microchannels. Smart Mater Struct 11(5):662

Xia GD, Li YF, Wang J, Zhai YL (2016) Numerical and experimental analyses of planar micromixer with gaps and baffles based on field synergy principle. Int Commun Heat Mass Transfer 71:188–196

Yang Z, Goto H, Matsumoto M, Maeda R (2000) Active micromixer for microfluidic systems using lead- zirconate- titanate (PZT) generated ultrasonic vibration. ELECTROPHOR Int J 21(1):116-119

Yaralioglu GG, Wygant IO, Marentis TC, Khuri-Yakub BT (2004) Ultrasonic mixing in microfluidic channels using integrated transducers. Anal Chem 76(13):3694–3698

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gidde, R.R., Pawar, P.M. Flow feature and mixing performance analysis of RB-TSAR and EB-TSAR micromixers. Microsyst Technol 26, 517–530 (2020). https://doi.org/10.1007/s00542-019-04498-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-019-04498-w