Abstract

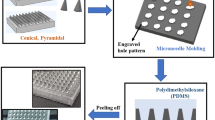

This paper reports a new technique of fabricating polystyrene microlenses with both convex and concave profiles that are integrated in polymer-based microfluidic system. The polystyrene microlenses, or microlens array, are fabricated using the free-surface thermal compression molding method. The laser fabricated poly(methyl methacrylate) (PMMA) sheet is used as the mold for the thermal compression molding process. With different surface treatment methods of the PMMA mold, microlenses with either convex or concave profiles could be achieved during the thermal molding process. By integrating the microlenses in the microfluidic systems, observing the flow inside the microchannels is easier. This new technique is rapid, low cost, and it does not require cleanroom facilities. Microlenses with both convex and concave profiles can be easily fabricated and integrated in microfluidic system with this technique.

Similar content being viewed by others

References

Abdelgawad M, Watson MWL, Wheeler AR (2009) Hybrid microfluidics: a digital-to-channel interface for in-line sample processing and chemical separations. Lab Chip 9(8):1046–1051. doi:10.1039/b820682a

Carter JC, Alvis RM, Brown SB, Langry KC, Wilson TS, McBride MT, Myrick ML, Cox WR, Grove ME, Colston BW (2006) Fabricating optical fiber imaging sensors using inkjet printing technology: a pH sensor proof-of-concept. Biosens Bioelectron 21(7):1359–1364. doi:10.1016/j.bios.2005.06.006

Domachuk P, Tsioris K, Omenetto FG, Kaplan DL (2010) Bio-microfluidics: biomaterials and Biomimetic Designs. Adv Mater 22(2):249–260. doi:10.1002/adma.200900821

Edwards CA, Presby HM, Dragone C (1993) Ideal microlenses for laser to fiber coupling. J Lightwave Technol 11(2):6

Etoh TG, Poggemann D (2003) An image sensor which captures 100 consecutive frames at 1000000 frames/s. IEEE Trans Electron Devices 50(1):7

Fakhfouri V, Cantale N, Mermoud G, Kim JY, Boiko D, Charbon E, Martinoli A, Brugger J (2008) Inkjet printing of SU-8 for polymer-based MEMS a case study for microlenses. In: Micro electro mechanical systems, 2008. MEMS 2008. IEEE 21st international conference on, 13–17 Jan. 2008. pp 407–410. doi:10.1109/memsys.2008.4443679

Fan YQ, Li HW, Foulds IG (2011) Fabrication of microlens and microlens array on polystyrene using CO2 laser. Adv Mater Res 403–408:3350–3353. doi:10.4028/www.scientific.net/AMR.403-408.3350

Fan Y, Li H, Conchouso D, Foulds IG (2013a) Simulation and fabrication of integrated polystyrene microlens in microfluidic system. SPIE Microtechnologies 8763:876318. doi:10.1117/12.2015509

Fan Y, Li H, Yi Y, Foulds I (2013b) PMMA to Polystyrene bonding for polymer based microfluidic systems. Microsyst Technol:1–6. doi:10.1007/s00542-013-1778-z

Gunther A, Jensen KF (2006) Multiphase microfluidics: from flow characteristics to chemical and materials synthesis. Lab Chip 6(12):1487–1503. doi:10.1039/b609851g

Iga K, Oikawa M, Misawa S, Banno J, Kokubun Y (1982) Stacked planar optics: an application of the planar microlens. Appl Opt 21(19):5

Kunnavakkam MV, Houlihan FM, Schlax M, Liddle JA, Kolodner P, Nalamasu O, Rogers JA (2003) Low-cost, low-loss microlens arrays fabricated by soft-lithography replication process. Appl Phys Lett 82(8):1152. doi:10.1063/1.1555694

Lim CS, Hong MH, Kumar AS, Rahman M, Liu XD (2006) Fabrication of concave micro lens array using laser patterning and isotropic etching. Int J Mach Tools Manuf 46(5):552–558. doi:10.1016/j.ijmachtools.2005.06.004

Mihailov S, Lazare S (1993) Fabrication of refractive microlens arrays by excimer laser ablation of amorphous Teflon. Appl Opt 32(31):6211–6218

O’Neill FT, Sheridan JT (2002) Photoresist reflow method of microlens production Part I: background and experiments. Optik Int J Light Electron Optics 113(9):391–404. doi:10.1078/0030-4026-00186

Partridge RH (1967) Vacuum-ultraviolet absorption spectrum of polystyrene. J Chem Phys 47(10):4223–4227

Yabu H, Shimomura M (2005) Simple fabrication of micro lens arrays. Langmuir 21(5):1709–1711. doi:10.1021/la046996z

Yang H, Chao C-K, Wei M-K, Lin C-P (2004) High fill-factor microlens array mold insert fabrication using a thermal reflow process. J Micromech Microeng 14(8):1197–1204. doi:10.1088/0960-1317/14/8/012

Yi C, Li C-W, Ji S, Yang M (2006) Microfluidics technology for manipulation and analysis of biological cells. Anal Chim Acta 560 (1–2):1–23. doi:http://dx.doi.org/10.1016/j.aca.2005.12.037

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, Y., Li, H. & Foulds, I.G. Integration of polystyrene microlenses with both convex and concave profiles in a polymer-based microfluidic system. Microsyst Technol 20, 815–819 (2014). https://doi.org/10.1007/s00542-013-2038-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-2038-y