Abstract

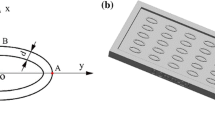

This paper reports a novel method to fabricate three-dimensional (3D) polydimethylsiloxane (PDMS) micro-pillars using a CO2 laser-machined poly(methyl methacrylate) (PMMA) mold with through-holes. This method eliminates the requirements of expensive and complicated facilities to fabricate a 3D mold. The micro-pillars were formed by the capillary force that draws PDMS into the through-holes of the PMMA mold. The tilt angles of the micro-pillars depend on the tilt angles of the through-holes in the mold, and the concave and convex micro-lens tip shapes of the PDMS micro-pillars can be modified by changing the surface wettability of the PMMA through-holes.

Similar content being viewed by others

References

Bertsch A, Lorenz H, Renaud P (1999) 3D microfabrication by combining microstereolithography and thick resist UV lithography. Sens Actuat A 73:14–23

Campbell M, Sharp DN, Harrison MT, Denning RG, Turberfield AJ (2000) Fabrication of photonic crystals for the visible spectrum by holographic lithography. Nature 404:53–56

Dauriac V, Descroix S, Chen Y, Peltre G, Sénéchal H (2008) Isoelectric focusing in an ordered micro-pillar array. Electrophoresis 29:2945–2952

Erdmann L, Gabriel KJ (2001) High-resolution digital integral photography by use of a scanning micro-lens array. Appl Opt 40:5592–5599

Galas JC, Belier B, Aassime A, Palomo J, Bouville D, Aubert J (2004) Fabrication of three-dimensional microsturctures using standard ultraviolet and electron-beam lithography. J Vac Sci Technol B 22:1160–1162

Kim J, Nayak S, Lyon LA (2005) Bioresponsive hydrogel micro-lenses. J Am Chem Soc 127:9588–9592

King C, Lin L, Wu M (1996) Out-of-plane refractive micro-lens fabricated by surface micromachining. IEEE Photon Technol Lett 8:1349–1351

Klank H, Kutter JP, Geschke O (2002) CO2-laser micromachining and back-end processing for rapid production of PMM-based microfluidic systems. Lab Chip 2:242–246

Kudryashov V, Yuan XC, Cheong WC, Radhakrishnan K (2003) Grey scale structures formation in SU-8 with e-beam and UV. Micro Electron Eng 67–68:306–311

Li HY, Dauriac V, Thibert V, Senechal H, Peltre G, Zhang XX, Descroix S (2010) Micro-pillar array chips toward new immunodiagosis. Lab Chip 10:2597–2604

Meisel DC, Wegener M, Busch K (2004) Three-dimensional photonic crystals by holographic lithography using the umbrella configuration: symmetries and complete photonic band gaps. Phys Rev B 70:165104

Moon MW, Cha TG, Lee KR, Vaziri A, Kim HY (2010) Tilted Janus polymer pillars. Soft Matter 6:3924–3929

Popovic ZD, Sprague RA, Connell GAN (1988) Technique for monolithic fabrication of micro-lens arrays. Appl Opt 27:1281–1284

Qu LT, Dai LM, Stone M, Xia ZH, Wang ZL (2008) Carbon nanotube arrays with strong shear binding-on and easy normal lifting-off. Science 322:238–242

Rahmawan Y, Moon MW, Kim KS, Lee KR, Suh KY (2010) Wrinkled, dual-scale structures of diamond-like carbon (DLC) for superhydrophobicity. Langmuir 26:484–491

Ruther P, Gerlach B, Gottert J, Ilie M, Mohr J, Muller A, Obmann C (1997) Fabrication and characterization of micro-lenses realized by a modified LIGA process. Pure Appl Opt 6:643–653

Sameoto D, Menon C (2009) A low-cost, high-yield fabrication method for producing optimized biomimetic dry adhesives. J Micromech Microeng 19:115002

Sankur H, Motamedi E, Hall R, Gunning WJ, Khoshnevisan M (1995) Fabrication of refractive micro-lens arrays. Proc SPIE 2383:179–183

Sharp DN, Campbell M, Dedman ER, Harrison MT, Denning RG, Turberfield AJ (2002) Photonic crystals for the visible spectrum by holographic lithography. Opt Quantum Electron 34:3

Xu YC, Xie FB, Qiu T, Xie L (2012) Rapid fabrication of a microdevice with concave microwells and its application in embryoid body formation. Biomicrofluidics 6:016504

Yang S, Ullal CK, Thomas EL, Chen G, Aizenberg J (2005) Micro-lens arrays with integrated pores as a multipattern photomask. Appl Phys Lett 86:201121

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Fan, Y., Conchouso, D. et al. Surface tension-induced PDMS micro-pillars with controllable tips and tilt angles. Microsyst Technol 21, 445–449 (2015). https://doi.org/10.1007/s00542-013-2031-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-2031-5