Abstract

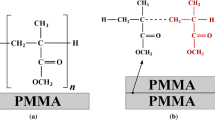

A thermal bonding technique for Poly (methylmethacrylate) (PMMA) to Polystyrene (PS) is presented in this paper. The PMMA to PS bonding was achieved using a thermocompression method, and the bonding strength was carefully characterized. The bonding temperature ranged from 110 to 125 °C with a varying compression force, from 700 to 1,000 N (0.36–0.51 MPa). After the bonding process, two kinds of adhesion quantification methods were used to measure the bonding strength: the double cantilever beam method and the tensile stress method. The results show that the bonding strength increases with a rising bonding temperature and bonding force. The results also indicate that the bonding strength is independent of bonding time. A deep-UV surface treatment method was also provided in this paper to lower the bonding temperature and compression force. Finally, a PMMA to PS bonded microfluidic device was fabricated successfully.

Similar content being viewed by others

References

Bhattacharyya A, Klapperich CM (2007) Mechanical and chemical analysis of plasma and ultraviolet? Ozone surface treatments for thermal bonding of polymeric microfluidic devices. Lab Chip 7:876. doi:10.1039/b700442g

Chen CS, Breslauer DN, Luna JI, Grimes A, Chin WC, Lee LP, Khine M (2008) Shrinky-dink microfluidics: 3D polystyrene chips. Lab Chip 8:622. doi:10.1039/b719029h

Fan YQ, Li HW, Foulds IG (2011) Fabrication of microlens and microlens array on polystyrene using CO2 laser. Adv Mater Res 403–408:3350–3353. doi:10.4028/www.scientific.net/AMR.403-408.3350

Fan Y, Liu Y, Li H, Foulds IG (2012) Printed wax masks for 254 nm deep-UV pattering of PMMA-based microfluidics. J Micromech Microeng 22:027001. doi:10.1088/0960-1317/22/2/027001

Kuswandi B, Nuriman Huskens J, Verboom W (2007) Optical sensing systems for microfluidic devices: a review. Anal Chim Acta 601:141–155. doi:10.1016/j.aca.2007.08.046

Pawde SM, Parab SS (2008) Spectroscopic and antimicrobial studies of polystyrene lms under air plasma and He–Ne laser treatment. J Pramana 70:935–948. doi:10.1007/s12043-008-0100-6

Puurunen RL, Suni T, Ylivaara OME, Kondo H, Ammar M, Ishida T, Fujita H, Bosseboeuf A, Zaima S, Kattelus H (2012) Silicon full wafer bonding with atomic layer deposited titanium dioxide and aluminum oxide intermediate films. Sens Actuators, A. doi:10.1016/j.sna.2012.05.006

Truckenmiiller R, Henzi P, Herrmann D, Saile V, Schomburg WK (2004) Bonding of polymer microstructures by UV irradiation and subsequent welding at low temperatures. Microsyst Technol 10:3

Tsao CW, Hromada L, Liu J, Kumar P, DeVoe DL (2007) Low temperature bonding of PMMA and COC microfluidic substrates using UV/ozone surface treatment. Lab Chip 7:499. doi:10.1039/b618901f

Upstone SL (2006) Ultraviolet/visible light absorption spectrophotometry in clinical chemistry. Encyclopedia of analytical chemistry. doi:10.1002/9780470027318.a0547

Vallin Ö, Jonsson K, Lindberg U (2005) Adhesion quantification methods for wafer bonding. Mater Sci Eng: R: Rep 50:109–165. doi:10.1016/j.mser.2005.07.002

Wagenblast GSG (1989) New perylene and violanthrone dyestuffs for fluorescent collectors. Dyes Pigments 11:14

Zhu X, Liu G, Guo Y, Tian Y (2006) Study of PMMA thermal bonding. Microsyst Technol 13:403–407. doi:10.1007/s00542-006-0224-x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, Y., Li, H., Yi, Y. et al. PMMA to Polystyrene bonding for polymer based microfluidic systems. Microsyst Technol 20, 59–64 (2014). https://doi.org/10.1007/s00542-013-1778-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-1778-z