Abstract

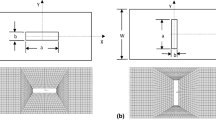

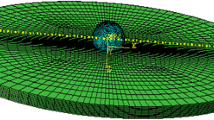

A novel three-dimensional progressive damage model based on generalized mixed finite element method (GMPDM) was established to investigate the strength and failure behavior of notched composite laminate plate. Firstly, the stress distribution of notched isotropic plate under tension is studied, and the results are compared with the analytical solution to verify the high accuracy of the generalized mixed finite element method. Then, the strength and failure modes of three notched composite laminates are studied. The results are compared with the several groups of results to verify the high-precision of the developed GMPDM method, respectively.

Similar content being viewed by others

References

Kozlov, M.V., Sheshenin, S.V.: Modeling the progressive failure of laminated composites. Mech. Compos. Mater. 51(6), 695–706 (2016)

Tay, T.E., Liu, G., Tan, V.B.C., et al.: Progressive failure analysis of composites. J. Compos. Mater. 42(18), 1921–1966 (2008)

Liu, G., Tang, K.: Study on stress concentration in notched cross-ply laminates under tensile loading. J. Compos. Mater. 50(3), 283–296 (2016)

Ridha, M., Wang, C.H., Chen, B.Y., et al.: Modelling complex progressive failure in notched composite laminates with varying sizes and stacking sequences. Compos. A Appl. Sci. Manuf. 58, 16–23 (2014)

Pineda, E.J., Waas, A.M., Bednarcyk, B.A., et al.: Progressive damage and failure modeling in notched laminated fiber reinforced composites. Int. J. Fract. 158(2), 125–143 (2009)

Tan, S.C., Perez, J.: Progressive failure of laminated composites with a hole under compressive loading. J. Reinf. Plast. Compos. 12(10), 1043–1057 (1993)

Zhang, J., Qi, D., Zhou, L., et al.: A progressive failure analysis model for composite structures in hygrothermal environments. Compos. Struct. 133, 331–342 (2015)

Tay, T.E., Liu, G., Tan, V.B.C.: Damage progression in open-hole tension laminates by the SIFT–EFM approach. J. Compos. Mater. 40(11), 971–992 (2006)

Eriksson, I., Aronsson, C.G.: Strength of tensile loaded graphite/epoxy laminates containing cracks, open and filled holes. J. Compos. Mater. 24(5), 456–482 (1990)

Kilic, H., Haj-Ali, R.: Progressive damage and nonlinear analysis of pultruded composite structures. Compos. B Eng. 34(3), 235–250 (2003)

Mines, R.A.W., Alias, A.: Numerical simulation of the progressive collapse of polymer composite sandwich beams under static loading. Compos. A Appl. Sci. Manuf. 33(1), 11–26 (2002)

Padhi, G.S., Shenoi, R.A., Moy, S.S.J., et al.: Progressive failure and ultimate collapse of laminated composite plates in bending. Compos. Struct. 40(3–4), 277–291 (1997)

Chen, J.F., Morozov, E.V., Shankar, K.: Simulating progressive failure of composite laminates including in-ply and delamination damage effects. Compos. A Appl. Sci. Manuf. 61, 185–200 (2014)

Qing G, Mao J, Liu Y. Generalized mixed finite element method for 3D elasticity problems[J]. Acta Mech. Sin. 34(2), 371–380 (2018)

Van Hoa, S., Feng, W.: Hybrid Finite Element Method for Stress Analysis of Laminated Composites. Springer, Berlin (2013)

Timoskenko, S.P., Goodier, J.N.: Theory of Elasticity, 2nd edn, p. 78. McGraw-Hill, New York (1951)

Hashin, Z.: Failure criteria for unidirectional fiber composites. J. Appl. Mech. 47(2), 329–334 (1980)

Dano, M.L., Gendron, G., Picard, A.: Stress and failure analysis of mechanically fastened joints in composite laminates. Compos. Struct. 50(3), 287–296 (2000)

Bakhshan, H., Afrouzian, A., Ahmadi, H., et al.: Progressive failure analysis of fiber-reinforced laminated composites containing a hole. Int. J. Damage Mech. 27(7), 963–978 (2018)

İnal, O., Balıkoğlu, F., Ataş, A.: Bolted joints in quasi-unidirectional glass-fiber NCF composite laminates. Compos. Struct. 183, 536–544 (2018)

Tserpes, K.I., Labeas, G., Papanikos, P., et al.: Strength prediction of bolted joints in graphite/epoxy composite laminates. Compos. B Eng. 33(7), 521–529 (2002)

Koh, R., Madsen, B.: Strength failure criteria analysis for a flax fiber reinforced composite. Mech. Mater. 124, 26–32 (2018)

Camanho, P.P., Matthews, F.L.: A progressive damage model for mechanically fastened joints in composite laminates. J. Compos. Mater. 33(24), 2248–2280 (1999)

de Miguel, A.G., Kaleel, I., Nagaraj, M.H., et al.: Accurate evaluation of failure indices of composite layered structures via various FE models. Compos. Sci. Technol. 167, 174–189 (2018)

Wang, B., Fang, G., Liu, S., et al.: Progressive damage analysis of 3D braided composites using FFT-based method. Compos. Struct. 192, 255–263 (2018)

Mandal, B., Chakrabarti, A.: Numerical failure assessment of multi-bolt FRP composite joints with varying sizes and preloads of bolts. Compos. Struct. 187, 169–178 (2018)

Olmedo, Á., Santiuste, C.: On the prediction of bolted single-lap composite joints. Compos. Struct. 94(6), 2110–2117 (2012)

Tserpes, K.I., Papanikos, P., Labeas, G., et al.: Fatigue damage accumulation and residual strength assessment of CFRP laminates. Compos. Struct. 63(2), 219–230 (2004)

Labeas, G.N., Belesis, S.D., Diamantakos, I., et al.: Adaptative progressive damage modeling for large-scale composite structures. Int. J. Damage Mech. 21(3), 441–462 (2012)

Liu, W., He, Z., Yu, F., et al.: A progressive damage model introducing temperature field for bolted composite joint with preload. Modell. Simul. Mater. Sci. Eng. 27(6), 065011 (2019)

Makris, A., Ramault, C., Van Hemelrijck, D., et al.: An investigation of the mechanical behavior of carbon epoxy cross ply cruciform specimens under biaxial loading. Polym. Compos. 31(9), 1554–1561 (2010)

Bathe, K.J., Ramm, E., Wilson, E.L.: Finite element formulations for large deformation dynamic analysis. Int. J. Numer. Methods Eng. 9(2), 353–386 (1975)

Bao H C, Liu G Y. Simulation on damage in quasi-isotropic fiber-reinforced composite laminates under open-hole tension [J]. Acta Mater. Compos. Sin. 33(5), 1026–1032 (2016)

Lessard, L.B., Chang, F.K.: Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings: part II—experiment. J. Compos. Mater. 25(1), 44–64 (1991)

Chang, F.K., Lessard, L.B.: Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings: part I—analysis. J. Compos. Mater. 25(1), 2–43 (1991)

Cui, H.B., Wen, W.D., Cui, H.T.: Three-dimensional progressive damage of laminated composites with a hole under compressive loading. Chin J. Mech. Eng. 42(8), 89–94 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

In the process of solving material nonlinearity, the total stress \(\sigma ^{n}\) should be expressed in terms of the sum of the previous stresses \(\sigma ^{n-1}\) and the incremental stresses \(\Delta \sigma \).

Equivalent expression of Eq. (4) without considering the body force is as follows:

Substituting Eq. (16) into Eq. (17), we can obtain

The simplified Eq. (18) is as follows:

We need to discretize the displacement field and stress field to get the displacement and stress of the node. Taking an example for 3D 8-nodes linear element, the discrete form is as follows:

where \(\Delta u\) and \(\Delta \sigma \) represent the incremental displacement field and incremental stress field of total elasticity, respectively. \(N_p =\left[ {{\begin{array}{ll} {N_q }&{} \\ &{} {N_q } \\ \end{array} }} \right] \), \(\hbox {Diag}\left( {N_q } \right) =\left[ {{\begin{array}{lll} {N_e }&{} {N_e }&{} {N_e } \\ \end{array} }} \right] \) and \(N_e =\left[ {N_1 ,N_2 \ldots N_8 } \right] \)

Substituting Eq. (20) into Eq. (19), we can obtain:

where j indicates the number of total elements.

Consider \(\Delta p\) and \(\Delta q\) as two independent variables. By \(\delta \prod _\mathrm{G} =0\), two Euler–Lagrange equations can be obtained:

In what follows, the superscript “i” will be dropped for clarity.

The matrix simplified expressions of the two Euler–Lagrange equations are as follows:

The iteration in each increment has to be repeated until the following condition is satisfied:

Once stress condition of an element satisfies the proposed failure criteria, material property C is discounted according to the proposed stiffness degradation model shown in Table 1. This degradation in property will affect the distribution of stress in the damaged area. The redistributed stresses in the elasticity after damage can be calculated by performing the Newton–Raphson iteration again with updated material properties. The procedure will be repeated until no additional damage is predicted at the given load level.

Rights and permissions

About this article

Cite this article

Liu, W., Yu, F., He, Z. et al. A high-precision progressive damage model based on generalized mixed finite element method. Arch Appl Mech 90, 559–571 (2020). https://doi.org/10.1007/s00419-019-01625-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-019-01625-x