Abstract

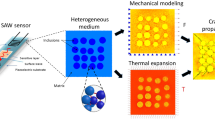

In the present investigation, a new equivalent micromechanics method is proposed, and then, an analysis model has been developed to estimate the nonlinear coefficients of thermal expansion (CTEs) of three-phase composites. As Compared with previous analytical models, the innovative point of this paper is that the influence of the debonding surface thickness is investigated. It is noted that the parameters of thickness of debonding surface have a significant effect on both the longitudinal CTEs and transverse CTEs. The CTEs of composites are also very sensitive to the different inclusion aspect ratios. The constitutive equation curves for different variable parameters can describe the influence of debonding damage on thermal expansion coefficients (CTEs) of the composites. The new model provides a direct prediction of CTEs and can account for the effects of inclusion aspect ratio, volume fractions and thickness of debonding surface.

Similar content being viewed by others

References

Yang, B.J., Kim, B.R., Lee, H.K.: Micromechanics-based viscoelastic damage model for particle-reinforced polymeric composites. Acta Mech. 223(6), 1307–1321 (2012)

Cheng, Y., Bian, L., Wang, Y., Farid, T.: Influences of reinforcing particle and interface bonding strength on material properties of Mg/Nano-particle composites. Int. J. Solids Struct. 51(18), 3168–3176 (2014)

Lee, K.Y., Kim, K.H., Jeoung, S.K., et al.: Thermal expansion behavior of composites based on axisymmetric ellipsoidal particles. Polymer 48(14), 4174–4183 (2007)

Shubin, S.N., Freidin, A.B., Akulichev, A.G.: Elastomer composites based on filler with negative thermal expansion coefficient in sealing application. Arch. Appl. Mech. 86(1–2), 351–360 (2016)

Bian, L., Liu, W., Pan, J.: Probability of debonding and effective elastic properties of particle-reinforced composites. J. Mech. 33(6), 789–796 (2017)

Eshelby, J.D.: The determination of the elastic field of an ellipsoidal inclusion and related problems. Proc. R. Soc. Lond. Ser. A. 240, 376–96 (1957)

Mori, T., Tanaka, K.: Average stress in matrix and average energy of materials with misfitting inclusions. Acta Metall. 21, 571–574 (1973)

Bian, L., Zhao, H.: Elastic properties of a single-walled carbon nanotube under a thermal environment. Compos. Struct. 121, 337–343 (2015)

Makarian, K., Santhanam, S., Wing, Z.N.: Coefficient of thermal expansion of particulate composites with ceramic inclusions. Ceram. Int. 42(15), 17659–17665 (2016)

Lu, P.: Further studies on Mori–Tanaka models for thermal expansion coefficients of composites. Polymer 54(6), 1691–1699 (2013)

Kumar, R., Kaur, M.: Reflection and refraction of plane waves at the interface of an elastic solid and microstretch thermoelastic solid with microtemperatures. Arch. Appl. Mech. 84(4), 571–590 (2014)

Gusev, A.A.: Effective coefficient of thermal expansion of n -layered composite sphere model: exact solution and its finite element validation. Int. J. Eng. Sci. 84(11), 54–61 (2014)

Sideridis, E.: Thermal expansion coefficients of fiber composites defined by the concept of the interphase. Compos. Sci. Technol. 51(3), 301–317 (1994)

Turner, P.S.: Thermal-expansion stress in reinforced plastics. J. Res. Natl. Bur. Stand. 37, 239–550 (1946)

Kerner, E.H.: The elastic and thermoelastic properties of composite media. Proc. Phys. Soc. B 69, 808–813 (1956)

Chensong, D.: Development of a model for predicting the transverse coefficients of thermal expansion of unidirectional carbon fiber reinforced composites. Appl. Compos. Mater. 15, 171–182 (2008)

Schapery, R.A.: Thermal expansion coefficients of composite materials based on energy principles. J. Compos. Mater. 2(3), 380–404 (1968)

Rupani, S.V., Dev, R., Jani, S.S., et al.: Experimental evaluation of coefficient of thermal expansion of carbon fiber reinforced polymer tube. Int. J. Adv. Eng. Res. Dev. 4(4), 428–433 (2017)

Islam, M.R., Sjölind, S.G., Pramila, A.: Finite element analysis of linear thermal expansion coefficients of unidirectional cracked composites. J. Compos. Mater. 35(19), 1762–1776 (2001)

Sideridis, E.P., Venetis, J.C.: Thermal expansion coefficient of particulate composites defined by the particle contiguity. Int. J. Microstruct. Mater. Prop. 9, 292–313 (2014)

Karadeniz, Z.H., Kumlutas, D.: A numerical study on the coefficients of thermal expansion of fiber reinforced composite materials. Compos. Struct. 78(1), 1–10 (2007)

Odegard, G.M., Harik, V.M., Wise, K.E., et al.: Constitutive modeling of nanotube-reinforced polymer composite systems. Compos. Sci. Technol. 63(11), 1671–1687 (2003)

Karevan, M., Pucha, R.V., Bhuiyan, M.A., Kalaitzidou, K.: Effect of interphase modulus and nanofiller agglomeration on the tensile modulus of graphite nanoplatelets and carbon nanotube reinforced polypropylene nanocomposites. Carbon Lett. 11(4), 325–331 (2010)

Nawab, Y., Jacquemin, F., Casari, P., Boyard, N., Borjon-Piron, Y., Sobotka, V.: Study of variation of thermal expansion coefficients in carbon/epoxy laminated composite plates. Compos. Part B: Eng. 50, 144–149 (2013)

Shaker, K., et al.: Effect of silica particle loading on shape distortion in glass/vinyl ester-laminated composite plates. J. Text. Inst. 109(5), 656–664 (2018)

González-Benito, J., Castillo, E., Caldito, J.F.: Coefficient of thermal expansion of TiO2 filled EVA based nanocomposites. A new insight about the influence of filler particle size in composites. Eur. Polym. J. 49(7), 1747–1752 (2013)

Shunmugasamy, V.C., Pinisetty, D., Gupta, N.: Thermal expansion behavior of hollow glass particle/vinyl ester composites. J. Mater. Sci. 47(14), 5596–5604 (2012)

Acknowledgements

This research was funded by the Science Research Foundation of Hebei Advanced Institutes (ZD2017075).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

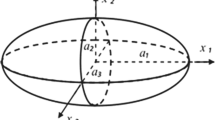

The components of Eshelby’s \( S_{mnpq} \) tensor for different shapes of inclusions are provided as follows.

For the fiber-liked particles ( \( a_1 >a_2 =a_3 ) \),

where \( \upsilon _m \) is the Poisson’s ratio of the matrix, \(\lambda \) is the aspect ratio of the particles ( \( \lambda =a_1 /a_3)\), and \( \varphi \) is given as

For the spherical particles \(( a_1 =a_2 =a_3 ) \),

For the penny-liked inclusions ( \( {a_1 }/{a_3 }\ll 0) \),

Rights and permissions

About this article

Cite this article

Bian, L., Guo, J. & Pan, J. Micromechanics analysis for thermal expansion coefficients of three-phase particle composites. Arch Appl Mech 89, 1641–1654 (2019). https://doi.org/10.1007/s00419-019-01533-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-019-01533-0