Abstract

Halogen ratios (Cl/Br) preserved in halogen-bearing minerals can be very useful to identify the sources of fluids interacting with crystalline rocks, as different fluid types have distinct halogen ratios. In this study we conduct exchange experiments for chlorine and bromine partitioning between scapolite and brine treated at variable fluid salinities ranging from 0.20 to 0.66 mol fraction of salt (NaCl + NaBr). Experiments involved two different natural scapolites, which were treated in the presence of brine and minor calcite in sealed platinum capsules at 0.32 to 1.52 GPa and 600 °C to 1000 °C for durations of 12–120 h. Neomorphic scapolite appeared as overgrowths on the initial scapolite, or, in some cases, fully recrystallized with no relict scapolite visible. The experiments show that the Ca/Na ratio of scapolite depends on the treatment temperature, the fluid salinity, and pressure. In contrast, the Cl/Br distribution coefficients between neomorphic scapolite and fluids do not depend on the temperature, composition of the mineral or the total salinity of the fluid. The Cl/Br distribution coefficient is, however, markedly pressure-dependent. The experimentally-determined partitioning coefficients of this study and previous work, ranging from 1 atm to 1.5 GPa, enable the use of Cl/Br ratios in scapolite to characterize the halogen ratio of fluids throughout the entire crust. The molar Cl/Br ratio of a fluid can be determined from the measured molar Cl/Br of scapolite via: Cl/Brfluid = Cl/Brscapolite x ( – 1.473 × P + 1.119 × P2 – 0.299 × P3 + 1.103)−1, where P is pressure in GPa, over the range of 0.0001–1.5 GPa.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fluids are critical for several first-order geological processes, ranging from mass transfer of economically relevant elements to partial melting of the crust and mantle due to fluid-induced melting reactions (e.g Seward and Barnes 1997; Yardley 2005, 2009). The presence of fluids is widespread in most rocks, as they are released and mobilized throughout diagenesis, (prograde) metamorphism, exhumation, and magmatic events (e.g., Ague 1994; Hedenquist and Lowenstern 1994; Vry et al. 2010; Shulaker et al. 2024). From a resources perspective, it is critical to identify the source of mineralizing fluids to develop models to contextualize how and where mineralized systems may form (e.g., Audétat et al. 1998; Klemm et al. 2008; Yardley and Cleverley 2015; Su et al. 2019). Halogens (Cl, Br, F, I) play an important role in fluid-induced mass transfer due to their complexing with base metals, for example, which then can be mobilized, concentrated and eventually deposited in mineralized zones (see Lecumberri-Sanchez and Bodnar 2018 and references therein). Halogen ratios (e.g., Cl/Br, Cl/I) are useful to identify fluid sources in the crust (e.g., Böhlke and Irwin 1992; Irwin and Roedder 1995; Seo et al. 2011; Kendrick et al. 2007; Kendrick 2012; Hammerli et. 2013; Fusswinkel et al. 2013) as different fluid reservoirs have distinct halogen signatures. For example, seawater has a molar (m) Cl/Br ratio of ~ 650 and halite has distinctly higher Cl/Br (m) ratio of > 10,000 because of the incompatibility of bromine in the halite crystal structure. It follows that saline fluids sourced from halite-rich lithologies contain Cl/Br ratios that are distinctly higher than if directly sourced from seawater. In addition to seawater and evaporites, the other two main saline fluid sources in the crust are residual bittern brines and magmatic fluids. Residual bittern brines form after halite extraction in evaporitic environments. These fluids are enriched in Br and have therefore lower Cl/Br (m) ratios than seawater (< 650). The Cl/Br ratios of fluids released from magmatic systems are more difficult to constrain but typically fall between 800 and 2000 (m) (Waelkens et al. 2021).

The only direct approach for measuring paleo-fluid compositions in the crust (and fluid tracers such as halogens) is the analysis of (primary) fluid inclusions, which ideally capture fluids present at the time of the formation of their host mineral. However, in many cases fluid inclusion assemblages can be too complex for meaningful interpretation; secondary processes may disturb the entrapped fluids, and/or fluid inclusions are simply too small to be analyzed via in-situ methods such as laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS). An alternative approach to document fluids in the crust is to find minerals that incorporate fluid tracers like halogens. Biotite, amphibole, apatite and scapolite are common minerals that can incorporate significant (wt%) amounts of halogens. While fluid-mineral partitioning of Cl into the above phases has been studied (Ellis 1978; Zhu and Sverjensky 1991, 1992; Benard et al. 2017; Jenkins 2019, Kusebauch et al. 2015), Cl and Br partitioning has only been systematically studied via experiments using scapolite and sodalite (Pan and Dong 2003). Compared to other halogen-bearing minerals, natural scapolite (and sodalite) can also incorporate elevated concentrations of Br, which permits in-situ quantification of Cl and Br via readily available micro-analytical techniques, such as electron probe micro-analyzer (EPMA) and LA-ICP-MS (Hammerli and Boroughs 2023).

Scapolite is commonly present in systems that interacted with high-salinity fluids, such as metasomatized rocks including skarns and mineralized systems (e.g., Vanko and Bishop 1982; Pan and Dong 1999; Hammerli et al. 2014; Zeng et al. 2019). The reason why scapolite group minerals can accommodate relatively high concentrations of halogens is their structure, which provides large “cage-sites” for anions that are surrounded by rings of (Al,Si) tetrahedra providing sufficient space for large ions, including iodine (Levien and Papike 1976). The formula of scapolite minerals is best described by M4(T12O24)A, where M represents Na, K, Ca, Sr, Ba and Fe2+, T represents Si, Al and Fe3+, and A (“cage-site”) stands for Cl, CO3, SO4, Br or I. Scapolite group minerals can be described as the result of combining three moles of plagioclase with a salt (i.e., NaCl, CaCO3, CaSO4) (e.g., Evans et al. 1969; Goldsmith 1976; Hassan and Buseck 1988; Teertstra and Sherriff 1997). Natural scapolite group minerals occur almost exclusively as a solid solution of several end-members. Marialite (Na4Al3Si9O24Cl = Mar) is the sodium chloride end-member and the two calcium carbonate end-members are meionite (Ca4Al6Si6O24CO3 = Me) and mizzonite (NaCa3Al5Si7O24CO3 = Mizz). The calcium sulfate scapolite end-member is defined as silvialite (Ca4Al6Si6O24SO4) (Newton and Goldsmith 1976; Teertstra and Sherriff 1997; Teertstra et al. 1999).

At present there is only a basic understanding of the stability of scapolite in pressure–temperature and temperature-composition space. The earliest experimental work on the stability of intermediate scapolites was done in the system NaAlSi3O8–CaAl2Si2O8–NaCl–CaCO3 at 750 °C and 0.4 GPa (Orville 1975). This study established that scapolite with an anorthite (An) equivalent composition in the range of An15–An75 (i.e., 15–75 mol% Me) is stable in the presence of halite and calcite with only a “trace” (1 wt%) of water present. This initial study was extended by Ellis (1978) at the same P–T conditions to investigate the stability of chloride- and carbonate-bearing scapolite in a wide range of NaCl–H2O solutions. He found that scapolite with a broad range of compositions (An25–An87 equivalent) was stable in NaCl-rich solutions, namely those with molar ratios of NaCl/(NaCl + H2O) ≥ 0.4. At lower concentrations, however, Mar-rich scapolite became increasingly unstable, so that only scapolite in the range of 18–48 mol% Mar was stable in pure water. The stability field of meionite under dry conditions and in the presence of oxalic acid was investigated by Newton and Goldsmith (1976) and Goldsmith and Newton (1977), respectively. The latter study provided better constraints on the lower-thermal stability limit of meionite, demonstrating it to be stable at 875–900 °C over the pressure range of 0.1–1.8 GPa. Carbonate-rich scapolites were investigated by Baker and Newton (1995) in the system CaAl2Si2O8–NaAlSi3O8-CaCO3 at 775–850 °C and 0.7 GPa. They observed that the substitution of Na for Ca and of Si for Al stabilizes scapolite to temperatures at least 100 °C below that of end-member meionite. The lower-thermal stability of end-member marialite relative to albite and halite in dry experiments and in the presence of concentrated NaCl brines was studied by Almeida and Jenkins (2017). They found marialite to be stable above 920–990 °C in the range of 0.65–2.0 GPa under dry conditions, but unstable in brines even with relatively small amounts of water with NaCl/(NaCl + H2O) < 0.8. Marialite was also found to be unstable below 0.5 GPa in the range of 800–950 °C. Finally, experimental work on a marialite-rich intermediate scapolite by Almeida and Jenkins (2019) demonstrated that the addition of only 15 mol% Me lowers the thermal stability of marialite by 330 °C from 950 to 620 °C at 1.5 GPa, and stabilizes the scapolite in brines with a molar ratio of NaCl/(NaCl + H2O) as low as ~ 0.2. Taken together, the experimentally-confirmed stability field of a typical intermediate scapolite (~ 50 mol% Me) lies broadly in the range of 600–1000 °C, 0.1–3.0 GPa, and in calcite-buffered NaCl brines with a minimum molar ratio of NaCl/(NaCl + H2O) of 0.2. However, the lower-thermal stability limit of scapolite is still unclear. Thermodynamic extrapolation of experimental data (Baker and Newton 1995; Almeida and Jenkins 2019) suggests specific intermediate scapolite compositions may be stable to temperatures as low as 350–550 °C. Similarly, mineral parageneses involving scapolite supports these low-temperature occurrences, where, for example, intermediate scapolite has been observed in greenschist-facies rocks that formed at < 500 °C (e.g., Hammerli and Rubenach 2018, and references therein), emphasizing the potentially wide thermal stability of intermediate scapolites.

There has only been one previous study of Cl and Br partitioning into scapolite, which was that of Pan and Dong (2003). These authors investigated halide-mineral exchange experiments involving scapolite treated in two different hydrous halide-rich melts (NaCl:NaBr in 1:1 and 2:1 ratios, by mass), sealed in capsules, and heated at 800 °C in a 1-atmosphere furnace. They used starting-material concentrated brines with a molar ratio of (NaCl + NaBr)/(NaCl + NaBr + H2O) = \({X}_{NaCl+NaBr}^{brine}\) = 0.52–0.66 and studied the diffusion of Cl and Br into scapolite using X-ray fluorescence and EPMA. Pan and Dong (2003) concluded that the Cl/Br distribution coefficient between fluids and scapolite (and sodalite) is ~ 1, which would mean that the measured halogen ratios in scapolite can be directly applied to identify fluid sources. The same study also reported the diffusivity of Br in marialite and found the diffusion coefficient to be comparable to that of Sr in apatite. Combining this with observations of natural scapolite, which can show strong zoning of Cl and Br on a micrometer scale (e.g., Hammerli and Boroughs 2023), it can be inferred that the diffusion of Cl and Br is not rapid and that diffusional changes in composition after scapolite formation will be minimal.

In this study we greatly expand the earlier study of Pan and Dong (2003) by conducting exchange experiments for chlorine and bromine partitioning into scapolite over the range of 600–1000 °C, 0.3–1.5 GPa, and using \({X}_{NaCl+NaBr}^{brine}\) values ranging from 0.2–0.66 to further investigate Cl/Br partitioning behavior between fluids and scapolite. Our findings indicate that the Cl/Br partitioning between fluid and scapolite is independent of both temperature and the fluid's salinity. However, we demonstrate that Cl/Br partitioning is pressure-dependent, with a positive correlation showing a preference for Br incorporation over Cl in scapolite as pressure increases. Combined with the results of Pan and Dong (2003), we establish an equation to determine Cl/Br partitioning between fluids and scapolite from 1 atm to 1.5 GPa.

These findings have important implications for tracing crustal fluids via geochemical analyses of scapolite and confirm scapolite as a useful mineral to characterize paleo-fluids in the crust and upper mantle.

Methods

Starting material scapolite

Gem-grade scapolite samples from Afghanistan, denoted as SC1 and SC4, acquired from online suppliers, served as the initial materials for the exchange experiments. These samples had their chemical compositions thoroughly examined beforehand (refer to JHSC1 and JHSC4 in Hammerli and Boroughs 2023).

The samples were ground and sieved to grain size fractions of ~ 50 μm and ~ 50–90 μm, which were then used in the experiments. Before grinding the samples, a concentration of 340 ± 30 ppm Br and 2.89 ± 0.07 wt% (2 SD) Cl was measured by EPMA in scapolite SC1, while scapolite starting material SC4 contains 1400 ± 151 ppm Br and 2.28 ± 0.02 wt. % Cl. Table 1 lists their full chemical composition along with the stoichiometrically calculated CO2 wt% and atomic formulae based on fixing the sum of Si + Al to 12. The meionite component (%) calculated via 100 × Ca/(Ca + Na) (see, e.g., Hasssan and Buseck 1988) are 32 and 47, respectively, which falls within the range of scapolite typically found in natural settings (e.g., Hammerli and Rubenach 2018).

Sample treatment and high-pressure apparatus

All experiments were done in sealed platinum capsules, which were made from 9 mm lengths of 2.5 mm outer-diameter platinum tubing with a 0.13 mm wall thickness. Scapolite was treated in concentrated NaCl–NaBr brines as follows. A mixture of synthetic reagent-grade NaCl (Fisher, Certified ACS, ≥ 99.0%) and NaBr (Alfa Aesar, 99.99%) was made using equal masses of both salts, in accord with one series of experiments done by Pan and Dong (2003). In addition, two experiments were done with mass ratios of NaCl/NaBr of 2:1 and 1:2. Individual experiments were made by mixing portions of a given scapolite with the NaCl–NaBr mixture along with synthetic CaCO3 (Baker Analyzed, 99.4%) in the crystalline form of calcite. The CaCO3 was added to maintain saturation of CaCO3 in the presence of intermediate scapolite (Orville 1975; Newton and Manning 2002), which in turn was used to fix the activity of CaCO3 for brines of variable concentration (Ellis 1978). All weighings were made with a Mettler–Toledo AG 245 semi-micro balance with reproducibility to 0.02 mg. The specific amounts of scapolite, NaCl, NaBr, calcite, and water added to each capsule are listed in Table 2. Experiments in which equal masses of both salts were used consisted typically of 46 wt% scapolite, 14 wt% each of NaCl and NaBr, 10 wt% calcite, and 16 wt% H2O. There is sufficient salt present, regardless of how the exchange runs, to maintain an essentially constant brine composition, such that complete substitution of Br or Cl for the A-site anions in scapolite consumes at most 5 wt% NaBr and 1 wt% NaCl, respectively. Each mixture was loaded into the open capsule and sufficient water was added to achieve a desired total brine mole fraction (\({X}_{NaCl+NaBr}^{brine}\)). Although not known with certainty, it is assumed that the brines used here, with \({X}_{NaCl+NaBr}^{brine}\) ranging from 0.1 to 0.66, are below saturation at the pressure and temperature conditions used here based on (1) minor extrapolations of the experimental results on halite saturation by Aranovich and Newton (1996) and (2) NaBr having greater solubility than NaCl and experiencing complete miscibility with NaCl (Zhang et al. 2022). Note that the total brine mole fraction excludes CaCO3 because its solubility is much lower that the halides (Newton and Manning 2002), and to remain consistent with the method of reporting brine concentrations in earlier studies (Ellis 1978).

Most experiments were done at a pressure of 1.5 GPa in a 12.3 cm inner-diameter piston-cylinder press at temperatures of 600, 800, and 1000 °C. Experiments at 600 and 800 °C were made with pressure media entirely made of NaCl inside and surrounding a straight cylindrical graphite furnace with estimated pressure uncertainties of ± 0.03 GPa. Experiments at 1000 °C were made with pressure media consisting of a NaCl outer sleeve, borosilicate-glass supported graphite furnace, and inner parts consisting of crushable MgO cylinders and finely powdered SrCO3 surrounding the sample. This is the same pressure media assemblage used by Cheng et al. (2019). This pressure assemblage was needed to support the graphite furnace from fracturing because of weakening of the NaCl outer sleeve at this relatively high temperature. Cheng et al. (2019) calibrated pressure transmission to the sample for this assemblage and found that a pressure correction of -6% was needed at 1000 °C, giving a true pressure of 1.41 ± 0.10 (2 SD) GPa at a nominal pressure of 1.5 GPa. Sealed capsules were flattened and positioned perpendicular to the chromel–alumel (type K) thermocouple to minimize thermal gradients across the capsules, with estimated temperature uncertainties of ± 10 °C for the 600 and 800 °C and ± 20°C for the 1000 °C experiments. One experiment was done at about 0.32 GPa in an internally-heated gas vessel using argon as the pressure medium. Details of this apparatus are given in Jenkins (2019).

After sample treatment, capsules were cleaned of any adhering salt or SrCO3 from the piston-cylinder pressure medium and weighed to assure no loss of capsule contents during the experiment. Final capsule weights were the same as the initial weights within weighing precision. Capsules were opened with a small cut using a razor blade and the capsule soaked in deionized water overnight to remove any excess salt, which was found to interfere with mounting the samples in epoxy for electron probe micro-analysis. Charges were loose powders that were very light blue to white in color.

Analytical methods

All samples were analyzed via powder X-ray diffraction (XRD) to determine the minerals present and to estimate their proportions using relative diffraction line intensities. XRD analysis was performed using a Panalytical Xpert PW3040-MPD diffractometer. Samples were mounted on a zero-background single-crystal quartz plate, with the operating settings at 40 kV and 20 mA, using CuKα radiation and a diffracted-beam graphite monochromator. All of the samples were analyzed in a continuous scan from 10° to 70° 2Θ with a step size of 0.040° at 1.0 s per step.

Selected experiments at 800 °C were analyzed for the Cl− and Br− contents of the salts precipitated after treatment to see if there were obvious changes in the amounts of chloride and bromide salts resulting from anion exchange with the scapolite. Unopened sample capsules were treated as before, being cleaned, weighed to ensure that it remained intact during treatment, and opened with a small cut. This time the capsule was put on a Pt dish (to capture any salt expelled during drying) and dried at 110 °C until a stable weight loss was obtained (typically 1–18 h) to assess the amount of water present in the capsule after treatment. The capsule and supporting dish were soaked for 1–2 days in deionized water having < 1 ppm Cl (analyzed by ion chromatography) to extract any soluble salts. The total volume of this leachate solution ranged from about 10–14 ml, which was subsequently analyzed for both chloride and bromide anions on a Dionex ICS-2000 ion chromatograph. Instrument calibration involved NIST traceable single anion solutions. Calibration of bromide was a linear curve using 3 standards at 1, 10 and 20 ppm. Calibration of chloride was a linear curve using 4 standards at 1, 50, 100 and 150 ppm. Samples were analyzed as received for strictly ionized chloride and bromide. No treatment or digestion process was used to convert other forms, such as the chlorite anion, to chloride, in an effort to obtain “total Cl−“, but it is also noted that there was no indication from the chromatograph pattern of any other anions than Cl−, Br−, and minor sulfate. This analysis provided a cross-check on both the amount of water present, via mass loss from the capsule after it was first cut and dried, and then the mass of soluble salt via the mass loss from the capsule after soaking for 1–2 days and drying it again. Analysis of the leachate for Cl− and Br− provided additional information on the composition of the salt remaining, as discussed below.

The experimental run products were subsequently mounted in 1-inch epoxy mounts and polished with water-based diamond solutions with grain sizes from 6 to 1 μm to expose the material for electron probe microanalysis (EPMA). Transmitted light microscopy images were captured before conducting EPMA spot analysis. Additionally, back-scattered electron (BSE) images were obtained using the JEOL 8500F Hyperprobe at the Washington State University Peter Hooper GeoAnalytical Laboratory. These images were collected for all samples to select the optimal locations for EPMA spot analysis. EPMA point measurements via the JEOL 8500F Hyperprobe of the “neomorphic” (reacted) scapolite and initial scapolite, the latter often present as cores, were acquired following the protocol as described in detail in Hammerli and Boroughs (2023) with spot sizes of 5 or 10 μm. Data were reduced using the Probe for EPMA (PFE) software package. In order to maximize on peak count time, and avoid complications due to background interferences, mean atomic number (MAN) background estimates were used. Standards used for EPMA analyses are listed in the supplementary material.

Results

Stability of scapolite at variable fluid salinities, temperatures, and pressures

Results of the experiments carried out in this study are given in Table 2, which indicates the conditions of treatment, masses of the materials encapsulated, the brines used, and the phases observed at the end of the treatment. Brines were chosen to cover a relatively wide range of halide concentrations while still remaining inside the stability field of scapolite. This was done to determine if there was any obvious dependence of halogen partitioning on the brine concentration. Experiments were also performed over the range of 0.32–1.50 GPa at 800 °C to look for any effect of pressure at this temperature, as well as time-series experiments at 800 °C to gauge any effect of time on halogen partitioning into scapolite in these experiments. Time-series experiments were also done at 600 °C but unfortunately the low temperatures and short durations did not produce sufficient neomorphic scapolite to be analyzed by EPMA. Electron probe micro-analyses of run-product scapolites and glass are given in Table 3.

The phase equilibria of these experiments are complicated by the intermediate compositions of the natural starting-material scapolite and variable brine concentrations used in this study, making most reactions non-univariant. It is useful, however, to establish some framework for understanding the limits of scapolite stability within which this study was made. Two general reactions limiting the stability of scapolite are:

where the square brackets indicate variable concentrations of those chemical species in the ambient brine. Because the majority of the experiments were done in the range of 1.4–1.5 GPa and the concentration of CaCO3 in the brine was buffered by the presence of excess calcite (or aragonite), the stability of scapolite is controlled at any given temperature primarily by variations in the concentrations of NaCl + NaBr (i.e., salt) in the brine. In particular, increases in the concentration (activity) of the salt will stabilize scapolite relative to plagioclase at high temperatures (Almeida and Jenkins 2019) and, by analogy with albite, shift the onset of scapolite melting to higher temperatures by decreasing the activity of H2O in the brine (Makhluf et al. 2016).

Experimental results from this study are shown in Fig. 1 in T-XSalt space. Boundaries shown on Fig. 1 are dashed to indicate they are defined only by spontaneously nucleated phases and not experimentally-reversed reaction boundaries, and that they are univariant approximations to what are probably higher-variance regions. Calcite (or aragonite at 600 °C) was always present after the treatments.

Experimental results from this study with approximate location of stability-field boundaries shown as dashed lines. Boundaries labeled (1), (2), and (5) refer to reactions discussed in the text. Scap(1) and Scap(2) along boundary 5 refer to the initial scapolite and Me-rich overgrowths, respectively (see text). Calcite-aragonite boundary based on Redfern (2000). Liquid (Liq) in this diagram refers to a silicate-rich liquid (melt) that quenched to a glass and is approximately plagioclase in composition. Salt refers to the NaCl + NaBr components in the brine. Abbreviations given in Table 2. Uncertainties are shown as 2 SD error bars where they are larger than the symbols

At 600 °C and 1.5 GPa, scapolite was stable in brines with \({X}_{NaCl+NaBr}^{brine}\)≥ 0.20. Aragonite rather than calcite formed at these treatment conditions, even though these experiments were done 5–10 °C inside the stability field of calcite (Fig. 1, Redfern 2000).

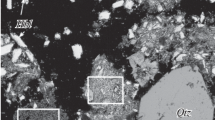

Most experiments at 800 °C were done at 1.5 GPa where scapolite was found to be stable in brines with \({X}_{NaCl+NaBr}^{brine}\) ≥ 0.2. Grossular was identified in the XRD patterns of almost all of the experimental products, often being enclosed by scapolite overgrowths, as seen in the BSE images in Fig. 2A–D. In these images, the grossular appears as electron-bright (white) inclusions in newly-formed scapolite (lighter grey) growing over the original core scapolite (darker grey). The origin of grossular in the 800 °C series is proposed to be related to shifts in the scapolite composition as considered in more detail in the Discussion section. The absence of grossular is attributed to either insufficient pressure (SC46-1) or limited shifts in the scapolite composition arising from the high salt content of the brine (SC12-3). The coexisting carbonate was calcite in all of these experiments.

Representative BSE images of reacted neomorphic scapolite formed at 1.5 GPa and 800 °C (A–C), at 0.6 GPa and 800 °C (D), and at 1.4 GPa and 1000 °C (E–F). Scapolite reacted at 800 °C and different bulk brine concentrations shows distinct zones of reacted light grey scapolite and dark grey cores of the original scapolite. Small grains of garnet (grossular) are typically clustered at the boundary between the initial and the reacted scapolite zones (A–D). Scapolite treated at 1000 °C and different brine concentrations are surrounded by glass (E–F). In case of experiment SC45-3b (\({{X}}_{{NaCl}+{NaBr}}^{{brine}}\) = 0.30), scapolite fully recrystallized and does not contain any of the original relics (E). In F scapolite grains are shown that were treated with a brine with a total mole fraction of 0.41. The reacted scapolite grains show thin rims of glass while the initial SC4 scapolite is present as distinct cores. The yellow circles show EPMA spot placements

At 1000 °C, scapolite completely melted in the most water-rich experiment, namely in a brine with \({X}_{NaCl+NaBr}^{brine}\) = 0.2. Scapolite was found to be stable in brines with \({X}_{NaCl+NaBr}^{brine}\) = 0.30–0.66; however, with \({X}_{NaCl+NaBr}^{brine}\) in the range of 0.30–0.40, the scapolite coexisted with silicate melt. Experiment SC45-3b (\({X}_{NaCl+NaBr}^{brine}\) = 0.30) had all of the original scapolite recrystallized (Fig. 2E). When treated at the higher salt concentration of \({X}_{NaCl+NaBr}^{brine}\) = 0.40 (SC45-7), only partial recrystallization of the original scapolite took place. In this sample the original scapolite is present as distinct cores mantled by “new” scapolite with glass also being present as a product (Fig. 2F). In brines with \({X}_{NaCl+NaBr}^{brine}\) of 0.50 and 0.66 no glass was found as a product. In these samples the original scapolite grains are present as distinct cores mantled by neomorphic (i.e., new) scapolite. Grossular was not observed in the 1000 °C series.

For comparison, Pan and Dong (2003) found that scapolite was stable at 1 atm, 800 °C and in a brine with \({X}_{NaCl+NaBr}^{brine}\) = 0.66, but they report scapolite breakdown at 1000 °C at the same salinity.

Composition of reacted scapolite

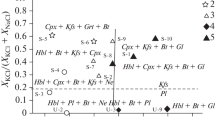

The composition of the neomorphic (i.e., new) scapolite that formed during the experiments are given in Table 3 and the full data set of EPMA analyses is available in the supplementary material. The initial scapolite grains (SC1 and SC4) contain minor amounts of K2O (~ 1.3–1.4 wt%), SO3 (0.8–0.9 wt%), and FeO (~ 0.13–0.14 wt%). In contrast, neomorphic scapolite is mostly devoid of these elements. Most neomorphic scapolite analyses closely follow the [Na4. Cl]Si2–[NaCa3 CO3]Al2 substitution vector (Hassan and Buseck 1988; Fig. 3A) and have meionite components (Me %), defined as 100 × Ca/(Ca + Na), between ~ 10% and 75%. The exception is scapolite treated at a pressure of 0.32 GPa, which led to neomorphic scapolite formation that reaches Me % of 85 and therefore plots along the [NaCa3. CO3]Si – [Ca4. CO3]Al substitution vector (Fig. 3D).

Scapolite compositions (mol% Me) versus Al/(Al + Si) of all treated scapolite samples. The solid line shows the [Na4. Cl]Si2–[NaCa3. CO3]Al2 and [NaCa3.CO3]Si–[Ca4CO3]Al substitutions separated by the intersection of the dashed lines at Me = 75%, and Al/(Al + Si) = 0.42 (Hassan and Buseck 1988). A Scapolite compositions of samples treated at high pressures (≥ 1.4 GPa). B Compositions of neomorphic scapolites formed at 1.5 GPa and 600 and 800 °C, treated with different total brine mole fractions. C Neomorphic scapolite compositions of samples treated at 1.41 GPa and 1000 °C and different total brine mole fractions. C Comparison of neomorphic scapolite compositions when treated at different pressures but constant temperatures and total brine mole fractions

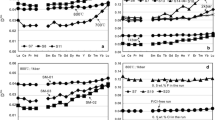

Experiments were run for different durations at both 600 and 800 °C to provide some indication of the approach to compositional equilibrium in the halogen values observed in this study. As mentioned previously, the 600 °C time series did not yield grains with suitable overgrowths for analysis. The results of the time-series experiments at 800 °C and 1.5 GPa are shown in Fig. 4A. One can see that the Cl/Br distribution coefficients observed at 48 h, and possibly even at 12 h, are statistically indistinguishable from those observed at 96 h, the latter being the duration used for most of the experiments at 800 °C. It has to be noted, however, that only one EPMA measurement for the 12 h run was possible. Given the general consistency of the results obtained at 600 °C using longer duration experiments (120 h) compared with the higher temperature experiments, we suggest that the 600 °C results likely represent equilibrium as well.

A \({{K}}_{{D scap}/{fluid}}^{{Cl}/{Br }}\) of time-series experiments at constant temperature (800°C), pressure (1.5 GPa) and \({{X}}_{\text{NaCl}+{NaBr}}^{{brine}}\) = 0.3. B Chlorine and C bromine concentrations in neomorphic scapolite with increasing \({{X}}_{{NaCl}+{NaBr}}^{{brine}}\) at ~ 1.5 GPa. Grey triangles show Cl content in neomorphic scapolite formed at 600°C, filled black circles at 800 °C, and empty squares at 1000°C. *indicates experiments for which only one EPMA measurement was possible. D The molar Cl/Br ratios in neomorphic scapolite vs. total brine concentration at ~ 1.5 GPa. E Distribution coefficient (KD) of Cl/Br between scapolite and fluid (\({{K}}_{{D scap}/{fluid}}^{{Cl}/{Br }}\)) vs. \({{X}}_{{NaCl}+{NaBr}}^{{brine}}\) at ~ 1.5 GPa. The mean KD of Cl/Br between scapolite and fluid of all experiments is 0.40 ± 0.09 (2 SD), which is shown as a dotted line with the 2 SD uncertainty as a grey bar. F Comparison of \({{K}}_{{D scap}/{fluid}}^{{Cl}/{Br }}\) of all experiments conducted at 1.5 GPa at different temperatures

Experimental runs at 600 °C and 1.5 GPa resulted in the formation of neomorphic scapolite with meionite components of ~ 10–15%. Scapolite treated at 800°C and 1.5 GPa contain meionite components between ~ 25 and ~ 42%, regardless of their original scapolite compositions (SC1 or SC4) (Fig. 3B). Experiments run at 1000 °C and 1.41 GPa formed scapolite with significantly different major element compositions depending on the fluid salinity (Fig. 3C and Table 3). In experiments with the lowest brine concentration, neomorphic scapolite grains have high meionite contents (~ 70 to 75%). An increase in the total brine concentration leads to lower meionite components in scapolite, such that scapolite treated at \({X}_{NaCl+NaBr}^{brine}\) = 0.66 has a lower meionite proportion (40–45%) than the initial scapolite (47%; SC4) (Fig. 3C).

In Fig. 3D, the meionite contents of the neomorphic scapolite are shown for experiments conducted at different pressures, but at a constant temperature of 800 °C and brine salinity of 0.3. The experiment at 1.52 GPa resulted in neomorphic rims with an average meionite content of 30 ± 4%, whereas the experiment at 0.32 GPa produced neomorphic scapolite rims with a meionite content of 76 ± 8%.

In general, neomorphic scapolite contains significantly lower Cl contents than the initial scapolite, and chlorine contents of neomorphic scapolite correlate with increasing total brine concentrations (Fig. 4B). Experiments conducted at 600 °C produced neomorphic scapolite rims with Cl contents of ~ 1.3 wt% at \({X}_{NaCl+NaBr}^{brine}\) = 0.2 and ~ 1.5 wt% Cl at \({X}_{NaCl+NaBr}^{brine}\) = 0.4. Scapolite treated at 800 °C and with the lowest brine concentration contains ~ 0.8 wt% Cl, whereas experiments at higher total brine concentrations formed new scapolite with Cl contents between ~ 1.0 and ~ 1.1 wt%. The increase of Cl in scapolite with increasing \({X}_{NaCl+NaBr}^{brine}\) is more significant in samples treated at 1000°C. Neomorphic scapolite in sample SC45-3b treated with a brine of \({X}_{NaCl+NaBr}^{brine}\) = 0.30 contains ~ 0.3 wt% Cl, whereas scapolite treated with \({X}_{NaCl+NaBr}^{brine}\) = 0.66 brine contains ~ 0.9 wt% Cl. A similar correlation is observed for Br, with the one exception: at 600 °C and \({X}_{NaCl+NaBr}^{brine}\) = 0.4, the Br content is lower (~ 3.7 wt%) than at \({X}_{NaCl+NaBr}^{brine}\) = 0.2, where the average Br content is ~ 4.9 wt%. However, for the \({X}_{NaCl+NaBr}^{brine}\) = 0.4 run only one EPMA measurement was obtained. In the 800 °C experiment series new scapolite grains treated in a brine of \({X}_{NaCl+NaBr}^{brine}\) = 0.20 incorporate ~ 2.6 wt% Br and the experimental runs with \({X}_{NaCl+NaBr}^{brine}\) ~0.50 generated scapolite with ~ 3.5 wt% Br. Scapolite formed in the experiments at 1000 °C contain between ~ 0.8 and ~ 2.9 wt% Br and, as in the experiments at 800 °C, Br concentrations increase with increasing total brine concentrations (Fig. 4C). The marked increase in Br in the newly formed scapolite compared to the starting-material scapolite is considered the main reason for the increased electron brightness of the overgrowths in the BSE images in Fig. 2, owing to the relatively high atomic mass of Br.

For the experiments conducted at ~ 1.5 GPa with a NaCl:NaBr mass ratio of 1, the concurrent increase of Cl and Br in neomorphic scapolite with increasing \({X}_{NaCl+NaBr}^{brine}\) results in relatively uniform molar Cl/Br ratios in scapolite, ranging from ~ 0.6 to ~ 0.9, regardless of the experimental conditions, temperature, or fluid salinity (Fig. 4D). When the Cl/Br ratio of the fluid and the mineral is known then a Cl/Br distribution coefficient can be determined. The expression for the distribution coefficient of this exchange equilibrium is: \({K}_{D scap/fluid}^{Cl/Br }\) = (XCl/XBr)scapolite/(XCl/XBr)fluid, where Xi is the concentration in mass % of element i in scapolite or the fluid. At pressures of ~ 1.5 GPa the resulting distribution coefficient of Cl/Br from the fluid into neomorphic scapolite is relatively constant at 0.40 ± 0.09 (2 SD) (Fig. 4E, F), reflecting the preferential partitioning of Br over Cl into the scapolite crystals. Importantly, the distribution coefficient appears to remain the same regardless of the Cl/Br ratio of the fluids, as evidenced by experiment SC48-1, where a NaCl:NaBr mass ratio of 2:1 was used instead of 1:1 as in the other experiments (Tables 2 and 3). This experiment yielded \({K}_{D scap/fluid}^{Cl/Br}\) = 0.42 ± 0.04 (2 SD) and is shown on Fig. 4F.

The Cl/Br distribution coefficient was found to be markedly dependent on pressure, as demonstrated by experiments run at the same temperatures and fluid salinities but at different pressures. Figure 5A shows that lower pressures result in higher Cl/Br ratios in the neomorphic scapolite. For instance, at 0.32 GPa a molar Cl/Br ratio of 1.31 ± 0.24 (2 SD) is observed, compared to 0.65 ± 0.05 at 1.52 GPa. Correspondingly, the distribution coefficient (\({K}_{D scap/fluid}^{Cl/Br }\)) varies from 0.74 ± 0.15 at 0.32 GPa to 0.37 ± 0.04 (2 SD) at 1.52 GPa (Fig. 5B).

Composition of glass in samples SC45-3b and SC45-7

EPMA measurements of glass that formed in the experimental runs SC45-3b and SC45-7 (1000 °C at \({X}_{NaCl+NaBr}^{brine}\) = 0.30 and 0.40) (Fig. 2E, F; Table 3) returned totals of ~ 90 wt%, suggesting the presence of ~ 10 wt% volatiles (i.e., H2O and/or CO2). The glasses produced in both runs SC45-3b and SC45-7 can be modeled as plagioclase, based on the Al2O3 and SiO2 contents, but with an excess of Na and Ca over that needed for scapolite. The molar Cl/Br ratio of the glass in SC45-3b and SC45-7 is 3.58 ± 0.37 (2 SD) and 3.73 ± 0.85 (2 SD), respectively, which is about 5 times greater than scapolite and indicates a stronger affinity of the glass for Cl. Glasses in both samples also contain higher K2O contents than neomorphic scapolite (0.27–0.48 wt% in glass vs. 0.03–0.07 wt% in scapolite, Table 3).

Anion concentrations of soluble salts

A selection of samples at 800 °C and 1.5 GPa had the soluble salts dissolved out for the purpose of analyzing their anion content, as described in the Methods section. Table 4 lists the concentrations of Cl− and Br− in the leachate using ion chromatography. These concentrations were then converted to an equivalent mass of NaCl and NaBr, where Na+ is the dominant cation in these experiments, and the resultant mass compared to the initial mass of these salts loaded into the capsules (Table 2). Figure 6 shows the percentage changes in the masses of NaCl and NaBr from the beginning to the end of the experiment, e.g., where ΔNaCl is the difference NaCl(final)–NaCl(initial). Within statistical error, there is essentially no net change in the NaCl. This is not surprising as the change in Cl contents between the initial and treated scapolite would only change the extracted brine by 1–3 ppm Cl− even if all of the scapolite (rather than just the rims) was involved. This is comparable to the uncertainty in the anion measurement. Because of the greater mass of Br compared to Cl, the incorporation of Br into scapolite should be easier to detect, with complete exchange of A-site anions for Br causing a drop of about 14 ppm in Br−; however, the scatter in these data (Fig. 6) combined with an uncertainty of 2–3 ppm (1σ) makes the Br− analyses less useful for deducing the overall amount of anion exchange in the scapolite. What can be deduced from Table 4 and Fig. 6 is that (a) there is sufficient brine that the concentration of Cl− and Br− remains relatively unaffected throughout the duration of the experiments, and (b) the molar ratio remains essentially unchanged, with the average Cl−/Br− ratio of 1.78 ± 0.56 (2 SD). This is the same as the initial ratio of 1.76 ± 0.12 (2 SD) (Table 2).

Discussion

Stability of scapolite at variable temperatures, pressures, and fluid salinities

Neomorphic scapolite that formed in these experiments has intermediate compositions that trend between the marialite-mizzonite and marialite-meionite solid solution lines (Fig. 3). For the sake of simplicity, we will report scapolite compositions as the Me % based solely on the Ca/(Ca + Na) ratio mentioned earlier. The product scapolite has similar compositions to scapolite found in natural settings, such as in skarns or metamorphic rocks (e.g., Mora and Valley 1991; Hammerli et al. 2014). As shown in previous studies (Orville 1975; Ellis 1978; Almeida and Jenkins 2017, 2019), the stability of scapolite at elevated temperatures and pressures is controlled by the fluid composition, where the fluid’s salinity and the concentration of water plays an important role. In the experiments conducted in this study scapolite is stable when treated with \({X}_{NaCl+NaBr}^{brine}\) ≥ 0.2, at 600 and 800 °C. Our results broadly agree with the previous high-pressure experiments of Almeida and Jenkins (2019), which imply that the minimum total molar brine fraction needed to stabilize scapolite is between 0.1 and 0.3 at 1.5 GPa and 660–720 °C.

In the experiments at 1000 °C scapolite completely melted when reacting with brine of \({X}_{NaCl+NaBr}^{brine}\) = 0.20 (Fig. 1). A silicate liquid (melt), present as a quenched glass, was observed to coexist with scapolite in two of the experiments (SC45-3b and SC45-7) at \({X}_{NaCl+NaBr}^{brine}\) = 0.30–0.40. These experiments showed a large change in the scapolite composition (Fig. 3C), largely toward Me enrichment, as discussed further below. In the experiments with higher salinities where glass was absent (SC45-4 and SC45-5) no other phase aside from neomorphic scapolite formed during the exchange experiments. In these higher-concentration brines the extent of scapolite compositional change was much less than in the lower-concentration brines (Fig. 3C).

Earlier experiments have mostly been conducted with NaCl as the sole salt (e.g., Ellis 1978; Almeida and Jenkins 2019) and it is therefore interesting to note that experiments conducted in this study that contain, in addition to NaCl, significant amounts of NaBr (Table 2) seem to broadly agree with previous findings, such as the minimum brine concentrations necessary to stabilize scapolite (Fig. 1). This suggests that the presence of high concentrations of NaBr does not impact the stability field of scapolite to a significant degree.

In the present study, scapolite was found to be stable over the entire range of pressure explored (0.32–1.5 GPa). Pan and Dong (2003) reported that the natural marialite (Mar88Me12) they treated at 800 °C and 1 atm was well preserved after treatment for 30 days, while the same sample underwent complete breakdown to albite and wollastonite after treatment at 1000 °C for 12 days. The lower-pressure stability of marialite-rich scapolite is not well defined. Orville (1975) determined marialite-rich scapolite in the compositional range of Mar100-85Me0-15 breaks down to the assemblage plagioclase (An5) + scapolite (Me15) + halite + calcite at 750 and 0.4 GPa. Based on the study of Almeida and Jenkins (2017), end-member marialite was observed to break down to albite + halite along a boundary that is estimated to have a shallow dP/dT slope, with break down occurring below, for example, 0.64 GPa at 930 °C. Both of these earlier studies suggest that the marialite-rich scapolite used by Pan and Dong (2003) would not be stable at 1 atm. It is suggested, therefore, that the 1 atm conditions used by Pan and Dong (2003) may have preserved scapolite metastably at 800 °C while reaction rates were sufficient at 1000 °C to allow complete breakdown.

Composition of treatment products

Previous studies on natural intermediate scapolite compositions have shown that higher temperatures stabilize scapolite with higher meionite contents (e.g., Hietanen 1967; Kwak 1977). The same temperature effect is observed in these experiments when we compare neomorphic scapolite that reacted with the same brine concentration at 600 °C, 800 °C, and at 1000 °C. For example, sample SC42-4 treated at 800 °C and \({X}_{NaCl+NaBr}^{brine}\) = 0.50 formed scapolite with a meionite content of 30 ± 4%, while run SC45-4 treated at 1000 °C and \({X}_{NaCl+NaBr}^{brine}\) = 0.50 formed scapolite with a meionite content of 46 ± 4% (Fig. 3A). This observation shows that at least in a calcite-buffered environment temperature directly affects the composition of scapolite.

Figure 3B and C also show that the brine concentration controls scapolite compositions. The correlation between scapolite compositions and \({X}_{NaCl+NaBr}^{brine}\) is more pronounced in the experiments run at 1000°C. For example, the experimental run with the lowest brine concentration (\({X}_{NaCl+NaBr}^{brine}\) = 0.32) produced scapolite with a meionite content of 72 ± 2%. Scapolite treated at the same temperature but with \({X}_{NaCl+NaBr}^{brine}\) of 0.66 led to the formation of scapolite with a meionite content of 42 ± 3%. For the experiments at 800°C, a similar but more subtle correlation was observed (Fig. 3B). In all experiments, the new scapolite is devoid of SO3, K2O and FeO, which means that these elements partitioned into the fluid/melt phase during the experiments (Table 3).

Our experiments demonstrate that pressure significantly influences the meionite content of scapolite (Fig. 3D). Conducted at 800 °C with \({X}_{NaCl+NaBr}^{brine}\) = 0.3 and pressures ranging from 0.32 to 1.52 GPa, the results indicate that higher pressure results in lower meionite contents of neomorphic scapolite. The experiment at 1.52 GPa produced neomorphic rims with an average meionite content of 30 ± 4% (2 SD), whereas the experiment at 0.32 GPa produced scapolite rims with a meionite content of 76 ± 8% (2 SD). This suggests that pressure, temperature, and fluid salinity may all impact the meionite content of scapolite.

The neomorphic scapolite rims in our study show relatively sharp grain boundaries with the original scapolite with grossular grains often forming in the vicinity of the contact. In some cases the new scapolite growth approaches euhedral shapes (e.g., Fig. 2A, B). Given the crystal shape of the neomorphic scapolite and the sharp boundaries between the non-reacted original seeds and the new scapolite (Fig. 2C), we suggest that diffusion played a minor role in the formation of the neomorphic scapolite and that precipitation and/or dissolution-reprecipitation was the dominant process for the formation of neomorphic scapolite.

Compositional effect of grossular, glass, and wollastonite formation

It is important to establish some degree of mass balance in experiments were additional phases spontaneously nucleated, generally resulting in noticeable shifts in neomorphic scapolite compositions. Grossular garnet (Ca3Al2Si3O12), which has essentially an ideal composition in the present chemical system, appeared as a coexisting phase in most of the experiments done at 800 °C. Its abundance, estimated qualitatively from the XRD patterns, decreases with increasing fluid salinity concentration, such that experiments at the highest salinities have either no, or barely detectable, grossular. The appearance of grossular with no discernible kyanite or quartz suggests that its appearance is not related to the low-temperature breakdown of the meionite component of the scapolite (Newton and Goldsmith 1976). Similarly, the lack of coexisting corundum, absence of any visible capsule bloating, and no obvious weight loss from the capsule that might be attributable to free CO2 does not support the formation of grossular by reaction of the anorthite component in scapolite with the excess calcite in the capsule, as observed in the low-pressure (0.4 GPa) and water-rich experiments of Orville (1975). The formation of grossular in this study appears to be governed by a different process. Figure 7A shows the starting bulk composition for the SC42-series experiments, along with scapolite overgrowth (rim) compositions and grossular, plotted on the CaO-Al2O3-Na2O ternary plane as projections from NaCl, NaBr, calcite, SiO2, and H2O. The component SiO2 rather than quartz, which is not observed in this study, is used as one of the points of projection to facilitate plotting the phases of interest on this diagram. In order to achieve mass balance, there needs to be some additional phase that is enriched in Al2O3 or some combination of Al2O3 + SiO2 + Na2O and possibly minor CaO. Without any evidence of a crystalline phase with the appropriate composition, it is suggested that trace amounts of alumino-silicate material are dissolved in the brine as a solute. In the absence of detailed information on the composition of brines coexisting with scapolite, some indication can be gleaned from recent studies on albite. Makhluf et al. (2020) studied the system albite-H2O over the range of 1.0–1.7 GPa and 630–1050 °C and found that a considerable amount of albite (41 wt%) can dissolve into water at 1.5 GPa at the solidus temperature (680 °C). With the addition of NaCl, the solubility of albite in an H2O-NaCl brine drops by a factor of 17 at 1.0 GPa and at the solidus temperature (690 °C) for a brine with XNaCl = 0.3 (Makhluf et al. 2016). At the brine concentrations dealt with in this study (\({X}_{NaCl+NaBr}^{brine}\) = 0.2–0.4) where clear grossular formation occurred, and assuming a similar reduction in silicate solubility with the addition of NaCl-NaBr salts, it is anticipated that the solubility of marialite-rich scapolite would be about 2–3 wt%.

A Phase compositions of grossular-bearing experiments at 800 °C and 1.5 GPa projected from SiO2, NaCl, NaBr, Calcite, and H2O onto the ternary CaO–Al2O3–Na2O. B Phase compositions observed in experiment SC45-3b at 1000 °C and 1.41 GPa. C Phase compositions at 800 °C and at 0.32 (solid lines) and 0.60 (dashed lines) GPa. Abbreviations as in Table 2

Figure 7A shows a possible composition range for brine-hosted alumino-silicate material (grey bar), though there is no direct analysis or unique way to constrain the composition of this material. If present, it would likely precipitate out of the brine upon quenching the run as a very thin amorphous coating on any coexisting grains. Based on this, the formation of grossular is attributed to the general simplified reaction:

Reaction (4) is one possible chemically balanced reaction involving the starting-material scapolite (SC4, Table 1), the product (neomorphic rim) scapolite from experiment SC42-2 (Table 3), along with grossular, calcite, NaBr and NaCl in the brine, and an alumino-silicate composition dissolved in the brine, modeled here as a combination of Al2O3 and SiO2:

In reaction (4), the mass fraction of the brine alumino-silicate is 18.4 wt% of the reactants. If approximately 25% of the scapolite undergoes this reaction and scapolite is approximately 50 wt% of the assemblage sealed in the capsule, then only about 2–3 wt% of this alumino-silicate is released to the brine, which agrees with the scapolite solubility range estimated above. Although the previous study by Wohlers et al. (2011) on the dissolution of albite and jadeite in the presence of quartz in pure water at high P–T conditions found the fluid to contain molar ratios of Na:Al greater than 1, this does not appear to be the case in this study done in concentrated brines. Overall, the net effect of forming grossular and the brine-hosted alumino-silicate is to cause the composition of the original scapolite to shift toward a more marialite-enriched composition.

The presence of glass in the 1000 °C experiments causes a compositional shift in the neomorphic scapolite rims primarily towards meionite enrichment (Fig. 3C). Figure 7B shows the phase compositions observed for one experiment (SC45-3b) for which both the glass and newly formed scapolite compositions are known and are significantly shifted from the starting bulk composition. Using the same projection as in Fig. 7A, it is clear that the scapolite shifted composition to essentially that of mizzonite (Fig. 3C) while the glass has a composition well below the meionite-marialite join. Once again, the re-equilibrated scapolite composition and glass are not in mass balance with the bulk composition; however, it is possible to achieve mass balance using the same brine-hosted silicate composition as used in Fig. 7A. For the experiments, which produced readily observable glass (SC45-3b and SC42-7) the following general reaction is proposed:

where the net effect is to shift a marialite-rich to meionite-rich scapolite by the formation of Na-Al-enriched liquid (quenched to glass) and brine-phase dissolved silicate. Reaction (6) is one possible chemically balanced reaction based on the initial scapolite SC4, reactant scapolite and glass from experiment SC45-3b, and involving a similar alumino-silicate in the brine as for reaction (4):

In the experiments in which glass formed it is assumed that the brine coexists with silicate melt below the critical curve for silicate melt + brine (or vapor in salt-free systems; Makhluf et al. 2020). The absence of glass in the experiments with higher brine concentrations suggests that the higher salinities, and accompanying lower activity of H2O in the brine, increased the solidus temperature above 1000 °C.

Experiments done at 800 °C and at 0.32 and 0.60 GPa showed considerable shift towards meionite enrichment in the rim overgrowths, with coexisting wollastonite or wollastonite and grossular. Formation of meionite-enriched rims in the lowest-pressure experiment again requires dissolution of alumino-silicate material, but with substantial Na as well, perhaps in the form of aqueous sodium metasilicate (Na2SiO3°aq). Sodium metasilicate was identified as a probable constituent of the quenched solute material in the albite dissolution experiments at 650 °C and 0.9 GPa by Shmulovich et al. (2001). One possible reaction, similar to 5, involving the average scapolite rim composition of experiment SC46-1 at 0.32 GPa (SC46-1-scap) is:

Figure 7C shows that the brine coexisting with wollastonite and the average scapolite rim composition (solid lines) is compatible with the SC4 scapolite bulk composition. Similarly, the dashed lines indicate that grossular coexisting with the average rim composition of the scapolite in SC46-2 treated at 800 °C and 0.60 GPa, along with the same brine composition as for the 0.32 GPa experiment, are compatible with the SC4 bulk composition. Therefore, either wollastonite or grossular are compatible with these scapolite rim compositions and the proposed Na-enriched alumino-silicate brine in Fig. 7C through this lower-pressure range.

Cl/Br partitioning between fluid and scapolite

Experiments run at ~ 1.5 GPa and 600–1000 °C with different brine concentrations resulted in the formation of new scapolite with molar Cl/Br ratios between 0.6 and 0.9 regardless of the temperature or total bulk salinity. Most of the experiments were initiated with the brine having a molar Cl/Br ratio of 1.76, with two experiments having molar Cl/Br ratios of 3.52 and 0.88 to provide some information on the effect of varying this initial Cl/Br ratio. However, only the experiment with a molar Cl/Br ratio of 3.52 produced measurable neomorphic scapolite rims.

Considering all of the data, we can monitor if different bulk salinities, temperature, or pressure affect Cl/Br distribution. In this study, no correlation was observed between the brine concentration or the experimental temperature and the Cl/Br ratios in the neomorphic scapolite (Fig. 4D, F). Furthermore, in the experiments where glass was formed as a product, Cl/Br ratios in new scapolite are indistinguishable from experiments that did not produce glass. This means that different concentrations of the brine (or temperature) do not impact the fractionation of Cl and Br between fluids and scapolite. Figure 8 displays molar Cl/Br ratios of the neomorphic (reacted) scapolite vs. their meionite contents (mol%), showing that no correlation between the scapolite compositions and their Cl/Br ratios exists; an observation that has also been made in previous studies on natural scapolite (e.g., Hammerli et al. 2014). This is an important finding as it means that at a constant pressure, Cl/Br ratios in scapolite are not controlled by the composition of the mineral or the total salinity of the fluid but simply by the Cl/Br ratio present in the fluid during fluid-mineral interaction.

Scapolite compositions (mol% Me) of neomorphic scapolite vs. measured molar Cl/Br ratios in neomorphic scapolite. Scapolite samples treated at 600 °C are shown as grey triangles, samples treated at 800 °C are shown in black circles and scapolite grains treated at 1000 °C are shown as empty squares. The plotted data shows no correlation between the scapolite compositions (meionite %) and Cl/Br ratios

While the above factors do not affect the Cl/Br partitioning between fluid and scapolite, this study shows that pressure plays a strong role (Fig. 5). The \({K}_{D scap/fluid}^{Cl/Br }\) decreases with increasing pressure from ~ 1.34 at 0.32 GPa down 0.71 at 1.52 GPa. This pressure dependence implies a relatively large change in ΔV for the exchange reaction:

from which the equilibrium constant and resultant distribution coefficient can be written as:

At present there are insufficient thermodynamic data to allow KD to be calculated as a function of pressure. Similarly, applying the relationship dlnKD/dP = – ΔV/RT to reaction (9), assuming ΔV is constant over the pressure range of this study, and inverting the relationship to solve for P as function of lnKD does not model the data well over more than about 0.5 GPa. We have, instead, used a 3rd-order polynomial to model our data (Fig. 9A). Extrapolation of this equation to 1 atm gives a value for \({K}_{D scap/fluid}^{Cl/Br }\) of 1.17 (Fig. 9A). This value is in excellent agreement with the \({K}_{D scap/fluid}^{Cl/Br }\) of 1.1 ± 0.1 at 1 atm found by Pan and Dong (2003). By combining our data with that of Pan and Dong (2003) and again using a 3rd-order polynomial (Fig. 9B), we can establish an equation to calculate the molar Cl/Br ratio of the fluid at different pressures. The equation is:

where Cl/Brfluid is the calculated molar ratio of the fluid, Cl/Brscapolite is the molar ratio measured in scapolite, and P is pressure in GPa.

A Polynomial function based on pressure-controlled partition coefficient values determined in this study. B Polynomial function based on pressure-controlled partition coefficient values determined in this study and including the value by Pan and Dong (2003) (solid square). *indicates experiments for which only one EPMA measurement was possible

Implications

Scapolite group minerals are common in metamorphic rocks and in mineralized systems, ranging from skarns to porphyry deposits to iron-oxide-apatite (IOA) systems. Their capability to incorporate halogens (especially Cl and Br, and in some cases I) to concentrations that permit in situ high-spatial resolution analysis via SIMS, LA-ICP-MS, or EPMA make these minerals valuable for tracing fluid sources. However, this is possible only under the condition that the halogen distribution coefficients between fluids and scapolite are known. The only previous study that aimed to experimentally-determine the Cl/Br distribution coefficient between scapolite and fluid (Pan and Dong 2003) reported a KD of ~ 1, meaning that halogen ratios in the fluids are mirrored in scapolite and hence that the halogen ratios in scapolite can be directly used to identify fluid sources without the need of accounting for the different partitioning of Cl and Br. Our study shows that the distribution coefficient between fluids and scapolite is pressure-dependent. Except for conditions close to the surface, Br is preferably incorporated into scapolite compared to Cl on an atomic or molar basis, which results in a KD between scapolite and fluid of < 1. This means that, for example, in the deep crust at 1.5 GPa, molar Cl/Br ratios measured in scapolite require multiplication by a factor of 2.5 for direct comparison with the fluid present at the time of scapolite formation and/or interaction.

If results of previous studies are adjusted to this new distribution coefficient the adjusted data may lead to different conclusions. However, for studies where halogen analyses in scapolite returned end-member ratios of distinct fluid sources, such as molar Cl/Br < 200 or > > 1000, the new partitioning coefficients will not affect data interpretation as the adjusted values still fall within a distinct field, such as the bittern brine or halite dissolution field for the above scenarios.

In environments characterized by low fluid-to-rock ratios, scapolite-induced fractionation of Cl and Br will influence the remaining fluid composition. This will result in elevated Cl/Br ratios in the residual fluid as scapolite selectively extracts Br, especially at deep crustal levels. The fractionation of Cl and Br will also impact the composition of fluids that may be released upon the breakdown of scapolite and therefore further complicate the tracing of fluids in settings that underwent multiple metamorphic events.

The rather interesting observation in this study that the partitioning of Br and Cl between scapolite and fluid appears to depend predominantly on pressure suggests the potential use of Equation (10) as a geobarometer, especially at pressures ≤ 0.5 GPa. Such an application would require an independent determination of the Cl/Br ratio of the scapolite-forming fluid, presumably from fluid inclusion data. If this can be determined, Equation (10) could be used to estimate the depth of scapolite formation and would have the greatest depth resolution at shallower or near-surface levels.

Conclusions

Exchange experiments conducted at pressures of 0.32 to 1.52 GPa and temperatures from 600 to 1000 °C, with total brine mole fractions (\({X}_{NaCl+NaBr}^{brine}\)) from 0.1 to 0.66, show that pressure, temperature, and fluid salinity all affect the composition (mol% Me) of neomorphic scapolite. However, the distribution coefficient of Cl/Br between the fluid and scapolite is not affected by the brine concentration, temperature, presence of melt (glass) in the experiments, or the composition of the scapolite over the range of 0.1–0.8 mol fraction of the meionite component. This indicates that halogen uptake by scapolite is not so dependent on the crystal chemistry of the host scapolite but more by the energetics of halogen exchange between the fluid and the A-site cage of scapolite. The net effect is that the composition of the scapolite does not impact the Cl/Br distribution between fluid and scapolite. Our experiments, however, reveal that the distribution coefficient of Cl/Br between the fluid and scapolite is affected by pressure, with increasing pressure correlating with a preferential uptake of Br over Cl by scapolite. This means that in rock-buffered environments, especially at mid to lower crustal levels, Cl and Br fractionation by scapolite enriches the residual fluid in Cl relative to Br due to scapolite’s preferential uptake of Br.

Based on the new experiments and previous data, the molar Cl/Br ratio of a fluid can be calculated from Cl/Br measurements in scapolite via the following formula: Cl/Brfluid = Cl/Brscapolite x (– 1.473 × P + 1.119 × P2 – 0.299 × P3 + 1.103)−1 where pressure (P) is in GPa and Cl/Brscapolite is the halogen molar ratio in scapolite. Our study shows that In-situ Cl/Br measurements in scapolite can be a powerful approach for identifying fluid sources in the crust, from shallow to deep crustal levels.

References

Ague JJ (1994) Mass transfer during Barrovian metamorphism of pelites, south-central connecticut; II, channelized fluid flow and the growth of staurolite and kyanite. Am J Sci 294:1061–1134. https://doi.org/10.2475/ajs.294.9.1061

Almeida KMF, Jenkins DM (2017) Stability field of the Cl-rich scapolite marialite. Am Miner 102:2484–2493. https://doi.org/10.2138/am-2017-6132

Almeida KMF, Jenkins DM (2019) A comparison between the stability fields of a Cl-rich scapolite and the end-member marialite. Am Miner 104:1788–1799. https://doi.org/10.2138/am-2019-6907

Aranovich LY, Newton RC (1996) H2O activity in concentrated NaCl solutions at high pressures and temperatures measured by the brucite-periclase equilibrium. Contrib Miner Petrol 125:200–212

Audétat A, Günther D, Heinrich CA (1998) Formation of a magmatic-hydrothermal ore deposit: insights with LA-ICP-MS analysis of fluid inclusions. Science 279:2091–2094. https://doi.org/10.1126/science.279.5359.2091

Baker J, Newton RC (1995) Experimentally determined activity-composition relations for Ca-rich scapolite in the system CaAl2Si2O8-NaAlSi3O8-CaCO3 at 7 kbar. Am Miner 80:744–751

Bénard A, Koga KT, Shimizu N et al (2017) Chlorine and fluorine partition coefficients and abundances in sub-arc mantle xenoliths (Kamchatka, Russia): Implications for melt generation and volatile recycling processes in subduction zones. Geochim Cosmochim Acta 199:324–350. https://doi.org/10.1016/j.gca.2016.10.035

Böhlke JK, Irwin JJ (1992) Laser microprobe analyses of Cl, Br, I, and K in fluid inclusions: implications for sources of salinity in some ancient hydrothermal fluids. Geochim Cosmochim Acta 56:203–225. https://doi.org/10.1016/0016-7037(92)90127-5

Cheng N, Jenkins DM, Holland TJB (2019) Low-pressure—temperature stability of pyrope + quartz relative to orthopyroxene + kyanite: a new model for aluminous orthopyroxene with vacancies. Contrib Miner Petrol 174:30

Ellis DE (1978) Stability and phase equilibria of chloride and carbonate bearing scapolites at 750°C and 4000 bar. Geochim Cosmochim Acta 42:1271–1281. https://doi.org/10.1016/0016-7037(78)90121-7

Evans BW, Shaw DM, Haughton DR (1969) Scapolite stoichiometry. Contrib Miner Petrol 24:293–305

Fusswinkel T, Wagner T, Wälle M, Wenzel T, Heinrich CA, Markl G (2013) Fluid mixing forms basement-hosted Pb-Zn deposits: Insight from metal and halogen geochemistry of individual fluid inclusions. Geology 41:679–682. https://doi.org/10.1130/G34092.1

Goldsmith JR (1976) Scapolites, granulites, and volatiles in the lower crust. Geol Soc Am Bull 87:161–168

Goldsmith JR, Newton RC (1977) Scapolite-plagioclase stability relations at high pressure and temperatures in the system NaAlSi3O8-CaAl2Si2O8-CaCO3-CaSO4. Am Miner 62:1063–1081

Hammerli J, Boroughs S (2023) Interference-free electron probe micro-analysis of bromine in halogen-bearing minerals and glasses: high-resolution measurements and quantitative elemental mapping. J Anal at Spectrom 38:1927–1933. https://doi.org/10.1039/D3JA00198A

Hammerli J, Rubenach M (2018) The role of halogens during regional and contact metamorphism. In: Harlov DE, Aranovich L (eds) The role of halogens in terrestrial and extraterrestrial geochemical processes. Springer International Publishing, Cham, pp 649–712

Hammerli J, Rusk B, Spandler C et al (2013) In situ quantification of Br and Cl in minerals and fluid inclusions by LA-ICP-MS: a powerful tool to identify fluid sources. Chem Geol 337–338:75–87. https://doi.org/10.1016/j.chemgeo.2012.12.002

Hammerli J, Spandler C, Oliver NHS, Rusk B (2014) Cl/Br of scapolite as a fluid tracer in the earth’s crust: insights into fluid sources in the Mary Kathleen Fold Belt, Mt. Isa Inlier, Australia. J Metamorph Geol 32:93–112. https://doi.org/10.1111/jmg.12060

Hassan I, Buseck PR (1988) HRTEM characterization of scapolite solid solutions. Am Miner 73:119–134

Hedenquist JW, Lowenstern JB (1994) The role of magmas in the formation of hydrothermal ore deposits. Nature 370:519–527. https://doi.org/10.1038/370519a0

Hietanen A (1967) Scapolite in the Belt Series in the St. Joe-Clearwater region, Idaho. Geol Soc Am Spec Pap 86:1–56

Irwin JJ, Roedder E (1995) Diverse origins of fluid in magmatic inclusions at Bingham (Utah, USA), Butte (Montana, USA), St. Austell (Cornwall, UK), and Ascension Island (mid-Atlantic, UK), indicated by laser microprobe analysis of Cl, K, Br, I, Ba + Te, U, Ar, Kr, and Xe. Geochim Cosmochim Acta 59:295–312. https://doi.org/10.1016/0016-7037(94)00285-T

Jenkins DM (2019) The incorporation of chlorine into calcium amphibole. Am Miner 104:514–524. https://doi.org/10.2138/am-2019-6768

Kendrick MA (2012) High precision Cl, Br and I determinations in mineral standards using the noble gas method. Chem Geol 292–293:116–126. https://doi.org/10.1016/j.chemgeo.2011.11.021

Kendrick MA, Mark G, Phillips D (2007) Mid-crustal fluid mixing in a proterozoic Fe oxide–Cu–Au deposit, Ernest Henry, Australia: evidence from Ar, Kr, Xe, Cl, Br, and I. Earth Planet Sci Lett 256:328–343. https://doi.org/10.1016/j.epsl.2006.12.032

Klemm LM, Pettke T, Heinrich CA (2008) Fluid and source magma evolution of the Questa porphyry Mo deposit, New Mexico, USA. Miner Deposita 43:533–552. https://doi.org/10.1007/s00126-008-0181-7

Kusebauch C, John T, Barnes JD, Klügel A, Austrheim HO (2015) Halogen element and stable chlorine isotope fractionation caused by fluid-rock interaction (Bamble Sector, SE Norway). J Petrol 56:299–324. https://doi.org/10.1093/petrology/egv001

Kwak TAP (1977) Scapolite compositional change in a metamorphic gradient and its bearing on the identification of meta-evaporite sequences. Geol Mag 114:343–354

Lecumberri-Sanchez P, Bodnar RJ (2018) Halogen geochemistry of ore deposits: contributions towards understanding sources and processes. In: Harlov DE, Aranovich L (eds) The role of halogens in terrestrial and extraterrestrial geochemical processes. Springer International Publishing, Cham, pp 261–305

Levien L, Papike JJ (1976) Scapolite crystal chemistry: aluminum-silicon distributions, carbonate group disorder, and thermal expansion. Am Mineral 61:864–877

Makhluf AR, Newton RC, Manning CE (2016) Hydrous albite magmas at lower crustal pressure: new results on liquidus H2O content, solubility, and H2O activity in the system NaAlSi3O8-H2O-NaCl at 1.0 GPa. Contr Mineral Petrol 171:75

Makhluf AR, Newton RC, Manning CE (2020) Experimental investigation of phase relations in the system NaAlSi3O8-H2O at high temperatures and pressures: liquidus relations, liquid-vapor mixing, and critical phenomena at deep crust-upper mantle conditions. Contrib Miner Petrol 175:76

Mora CI, Valley JW (1991) Prograde and retrograde fluid-rock interaction in calc-silicates northwest of the Idaho batholith: stable isotopic evidence. Contrib Miner Petrol 108:162–174. https://doi.org/10.1007/BF00307335

Newton RC, Goldsmith JR (1976) Stability of the end-member scapolites: 3NaAlSi3O8 · NaCl, 3CaAl2Si2O8 · CaCO3, 3CaAl2Si2O8 · CaSO4. Zeitschrift Für Kristallographie - Cryst Mater 143:333–353. https://doi.org/10.1524/zkri.1976.143.jg.333

Newton RC, Manning CE (2002) Experimental determination of calcite solubility in H2O-NaCl solutions at deep crust/upper mantle pressure and temperatures: Implications for metasomatic processes in shear zones. Am Miner 87:1401–1409

Orville PM (1975) Stability of scapolite in the system Ab-An-NaCl-CaCO3 at 4 kb and 750 °C. Geochim Cosmochim Acta 39:1091–1105

Pan Y, Dong P (1999) The Lower Changjiang (Yangzi/Yangtze River) metallogenic belt, east central China: intrusion- and wall rock-hosted Cu–Fe–Au, Mo, Zn, Pb, Ag deposits. Ore Geol Rev 15:177–242. https://doi.org/10.1016/S0169-1368(99)00022-0

Pan Y, Dong P (2003) Bromine in scapolite-group minerals and sodalite: Bromine in scapolite-group minerals and sodalite: XRF microprobe analysis, exchange experiments, and application to skarn deposits. Can Mineral 41:529–540

Redfern SAT (2000) Structural variations in carbonates. Rev Mineral Geochem 41:289–308

Seo JH, Guillong M, Aerts M et al (2011) Microanalysis of S, Cl, and Br in fluid inclusions by LA–ICP-MS. Chem Geol 284:35–44. https://doi.org/10.1016/j.chemgeo.2011.02.003

Seward TM, Barnes HL (1997) Metal transport in hydrothermal ore fluids. In: Barnes HL (ed) Geochemistry of hydrothermal ore deposits, 3rd edn. Wiley Interscience, New York, pp 435–486

Shmulovich K, Graham C, Yardley B (2001) Quartz, albite and diopside solubilities in H2O-NaCl and H2O-CO2 fluids at 0.5-0.9 GPa. Contrib Mineral Petrol 141:95–108. https://doi.org/10.1007/s004100000224

Shulaker DZ, Gordon SM, Hammerli J, DesOrmeau JW (2024) Fluid-driven mass transfer during retrograde metamorphism and exhumation of the UHP Western Gneiss region Terrane, Norway. Geochem Geophys Geosyst 25:e2022GC010659. https://doi.org/10.1029/2022GC010659

Su Z-K, Zhao X-F, Zeng L-P et al (2019) Tourmaline boron and strontium isotope systematics reveal magmatic fluid pulses and external fluid influx in a giant iron oxide-apatite (IOA) deposit. Geochim Cosmochim Acta 259:233–252. https://doi.org/10.1016/j.gca.2019.06.006

Teertstra DK, Sherriff BL (1997) Substitutional mechanisms, compositional trends and the end-member formulae of scapolite. Chem Geol 136:233–260. https://doi.org/10.1016/S0009-2541(96)00146-5

Teertstra DK, Schindler M, Sherriff BL, Hawthorne FC (1999) Silvialite, a new sulfate-dominant member of the scapolite group with an Al-Si composition near the I4/m–P42/n phase transition. Mineral Mag 63:321–321

Vanko DA, Bishop FC (1982) Occurrence and origin of marialitic scapolite in the Humboldt Lopolith, N. W Nevada. Contr Mineral Petrol 81:277–289

Vry J, Powell R, Golden KM, Petersen K (2010) The role of exhumation in metamorphic dehydration and fluid production. Nat Geosci 3:31–35. https://doi.org/10.1038/ngeo699

Waelkens CM, Stix J, Monteleone B, Burckel P (2021) Efficient release of bromine by super-eruptions. Geology 49:1416–1420. https://doi.org/10.1130/G49114.1

Wohlers A, Manning CE, Thompson AB (2011) Experimental investigation of the solubility of albite and jadeite in H2O, with paragonite + quartz at 500 and 600 °C, and 1–2.25 GPa. Geochim Cosmochim Acta 75:2924–2939

Yardley BW (2005) Metal concentrations in crustal fluids and their relationship to ore formation. Econ Geol 100:613–632

Yardley BWD (2009) The role of water in the evolution of the continental crust. J Geol Soc 166:585–600. https://doi.org/10.1144/0016-76492008-101

Yardley BWD, Cleverley JS (2015) The role of metamorphic fluids in the formation of ore deposits. Geol Soc Lond Spec Publ 393:117–134. https://doi.org/10.1144/SP393.5

Zeng L-P, Zhao X-F, Hammerli J et al (2019) Tracking fluid sources for skarn formation using scapolite geochemistry: an example from the Jinshandian iron skarn deposit, Eastern China. Miner Deposita 55:1029–1046. https://doi.org/10.1007/s00126-019-00914-3

Zhang Y, Hou Y, Li Y, Guo H, Liu X, Cao J (2022) Study on the phase equilibria of the ternary mixed solvent system NaCl-NaBr-CH3OH-H2O at 298 and 323 K. J Chem Eng Data 67:2767–2774

Zhu C, Sverjensky DA (1991) Partitioning of F-Cl-OH between minerals in hydrothermal fluids. Geochim Cosmochim Acta 55:1837–1858

Zhu C, Sverjensky DA (1992) F-Cl-OH partitioning between biotite and apatite. Geochim Cosmochim Acta 56:3435–3467

Acknowledgements

We would like to thank the two anonymous reviewers for their valuable and constructive suggestions that greatly contributed to the improvement of this manuscript. We thank Editor Hans Keppler for handling this paper. Scott Boroughs from the Peter Hooper GeoAnalytical lab at Washington State University is thanked for help with the EPMA measurements. This research was supported by a WSU start-up grant to JH.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Othmar Müntener.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hammerli, J., Jenkins, D.M. & Collins, D.P. Exchange experiments for chlorine and bromine partitioning in scapolite at variable fluid salinities, pressures, and temperatures: implications for tracing crustal fluid sources via Cl/Br ratios in scapolite. Contrib Mineral Petrol 179, 92 (2024). https://doi.org/10.1007/s00410-024-02162-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00410-024-02162-9