Abstract

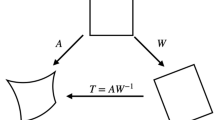

In the target matrix optimization paradigm (TMOP), it has long been understood that one must create a set of target matrices before the mesh can be optimized. But there is still no general method to create correct, effective targets in response to a specific mesh quality improvement goal. The TMOP literature describes how certain sets of target matrices can be used to control the shape or size of mesh elements, but those examples address only a fraction of the problems that can occur in mesh quality improvement and were not derived from a general framework for target matrix construction. In this work, a general method of target construction is introduced based on an independent set of geometric parameters that are intrinsic to the Jacobian matrices upon which TMOP is based. The parameters enable a systematic approach to target definition and construction. The approach entails two parts. The first part defines correspondences between available primary data (stuff about the mesh and/or the physical solution) and secondary data (e.g., a field of error estimates). Once the correspondences are established, the primary data are processed into intermediate field data existing on mesh sample points. The second part creates a model that represents the values of the geometric target parameters as functions of the secondary data. The model is then tested numerically to establish model constants and effectiveness. This systematic approach to target construction is illustrated in a set of examples to show how it can be applied to common problems in mesh optimization such as equalization of geometric properties, preservation of existing good quality, and adaptation of the mesh to the physical solution. The result is a systematic method of target construction for TMOP that can be applied to a wide variety of planar and volume mesh quality improvement tasks.

Similar content being viewed by others

Notes

The active matrix is \(3 \times 2\) for a mesh on some surface.

It is expected that, over time, more and more methods for assigning target parameter values will be developed so that one will not have to develop a new method each time a mesh is to be optimized.

We shall discuss what we mean by primary data in Sect. 3.1.3.

For 2D meshes, each parameter group has one parameter. For 3D meshes, some parameter groups contain more than one variable. For example, while in 2D, there is only one skew parameter \(\phi \), in 3D there are three skew parameters \(\phi _1,\phi _2, \phi _3\) that form the skew group.

If one wants to control a particular parameter within a parameter group, one will usually want to control all the other parameters in the group as well. There may be the rare occasions where one wants to control only some of the parameters within a group.

An extensive discussion of ‘metric type’ and how it is determined by the control decision can be found in [17].

It is recognized that, in more complex situations, the mesh quality improvement goal may require one to make multiple control decisions, for example, one for each sub-region of the physical domain.

The term “equalize” is used to mean “making the values of a geometric parameter equal at all sample points of the mesh.” Equalize is a special case of “equi-distribution” in which the product of a geometric parameter and a scalar weight is made the same over all sample points. Non-trivial equi-distribution is included under the “improve” option of PIE.

These coordinates are not unique, but uniqueness is not needed for the present purpose.

In some rare instances, one might wish to choose \(Y = I\), if one has some a priori knowledge about the skew angles.

If \(\mathbf{w}\) is a non-zero vector in \(\mathfrak {R}^2\), then we use the notation \(\mathbf{w}^\perp \) to indicate the vector that is perpendicular to \(\mathbf{w}\) and obeys \({\text {det}} \left[ \mathbf{w}, \mathbf{w}^\perp \right] > 0\).

References

Brackbill J, Saltzman J (1981) Adaptive zoning for singular problems in two dimensions. J Comput Phys 46:342–368

Brackbill J (1993) An adaptive grid with directional control. J Comput Phys 108:38–50

Cao W (2007) An interpolation error estimate on anisotropic meshes in \(\Re ^n\) and optimal meshes for mesh refinement. SIAM J Numer Anal 45(6):2368–2391

Chen L, Sun P, Xu J (2007) Optimal anisotropic meshes for minimizing interpolation errors in \(L^p\)-norm. Math Comput 76:179–204

Coulaud O, Loseille A (2016) Very high order anisotropic metric-based mesh adaptation in 3D. Procedia Eng 163:353–365

Du L, Yan N (2001) Gradient recovery type a posteriori error estimate for finite element approximation on non-uniform meshes. Adv Comput Math 14(2):175–193

Dvinsky A (1991) Adaptive grid generation from harmonic maps on Riemannian manifolds. J Comput Phys 95(2):450–476

Guo H, Zhang Z, Zhao R (2017) Hessian recovery for finite element methods. Math Comput 86(306):1671–1692

Hetmaniuk U, Knupp P (2008) A mesh optimization algorithm to decrease the maximum error in finite element computations. In: Proceedings of the 17th international meshing roundtable, pp 533–550

Huang W, Russell R (2011) Adaptive moving meshes. In: Bloch A, Epstein CL, Goriely A, Greengard L (eds) Applied mathematical sciences series, vol 174. Springer, New York

Ilyas M, Lamichhane B, Meylan M (2017) A gradient recovery method based on an oblique projection and boundary modification. ANZIAM J 58:C38–C45

Kamenski L, Huang W (2014) How a nonconvergent recovered Hessian works in mesh adaptation. SIAM J Numer Anal 52(4):1692–1708

Knupp P (1995) Mesh generation using vector fields. J Comput Phys 119:142–148

Knupp P (2007) Updating meshes on deforming domains. Commun Numer Methods Eng 24(6):467–476

Knupp P (2012) Introducing the target matrix paradigm for mesh optimization via node movement. Eng Comput 28(4):419–429

Knupp P (2019) Target formulation and construction in mesh quality improvement. LLNL-TR-795097, Lawrence Livermore National Laboratory, Livermore, CA

Knupp P (2020) Metric type in the target-matrix mesh optimization paradigm, LLNL-TR-817490. Lawrence Livermore National Laboratory, Livermore, CA

Lakkis O, Pryer T (2012) Gradient recovery in adaptive finite-element methods for parabolic problems. IMA J Numer Anal 32(1):246–278

Leng J, Zhang Y, Xu G (2013) A novel geometric flow approach for quality improvement of multi-component tetrahedral meshes. Comput Aided Des 45(10):1182–1197

Liseikin V (1999) Grid generation methods. Springer, Berlin

Lipnikov K, Vassilveski Y (2007) Analysis of Hessian recovery methods for generating adaptive meshes. In: Proceedings of the 15th international meshing roundtable, pp 163–171

Quadros WR, Vyas V, Brewer M, Owen SJ, Shimada K (2005) A computational framework for generating sizing function in assembly meshing. In: Hanks BW (eds) Proceedings of the 14th international meshing roundtable. Springer, Berlin, Heidelberg

Steinberg S, Roache P (1986) Variational grid generation. Numer Methods PDEs 2:71–96

Thompson J, Thames F, Mastin C (1974) Automatic numerical grid generation of boundary-fitted curvilinear coordinates for field containing any number of arbitrary two-dimensional bodies. J Comput Phys 15:299–319

Winslow A (1967) Numerical solution of the quasilinear Poisson equations in a non-uniform triangle mesh. J Comput Phys 2:149–172

Zhang Y, Bajaj C, Xu G (2009) Surface smoothing and quality improvement of quadrilateral/hexahedral meshes with geometric flow. J Commun Numer Methods Eng 25(1):1–18

Zienkiewicz O, Zhu J (1992) The superconvergence patch recovery and a posteriori error estimates, part I. Int J Numer Methods Eng 33:1331–1364

Acknowledgements

The author would like to thank members of the ETHOS team: Veselin Dobrev, Tzanio Kolev, Ketan Mittal, and Vladimir Tomov. Funding was supported by Lawrence Livermore National Laboratory (B615479).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Dihedral LLC Support provided by the ETHOS project, LLNL Subcontract B615479.

Rights and permissions

About this article

Cite this article

Knupp, P. A target construction methodology for mesh quality improvement. Engineering with Computers 38, 4451–4474 (2022). https://doi.org/10.1007/s00366-022-01653-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-022-01653-2