Abstract

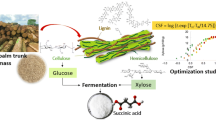

Due to the world’s dwindling energy supplies, greater thrust has been placed on the utilization of renewable resources for global succinate production. Exploration of such biotechnological route could be seen as an act of counterbalance to the continued fossil fuel dominance. Malaysia being a tropical country stands out among many other nations for its plenty of resources in the form of lignocellulosic biomass. To date, oil palm frond (OPF) contributes to the largest fraction of agricultural residues in Malaysia, while kenaf, a newly introduced fiber crop with relatively high growth rate, holds great potential for developing sustainable succinate production, apart from OPF. Utilization of non-food, inexhaustible, and low-cost derived biomass in the form of OPF and kenaf for bio-based succinate production remains largely untapped. Owing to the richness of carbohydrates in OPF and kenaf, bio-succinate commercialization using these sources appears as an attractive proposition for future sustainable developments. The aim of this paper was to review some research efforts in developing a biorefinery system based on OPF and kenaf as processing inputs. It presents the importance of the current progress in bio-succinate commercialization, in addition to describing the potential use of different succinate production hosts and various pretreatments–saccharifications under development for OPF and kenaf. Evaluations on the feasibility of OPF and kenaf as fermentation substrates are also discussed.

Similar content being viewed by others

References

Ahn JH, Jang Y-S, Lee SY (2016) Production of succinic acid by metabolically engineered microorganisms. Curr Opin Biotechnol 42:54–66

Akhtar J, Idris A, Abd Aziz R (2014) Recent advances in production of succinic acid from lignocellulosic biomass. Appl Microbiol Biotechnol 98:987–1000. doi:10.1007/s00253-013-5319-6

Amirkhani H, Yunus R, Rashid U, Salleh SF, Radhiah ABD, Syam S (2015) Low-temperature dilute acid hydrolysis of oil palm frond. Chem Eng Commun 202:1235–1244. doi:10.1080/00986445.2014.918881

Andersson C, Helmerius J, Hodge D, Berglund KA, Rova U (2009) Inhibition of succinic acid production in metabolically engineered Escherichia coli by neutralizing agent, organic acids, and osmolarity. Biotechnol Prog 25:116–123. doi:10.1002/btpr.127

Ang LS, Leh CP, Lee CC (2010) Effects of alkaline pre-impregnation and pulping on Malaysia cultivated kenaf (Hibiscus cannabinus). Bioresources 5:1446–1462

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Radiat Res Appl Sci 7:163–173. doi:10.1016/j.jrras.2014.02.003

Arikawa Y, Kobayashi M, Kodaira R, Shimosaka M, Muratsubaki H, Enomoto K, Okazaki M (1999) Isolation of sake yeast strains possessing various levels of succinate- and/or malate-producing abilities by gene disruption or mutation. J Biosci Bioeng 87:333–339

Ashori A (2006) Pulp and paper from kenaf bast fibers. Fiber Polym 7:26–29. doi:10.1007/bf02933598

Ashori A, Harun J, Raverty WD, Yusoff MNM (2006) Chemical and morphological characteristics of Malaysian cultivated kenaf (Hibiscus cannabinus) fiber. Polym Plast Technol Eng 45:131–134

Atnaw SM, Sulaiman SA, Yusup S (2013) Syngas production from downdraft gasification of oil palm fronds. Energy 61:491–501. doi:10.1016/j.energy.2013.09.039

Azelee NIW, Md Jahim J, Rabu A, Abdul Murad AM, Abu Bakar FD, Md Illias R (2014) Efficient removal of lignin with the maintenance of hemicellulose from kenaf by two-stage pretreatment process. Carbohydr Polym 99:447–453. doi:10.1016/j.carbpol.2013.08.043

Azelee NIW, Jahim JM, Ismail AF, Fuzi SFZM, Rahman RA, Md Illias R (2016) High xylooligosaccharides (XOS) production from pretreated kenaf stem by enzyme mixture hydrolysis. Ind Crop Prod 81:11–19. doi:10.1016/j.indcrop.2015.11.038

Barcelos E, Rios SA, Cunha RNV, Lopes R, Motoike SY, Babiychuk E, Skirycz A, Kushnir S (2015) Oil palm natural diversity and the potential for yield improvement. Front Plant Sci 6:190. doi:10.3389/fpls.2015.00190

Beach ES, Weeks BR, Stern R, Anastas PT (2013) Plastics additives and green chemistry. Pure Appl Chem 85:1611–1624

Beauprez JJ, De Mey M, Soetaert WK (2010) Microbial succinic acid production: natural versus metabolic engineered producers. Process Biochem 45. doi:10.1016/j.procbio.2010.03.035

Bechthold I, Bretz K, Kabasci S, Kopitzky R, Springer A (2008) Succinic acid: a new platform chemical for biobased polymers from renewable resources. Chem Eng Technol 31. doi:10.1002/ceat.200800063

Becker J, Reinefeld J, Stellmacher R, Schafer R, Lange A, Meyer H, Lalk M, Zelder O, von Abendroth G, Schroder H, Haefner S, Wittmann C (2013) Systems-wide analysis and engineering of metabolic pathway fluxes in bio-succinate producing Basfia succiniciproducens. Biotechnol Bioeng 110:3013–3023. doi:10.1002/bit.24963

Bevilaqua DB, Montipó S, Pedroso GB, Martins AF (2015) Sustainable succinic acid production from rice husks. Sust Chem Pharm 1:9–13. doi:10.1016/j.scp.2015.09.001

Bhattacharya S (2002) Biomass energy and densification: a global review with emphasis on developing countries. In: Proceedings of The First World Conference on Pellets, Stockholm, September. Citeseer, pp 2–4

Biddy MJ, Scarlata C, Kinchin C (2016) Chemicals from biomass: a market assessment of bioproducts with near-term potential. NREL (National Renewable Energy Laboratory (NREL), Golden, CO (United States))

Borges ER, Pereira N (2010) Succinic acid production from sugarcane bagasse hemicellulose hydrolysate by Actinobacillus succinogenes. J Ind Microbiol Biotechnol 38:1001–1011. doi:10.1007/s10295-010-0874-7

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem 12:539–554. doi:10.1039/B922014C

Brink HG, Nicol W (2014) Succinic acid production with Actinobacillus succinogenes: rate and yield analysis of chemostat and biofilm cultures. Microb Cell Factories 13:1–12. doi:10.1186/s12934-014-0111-6

Brodeur G, Yau E, Badal K, Collier J, Ramachandran KB, Ramakrishnan S (2011) Chemical and physicochemical pretreatment of lignocellulosic biomass: a review. Enzyme Res 2011:17. doi:10.4061/2011/787532

Cavani F, Albonetti S, Basile F, Gandini AA (2016) Chemicals and fuels from bio-based building blocks. Wiley Online Library. doi:10.1002/9783527698202.fmatter

Chan S, Kanchanatawee S, Jantama K (2012) Production of succinic acid from sucrose and sugarcane molasses by metabolically engineered Escherichia coli. Bioresour Technol 103:329–336. doi:10.1016/j.biortech.2011.09.096

Chandel AK, Kapoor RK, Singh A, Kuhad RC (2007) Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM 3501. Bioresour Technol 98:1947–1950

Chassard C, Delmas E, Robert C, Lawson PA, Bernalier-Donadille A (2012) Ruminococcus champanellensis sp. nov., a cellulose-degrading bacterium from human gut microbiota. Int J Syst Evol Microbiol 62:138–143. doi:10.1099/ijs.0.027375-0

Chaturvedi V, Verma P (2013) An overview of key pretreatment processes employed for bioconversion of lignocellulosic biomass into biofuels and value added products. 3 Biotech 3:415–431. doi:10.1007/s13205-013-0167-8

Cheng KK, Wu J, Wang GY, Li WY, Feng J, Zhang JA (2013) Effects of pH and dissolved CO2 level on simultaneous production of 2,3-butanediol and succinic acid using Klebsiella pneumoniae. Bioresour Technol 135:500–503. doi:10.1016/j.biortech.2012.08.100

Choi IS, Wi SG, Kim S-B, Bae H-J (2012) Conversion of coffee residue waste into bioethanol with using popping pretreatment. Bioresour Technol 125. doi:10.1016/j.biortech.2012.08.080

Choi S, Song H, Lim SW, Kim TY, Ahn JH, Lee JW, Lee MH, Lee SY (2016) Highly selective production of succinic acid by metabolically engineered Mannheimia succiniciproducens and its efficient purification. Biotechnol Bioeng 113:2168–2177

Chong PS, Jahim JM, Harun S, Lim SS, Mutalib SA, Hassan O, Nor MTM (2013) Enhancement of batch biohydrogen production from prehydrolysate of acid treated oil palm empty fruit bunch. Int J Hydrog Energy 38:9592–9599. doi:10.1016/j.ijhydene.2013.01.154

Cok B, Tsiropoulos I, Roes AL, Patel MK (2014) Succinic acid production derived from carbohydrates: an energy and greenhouse gas assessment of a platform chemical toward a bio-based economy. Biofuels Bioprod Biorefin 8:16–29

Cuissinat C, Navard P, Heinze T (2008) Swelling and dissolution of cellulose. Part IV: free floating cotton and wood fibres in ionic liquids. Carbohydr Polym 72:590–596

Danalatos N, Archontoulis S (2004) Potential growth and biomass productivity of kenaf (Hibiscus cannabinus L.) under central Greek conditions: II. The influence of variety, sowing time and plant density. In: 2nd World Conference on Biomass for Energy, Industry and Climate Protection. pp 10–14

Danalatos NG, Archontoulis SV (2010) Growth and biomass productivity of kenaf (Hibiscus cannabinus, L.) under different agricultural inputs and management practices in central Greece. Ind Crop Prod 32:231–240. doi:10.1016/j.indcrop.2010.04.013

Duarte JC, Valença GP, Moran PJS, Rodrigues JAR (2015) Microbial production of propionic and succinic acid from sorbitol using Propionibacterium acidipropionici. AMB Express 5:13. doi:10.1186/s13568-015-0095-6

Duckart L, Byers E, Thompson N (1988) The structure of a xylan from kenaf (Hibiscus cannabinus). Cellul Chem Technol 22:29–37

Fazilah A, Mohd Azemi MN, Karim AA, Norakma MN (2009) Physicochemical properties of hydrothermally treated hemicellulose from oil palm frond. J Agric Food Chem 57:1527–1531. doi:10.1021/jf8028013

Fišerová M, Opálená E, Illa A (2013) Comparative study of hemicelluloses extraction from beech and oak wood. Wood Res 58:543–554

Galaction AI, Rotaru R, Kloetzer L, Vlysidis A, Webb C, Turnea M, Cascaval D (2011) External and internal glucose mass transfers in succinic acid fermentation with stirred bed of immobilized Actinobacillus succinogenes under substrate and product inhibitions. J Microbiol Biotechnol 21:1257–1263

Galaction A-I, Caşcaval D, Matran R-M, Tucaliuc A (2016) Production of succinic acid in basket and mobile bed bioreactors—comparative analysis of substrate mass transfer aspects. Chin J Chem Eng 24:513–520. doi:10.1016/j.cjche.2016.01.003

Gallmetzer M, Meraner J, Burgstaller W (2002) Succinate synthesis and excretion by Penicillium simplicissimum under aerobic and anaerobic conditions. FEMS Microbiol Lett 210:221–225

Goh CS, Lee KT, Bhatia S (2010a) Hot compressed water pretreatment of oil palm fronds to enhance glucose recovery for production of second generation bio-ethanol. Bioresour Technol 101:7362–7367. doi:10.1016/j.biortech.2010.04.048

Goh CS, Tan HT, Lee KT, Mohamed AR (2010b) Optimizing ethanolic hot compressed water (EHCW) cooking as a pretreatment to glucose recovery for the production of fuel ethanol from oil palm frond (OPF). Fuel Process Technol 91:1146–1151. doi:10.1016/j.fuproc.2010.03.029

Gurram RN, Menkhaus TJ (2014) Continuous enzymatic hydrolysis of lignocellulosic biomass with simultaneous detoxification and enzyme recovery. Appl Biochem Biotechnol 173:1319–1335. doi:10.1007/s12010-014-0873-7

Harmsen P, Huijgen W, Bermudez L, Bakker R (2010) Literature review of physical and chemical pretreatment processes for lignocellulosic biomass. Energy Research Centre of the Netherlands:10–13

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315. doi:10.1126/science.1137016

Hina S, Zhang Y, Wang H (2015) Role of ionic liquids in dissolution and regeneration of cellulose. Rev Adv Mater Sci 40:215–226

Hong LS, Ibrahim D, Omar IC (2012) Oil palm frond for the production of bioethanol. Int J Biochem Biotechnol 1:7–11

Hong SH, Kim JS, Lee SY, In YH, Choi SS, Rih JK, Kim CH, Jeong H, Hur CG, Kim JJ (2004) The genome sequence of the capnophilic rumen bacterium Mannheimia succiniciproducens. Nat Biotechnol 22. doi:10.1038/nbt1010

Hong L, Ibrahim D, Omar I (2008) Microscopic studies of oil palm frond during processing for saccharification. Int J Bioeng 4:7–11

Horwitz W, Chichilo P, Reynolds H (1970) Official methods of analysis of the Association of Official Analytical Chemists. Washington, DC, USA

Isar J, Agarwal L, Saran S, Saxena RK (2006) Succinic acid production from Bacteroides fragilis: process optimization and scale up in a bioreactor. Anaerobe 12:231–237. doi:10.1016/j.anaerobe.2006.07.001

Isar J, Agarwal L, Saran S, Kaushik R, Saxena RK (2007) A statistical approach to study the interactive effects of process parameters on succinic acid production from Bacteroides fragilis. Anaerobe 13:50–56. doi:10.1016/j.anaerobe.2006.12.002

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6:4497–4559

Jiang G, Huang W, Zhu T, Zhang C, Kumi AK, Zhang Y, Wang H, Hu L (2011) Diffusion dynamics of 1-Butyl-3-methylimidazolium chloride from cellulose filament during coagulation process. Cellulose 18:921–928

Jiang M, Xu R, Xi YL, Zhang JH, Dai WY, Wan YJ, Chen KQ, Wei P (2013) Succinic acid production from cellobiose by Actinobacillus succinogenes. Bioresour Technol 135:469–474. doi:10.1016/j.biortech.2012.10.019

Jiang M, Dai W, Xi Y, Wu M, Kong X, Ma J, Zhang M, Chen K, Wei P (2014) Succinic acid production from sucrose by Actinobacillus succinogenes NJ113. Bioresour Technol 153:327–332. doi:10.1016/j.biortech.2013.11.062

Johar N, Ahmad I, Dufresne A (2012) Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crop Prod 37:93–99. doi:10.1016/j.indcrop.2011.12.016

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112. doi:10.1016/j.biortech.2015.10.009

Jørgensen H, Kristensen JB, Felby C (2007) Enzymatic conversion of lignocellulose into fermentable sugars: challenges and opportunities. Biofuels Bioprod Biorefin 1:119–134. doi:10.1002/bbb.4

Jung YH, Kim S, Yang TH, Lee HJ, Seung D, Park YC, Seo JH, Choi IG, Kim KH (2012) Aqueous ammonia pretreatment, saccharification, and fermentation evaluation of oil palm fronds for ethanol production. Bioprocess Biosyst Eng 35:1497–1503. doi:10.1007/s00449-012-0739-8

Jusoh N, Othman N, Idris A, Nasruddin A (2014) Characterization of liquid pineapple waste as carbon source for production of succinic acid. Jurnal Teknologi 69

Kamireddy SR, Degenstein J, Berti M, Ji Y (2013) Pretreatment and enzymatic hydrolysis of kenaf as a potential source for lignocellulosic biofuel and green chemicals. Curr Org Chem 17:1624–1632

Kamireddy SR, Kozliak EI, Tucker M, Ji Y (2014) Kinetic features of xylan de-polymerization in production of xylose monomer and furfural during acid pretreatment for kenaf, forage sorghums and sunn hemp feedstocks. Int J Agric Biol Eng 7:86

Khalil HA, Rozman H, Ahmad M, Ismail H (2000) Acetylated plant-fiber-reinforced polyester composites: a study of mechanical, hygrothermal, and aging characteristics. Polym Plast Technol Eng 39:757–781

Khalil HPSA, Yusra AFI, Bhat AH, Jawaid M (2010) Cell wall ultrastructure, anatomy, lignin distribution, and chemical composition of Malaysian cultivated kenaf fiber. Ind Crop Prod 31:113–121. doi:10.1016/j.indcrop.2009.09.008

Khalil HPSA, Mohamad J, Mohd H, Zaidon A (2012) Oil palm biomass fibres and recent advancement in oil palm biomass fibres based hybrid biocomposites. In: Composites and Their Applications. InTech, Croatia, pp 187–220. doi:10.5772/48235

Khristova P, Karar I (1999) Soda-anthraquinone pulp from three Acacia nilotica subspecies. Bioresour Technol 68:209–213. doi:10.1016/S0960-8524(98)00161-8

Kim DY, Yim SC, Lee PC, Lee WG, Lee SY, Chang HN (2004a) Batch and continuous fermentation of succinic acid from wood hydrolysate by Mannheimia succiniciproducens MBEL55E. Enzym Microb Technol 35:648–653

Kim P, Laivenieks M, Vieille C, Gregory Zeikus J (2004b) Effect of overexpression of Actinobacillus succinogenes phosphoenolpyruvate carboxykinase on succinate production in Escherichia coli. Appl Environ Microbiol 70:1238–1241. doi:10.1128/AEM.70.2.1238-1241.2004

Kim Y, Kreke T, Hendrickson R, Parenti J, Ladisch MR (2013) Fractionation of cellulase and fermentation inhibitors from steam pretreated mixed hardwood. Bioresour Technol 135:30–38. doi:10.1016/j.biortech.2012.10.130

Koch-Koerfges A, Pfelzer N, Platzen L, Oldiges M, Bott M (2013) Conversion of Corynebacterium glutamicum from an aerobic respiring to an aerobic fermenting bacterium by inactivation of the respiratory chain. Biochimica et Biophysica Acta (BBA) - Bioenergetics 1827:699–708. doi:10.1016/j.bbabio.2013.02.004

Kont R, Kurašin M, Teugjas H, Väljamäe P (2013) Strong cellulase inhibitors from the hydrothermal pretreatment of wheat straw. Biotechnol Biofuels 6:1–14. doi:10.1186/1754-6834-6-135

Kristensen JB, Felby C, Jørgensen H (2009) Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol Biofuels 2. doi:10.1186/1754-6834-2-11

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729. doi:10.1021/ie801542g

Lee PC, Lee SY, Hong SH, Chang HN (2002) Isolation and characterization of a new succinic acid-producing bacterium, Mannheimia succiniciproducens MBEL55E, from bovine rumen. Appl Microbiol Biotechnol 58:663–668. doi:10.1007/s00253-002-0935-6

Lee PC, Lee SY, Hong SH, Chang HN (2003a) Batch and continuous cultures of Mannheimia succiniciproducens MBEL55E for the production of succinic acid from whey and corn steep liquor. Bioprocess Biosyst Eng 26:63–67. doi:10.1007/s00449-003-0341-1

Lee PC, Lee SY, Hong SH, Chang HN, Park SC (2003b) Biological conversion of wood hydrolysate to succinic acid by Anaerobiospirillum succiniciproducens. Biotechnol Lett 25:111–114. doi:10.1023/a:1021907116361

Lee H, Hamid S, Zain S (2014) Conversion of lignocellulosic biomass to nanocellulose: structure and chemical process. Scientific World J 2014

Lee JW, Yi J, Kim TY, Choi S, Ahn JH, Song H, Lee M-H, Lee SY (2016) Homo-succinic acid production by metabolically engineered Mannheimia succiniciproducens. Metab Eng 38:409–417

Lips SJ, van Dam JE (2013) Kenaf fibre crop for bioeconomic industrial development. Kenaf: a multi-purpose crop for several industrial applications. Springer. doi:10.1007/978-1-4471-5067-1_6

Liu R, Liang L, Li F, Wu M, Chen K, Ma J, Jiang M, Wei P, Ouyang P (2013) Efficient succinic acid production from lignocellulosic biomass by simultaneous utilization of glucose and xylose in engineered Escherichia coli. Bioresour Technol 149:84–91. doi:10.1016/j.biortech.2013.09.052

Londono AO (2010) Separation of succinic acid from fermentation broths and esterification by a reactive distillation method. Michigan State University, East Lansing

Loow YL, Wu TY, Jahim JM, Mohammad AW, Teoh WH (2016) Typical conversion of lignocellulosic biomass into reducing sugars using dilute acid hydrolysis and alkaline pretreatment. Cellulose 23:1491–1520

Loyarkat S, Cheirsilp B, Prasertsan P (2015) Two-stage repeated-batch fermentation of immobilized Clostridium beijerinckii on oil palm fronds for solvents production. Process Biochem 50:1167–1176. doi:10.1016/j.procbio.2015.04.016

Luthfi AAI, Jahim JM, Harun S, Tan JP, Mohammad AW (2016) Biorefinery approach towards greener succinic acid production from oil palm frond bagasse. Process Biochem 51:1527–1537. doi:10.1016/j.procbio.2016.08.011

Magnuson JK, Lasure LL (2004) Organic acid production by filamentous fungi. In: Tkacz JS, Lange L (eds) Advances in Fungal Biotechnology for Industry, Agriculture, and Medicine. Springer US, Boston, MA, pp 307–340. doi:10.1007/978-1-4419-8859-1_12

Maharaj K, Bradfield MFA, Nicol W (2014) Succinic acid-producing biofilms of Actinobacillus succinogenes: reproducibility, stability and productivity. Appl Microbiol Biotechnol 98:7379–7386. doi:10.1007/s00253-014-5779-3

Mammoli A, Brebbia C (2009) Energy and sustainability II vol 121. WIT Press, Southampton

Marketsandmarkets.com (2016) Succinic acid market worth 701.0 Million USD by 2021. The Free Library. http://www.thefreelibrary.com/Succinic+Acid+Market+Worth+701.0+Million+USD+by+2021.-a0457306294. Accessed 23 Sept 2016

McAloon A, Taylor F, Yee W, Ibsen K, Wooley R (2000) Determining the cost of producing ethanol from corn starch and lignocellulosic feedstocks. NREL/TP-580-28893. National Renewable Energy Laboratory, Golden, CO (USA)

McKinlay JB, Vieille C (2008) 13C-metabolic flux analysis of Actinobacillus succinogenes fermentative metabolism at different NaHCO3 and H2 concentrations. Metab Engin 10. doi:10.1016/j.ymben.2007.08.004

McKinlay JB, Zeikus JG, Vieille C (2005) Insights into Actinobacillus succinogenes fermentative metabolism in a chemically defined growth medium. Appl Environ Microbiol 71. doi:10.1128/aem.71.11.6651-6656.2005

McKinlay JB, Laivenieks M, Schindler BD, McKinlay AA, Siddaramappa S, Challacombe JF, Lowry SR, Clum A, Lapidus AL, Burkhart KB, Harkins V, Vieille C (2010) A genomic perspective on the potential of Actinobacillus succinogenes for industrial succinate production. BMC Genomics 11:1–16. doi:10.1186/1471-2164-11-680

Meijer S, Otero J, Olivares R, Andersen MR, Olsson L, Nielsen J (2009) Overexpression of isocitrate lyase—glyoxylate bypass influence on metabolism in Aspergillus niger. Metab Eng 11:107–116. doi:10.1016/j.ymben.2008.12.002

Meynial-Salles I, Dorotyn S, Soucaille P (2008) A new process for the continuous production of succinic acid from glucose at high yield, titer, and productivity. Biotechnol Bioeng 99:129–135. doi:10.1002/bit.21521

Moon SK, Wee YJ, Yun JS, Ryu HW (2004) Production of fumaric acid using rice bran and subsequent conversion to succinic acid through a two-step process. Appl Biochem Biotechnol 113-116:843–855

Morales M, Ataman M, Badr S, Linster S, Kourlimpinis I, Papadokonstantakis S, Hatzimanikatis V, Hungerbuhler K (2016) Sustainability assessment of succinic acid production technologies from biomass using metabolic engineering. Energy Environ Sci 9:2794–2805. doi:10.1039/C6EE00634E

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686. doi:10.1016/j.biortech.2004.06.025

Moulthrop JS, Swatloski RP, Moyna G, Rogers RD (2005) High-resolution 13C NMR studies of cellulose and cellulose oligomers in ionic liquid solutions. Chem Commun:1557–1559

Mun LK (2015) Potential for waste-to-energy in Malaysia. In: Bioenergy Symposium & Business Matching, Sarawak, Malaysia

Muzumdar AV, Sawant SB, Pangarkar VG (2004) Reduction of maleic acid to succinic acid on titanium cathode. Org Process Res Dev 8:685–688. doi:10.1021/op0300185

Ng SH, Tahir PM, Mohamad R, Abdullah LC, Choo ACY, Liong YY (2013) Effect of pretreatment process on bioconversion of kenaf (Hibiscus cannabinus L.) core to glucose vol 8. 2013, vol 2.

Ninomiya K, Kamide K, Takahashi K, Shimizu N (2012) Enhanced enzymatic saccharification of kenaf powder after ultrasonic pretreatment in ionic liquids at room temperature. Bioresour Technol 103:259–265. doi:10.1016/j.biortech.2011.10.019

Nur AMN, Anuar H, Nurhafizah SM, Zakaria S (2015) Effects of dilute acid pretreatment on chemical and physical properties of kenaf biomass. J Nat Fib 12:256–264. doi:10.1080/15440478.2014.919894

Ofori-Boateng C, Lee KT (2013) Sustainable utilization of oil palm wastes for bioactive phytochemicals for the benefit of the oil palm and nutraceutical industries. Phytochem Rev 12:173–190. doi:10.1007/s11101-013-9270-z

Ofori-Boateng C, Lee KT, Saad B (2014) A biorefinery concept for simultaneous recovery of cellulosic ethanol and phenolic compounds from oil palm fronds: process optimization. Energy Convers Manag 81:192–200. doi:10.1016/j.enconman.2014.02.030

Ohtani Y, Mazumder BB, Sameshima K (2001) Influence of the chemical composition of kenaf bast and core on the alkaline pulping response. J Wood Sci 47:30–35. doi:10.1007/bf00776642

Okino S, Noburyu R, Suda M, Jojima T, Inui M, Yukawa H (2008) An efficient succinic acid production process in a metabolically engineered Corynebacterium glutamicum strain. Appl Microbiol Biotechnol 81:459–464. doi:10.1007/s00253-008-1668-y

Pandey A, Negi S, Binod P, Larroche C (2014) Pretreatment of biomass: processes and technologies. Elsevier Science, Amsterdam

Pardo MES, Cassellis MER, Escobedo RM, García EJ (2014) Chemical characterisation of the industrial residues of the pineapple (Ananas comosus). J Agric Chem Environ 3:53

Pasma SA, Daik R, Maskat MY (2013) Production of succinic acid from oil palm empty fruit bunch cellulose using Actinobacillus succinogenes. AIP Conf Proc 1571:753–759. doi:10.1063/1.4858745

Phalan B, Green R, Balmford A (2014) Closing yield gaps: perils and possibilities for biodiversity conservation. Philos T Roy Soc B 369. doi:10.1098/rstb.2012.0285

Pienaar C, Kruger AJ, Venter EC, Pitout JDD (2003) Anaerobiospirillum succiniciproducens bacteraemia. J Clin Pathol 56:316–318

Pu Y, Hu F, Huang F, Davison BH, Ragauskas AJ (2013) Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol Biofuels 6:15. doi:10.1186/1754-6834-6-15

Pv VS, Robertson J, Lewis B (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Qing Q, Yang B, Wyman CE (2010) Xylooligomers are strong inhibitors of cellulose hydrolysis by enzymes. Bioresour Technol 101. doi:10.1016/j.biortech.2010.06.137

Raab AM, Gebhardt G, Bolotina N, Weuster-Botz D, Lang C (2010) Metabolic engineering of Saccharomyces cerevisiae for the biotechnological production of succinic acid. Metab Eng 12:518–525. doi:10.1016/j.ymben.2010.08.005

Rahnama N, Foo HL, Abdul Rahman NA, Ariff A, Md Shah UK (2014) Saccharification of rice straw by cellulase from a local Trichoderma harzianum SNRS3 for biobutanol production. BMC Biotechnol 14:103. doi:10.1186/s12896-014-0103-y

Reeb CW, Venditti R, Gonzalez R, Kelley S (2016) Environmental LCA and financial analysis to evaluate the feasibility of bio-based sugar feedstock biomass supply globally: Part 2. Application of multi-criteria decision-making analysis as a method for biomass feedstock comparisons vol 11. 2016, vol 3.

Rowell RM, Han JS, Rowell JS (2000) Characterization and factors effecting fiber properties. Natural polymers and agrofibers based composites:115–134

Ryu HW, Wee YJ (2001) Characterization of bioconversion of fumarate to succinate by alginate immobilized Enterococcus faecalis RKY1. Appl Biochem Biotechnol 91-93:525–535

Saba N, Jawaid M, Hakeem KR, Paridah MT, Khalina A, Alothman OY (2015) Potential of bioenergy production from industrial kenaf (Hibiscus cannabinus L.) based on Malaysian perspective. Renew Sust Energ Rev 42:446–459. doi:10.1016/j.rser.2014.10.029

Sabiha-Hanim S, Noor MAM, Rosma A (2011) Effect of autohydrolysis and enzymatic treatment on oil palm (Elaeis guineensis Jacq.) frond fibres for xylose and xylooligosaccharides production. Bioresour Technol 102:1234–1239. doi:10.1016/j.biortech.2010.08.017

Sabiha-Hanim S, Norazlina I, Noraishah A, Suhaila MHN (2012) Reducing sugar production from oil palm fronds and rice straw by acid hydrolysis. In: 2012 I.E. Colloquium on Humanities, Science and Engineering (CHUSER), 3–4 Dec. 2012 . pp 642–645. doi:10.1109/CHUSER.2012.6504391

Saleh SH, Shah SNMD, Khalil KA, Bujang A (2016) Xylooligosaccharides production from oil palm frond by Trichoderma longibrachiatum xylanase. Mal J Anal Sci 20:525–530

Salvachúa D, Smith H, St. John PC, Mohagheghi A, Peterson DJ, Black BA, Dowe N, Beckham GT (2016) Succinic acid production from lignocellulosic hydrolysate by Basfia succiniciproducens. Bioresour Technol 214:558–566. doi:10.1016/j.biortech.2016.05.018

Samuelov NS, Datta R, Jain MK, Zeikus JG (1999) Whey fermentation by Anaerobiospirillum succiniciproducens for production of a succinate-based animal feed additive. Appl Environ Microbiol 65:2260–2263

Sandstrom AG, Almqvist H, Portugal-Nunes D, Neves D, Liden G, Gorwa-Grauslund MF (2014) Saccharomyces cerevisiae: a potential host for carboxylic acid production from lignocellulosic feedstock? Appl Microbiol Biotechnol 98:7299–7318. doi:10.1007/s00253-014-5866-5

Scholten E, Renz T, Thomas J (2009) Continuous cultivation approach for fermentative succinic acid production from crude glycerol by Basfia succiniciproducens DD1. Biotechnol Lett 31:1947–1951. doi:10.1007/s10529-009-0104-4

Shaikh Z, Qureshi P (2013) Screening and isolation of organic acid producers from samples of diverse habitats. Int J Curr Microbiol Appl Sci 2:39–44

Silva ASAd, Teixeira RSS, Moutta RdO, Ferreira-Leitão VS, Barros RdROd, Ferrara MA, Bon EPdS (2013) Sugarcane and woody biomass pretreatments for ethanol production. Sustainable degradation of lignocellulosic biomass—techniques, applications and commercialization. doi:44366

Singh S, Simmons BA (2013) Ionic liquid pretreatment: mechanism, performance, and challenges. Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals:223–238

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. NREL Laboratory Analytical Procedures (LAP), National Renewable Energy Laboratory, Golden, CO, USA

Song H, Lee SY (2006) Production of succinic acid by bacterial fermentation. Enzym Microb Technol 39:352–361. doi:10.1016/j.enzmictec.2005.11.043

Song H, Lee JW, Choi S, You JK, Hong WH, Lee SY (2007) Effects of dissolved CO2 levels on the growth of Mannheimia succiniciproducens and succinic acid production. Biotechnol Bioeng 98. doi:10.1002/bit.21530

Standard T (1999) Method T222 om-88. TAPPI test methods

Sukri SSM, Rahman RA, Md Illias R, Yaakob H (2014) Optimization of alkaline pretreatment conditions of oil palm fronds in improving the lignocelluloses contents for reducing sugar production. Rom Biotechnol Lett 19:9006–9018

Sultana A, Kumar A (2012) Ranking of biomass pellets by integration of economic, environmental and technical factors. Biomass Bioenergy 39:344–355. doi:10.1016/j.biombioe.2012.01.027

Tan HT, Lee KT, Mohamed AR (2011) Pretreatment of lignocellulosic palm biomass using a solvent-ionic liquid [BMIM]Cl for glucose recovery: an optimisation study using response surface methodology. Carbohydr Polym 83:1862–1868. doi:10.1016/j.carbpol.2010.10.052

Tan JP, Jahim JM, Wu TY, Harun S, Kim BH, Mohammad AW (2014) Insight into biomass as a renewable carbon source for the production of succinic acid and the factors affecting the metabolic flux toward higher succinate yield. Ind Eng Chem Res 53:16123–16134. doi:10.1021/ie502178j

Tan JP, Jahim JM, Harun S, Wu TY, Mumtaz T (2016) Utilization of oil palm fronds as a sustainable carbon source in biorefineries. Int J Hydrog Energy 41:4896–4906. doi:10.1016/j.ijhydene.2015.08.034

Thakker C, Bhosale S, Ranade D (2006a) Formation of succinic acid by Klebsiella pneumoniae MCM B-325 under aerobic and anaerobic conditions. J Microbiol Biotechnol 16:870–879

Thakker C, Burhanpurwala Z, Rastogi G, Shouche Y, Ranade D (2006b) Isolation and characterization of a new osmotolerant, non-virulent Klebsiella pneumoniae strain SAP for biosynthesis of succinic acid. Indian J Exp Biol 44:142–150

Vemuri GN, Eiteman MA, Altman E (2002) Succinate production in dual-phase Escherichia coli fermentations depends on the time of transition from aerobic to anaerobic conditions. J Ind Microbiol Biotechnol 28:325–332. doi:10.1038/sj/jim/7000250

Werpy T, Petersen G (2004) Top value added chemicals from biomass Volume 1—results of screening for potential candidates from sugars and synthesis gas

Wi SG, Chung BY, Lee YG, Yang DJ, Bae H-J (2011) Enhanced enzymatic hydrolysis of rapeseed straw by popping pretreatment for bioethanol production. Bioresour Technol 102:5788–5793

Wi SG, Choi IS, Kim KH, Kim HM, Bae H-J (2013) Bioethanol production from rice straw by popping pretreatment. Biotechnol Biofuels 6:1–7. doi:10.1186/1754-6834-6-166

Wi SG, Kim S-B, Lee D-S, Kim HM, Bae H-J (2015) A comparative study on enzymatic hydrolysis of kenaf from two different harvest time-points, with- and without pretreatment. Ind Crop Prod 76:237–243. doi:10.1016/j.indcrop.2015.06.054

Wolfrum EJ, Lorenz AJ, deLeon N (2009) Correlating detergent fiber analysis and dietary fiber analysis data for corn stover collected by NIRS. Cellulose 16:577–585. doi:10.1007/s10570-009-9318-9

Yamauchi Y, Hirasawa T, Nishii M, Furusawa C, Shimizu H (2014) Enhanced acetic acid and succinic acid production under microaerobic conditions by Corynebacterium glutamicum harboring Escherichia coli transhydrogenase gene pntAB. J Gen Appl Microbiol 60:112–118

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod Biorefin 2:26–40. doi:10.1002/bbb.49

Yang S-T, El-Ensashy H, Thongchul N (2013) Bioprocessing technologies in biorefinery for sustainable production of fuels, chemicals, and polymers. John Wiley & Sons, Hoboken

Yang L, Lübeck M, Lübeck PS (2015) Effects of heterologous expression of phosphoenolpyruvate carboxykinase and phosphoenolpyruvate carboxylase on organic acid production in Aspergillus carbonarius. J Ind Microbiol Biotechnol 42:1533–1545. doi:10.1007/s10295-015-1688-4

Yang L, Lubeck M, Ahring BK, Lubeck PS (2016) Enhanced succinic acid production in Aspergillus saccharolyticus by heterologous expression of fumarate reductase from Trypanosoma brucei. Appl Microbiol Biotechnol 100:1799–1809. doi:10.1007/s00253-015-7086-z

Yasin NHM, Fukuzaki M, Maeda T, Miyazaki T, Hakiman Che Maail CM, Ariffin H, Wood TK (2013) Biohydrogen production from oil palm frond juice and sewage sludge by a metabolically engineered Escherichia coli strain. Int J Hydrog Energy 38:10277–10283. doi:10.1016/j.ijhydene.2013.06.065

Ying TY, Teong LK, Abdullah WNW, Peng LC (2014) The effect of various pretreatment methods on oil palm empty fruit bunch (EFB) and kenaf core fibers for sugar production. Procedia Environ Sci 20:328–335. doi:10.1016/j.proenv.2014.03.041

Y-l X, Dai W-y XR, J-h Z, K-q C, Jiang M, Wei P, P-k O (2013) Ultrasonic pretreatment and acid hydrolysis of sugarcane bagasse for succinic acid production using Actinobacillus succinogenes. Bioprocess Biosyst Eng 36:1779–1785. doi:10.1007/s00449-013-0953-z

Zahari MA, Zakaria MR, Ariffin H, Mokhtar MN, Salihon J, Shirai Y, Hassan MA (2012) Renewable sugars from oil palm frond juice as an alternative novel fermentation feedstock for value-added products. Bioresour Technol 110:566–571. doi:10.1016/j.biortech.2012.01.119

Zahari MAKM, Abdullah SSS, Roslan AM, Ariffin H, Shirai Y, Hassan MA (2014) Efficient utilization of oil palm frond for bio-based products and biorefinery. J Clean Prod 65:252–260. doi:10.1016/j.jclepro.2013.10.007

Zahari MAKM, Ariffin H, Mokhtar MN, Salihon J, Shirai Y, Hassan MA (2015) Case study for a palm biomass biorefinery utilizing renewable non-food sugars from oil palm frond for the production of poly(3-hydroxybutyrate) bioplastic. J Clean Prod 87:284–290. doi:10.1016/j.jclepro.2014.10.010

Zakaria MR, Fujimoto S, Hirata S, Hassan MA (2014) Ball milling pretreatment of oil palm biomass for enhancing enzymatic hydrolysis. Appl Biochem Biotechnol 173:1778–1789. doi:10.1007/s12010-014-0964-5

Zakaria MR, Hirata S, Fujimoto S, Hassan MA (2015a) Combined pretreatment with hot compressed water and wet disk milling opened up oil palm biomass structure resulting in enhanced enzymatic digestibility. Bioresour Technol 193:128–134. doi:10.1016/j.biortech.2015.06.074

Zakaria MR, Hirata S, Hassan MA (2015b) Hydrothermal pretreatment enhanced enzymatic hydrolysis and glucose production from oil palm biomass. Bioresour Technol 176:142–148. doi:10.1016/j.biortech.2014.11.027

Zhang T (2003) Improvement of kenaf yarn for apparel applications. Faculty of the Louisiana State University and Agricultural and Mechanical College in partial fulfillment of the requirements for the degree of Master of Science in The School of Human Ecology by Ting Zhang BS, Beijing University of Chemical Technology

Zhao X, Cheng K, Liu D (2009) Organosolv pretreatment of lignocellosic biomass for enzymatic hydrolysis. Appl Microbial Biotechnol 82. doi:10.1007/s00253-009-1883-1

Zheng P, Dong JJ, Sun ZH, Ni Y, Fang L (2009) Fermentative production of succinic acid from straw hydrolysate by Actinobacillus succinogenes. Bioresour Technol 100:2425–2429. doi:10.1016/j.biortech.2008.11.043

Zheng P, Fang L, Xu Y, Dong JJ, Ni Y, Sun ZH (2010) Succinic acid production from corn stover by simultaneous saccharification and fermentation using Actinobacillus succinogenes. Bioresour Technol 101:7889–7894. doi:10.1016/j.biortech.2010.05.016

Zhou Z, Wang C, Chen Y, Zhang K, Xu H, Cai H, Chen Z (2015) Increasing available NADH supply during succinic acid production by Corynebacterium glutamicum. Biotechnol Prog 31:12–19. doi:10.1002/btpr.1998

Acknowledgments

The authors wish to thank the Ministry of Higher Education, Malaysia for financial support of this work through the grant provided under Long term Research Grant Scheme (LRGS 2013). This research is funded by the Ministry of Higher Education, Malaysia under LRGS/2013/UKM-UKM/PT/01 on a project entitled “Biochemical Platform for Conversion of Diversified Lignocellulosic Biomass to Priceless Precursor and Biobased Fine Chemicals.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain any studies with human participants or animals performed by any of the authors. All authors confirm that ethical principles have been followed in manuscript preparation and approved this submission.

Funding sources

This research was funded by the Ministry of Higher Education, Malaysia [LRGS/2013/UKM-UKM/PT/01] on the project entitled “Biochemical Platform for Conversion of Diversified Lignocellulosic Biomass to Priceless Precursor and Biobased Fine Chemicals.”

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Luthfi, A.A.I., Manaf, S.F.A., Illias, R.M. et al. Biotechnological route for sustainable succinate production utilizing oil palm frond and kenaf as potential carbon sources. Appl Microbiol Biotechnol 101, 3055–3075 (2017). https://doi.org/10.1007/s00253-017-8210-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8210-z