Abstract

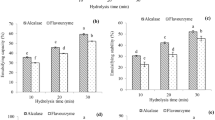

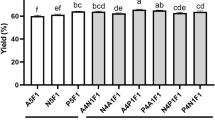

The aim of this study was to compare the sensory and antigenic properties of enzymatic wheat gluten hydrolysates produced with Flavourzyme and glutaminase in batch and continuous process, respectively. The hydrolysate samples were obtained by a standard batch process with microfiltration (16 µm) and ultrafiltration (10 kDa) and an optimized continuous enzyme membrane reactor (EMR) process with an ultrafiltration membrane (10 kDa). Two drying methods were applied: oven and freeze drying. Sensory evaluation showed that the EMR hydrolysates were significantly different and had an improved taste impact for the attributes “overall intensity,” “salty,” “umami” and “mushroom.” The antigenic potential of the EMR hydrolysates was reduced (222 ± 4 ppm gliadin) compared to batch microfiltered hydrolysate (9030 ± 89 ppm) and batch ultrafiltered hydrolysate (843 ± 49 ppm). The superior quality of wheat gluten hydrolysate from the EMR process compared to batch process was proven since sensory properties of wheat gluten hydrolysate were improved and the antigenic potential was reduced.

Similar content being viewed by others

Abbreviations

- AN:

-

Amino nitrogen

- CSTR:

-

Continuously stirred reactor

- EMR:

-

Enzyme membrane reactor

- FAA:

-

Free amino groups

- GTU:

-

Glutamine transforming units

- p-NA:

-

para-Nitroaniline

- MF:

-

Microfiltration

- PPM:

-

Parts per million

- TN:

-

Total nitrogen

- UF:

-

Ultrafiltration

References

Schlichterle-Cerny HAR, Amado R (2002) Analysis of taste-active compounds in an enzymatic hydrolysate of deamidated wheat gluten. J Agric Food Chem 50:1515–1522

Li-Chan ECY, Cheung IWY (2010) In: Mine Y, Li-Chan E, Jiang B (eds) Bioactive proteins and peptides as functional foods and nutraceuticals. Wiley, Oxford

Aaslyng MD, Poll L, Nielsen PM, Flyge H (1999) Sensory, chemical, and sensometric studies of hydrolyzed vegetable protein produced by various processes. Eur Food Res Technol 209:227–236

van den Oord AHA, van Wassenaar PD (1997) Umami peptides. Assessment of their alleged taste properties. Z Lebensm Unters For 205:125–130

Park J-N, Ishida K, Watanabe T, Endoh K-I, Watanabe K, Murakami M, Abe H (2002) Taste effects of oligopeptides in a Vietnamese fish sauce. Fisheries Sci 68:921–928

Beksan E, Schieberle P, Robert F, Blank I, Fay LB, Schlichtherle-Cerny H, Hofmann T (2003) Synthesis and sensory characterization of novel umami-tasting glutamate glycoconjugates. J Agric Food Chem 51:5428–5436

M’Hir S, Rizzello CG, Di Cagno R, Cassone A, Hamdi M (2009) Use of selected enterococci and Rhizopus oryzae proteases to hydrolyse wheat proteins responsible for celiac disease. J Appl Microbiol 106:421–431

Cabrera-Chavez F, Calderon de la Barca AM (2010) Trends in wheat technology and modification of gluten proteins for dietary treatment of coeliac disease patients. J Cereal Sci 52:337–341

Merz M, Kettner L, Langolf E, Appel D, Blank I, Stressler T, Fischer L (2015) Production of wheat gluten hydrolysates with reduced antigenicity employing enzymatic hydrolysis combined with downstream unit operations. J Sci Food Agric 96:3358–3364

Caputo I, Lepretti M, Martucciello S, Esposito C (2010) Enzymatic strategies to detoxify gluten: implications for celiac disease. Enzyme Res 2010:174354

Kammoun R, Bejar S, Ellouz R (2003) Protein size distribution and inhibitory effect of wheat hydrolysates on Neutrase. Bioresource Technol 90:249–254

Grimrath A, Berends P, Rabe S, Berger RG, Linke D (2011) Koji fermentation based on extracellular peptidases of Flammulina velutipes. Eur Food Res Technol 232:415–424

Berends P, Appel D, Eisele T, Rabe S, Fischer L (2014) Performance of the enzymatic wheat gluten hydrolysis in batch and continuous processes using Flavourzyme. LWT-Food Sci Technol 58:534–540

Merz M, Ewert J, Baur C, Appel D, Blank I, Stressler T, Fischer L (2015) Wheat gluten hydrolysis using isolated Flavourzyme peptidases: product inhibition and determination of synergistic effects using response surface methodology. J Mol Catal B-Enzym 122:218–226

Giorno L, Drioli E (2000) Biocatalytic membrane reactors: applications and perspectives. Trends Biotechnol 18:339–349

Eisele T, Stressler T, Kranz B, Fischer L (2013) Bioactive peptides generated in an enzyme membrane reactor using Bacillus lentus alkaline peptidase. Eur Food Res Technol 236:483–490

Merz M, Eisele T, Claaßen W, Appel D, Rabe S, Stressler T, Fischer L (2015) Continuous long-term hydrolysis of wheat gluten using a principally food-grade enzyme membrane reactor system. Biochem Eng J 27:114–123

Berends P, Merz M, Kranz B, Thaler T, Appel D, Rabe S, Blank I, Stressler T, Fischer L (2016) Optimization of an enzymatic wheat gluten hydrolysis process in an enzyme membrane reactor using a design of experiment approach. Eur Food Res Technol. doi:10.1007/s00217-016-2673-5

Anjani K, Kailasapathy K, Phillips M (2007) Microencapsulation of enzymes for potential application in acceleration of cheese ripening. Int Dairy J 17:79–86

Novozymes (2001) Product Sheet Flavourzyme

Kheadr EE, Vuillemard JC, El-Deeb SA (2003) Impact of liposome-encapsulated enzyme cocktails on cheddar cheese ripening. Food Res Int 36:241–252

Eisele T, Stressler T, Kranz B, Fischer L (2013) Bioactive peptides generated in an enzyme membrane reactor using Bacillus lentus alkaline peptidase. Eur Food Res Technol 236:483–490

Matissek R, Steiner G, Fischer M (2014) Lebensmittelanalytik. Springer, Heidelberg

Eidgenossenschaft S (2007) Aminosäurestickstoff in Fleischextrakt. Sulze, Würze

Waters (2012) Acquity UPLC H-Class and H-Class bio amino acid analysis system guide. Waters, Milford

Olsen JV, de Godoy LMF, Li G, Macek B, Mortensen P, Pesch R, Makarov A, Lange O, Horning S, Mann M (2005) Parts per million mass accuracy on an orbitrap mass spectrometer via lock mass injection into a C-trap. Mol Cell Proteomics 4:2010–2021

Seki T, Kawasaki Y, Tamura M, Tada M, Okai H (1990) Further study on the salty peptide, ornithyl-β-alanine. Some effects of pH and additive ions on the saltiness. J Agric Food Chem 38:25–29

Minkiewicz P, Dziuba J, Iwaniak A, Dziuba M, Darewicz M (2008) BIOPEP database and other programs for processing bioactive peptide sequences. J AOAC Int 91:965–980

Clemente A (2001) Enzymatic protein hydrolysates in human nutrition. Trends Food Sci Tech 11:254–262

Oita S, Hayashi T, Ohnishi-Kameyama M (2009) Degradation of epitope peptides of wheat gliadin and glutenin for atopic dermatitis by crude proteases from germinated wheat seeds. Food Sci Technol Res 15:639–644

Kahlenberg F, Sanchez D, Lachmann I, Tuckova L, Tlaskalova H, Mendez E, Mothes T (2006) Monoclonal antibody R5 for detection of putatively coeliac-toxic gliadin peptides. Eur Food Res Technol 222:78–82

Valdes I, Garcia E, Llorente M, Mendez E (2003) Innovative approach to low-level gluten determination in foods using a novel sandwich enzyme-linked immunosorbent assay protocol. Eur J Gastroenterol Hepatol 15:465–474

Businco L, Dreborg S, Einarsson R, Giampietro PG, Host A, Keller KM, Strobel S, Wahn U, Bjorksten B, Kjellman MN et al (1993) Hydrolysed cow’s milk formulae. Allergenicity and use in treatment and prevention. An ESPACI position paper. European Society of Pediatric Allergy and Clinical Immunology. Pediatr Allergy Immunol 4:101–111

Hoffman KM, Sampson HA (1997) Serum specific-IgE antibodies to peptides detected in a casein hydrolysate formula. Pediatr Allergy Immunol 8:185–189

Laurie GW, Ciclitira PJ, Ellis HJ, Pogany G (1995) Immunological and partial sequence identity of mouse BM180 with wheat α-gliadin. Biochem Bioph Res Co 217:10–15

Sissons MJ, Blundell MJ, Hill AS, Skerritt JH (1999) Antibodies to N-terminal peptides of low Mr subunits of wheat glutenin. Part 1. Characterisation of the antibody response. J Cereal Sci 30:267–281

Cornell HJ (1998) Partial in vitro digestion of active gliadin-related peptides in celiac disease. J Protein Chem 17:739–744

Cornell HJ, Maxwell RJ (1982) Amino acid composition of gliadin fractions which may be toxic to individuals with coeliac disease. Clin Chim Acta 123:311–319

Cornell HJ, Mothes T (1993) The activity of wheat gliadin peptides in in vitro assays for coeliac disease. Biochim Biophys Acta 1181:169–173

Cornell HJ, Skerritt JH, Puy R, Javadpour M (1994) Studies of in vitro gamma-interferon production in coeliac disease as a response to gliadin peptides. Biochim Biophys Acta 1226:126–130

Aaslyng MD, Martens M, Poll L, Nielsen PM, Flyge H, Larsen LM (1998) Chemical and sensory characterization of hydrolyzed vegetable protein, a savory flavoring. J Agr Food Chem 46:481–489

Krupickova S, Tuckova L, Flegelova Z, Michalak M, Walters JRF, Whelan A, Harries J, Vencovsky J, Tlaskalova-Hogenova H (1999) Identification of common epitopes on gliadin, enterocytes, and calreticulin recognized by antigliadin antibodies of patients with coeliac disease. Gut 44:168–173

Stern M, Ciclitira PJ, Van Eckert R, Feighery C, Janssen FW, Mendez E, Mothes T, Troncone R, Wieser H (2001) Analysis and clinical effects of gluten in coeliac disease. Eur J Gastroen Hepat 13:741–747

Macritchie F (1992) Physicochemical properties of wheat proteins in relation to functionality. Adv Food Nutr Res 36:1–87

Sturgess R, Day P, Ellis HJ, Lundin KE, Gjertsen HA, Kontakou M, Ciclitira PJ (1994) Wheat peptide challenge in coeliac disease. Lancet 343:758–761

Vader LW, Stepniak DT, Bunnik EM, Kooy YMC, De Haan W, Drijfhout JW, Van Veelen PA, Koning F (2003) Characterization of cereal toxicity for celiac disease patients based on protein homology in grains. Gastroenterology 125:1105–1113

McLachlan A, Cullis PG, Cornell HJ (2002) The use of extended amino acid motifs for focussing on toxic peptides in coeliac disease. J Biochem Mol Biol 6:319–324

Camarca A, Anderson RP, Mamone G, Fierro O, Facchiano A, Costantini S, Zanzi D, Sidney J, Auricchio S, Sette A, Troncone R, Gianfrani C (2009) Intestinal T cell responses to gluten peptides are largely heterogeneous: Implications for a peptide-based therapy in celiac disease. J Immunol 182:4158–4166

Acknowledgments

The authors would like to thank Nestlé PTC Singen for supporting this research. In addition, we thank Jens Pfannstiel and Berit Würtz (University of Hohenheim, Service Unit Mass Spectrometry) for the LC–ESI–MS/MS measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Berends, P., Merz, M., Kochjohann, A. et al. Sensory and antigenic properties of enzymatic wheat gluten hydrolysates produced in an enzyme membrane reactor in comparison with batch. Eur Food Res Technol 243, 807–816 (2017). https://doi.org/10.1007/s00217-016-2794-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-016-2794-x